Method for preparing bismuth film by pulse plating process

A pulse electroplating and process technology, applied in the field of preparation of metal bismuth thin films, to achieve stable performance, simple preparation process, and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

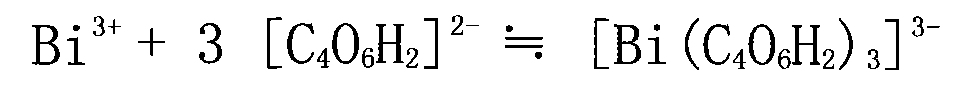

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a bismuth film by a pulse electroplating process, comprising the following steps:

[0036] a. Preparation of electroplating solution: mainly bismuth trichloride 40g / L, potassium sodium tartrate 100g / L, potassium citrate 55g / L, antimony potassium tartrate 0.35g / L, potassium chloride 50g / L, dodecyl sulfate The composition and content of sodium 0.02g / L, thiourea 0.35g / L, get each component, mix with water, adjust with potassium hydroxide aqueous solution (can be the potassium hydroxide aqueous solution of 40% concentration by mass percentage, the same hereinafter) The pH value of the mixed solution is 7.5 to 8.5 to prepare the electroplating solution;

[0037] b. Pulse electroplating: inject the electroplating solution into the electroplating equipment, use the copper sheet as the cathode and the pure gold plate as the anode, at a current density of 0.55A / dm 2 , the frequency is 500Hz, the duty ratio is 1:7, the temperature of the electroplating sol...

Embodiment 3

[0039] A method for preparing a bismuth film by a pulse electroplating process, comprising the following steps:

[0040] a, preparation of electroplating solution: mainly by the composition and content of bismuth trichloride 80g / L, potassium sodium tartrate 190g / L, potassium citrate 50g / L, antimony potassium tartrate 0.35g / L, potassium chloride 50g / L, take Each component is mixed with water, and the pH value of the mixed solution is adjusted to 8.5 to 9.5 with an aqueous potassium hydroxide solution to obtain an electroplating solution;

[0041] b. Pulse electroplating: inject the electroplating solution into the electroplating equipment, use the copper sheet as the cathode and the pure gold plate as the anode, at a current density of 0.65A / dm 2 , the frequency is 600Hz, the duty ratio is 1:8, the temperature of the electroplating solution is 35°C, the electrode spacing is 7cm, and the pH value is 8.5-9.5, and the film deposited on the surface of the cathode copper sheet is pr...

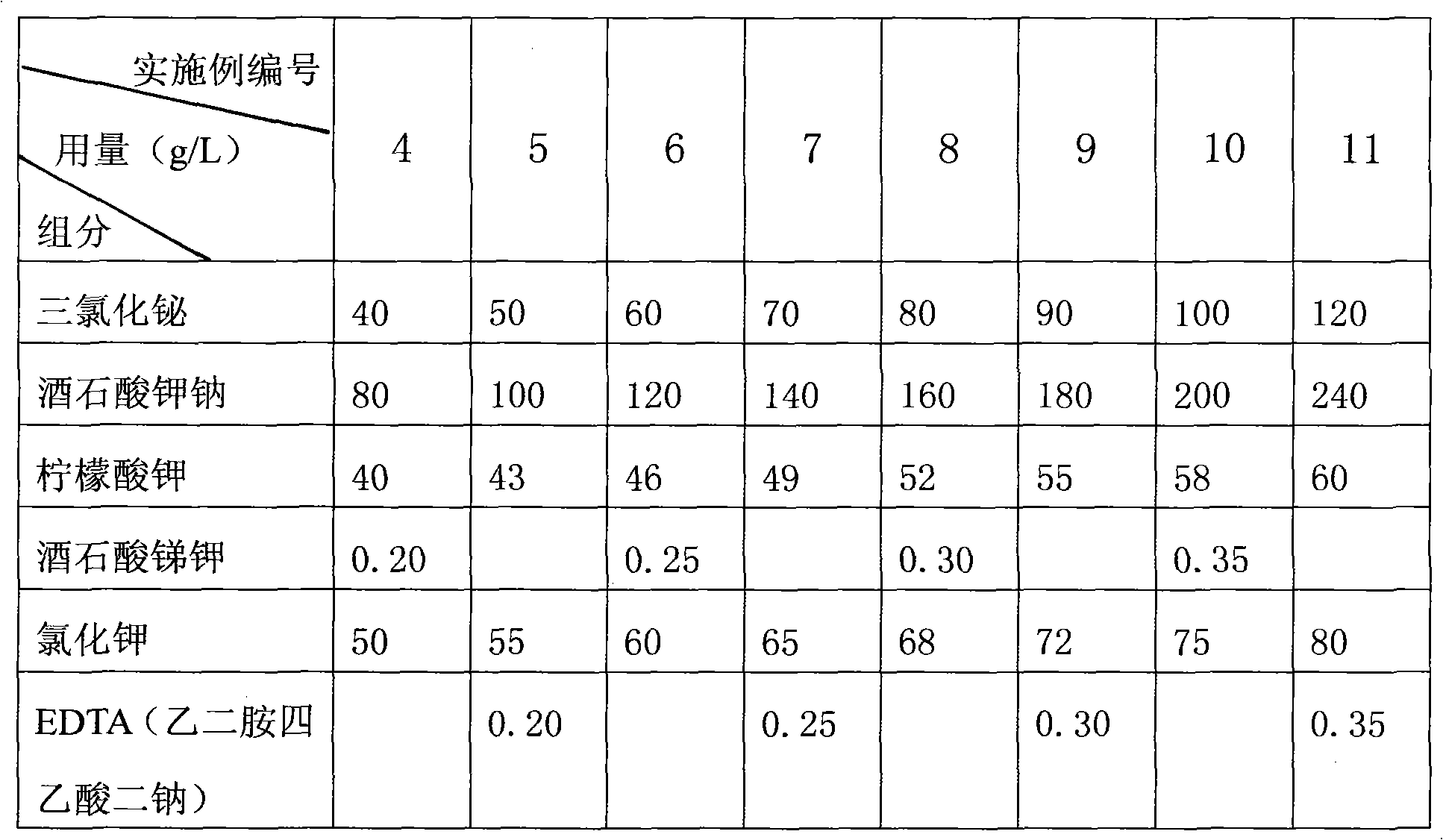

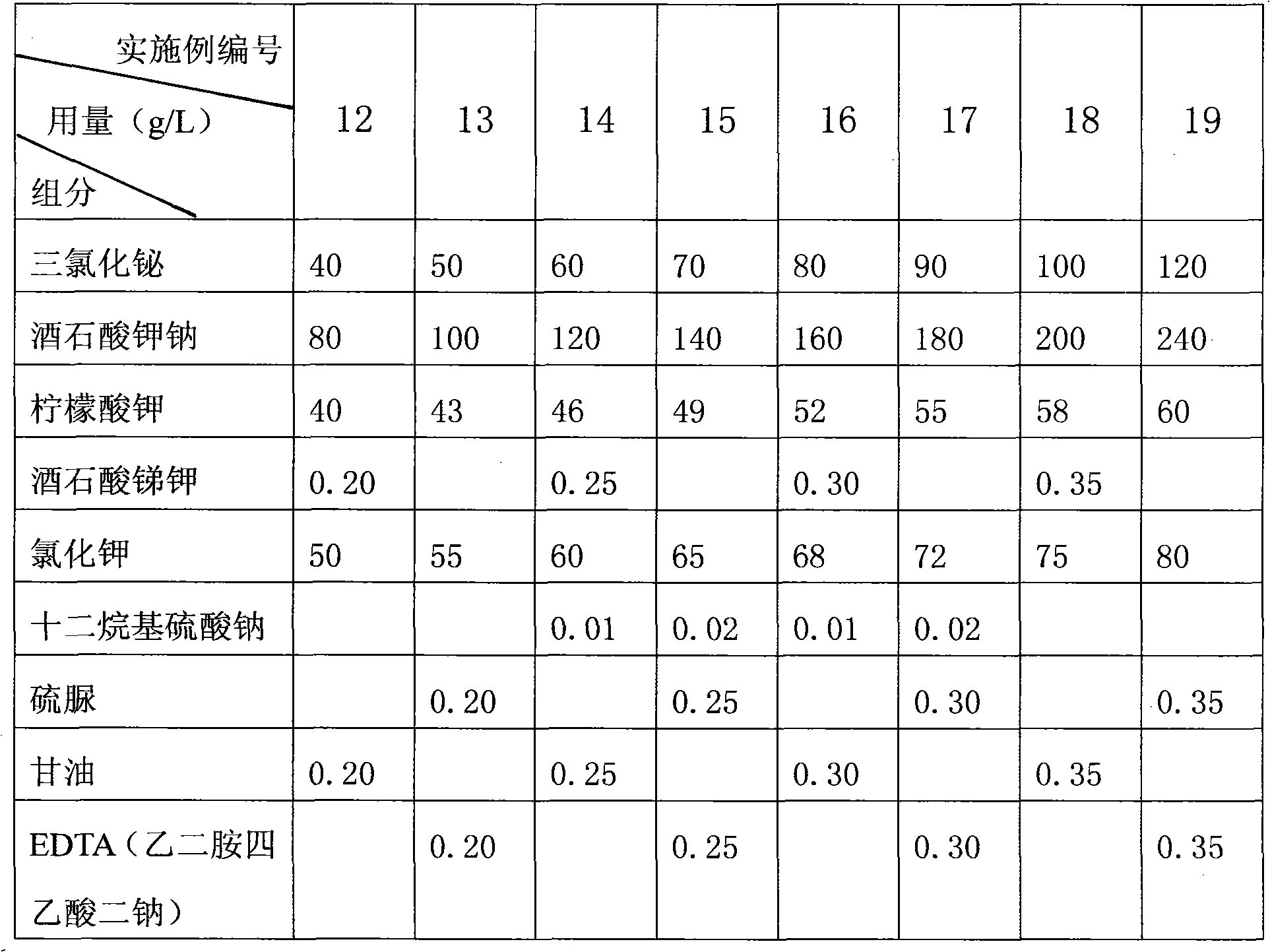

Embodiment 4-11

[0047] A method for preparing a bismuth film by a pulse electroplating process, comprising the following steps:

[0048] a. Preparation of electroplating solution: see the following table for the composition and content of the electroplating solution, take each component, mix with water, adjust the pH value of the mixed solution to 7.5-11.5, and prepare the electroplating solution;

[0049]

[0050] b. Pulse electroplating: inject the electroplating solution into the electroplating equipment, use the copper sheet as the cathode and the pure gold plate as the anode, at a current density of 0.55-0.85A / dm 2 , The frequency is 500-700Hz, the duty ratio is 1:7-1:11, the temperature of the electroplating solution is 25-50°C, the distance between the cathode copper sheet and the anode pure gold plate is 5-8cm, and the pH value is 7.5 Electroplating is carried out under the process conditions of ~11.5 (it can be any point or a combination of intervals under the process conditions),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com