Method and device for treating oil refining salt-containing sewage by using oil refining waste catalyst and ozone

A technology for oil refinery waste catalyst and ozone treatment, which is applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc. It can solve the problems of poor catalyst technical economy, heterogeneous catalyst compaction, unfavorable ozone-catalyst-pollutant Mass transfer and other issues, to achieve the effect of promoting clean production and circular economy, improving ozone utilization rate, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

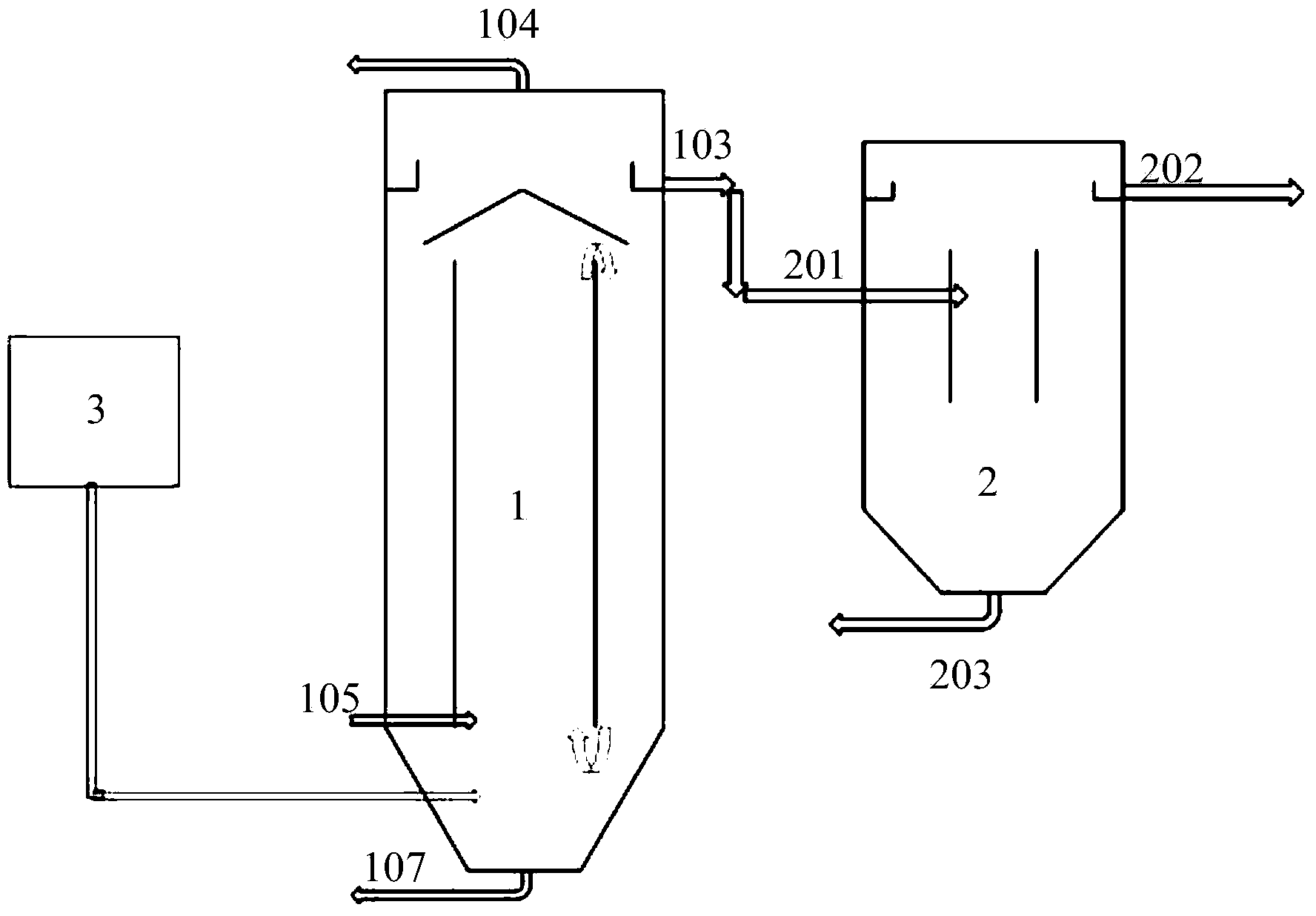

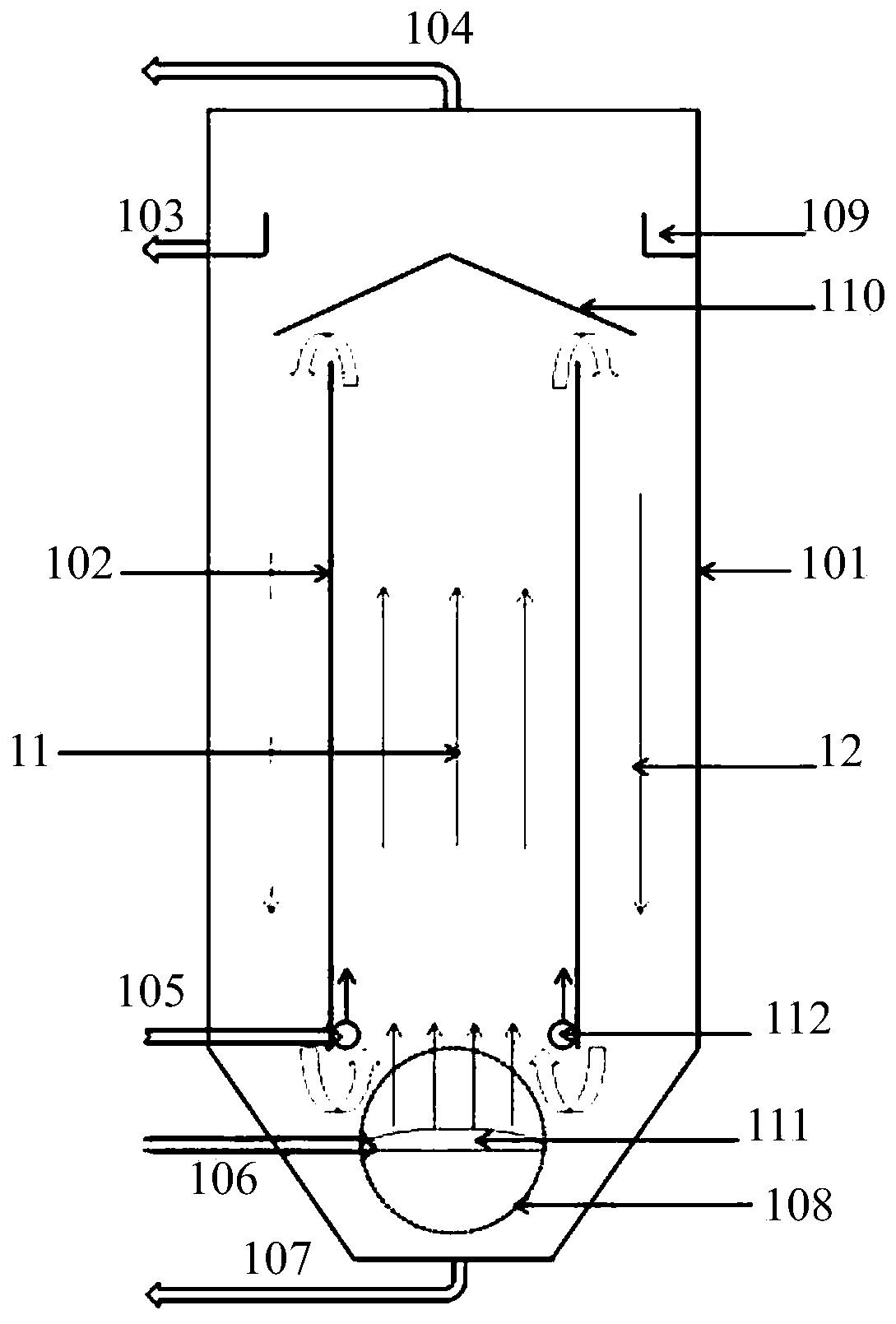

[0041] This embodiment provides a device for treating oil refinery salty sewage by utilizing spent refinery catalyst and ozone, such asfigure 1 and figure 2 As shown, the device includes a fluidized bed reactor 1, a vertical flow sedimentation tank 2 and an air source ozone generator 3; the fluidized bed reactor 1 includes a reactor outer cylinder 101, and is located outside the reactor The inner lifting cylinder 102 in the cylinder 101; the top of the reactor outer cylinder 101 is provided with a liquid outlet 103 and an ozone tail gas outlet 104, and the bottom is provided with a sewage inlet 105, an ozone inlet 106, a vent 107, a sight glass or a manhole 108, and the reaction The upper part of the inner wall of the outer cylinder 101 is provided with an overflow cofferdam 109; the upper part of the inner lifting cylinder 102 is provided with a shroud 110, the lower part is provided with an ozone microporous aeration disc 111, and the inner lower end of the inner lifting cyl...

Embodiment 2

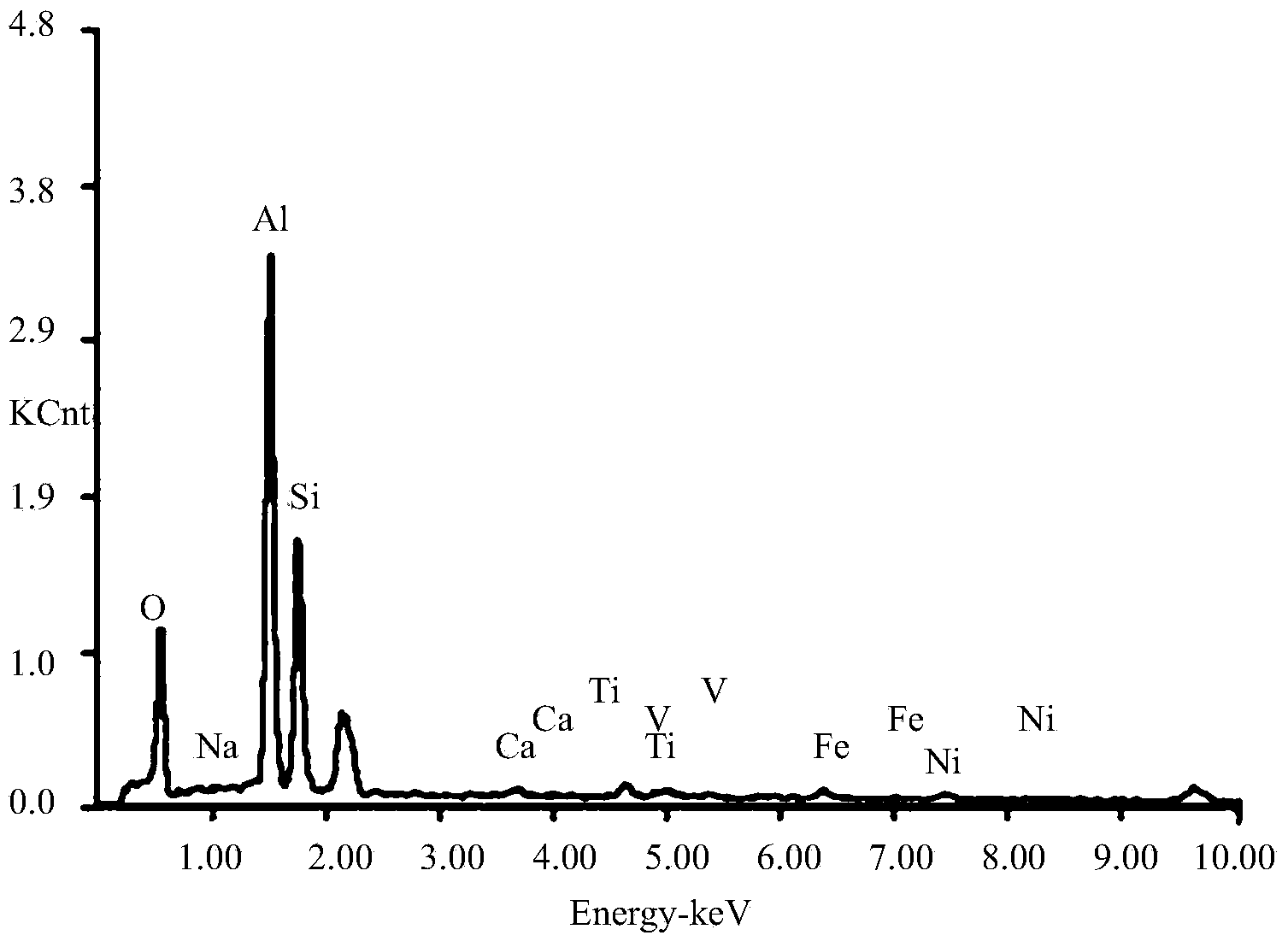

[0045] This example provides a spent oil refinery catalyst after activation treatment, which is prepared by the following method: put the spent FCC catalyst into a NaOH or KOH solution with a mass concentration of 5m%-10m% at 40°C-90°C for cleaning 1-2 hours; after taking it out, dry it at room temperature for 24-48 hours, and then dry it in an oven at 80°C-120°C for 2-4 hours; after drying, the spent FCC catalyst is roasted at 550°C-650°C for 2-3 hours. The spent oil refinery catalyst after activation treatment is obtained. The main components of the prepared catalyst are as follows: NiO is 2.0m%, Fe 2 o 3 2.3m%, V 2 o 5 1.57m%, SiO 2 38.46m%, Al 2 o 3 It is 49.48m%. The total specific surface area of the activated refinery waste catalyst is 84.4m 2 / g, the pore volume is 0.22cm 3 / g, the average pore diameter is 7.58nm. The surface X-ray energy spectrum analysis diagram and scanning electron microscope diagram of the spent oil refinery catalyst after the activati...

Embodiment 3

[0047] In this example, a gas-liquid-solid three-phase fluidized bed reactor is used to catalyze and oxidize the salty sewage of oil refinery, and the spent oil refinery catalyst after the activation treatment of "cleaning-drying-roasting" is used as an ozone synergistic catalyst to provide a method for utilizing waste oil refining Catalyst and ozone treatment method for oil refinery saline sewage, specifically adopt the device provided in embodiment 1 and the catalyst provided in embodiment 2, the steps are: make the oil refinery salty sewage to be treated and ozone-containing gas flow in the fluidized bed reactor 1 The bottom of the inner lifting cylinder 102 is input, and under the joint action of the upwardly flowing water and the ozone-containing gas, the "cleaning-drying-roasting" activation treatment in the inner lifting cylinder 102 (fluidized reaction zone 11) The spent refining catalyst particles are in a fluidized state, and undergo sufficient mass transfer and react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com