Preparation method of shell-like mesoporous carbon material for super capacitors

A supercapacitor, shell-like technology, applied in the field of carbon material preparation, can solve the problems of low specific surface area of hard carbon materials, low specific surface area of porous carbon, large average pore size, etc., and achieve good rate performance, cycle stability, and rate performance. , the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

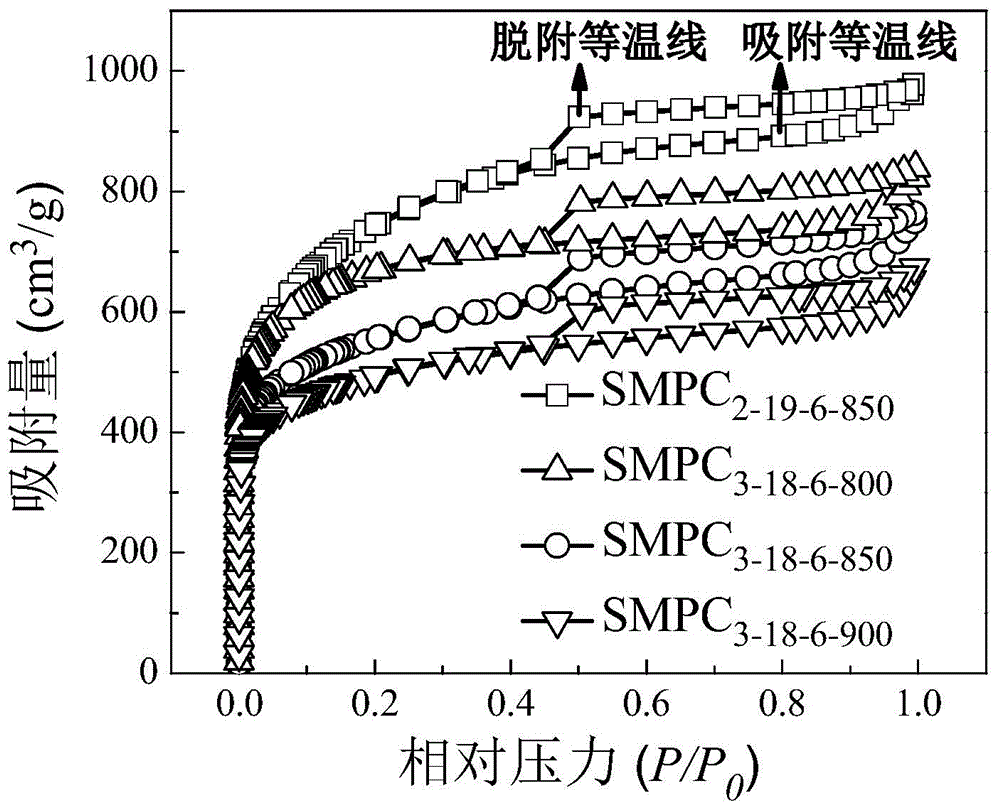

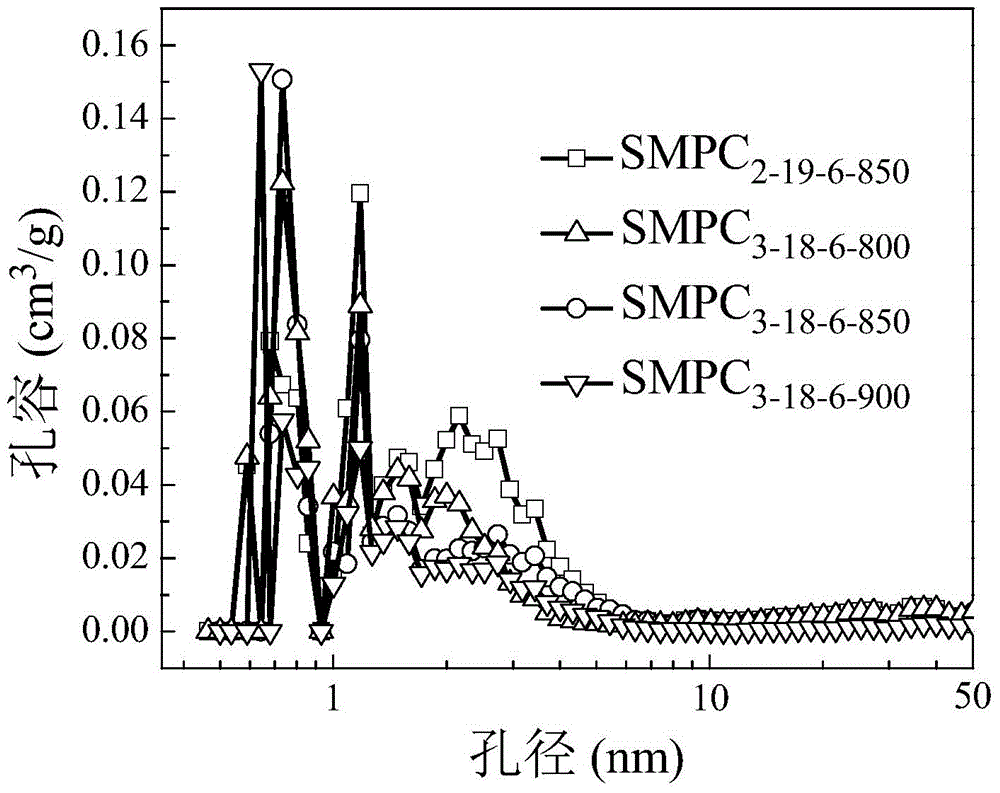

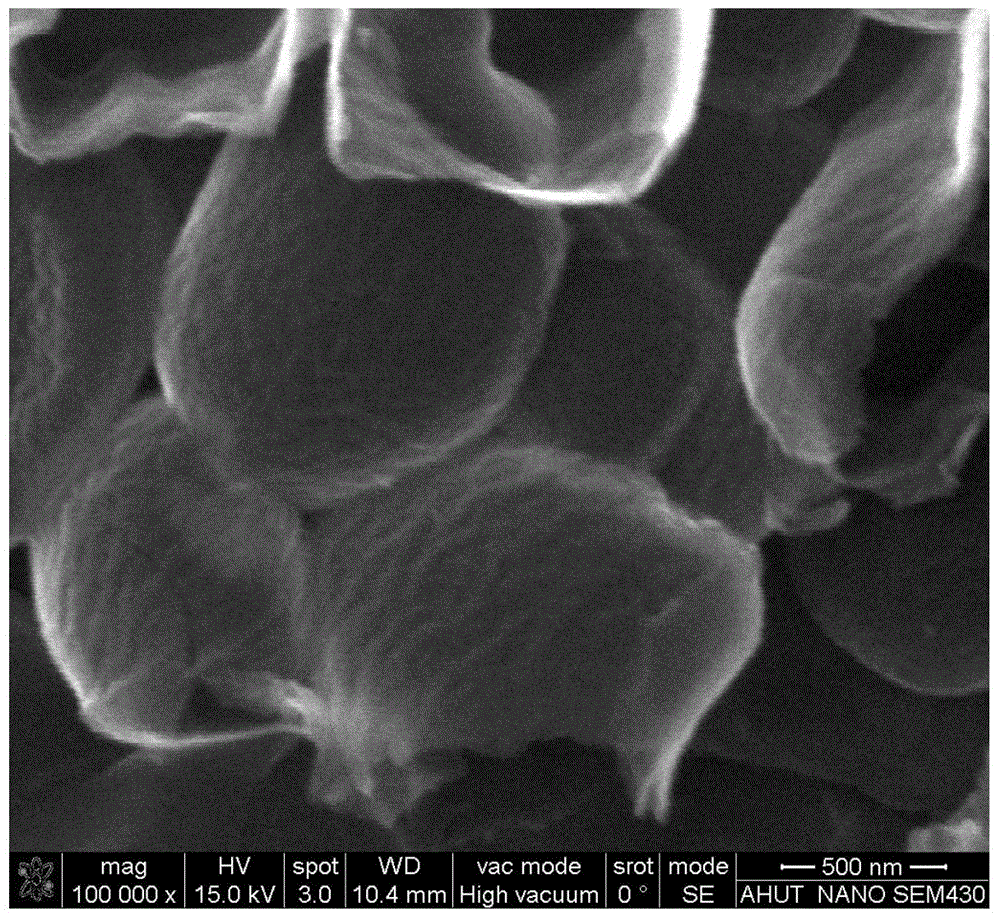

[0024] Example 1: shell-like mesoporous carbon SMPC 2-19-6-850 The specific preparation process is as follows:

[0025] (1) Pretreatment of reactants: Weigh 2g of petroleum pitch and put it into a mortar, add 19g of nano-zinc oxide (particle size between 100-150nm), and then add 6g of potassium hydroxide, and the mixture of the three obtained is ground evenly get reactants.

[0026] (2) Preparation of shell-shaped mesoporous carbon material: put the reactant obtained in step (1) into a porcelain boat, then place the porcelain boat in a tube furnace, and feed argon gas into the tube furnace Exhaust the air, keep the argon gas rate at 60mL / min, heat the tube furnace to 200°C at a heating rate of 5°C / min, keep the temperature for 30min, and continue to heat the tube furnace to 850 at a heating rate of 5°C / min After ℃, keep the temperature for 60min, and cool down to room temperature naturally. Grind the obtained product and put it into a beaker, add a certain amount of 2mol / L ...

Embodiment 2

[0027] Example 2: shell-like mesoporous carbon SMPC 3-18-6-800 The specific preparation process is as follows:

[0028] (1) Pretreatment of reactant: implement according to the same method as step (1) in Example 1, the difference is that the petroleum pitch taken by weighing is 3g, and nano-zinc oxide is 18g.

[0029] (2) Carry out the same method as step (2) in Example 1, except that the tube furnace is heated to 800°C. The resulting shell-like mesoporous carbon is labeled as SMPC 3-18-6-800 . SMPC3-18-6-800 As a supercapacitor electrode material, its specific volume reaches 237F / g at a current density of 0.05A / g in a 6mol / L KOH electrolyte.

Embodiment 3

[0030] Example 3: shell-like mesoporous carbon SMPC 3-18-6-850 The specific preparation process is as follows:

[0031] (1) Pretreatment of reactant: implement according to the same method as step (1) in Example 1, the difference is that the petroleum pitch taken by weighing is 3g, and nano-zinc oxide is 18g.

[0032] (2) Carry out in the same manner as step (2) in Example 1. The resulting shell-like mesoporous carbon material is marked as SMPC 3-18-6-850 . SMPC 3-18-6-850 As a supercapacitor electrode material, its specific volume reaches 263F / g at a current density of 0.05A / g in a 6mol / L KOH electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com