Oil-shrinking cathodic electrophoretic coating and preparation method thereof

A cathodic electrophoretic coating, polydimethylsiloxane technology, applied in electrophoretic coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problem of failure to achieve multiple sustained effects, limit development and application, Paint film shrinkage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

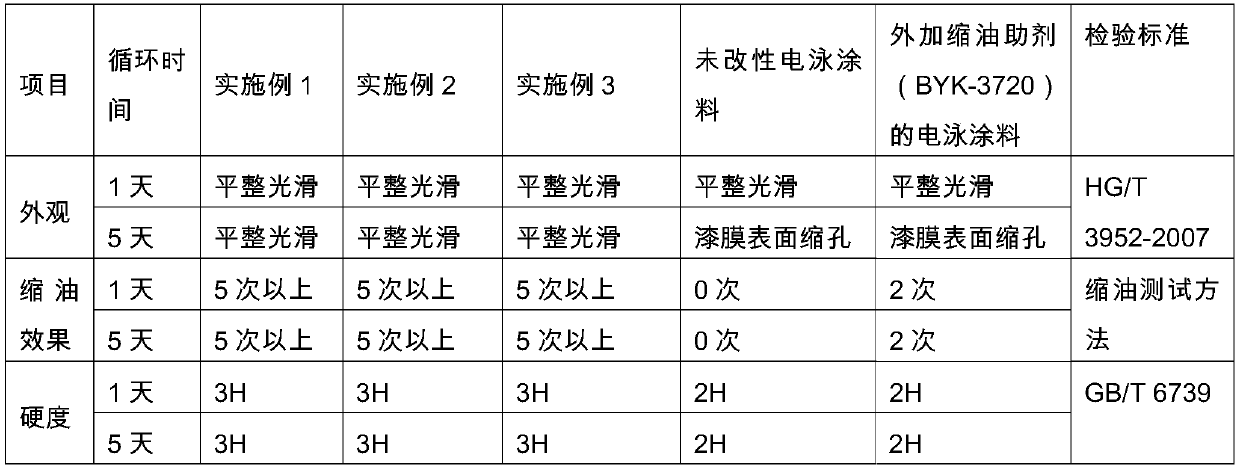

Examples

Embodiment 1

[0034] A kind of shrink oil cathodic electrophoretic paint, comprises by weight parts:

[0035] 30 parts of toluene diisocyanate;

[0036] 5 parts of methyl isobutyl ketone;

[0037] 5 parts of carboxy-terminated polydimethylsiloxane;

[0038] 40 parts of ethylene glycol butyl ether;

[0039] 200 parts of epoxy resin;

[0040] 10 parts of acetic acid;

[0041] 900 parts of pure water.

[0042] In addition, a preparation method for preparing the above-mentioned shrink oil cathodic electrophoretic coating is provided: comprising the following steps,

[0043] Add toluene diisocyanate and methyl isobutyl ketone into a stirred and condensed reaction vessel, blow nitrogen, raise the temperature to 60±2°C, and then slowly drop carboxy-terminated polydimethylsiloxane into the reaction vessel , the dropping time is 30±5 minutes, the dropping process maintains the temperature at 60±2°C, after the dropping is completed, the temperature rises to 80±2°C, and the reaction takes 2 hour...

Embodiment 2

[0046] A kind of shrink oil cathodic electrophoretic paint, comprises by weight parts:

[0047] 65-70 parts of isophorone diisocyanate;

[0048] 10-15 parts of methyl isobutyl ketone;

[0049] 8-10 parts of amino-terminated polydimethylsiloxane;

[0050] 55-60 parts of ethylene glycol butyl ether;

[0051] 300-350 parts of epoxy resin;

[0052] 15-20 parts of acetic acid;

[0053] 900-1000 parts of pure water.

[0054] The preparation method is the same as the aforementioned method.

Embodiment 3

[0056] A kind of shrinkage cathodic electrophoretic paint, comprising by weight: 68 parts of diphenylmethane diisocyanate;

[0057] 13 parts of methyl isobutyl ketone;

[0058] 9 parts of amodimethicone;

[0059] 58 parts of ethylene glycol butyl ether;

[0060] 325 parts of epoxy resin;

[0061] 18 parts of acetic acid;

[0062] 950 parts of pure water.

[0063] The preparation method is the same as the aforementioned method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com