Production method of washable electromagnetic shielding fabric

A technology of electromagnetic shielding and production methods, applied in the direction of fiber type, textile and paper making, fiber treatment, etc., can solve the problems of poor washing resistance, susceptibility to oxidation, performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

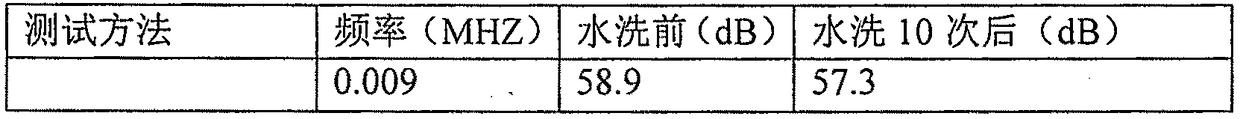

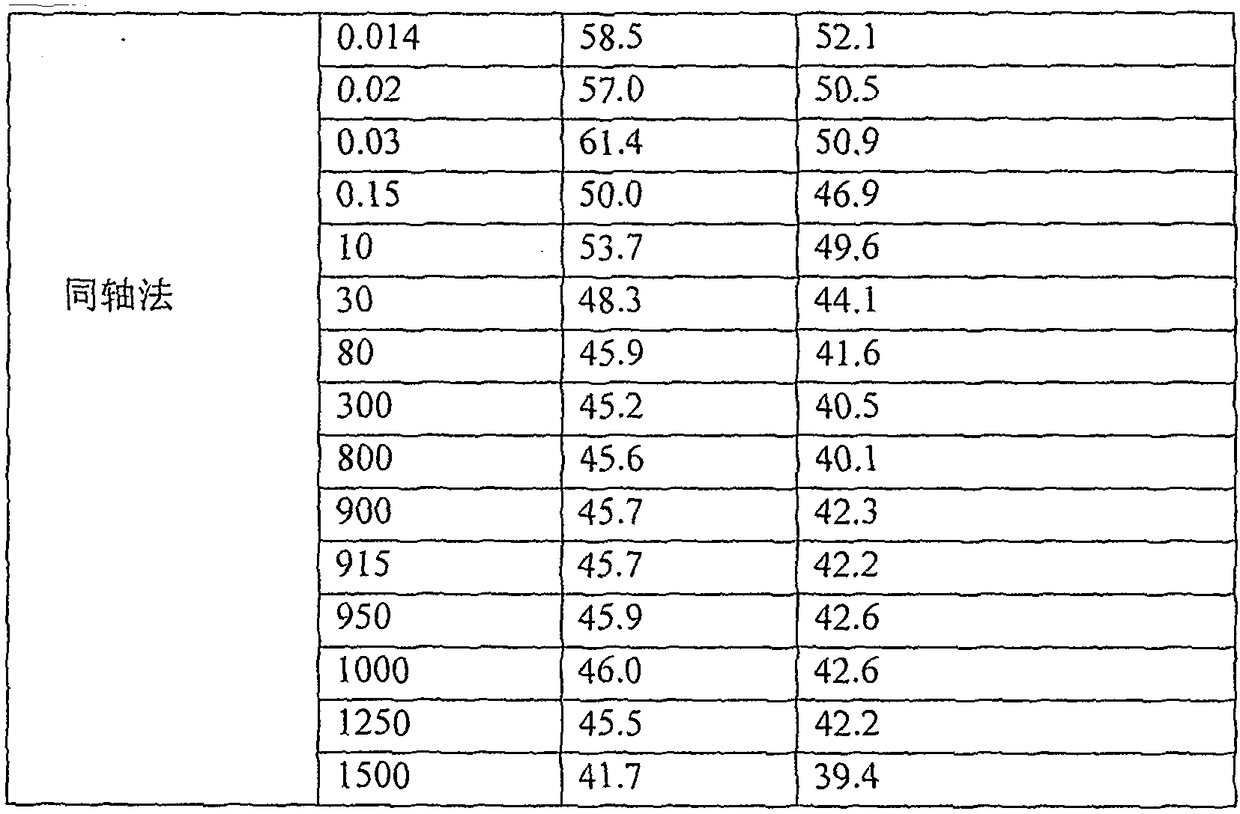

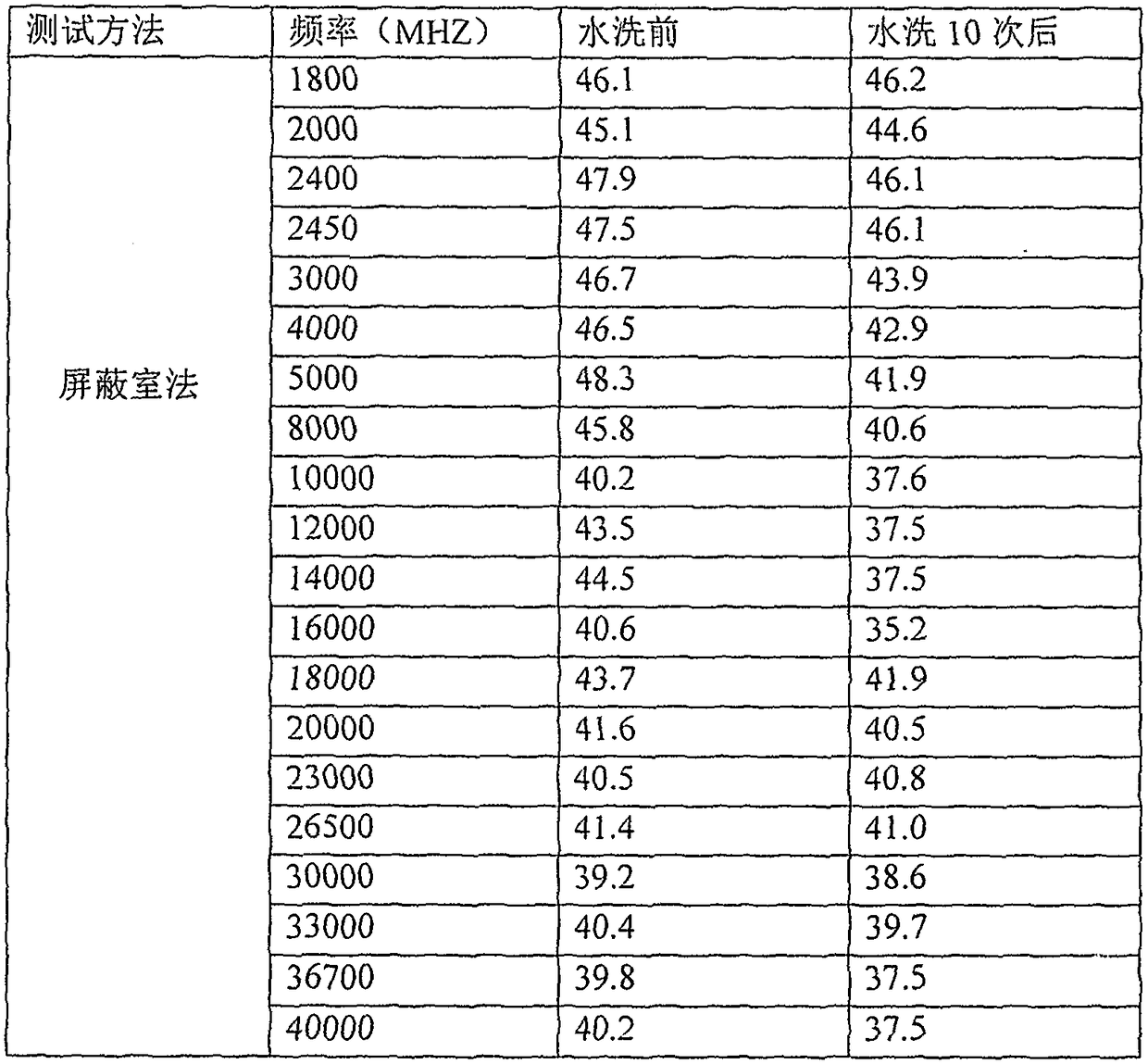

Image

Examples

Embodiment 1

[0016] In this embodiment, the acrylic yarn is the conventional 21 yarn purchased from Shanghai Jinshan Acrylic Fiber Factory s yarn. The reagents used are all industrial grade and no further purification is required during use.

[0017] The bath ratio and the percentages of each chemical reagent in the formula are the ratios to the mass of the acrylic yarn. The specific formula is as follows: acrylic yarn 100g; copper sulfate 25%-35%; silver nitrate 1-2%; potassium sodium tartrate 2-3%; sodium thiosulfate 20%-30%; sodium sulfite 1%-3%; penetrant JFC 0.2-0.7%; cationic surfactant 1227 0.1-0.3%; adjust the pH value to 2 with sulfuric acid. The liquor ratio is 1:50.

[0018] In the embodiment, the heating rate is 0.5°C / min, the cooling rate is 1°C / min, and the heating curve is: initial temperature (room temperature)→25°C for 5min→30°C for 10min→35°C for 15min→40°C 20min→45°C for 25min→50°C for 40min→55°C for 20min→60°C for 20min→65°C for 20min→70°C for 25min→75°C for 40min→8...

Embodiment 2

[0027] In this embodiment, the raw material is the conventional 21s yarn purchased from Shanghai Jinshan Acrylic Fiber Factory, and the knitted fabric and the woven fabric are respectively made by themselves on conventional knitting and weaving equipment. The reagents used are all industrial grade and no further purification is required during use. The bath ratio and the percentages of each chemical reagent in the formula are the ratios to the mass of the acrylic fiber cloth.

[0028] The specific formula is as follows: 100g of acrylic fabric; 25%-35% of copper sulfate; 1-2% of silver nitrate; 2-3% of potassium sodium tartrate; 20%-30% of sodium thiosulfate; 1%-3% of sodium sulfite; JFC0. 2~0.7%; 1227 or CD, RCT 0.1~0.3%; adjust the pH value to 2 with sulfuric acid. The liquor ratio is 1:50.

[0029] In an embodiment, the heating curve is: initial temperature (room temperature)→25°C for 5min→30°C for 10min→35°C for 15min→40°C for 20min→45°C for 25min→50°C for 40min→55°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com