Electrolysis device

a technology of electrolysis device and electrode, which is applied in the direction of electrolysis components, water treatment parameter control, chemistry apparatus and processes, etc., can solve the problems of reducing reducing the production amount per unit, and affecting the efficiency of electrolysis, so as to facilitate the electrode reaction and reduce the production cost. , the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

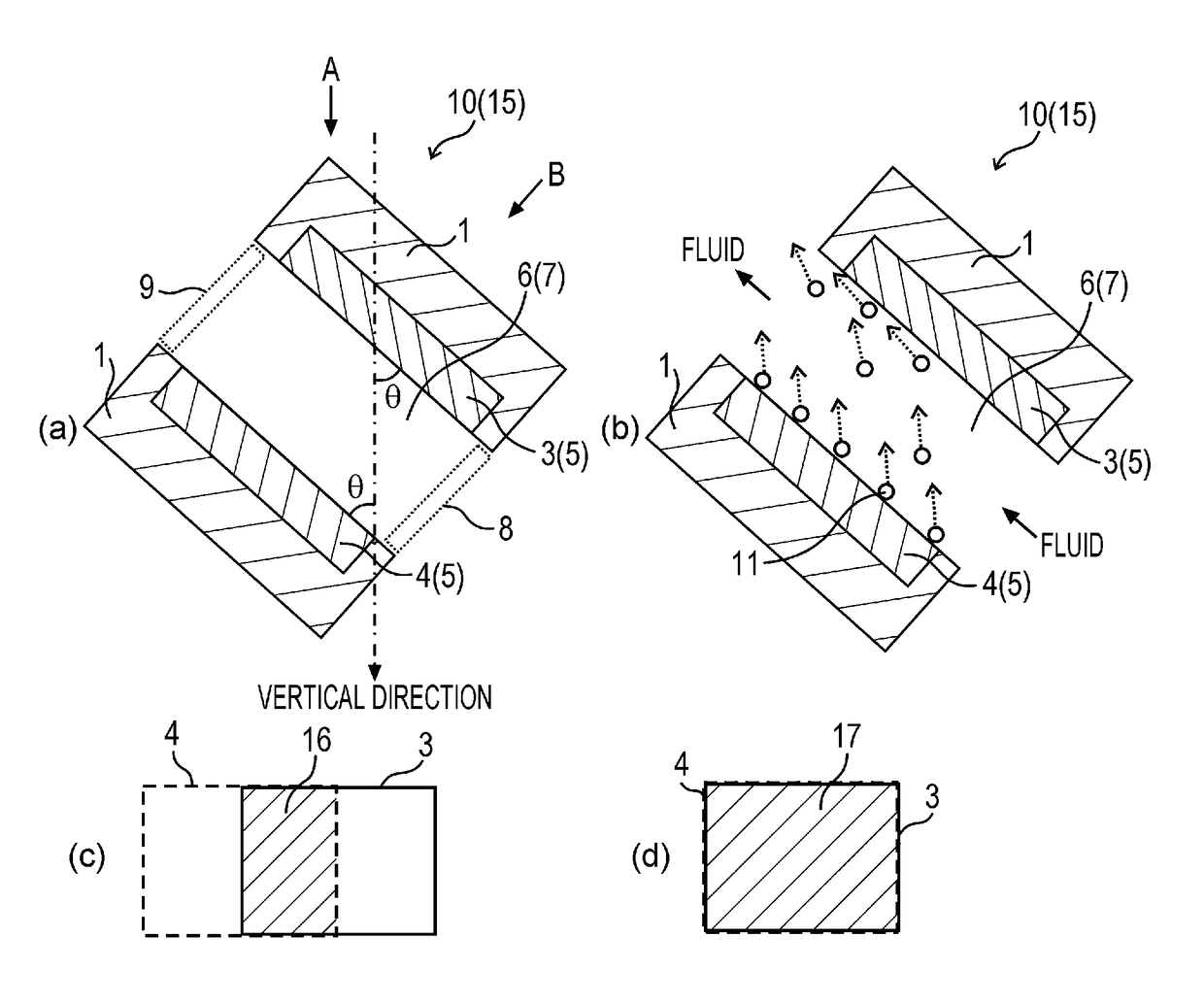

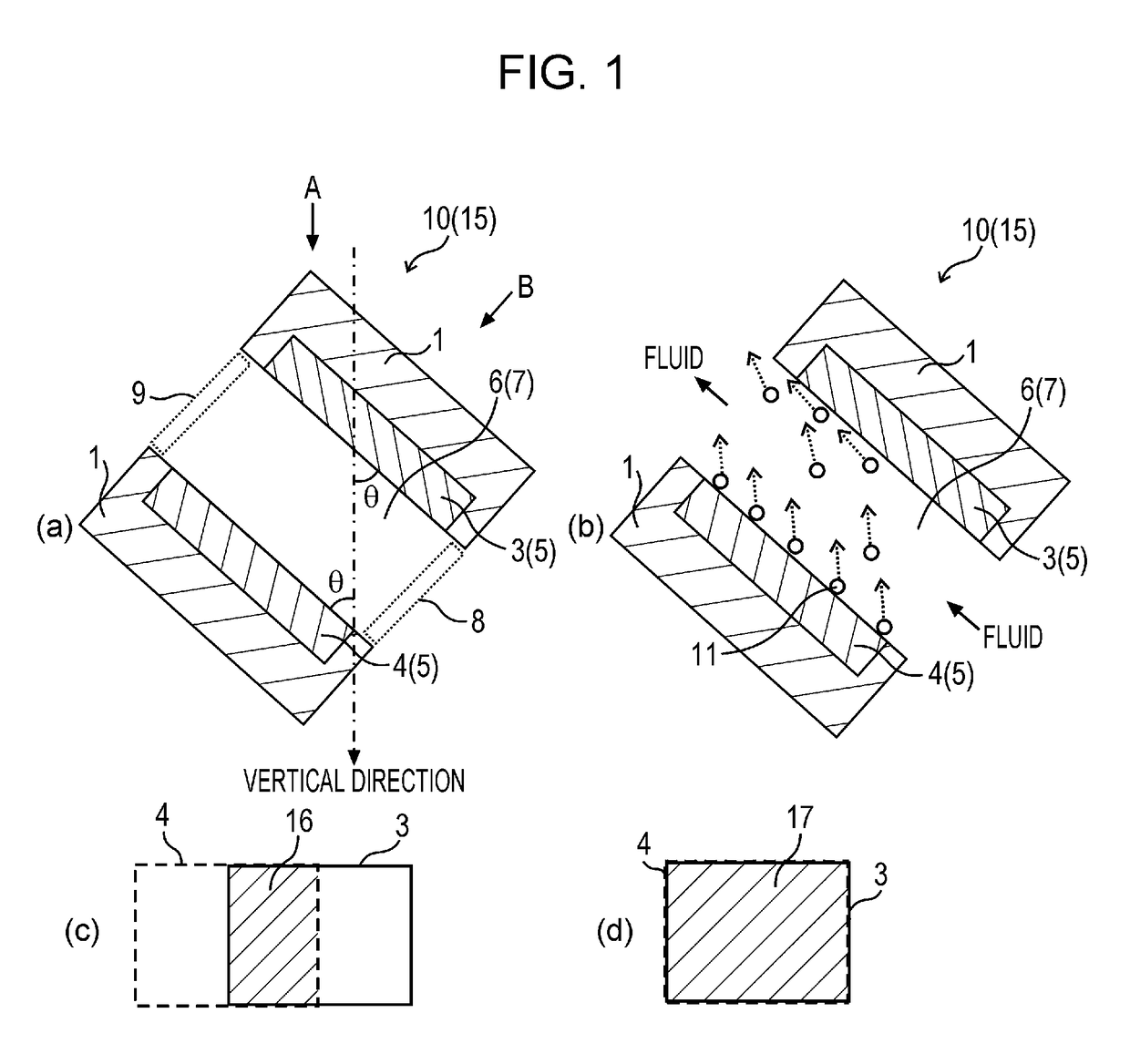

[0106]FIGS. 1(a) and 1(b) are schematic sectional views of an electrolysis device according to the first embodiment. FIG. 1(c) is a diagram for describing an overlap of an upper electrode and a lower electrode when the electrolysis device in FIG. 1(a) is viewed in a vertical direction A. FIG. 1(d) is a diagram for describing an overlap of an upper electrode and a lower electrode when the electrolysis device in FIG. 1(a) is viewed in a direction B perpendicular to a principal surface of the lower electrode.

[0107]An electrolysis device 15 according to the first embodiment includes an electrolysis unit 10. The electrolysis unit 10 includes a channel 7 for fluid to be treated, at least one electrolysis electrode pair 5, a flow inlet 8, and a flow outlet 9. The electrolysis electrode pair 5 is disposed so as to incline with respect to the vertical direction, includes an upper electrode 3 and a lower electrode 4 disposed so as to face each other, and is disposed so that an electrode react...

second embodiment

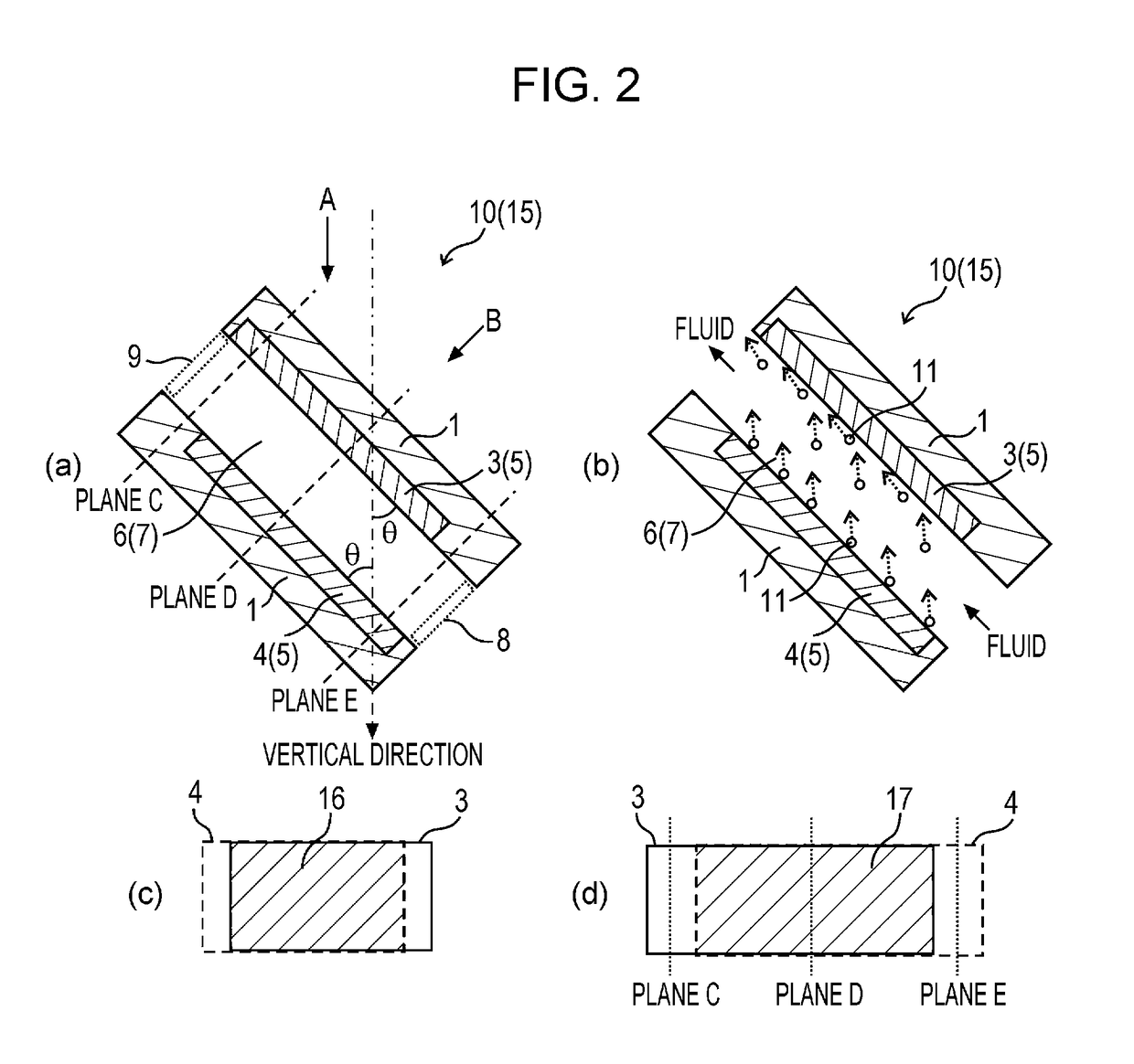

[0134]FIGS. 2(a) and 2(b) are schematic sectional views of an electrolysis device according to the second embodiment. FIG. 2(c) is a diagram for describing an overlap of an upper electrode and a lower electrode when the electrolysis device in FIG. 2(a) is viewed in a vertical direction A. FIG. 2(d) is a diagram for describing an overlap of an upper electrode and a lower electrode when the electrolysis device in FIG. 2(a) is viewed in a direction B perpendicular to a principal surface of the lower electrode.

[0135]In the electrolysis device in FIG. 1, the upper electrode 3 and the lower electrode 4 are disposed so that substantially the entire surfaces of the upper electrode 3 and the lower electrode 4 overlap each other when viewed in the direction B. However, in the electrolysis device 15 according to the second embodiment, the upper electrode 3 is disposed so as to shift upward. Specifically, as illustrated in FIG. 2(d), when viewed in the direction B perpendicular to the principal...

third embodiment

[0140]FIG. 3(a) is a schematic sectional view of an electrolysis device according to the third embodiment. FIG. 3(b) is a diagram for describing an overlap of an upper electrode and a lower electrode when the electrolysis device in FIG. 3(a) is viewed in a vertical direction A. FIG. 3(c) is a diagram for describing an overlap of an upper electrode and a lower electrode when the electrolysis device in FIG. 3(a) is viewed in a direction B perpendicular to an electrode surface of the lower electrode.

[0141]In the electrolysis devices 15 illustrated in FIGS. 1 and 2, the electrode surface of the upper electrode 3 and the electrode surface of the lower electrode 4 have substantially the same size. However, in the electrolysis device 15 according to the third embodiment, the electrode surface of the lower electrode 4 is larger than that of the upper electrode 3. Furthermore, as illustrated in FIG. 3(c), ower electrode 4 can be disposed so that when the electrolysis device 15 is viewed in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inclination angle | aaaaa | aaaaa |

| inclination angle | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com