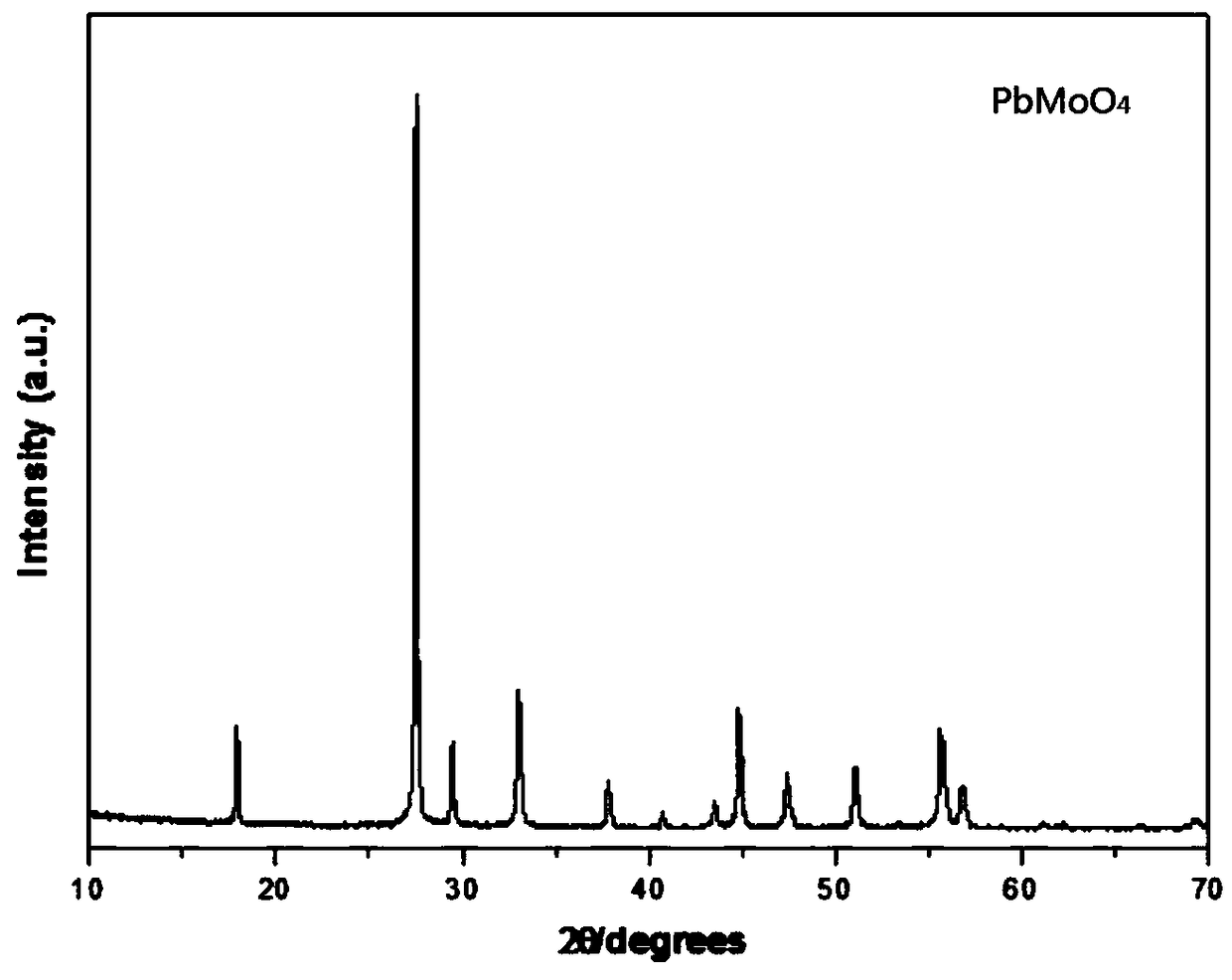

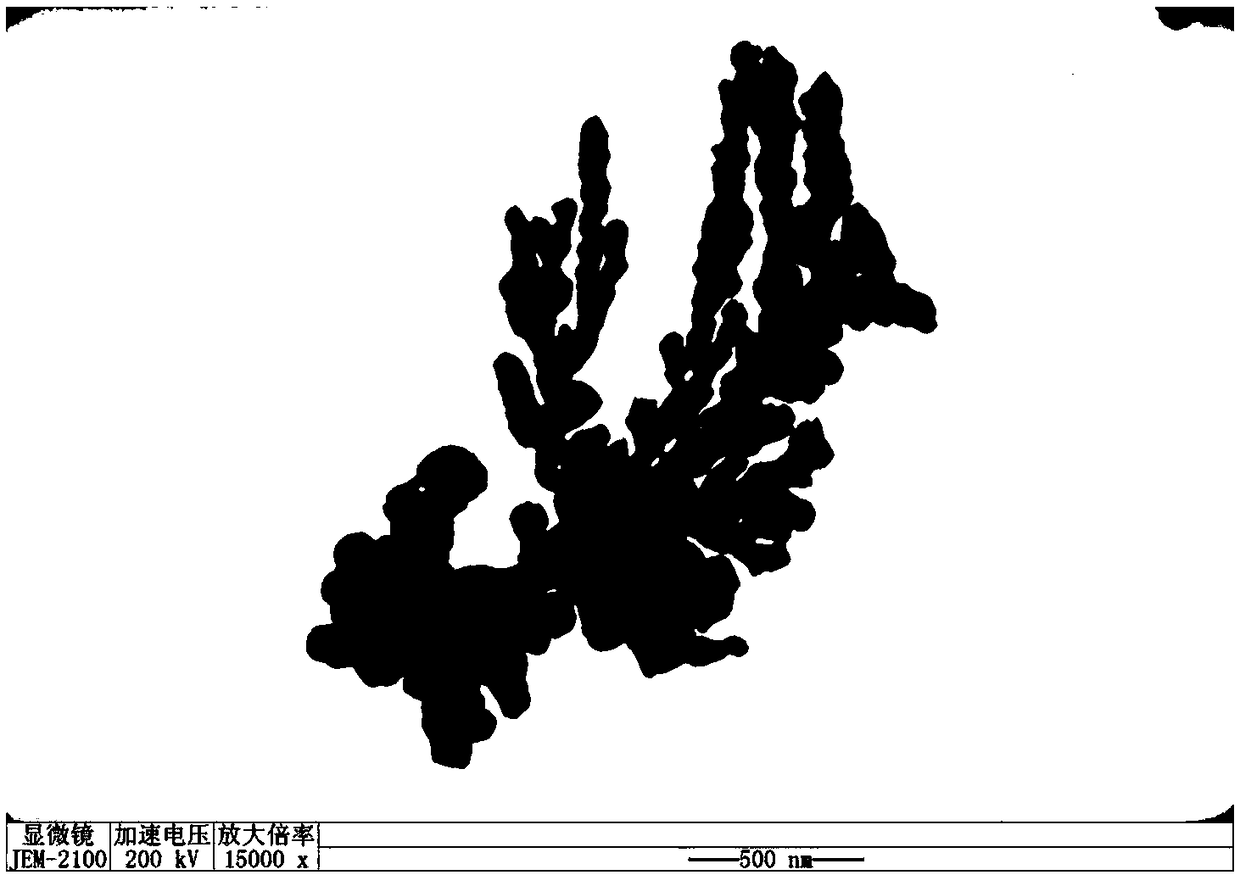

Preparation method of lead molybdate dendritic crystal

A technology of dendrites and lead molybdate is applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry and other directions to achieve the effects of controllable morphology, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Potassium sodium tartrate is dissolved in deionized water to form potassium sodium tartrate aqueous solution, and the concentration of potassium sodium tartrate in the solution is adjusted to be 0.2mol / L;

[0033] 2) dissolving lead nitrate in deionized water to form an aqueous solution of lead nitrate, adjusting the concentration of lead nitrate in the solution to be 0.2mol / L;

[0034] 3) the potassium sodium tartrate aqueous solution prepared in step 1) and the lead nitrate aqueous solution prepared in step 2) are mixed to obtain a lead tartrate precipitation solution (that is, a mixed solution of potassium nitrate and sodium nitrate containing lead tartrate precipitation), wherein tartaric acid The molar ratio of potassium sodium and lead nitrate is 1:1;

[0035] 4) Sodium molybdate is dissolved in deionized water to form an aqueous solution of sodium molybdate, and the concentration of sodium molybdate in the adjustment solution is 0.3mol / L;

[0036] 5) dissolvi...

Embodiment 2

[0041] 1) Sodium potassium tartrate is dissolved in deionized water to form a sodium potassium tartrate aqueous solution, and the concentration of sodium sodium tartrate in the adjustment solution is 0.8mol / L;

[0042] 2) dissolving lead nitrate in deionized water to form an aqueous solution of lead nitrate, adjusting the concentration of lead nitrate in the solution to be 0.8mol / L;

[0043] 3) the potassium sodium tartrate aqueous solution prepared in step 1) and the lead nitrate aqueous solution prepared in step 2) are mixed to obtain a lead tartrate precipitation solution (that is, a mixed solution of potassium nitrate and sodium nitrate containing lead tartrate precipitation), wherein tartaric acid The molar ratio of potassium sodium and lead nitrate is 1:1;

[0044] 4) Sodium molybdate is dissolved in deionized water to form an aqueous solution of sodium molybdate, and the concentration of sodium molybdate in the adjustment solution is 1.2mol / L;

[0045] 5) dissolving po...

Embodiment 3

[0050] 1) Potassium sodium tartrate is dissolved in deionized water to form an aqueous solution of potassium sodium tartrate, and the concentration of potassium sodium tartrate in the solution is adjusted to be 1.0mol / L;

[0051] 2) dissolving lead nitrate in deionized water to form a lead nitrate aqueous solution, adjusting the concentration of lead nitrate in the solution to be 1.0mol / L;

[0052] 3) the potassium sodium tartrate aqueous solution prepared in step 1) and the lead nitrate aqueous solution prepared in step 2) are mixed to obtain a lead tartrate precipitation solution (that is, a mixed solution of potassium nitrate and sodium nitrate containing lead tartrate precipitation), wherein tartaric acid The molar ratio of potassium sodium and lead nitrate is 1:1;

[0053] 4) Sodium molybdate is dissolved in deionized water to form an aqueous solution of sodium molybdate, and the concentration of sodium molybdate in the adjustment solution is 1.5mol / L;

[0054] 5) dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com