Clay brick recycled aggregate concrete partition slat

A technology of recycled aggregate and partition wall slats, which is applied in the field of building wall panels to achieve superior performance, control wall cracks, and moderate density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 , Clay brick recycled aggregate preparation

[0032] Sorting waste clay bricks from brick-concrete structure construction waste and reinforced concrete structure construction waste by mechanical or manual methods can be divided into:

[0033] Construction waste at the construction site: Clay bricks, concrete, waste wood blocks, waste plastics, waste ceramics, etc. in the construction waste are sorted and piled up on the construction site.

[0034] Factory construction waste: The collected construction waste is sorted and stacked according to brick-concrete construction waste and reinforced concrete construction waste, and clay bricks are sorted from brick-concrete construction waste and reinforced concrete construction waste.

[0035] The clay brick recycled aggregate is broken into two kinds of clay brick aggregate with particle size below 3mm and 3-10mm by crushing equipment such as jaw crusher, impact crusher, cone crusher, impact crusher or hammer crushe...

Embodiment 2

[0036] Example 2 , Prepare clay brick recycled aggregate concrete partition wall slab components

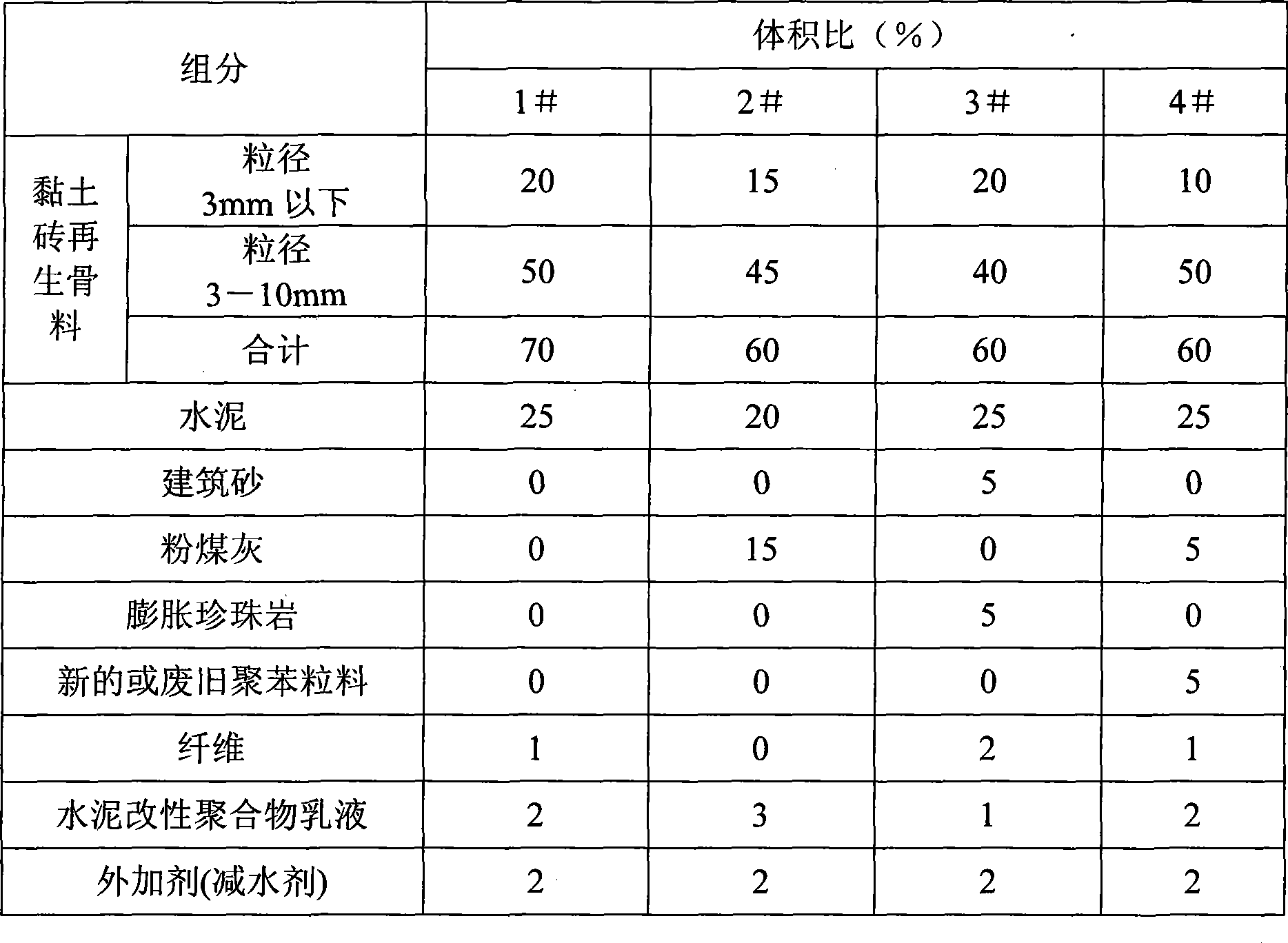

[0037] According to the formula shown in Table 1, measure the components of the partition wall slats in proportion, add water according to the water-cement ratio of 0.3-0.45, and stir in the mixer to mix the components evenly for later use.

[0038] Table 1

[0039]

Embodiment 3

[0040] Example 3 , Production of clay brick recycled aggregate concrete partition wall slats

[0041] Follow the steps below to prepare clay brick recycled aggregate concrete partition wall slats:

[0042] A, the components of the partition wall batten shown in Table 1 of Example 2 are measured in proportion, add water according to the water-cement ratio 0.3-0.45, mix and stir;

[0043] B. Send the uniformly stirred components into a screw extruder for extrusion molding;

[0044] C. Cut the formed sheet into required specifications;

[0045] D, from the board;

[0046] E. Packing and binding;

[0047] F. Natural conservation or steam conservation.

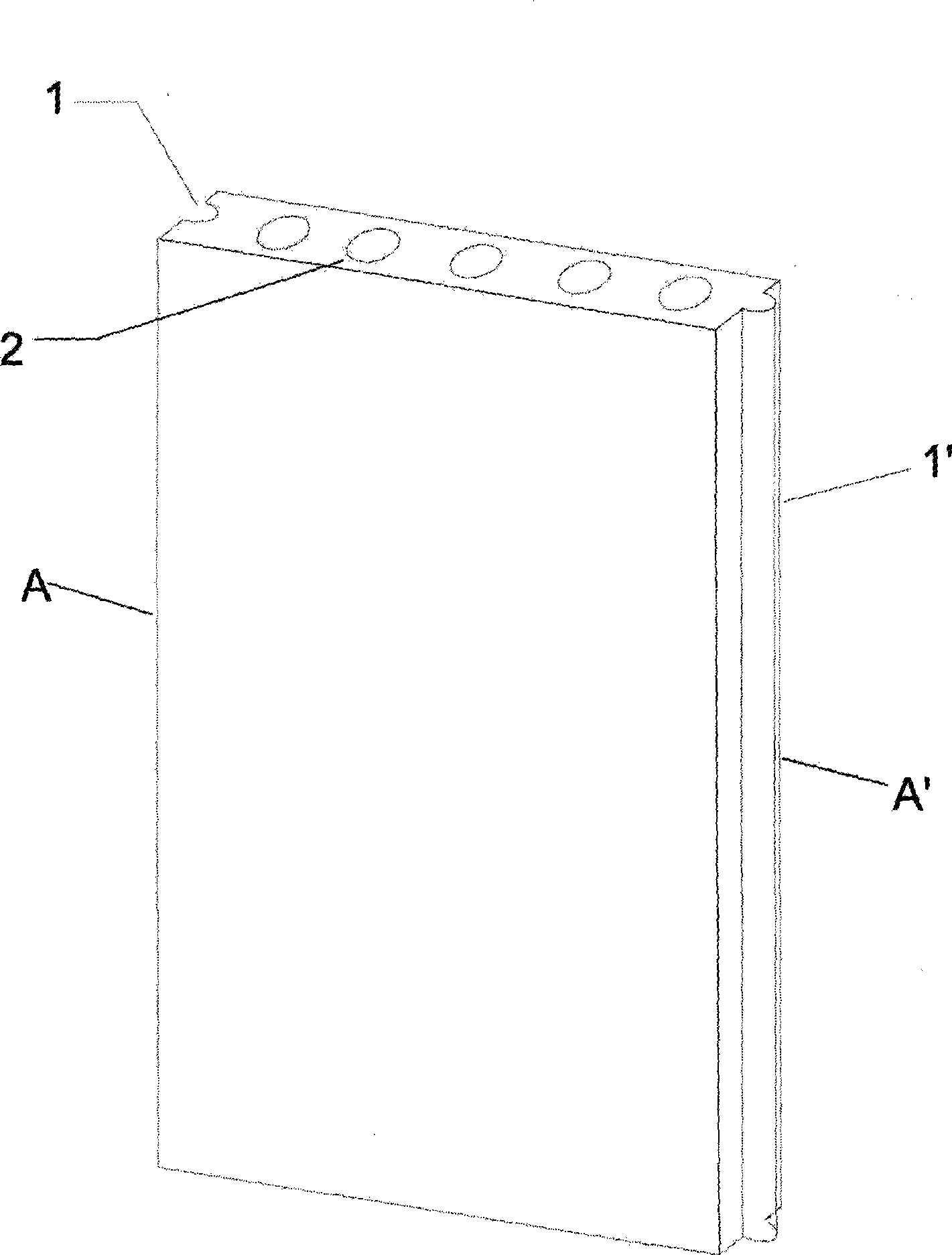

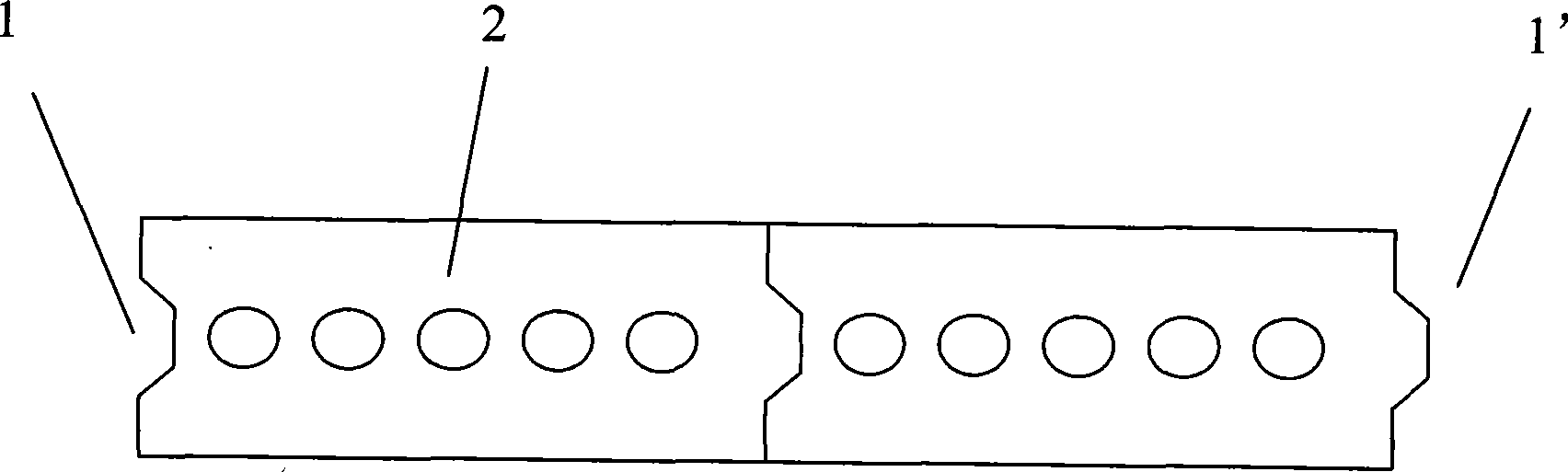

[0048] The size of the clay brick recycled aggregate concrete partition wall slab made according to the above method has three specifications: length × width × thickness = 2500-3000mm × 600mm × 60mm; 2500-3000mm × 600mm × 90mm; 2500-3000mm × 600mm × 120mm .

[0049] The molded clay brick recycled aggregate concrete partitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com