Lightweight concrete with electromagnetic shielding functions, and preparation method thereof

A lightweight concrete and electromagnetic shielding technology, which is applied in the field of concrete and its preparation, can solve the problems of increasing the amount of carbon fiber, not significantly improving the shielding efficiency of concrete, and decreasing the performance of concrete such as compression resistance and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

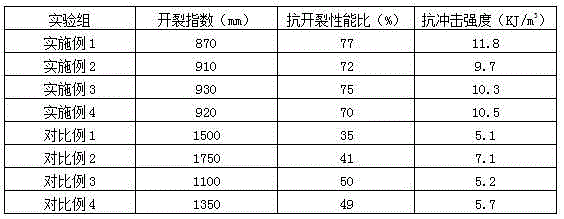

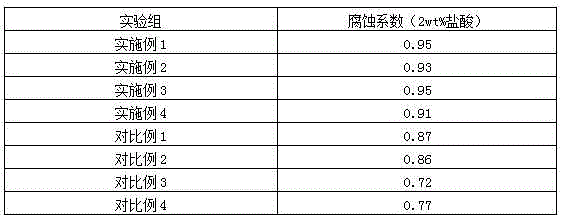

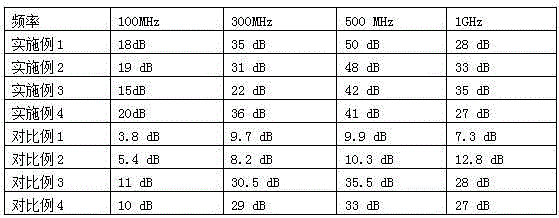

Examples

Embodiment 1

[0027] The present embodiment provides a kind of lightweight concrete with electromagnetic shielding function, and its raw material comprises by weight:

[0028] Portland cement 51 parts;

[0029] Carbon fiber 7 parts;

[0030] 4 parts of waste polypropylene particles;

[0031] Iron powder 6 parts;

[0032] 15 parts of river sand;

[0033] 25 parts of water;

[0034] Admixture 2 parts;

[0035] The admixture comprises 55 parts by weight of polycarboxylate water reducer, 4 parts of butylene glycol ester, 12 parts of oxaloacetic acid and 7 parts of sodium persulfate.

[0036] The length of the carbon fiber is 4 mm; the particle size of the waste polypropylene is 5 mm; the particle size of the iron powder is 10 μm. The river sand is made by mixing coarse sand with a fineness modulus of 3.1 mm and fine sand with a fineness modulus of 2.2 mm at a mass ratio of 4:1.

[0037] Present embodiment also provides a kind of method for preparing above-mentioned lightweight concrete, ...

Embodiment 2

[0044] The present embodiment provides a kind of lightweight concrete with electromagnetic shielding function, and its raw material comprises by weight:

[0045] Portland cement 40 parts;

[0046] Carbon fiber 10 parts;

[0047] 3 parts of waste polypropylene particles;

[0048] Iron powder 8 parts;

[0049] 10 parts of river sand;

[0050] 30 parts of water;

[0051] Admixture 1 part;

[0052] The additives include 70 parts by weight of polycarboxylate water reducer, 1 part of butylene glycol ester, 15 parts of oxaloacetic acid and 5 parts of sodium persulfate. The PC-1026 of the preferred SUNBO company of described polycarboxylate water reducing agent

[0053] The Portland cement is preferably a commercially available Portland cement with a P.I strength grade of 42.5R.

[0054] The length of the carbon fiber is 5 mm; the particle size of the waste polypropylene is 1 mm; the particle size of the iron powder is 15 μm. The river sand is made by mixing coarse sand with a...

Embodiment 3

[0057] The present embodiment provides a kind of lightweight concrete with electromagnetic shielding function, and its raw material comprises by weight:

[0058] Portland cement 60 parts;

[0059] Carbon fiber 5 parts;

[0060] 5 parts of waste polypropylene particles;

[0061] Iron powder 4 parts;

[0062] 20 parts of river sand;

[0063] 15 parts of water;

[0064] 3 parts of admixture;

[0065] The additives include 50 parts by weight of polycarboxylate water reducer, 10 parts of butylene glycol ester, 15 parts of oxaloacetic acid and 5 parts of sodium persulfate.

[0066] The length of the carbon fiber is 3 mm; the particle size of the waste polypropylene is 15 mm; the particle size of the iron powder is 10 μm. The river sand is made by mixing coarse sand with a fineness modulus of 3.1 mm and fine sand with a fineness modulus of 2.2 mm at a mass ratio of 4:1.

[0067] The lightweight concrete of this embodiment is made by the method provided in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com