Microelectrolysis filler and process for treating printing and dyeing wastewater

A printing and dyeing wastewater, micro-electrolysis technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of avoiding interference and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

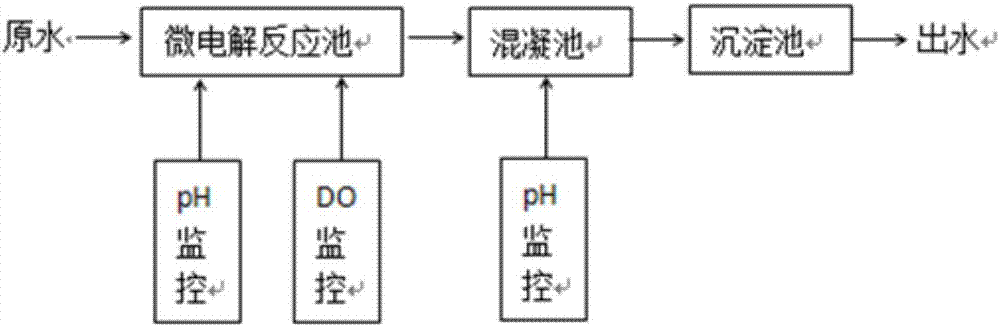

Image

Examples

Embodiment 1

[0044] A micro-electrolytic filler for treating printing and dyeing wastewater. The micro-electrolytic filler is a ternary filler based on Fe, C, and Al. The composition of the ternary micro-electrolytic filler is:

[0045] Iron 20%

[0046] Activated carbon 30%

[0047] Aluminum 25%

[0048] Clay 20%

[0049] Sodium Carboxymethyl Cellulose 5%

[0050] After the filler granulation is completed, it is fired at 800°C for 2 hours.

[0051] A micro-electrolysis process for treating printing and dyeing wastewater, using the above-mentioned micro-electrolysis filler, the printing and dyeing wastewater uses anthraquinone dyes as the main pollutant, comprising the following steps:

[0052] A. Introduce printing and dyeing wastewater into the micro-electrolysis reaction pool;

[0053] B, monitor the pH of the waste water to be about 8, and add sodium hydroxide reagent to adjust the pH of the printing and dyeing waste water in the micro-electrolysis reaction pool, so that the pH is...

Embodiment 2

[0059] A micro-electrolytic filler for treating printing and dyeing wastewater. The micro-electrolytic filler is a ternary filler based on Fe, C, and Al. The composition of the ternary micro-electrolytic filler is:

[0060] Iron 15%

[0061] Activated carbon 30%

[0062] Aluminum 15%

[0063] Clay 30%

[0064] Sodium Carboxymethyl Cellulose 10%

[0065] After the filler granulation is completed, bake at 1000°C for 2 hours

[0066] A micro-electrolysis process for treating printing and dyeing wastewater, using the above-mentioned micro-electrolysis filler, comprising the steps of:

[0067] A. Introduce printing and dyeing wastewater into the micro-electrolysis reaction pool;

[0068] B, monitor the pH of the waste water to be about 10, and add sodium hydroxide reagent to adjust the pH of the printing and dyeing waste water in the micro-electrolysis reaction pool, so that the pH is 11-12;

[0069] C. Monitor and turn on the aeration device to adjust the DO of the printing ...

Embodiment 3

[0074] A micro-electrolytic filler for treating printing and dyeing wastewater. The micro-electrolytic filler is a ternary filler based on Fe, C, and Al. The composition of the ternary micro-electrolytic filler is:

[0075] Iron 20%

[0076] Activated carbon 30%

[0077] Aluminum 20%

[0078] Clay 25%

[0079] Sodium Carboxymethyl Cellulose 5%

[0080] After the filler granulation is completed, bake at 900°C for 2 hours

[0081] A micro-electrolysis process for treating printing and dyeing wastewater, using the above-mentioned micro-electrolysis filler, the printing and dyeing wastewater is comprehensive wastewater from multiple printing and dyeing factories, including the following steps:

[0082] A. Introduce printing and dyeing wastewater into the micro-electrolysis reaction pool;

[0083] B, monitor the pH of this waste water to be about 11.8;

[0084] C. Monitor and turn on the aeration device to adjust the DO in the printing and dyeing wastewater in the micro-elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com