Patents

Literature

60results about How to "Significant growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

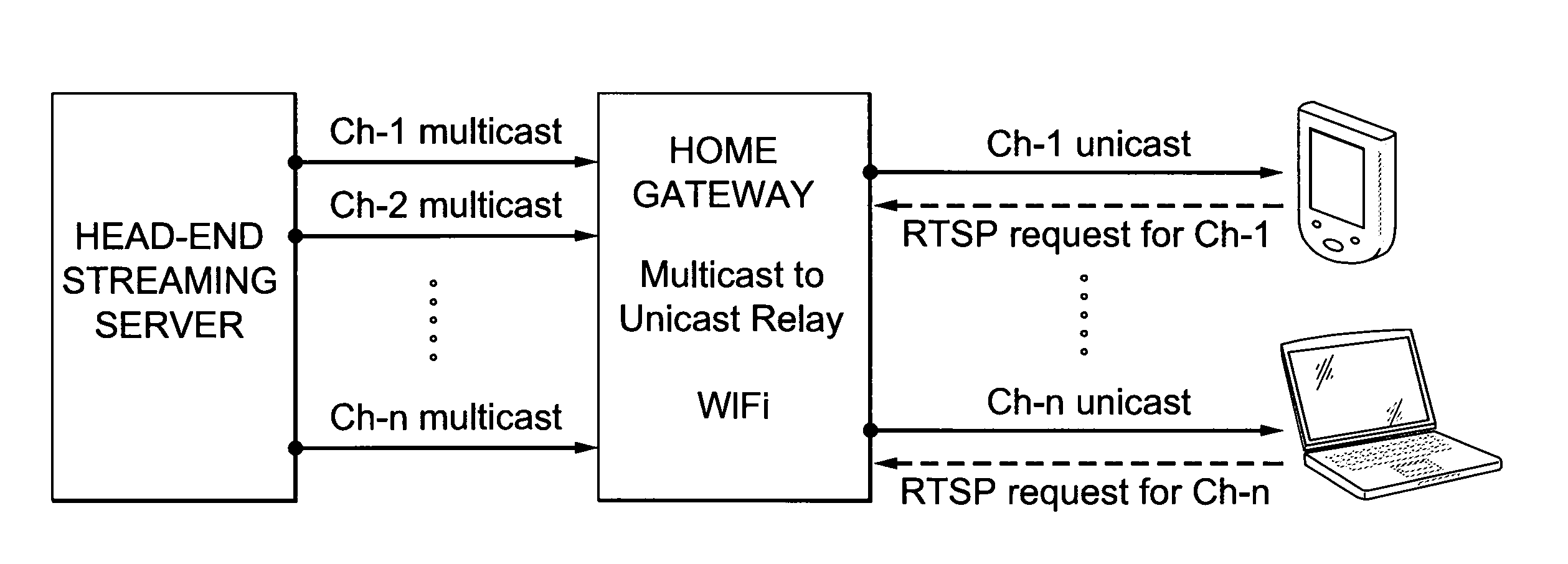

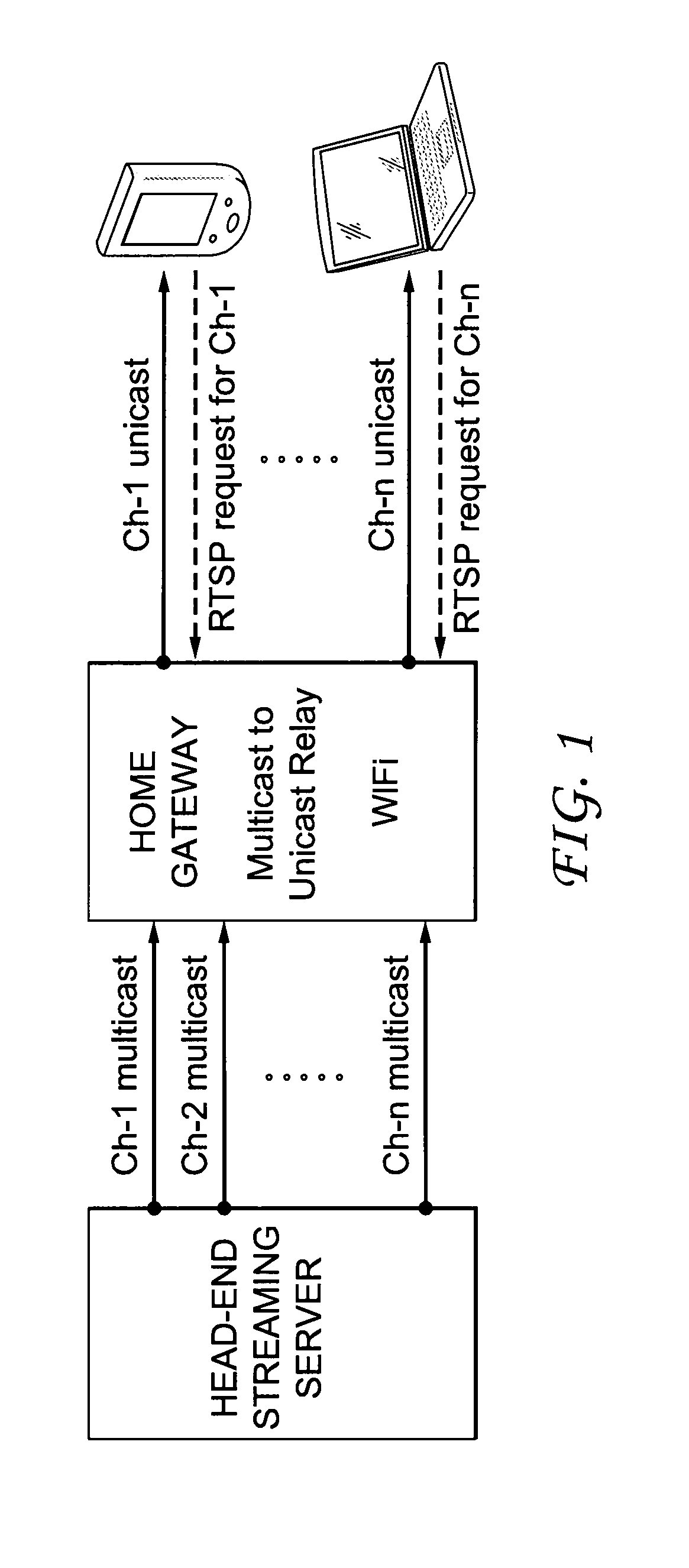

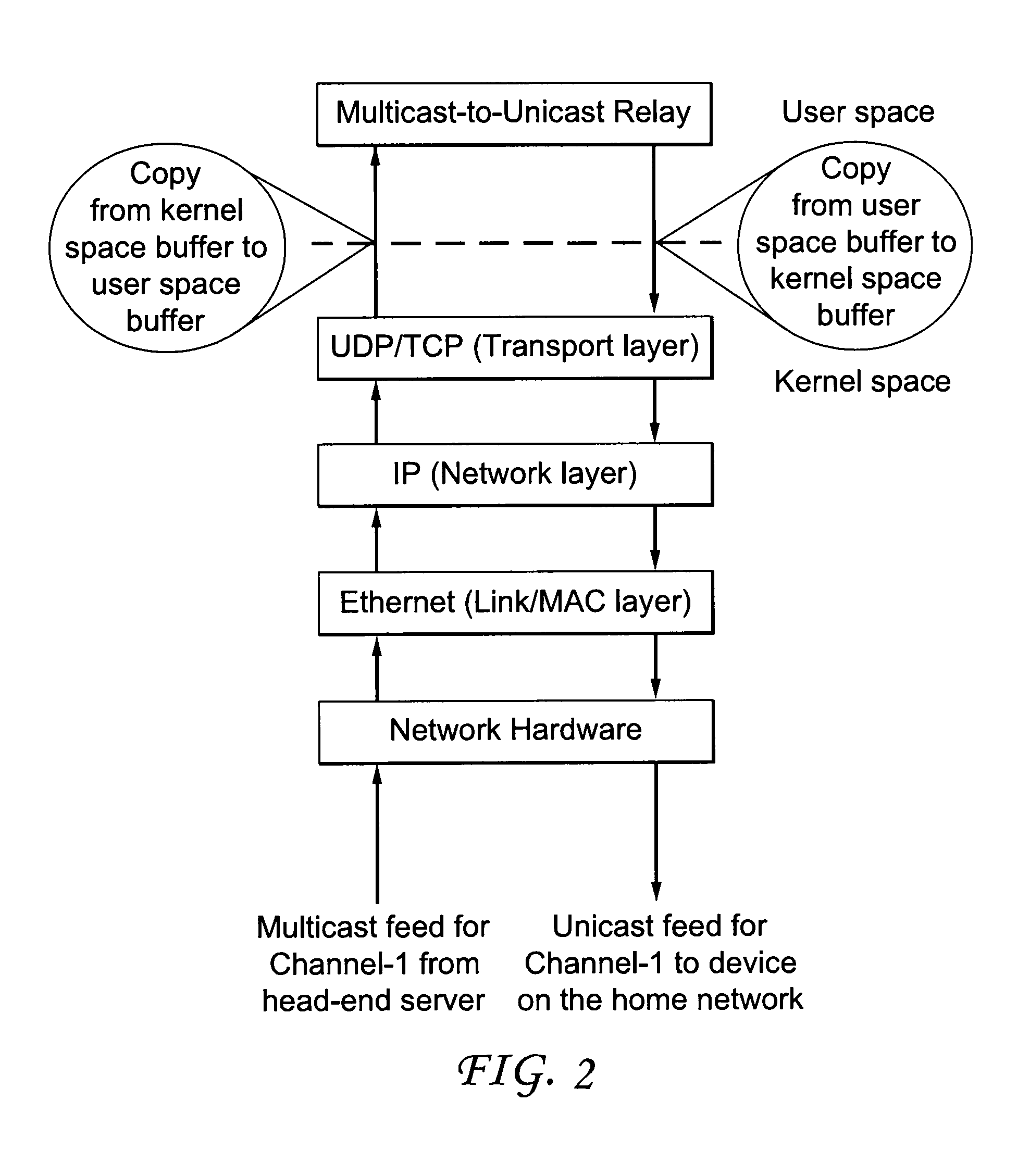

Method and apparatus for converting a multicast session to a unicast session

InactiveUS20130128889A1Avoid overheadImprove error recovery of dataData switching by path configurationNetwork packetClient-side

A method and apparatus are described including receiving a data Packet having a data packet header, storing the received data packet as shared payload, determining if the received data packet is a first data packet, initializing a sequence starting number responsive to the determination, generating a new data packet header, calculating a sequence number for the received data packet using the sequence starting number, inserting the new sequence number into the new data packet header, unicasting the new data packet header and the shared payload to a plurality of client devices.

Owner:MAGNOLIA LICENSING LLC

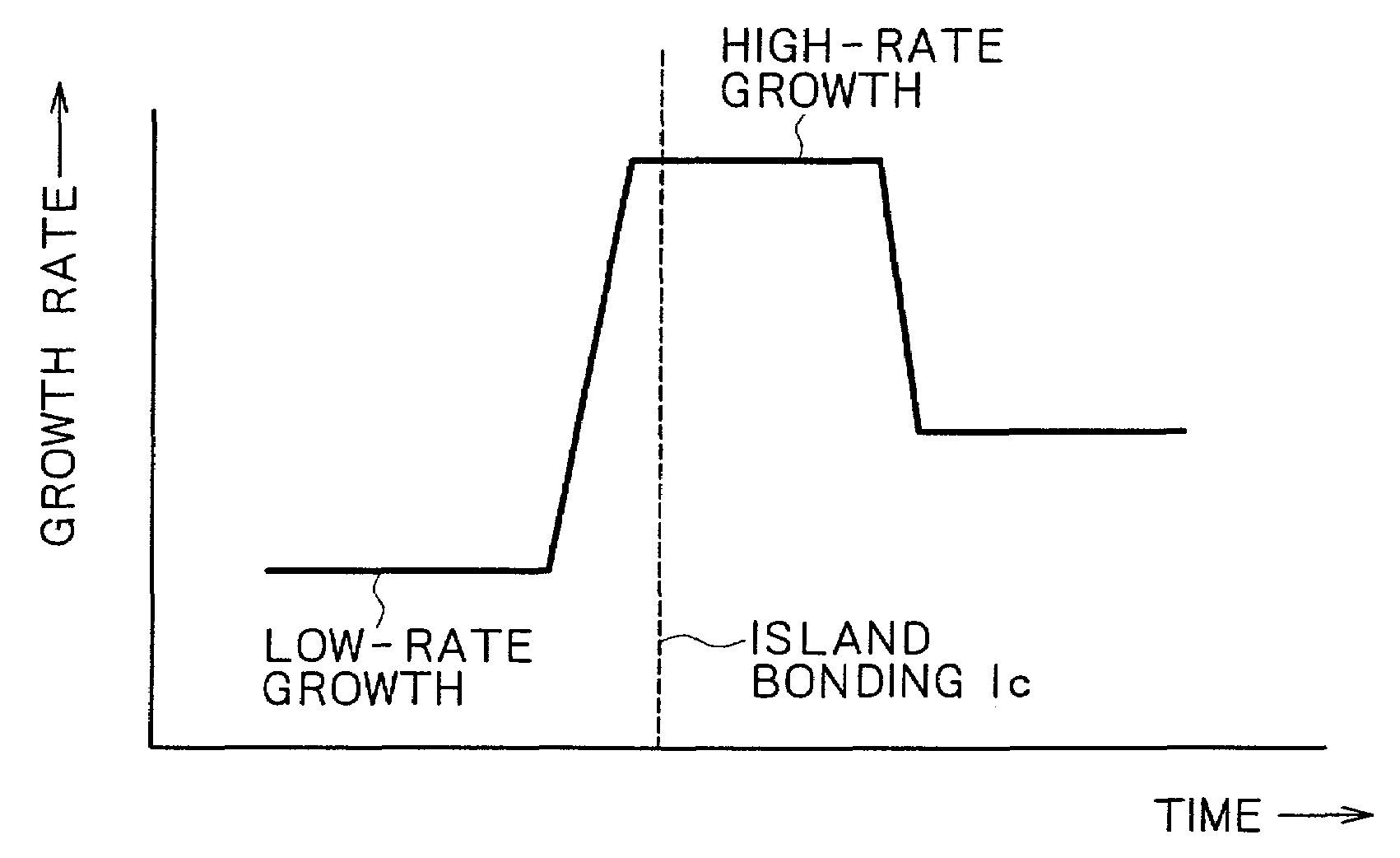

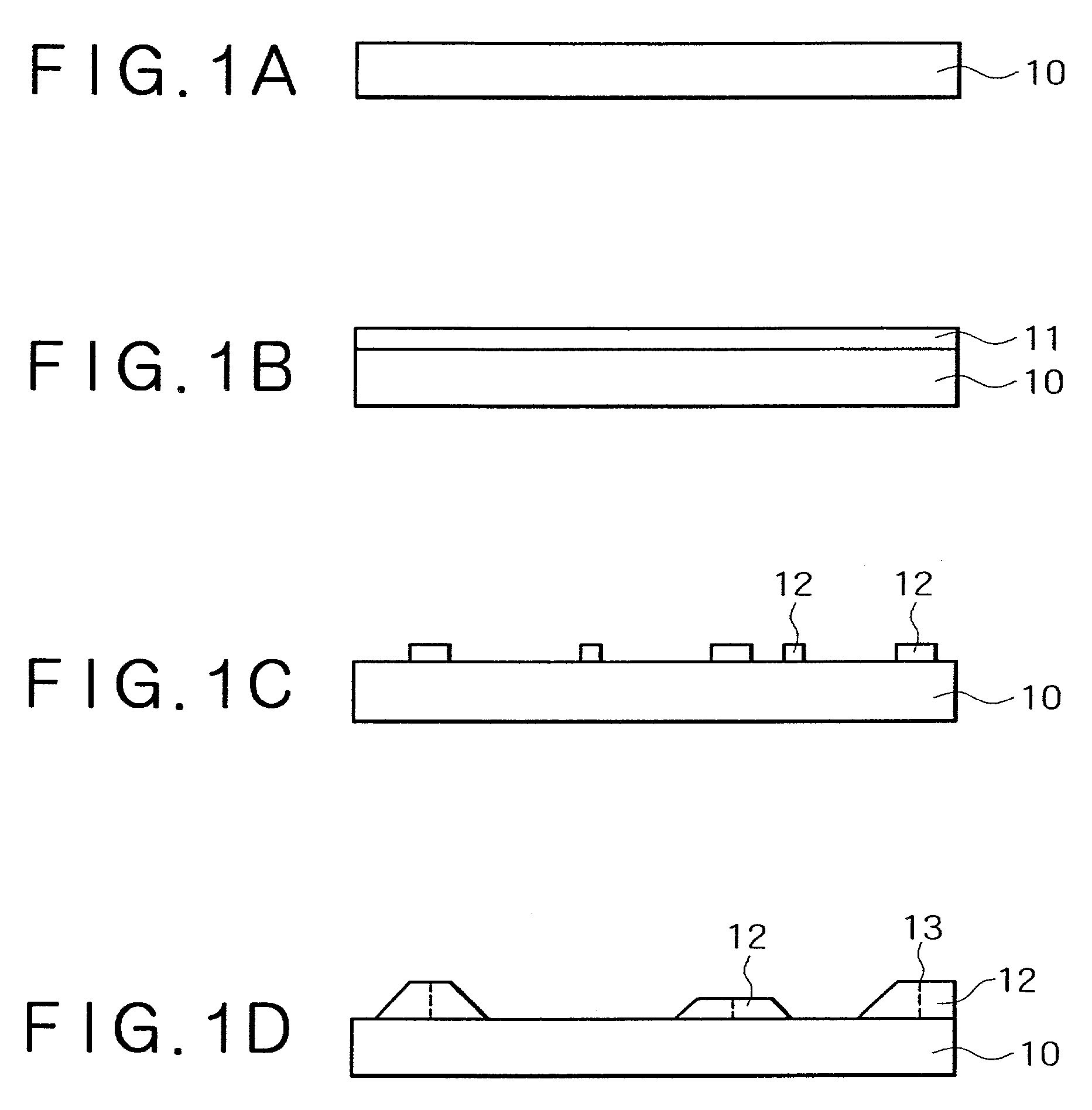

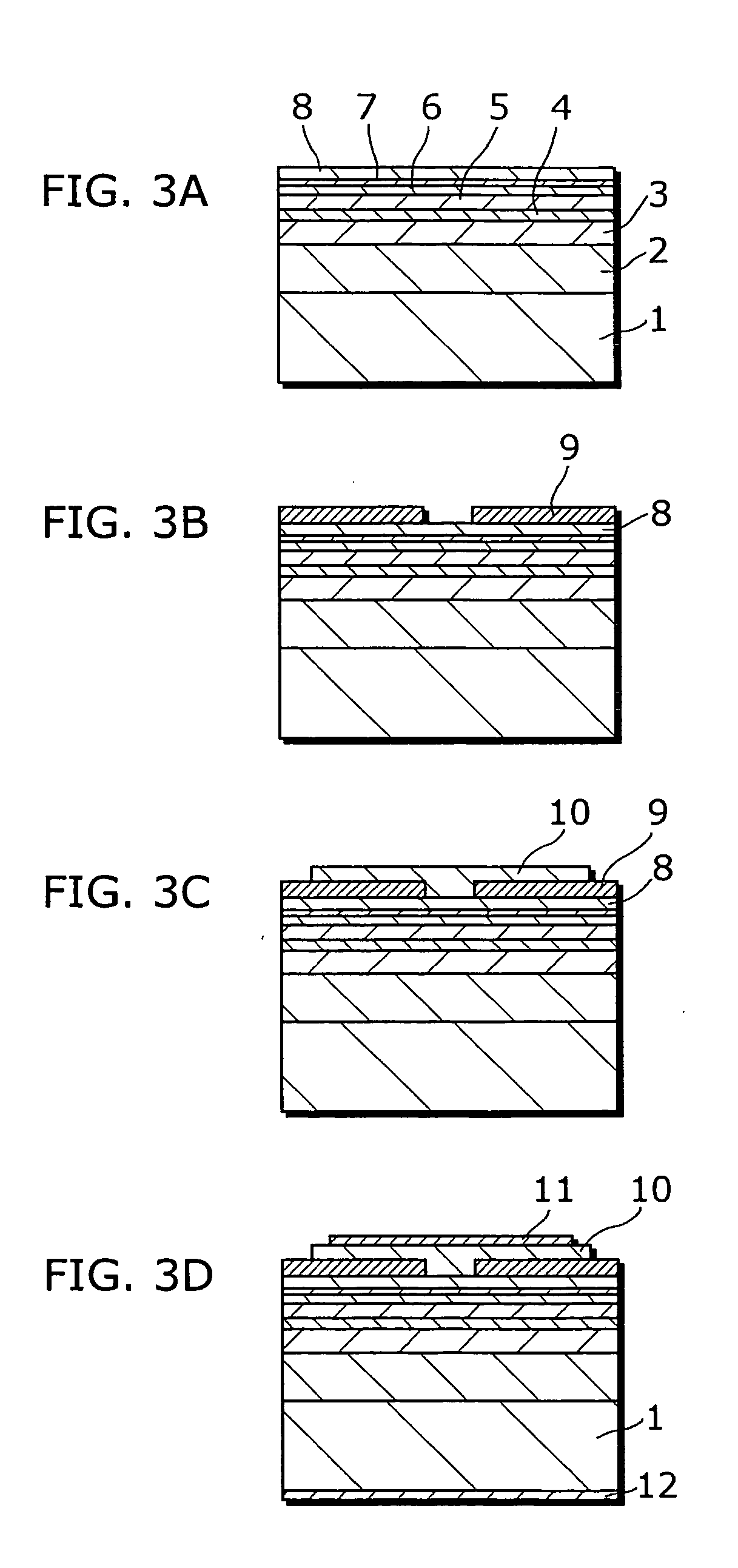

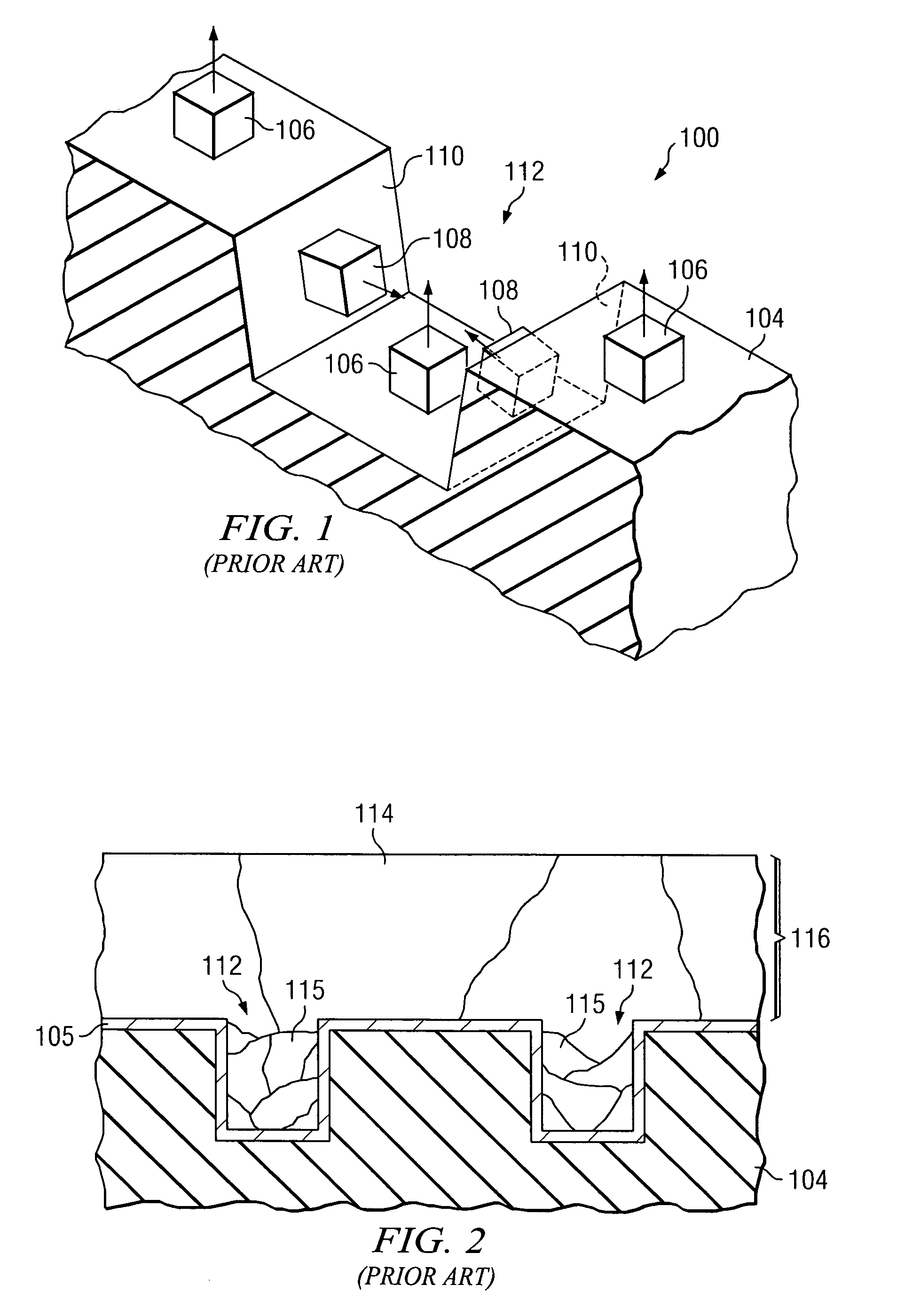

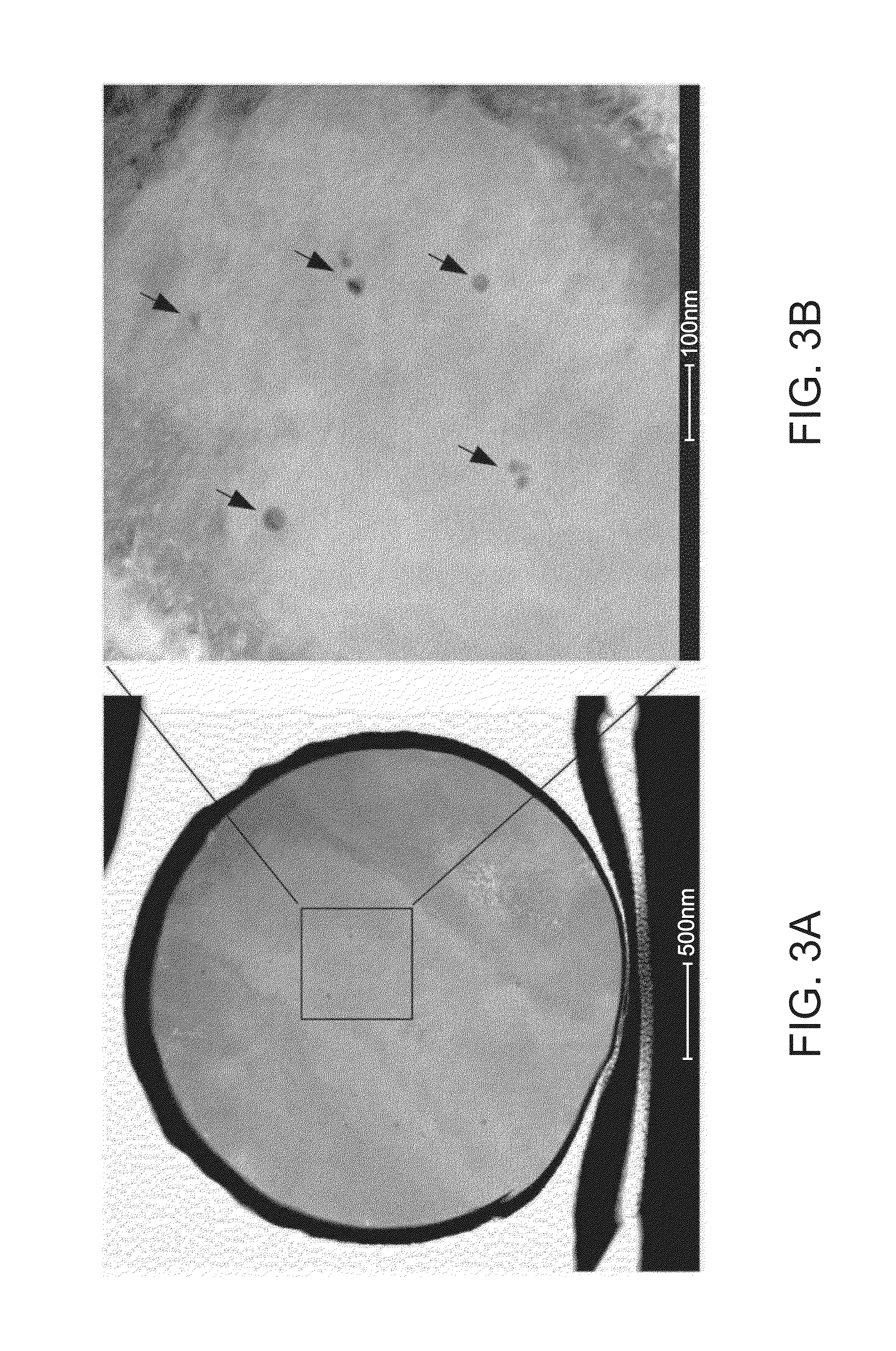

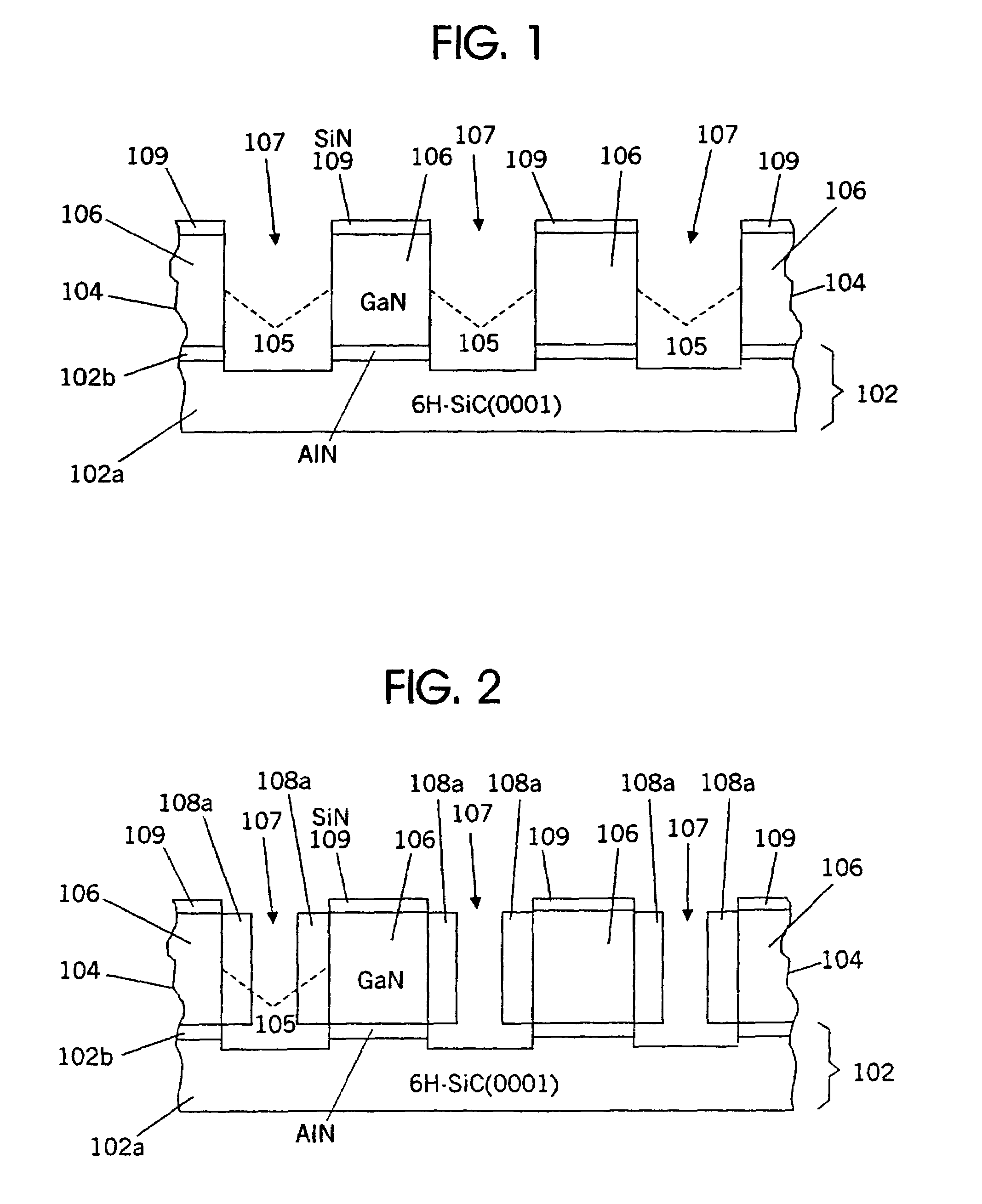

Crystal growth method for nitride semiconductor and formation method for semiconductor device

InactiveUS7033436B2Improving performance lifeExtended service lifePolycrystalline material growthLaser detailsSemiconductor materialsCrystal growth rate

Methods of crystal growth for semiconductor materials, such as nitride semiconductors, and methods of manufacturing semiconductor devices are provided. The method of crystal growth includes forming a number of island crystal regions during a first crystal growth phase and continuing growth of the island crystal regions during a second crystal growth phase while bonding of boundaries of the island crystal regions occurs. The second crystal growth phase can include a crystal growth rate that is higher than the crystal growth rate of the first crystal growth phase and / or a temperature that is lower than the first crystal growth phase. This can reduce the density of dislocations, thereby improving the performance and service life of a semiconductor device which is formed on a nitride semiconductor made in accordance with an embodiment of the present invention.

Owner:SONY CORP

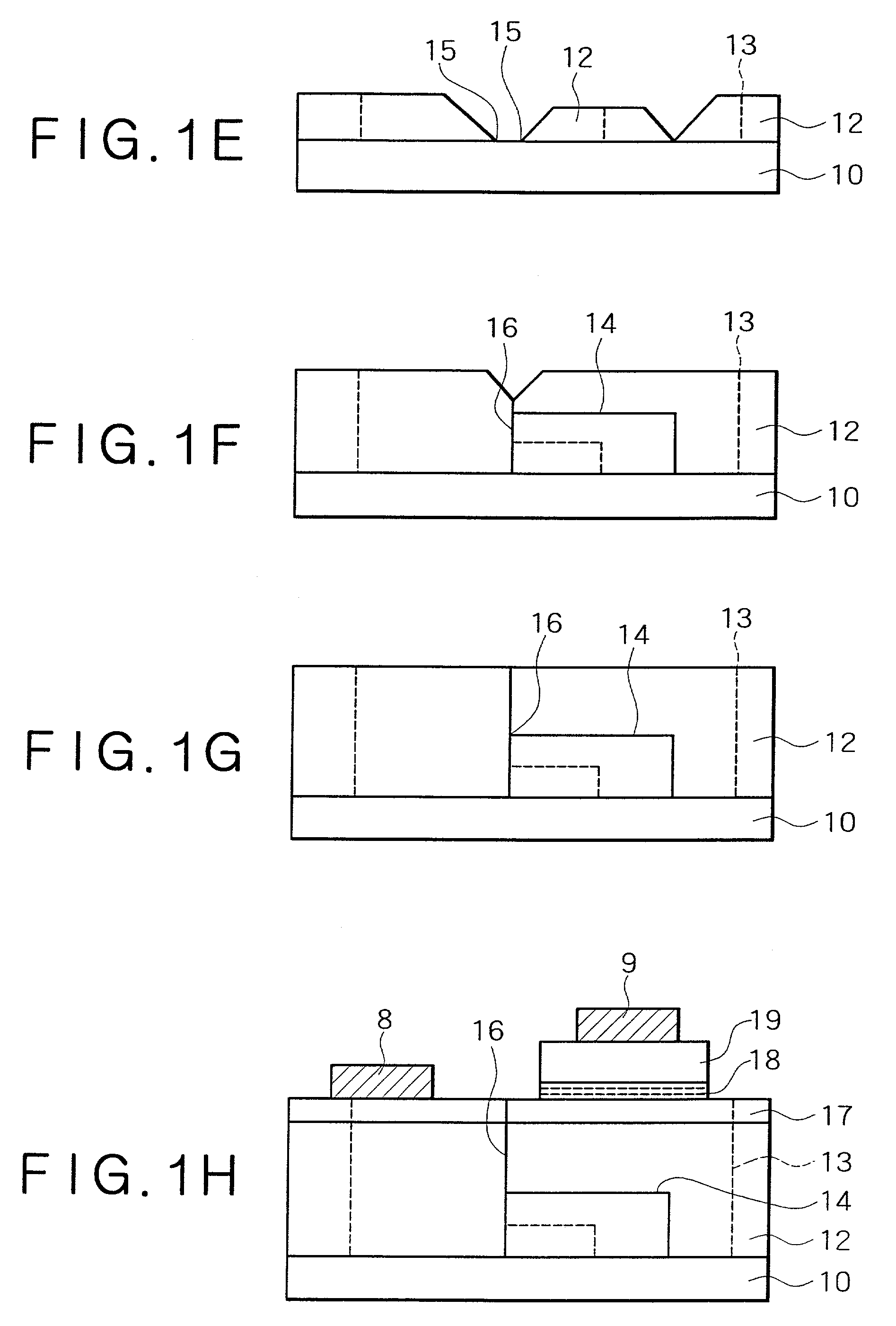

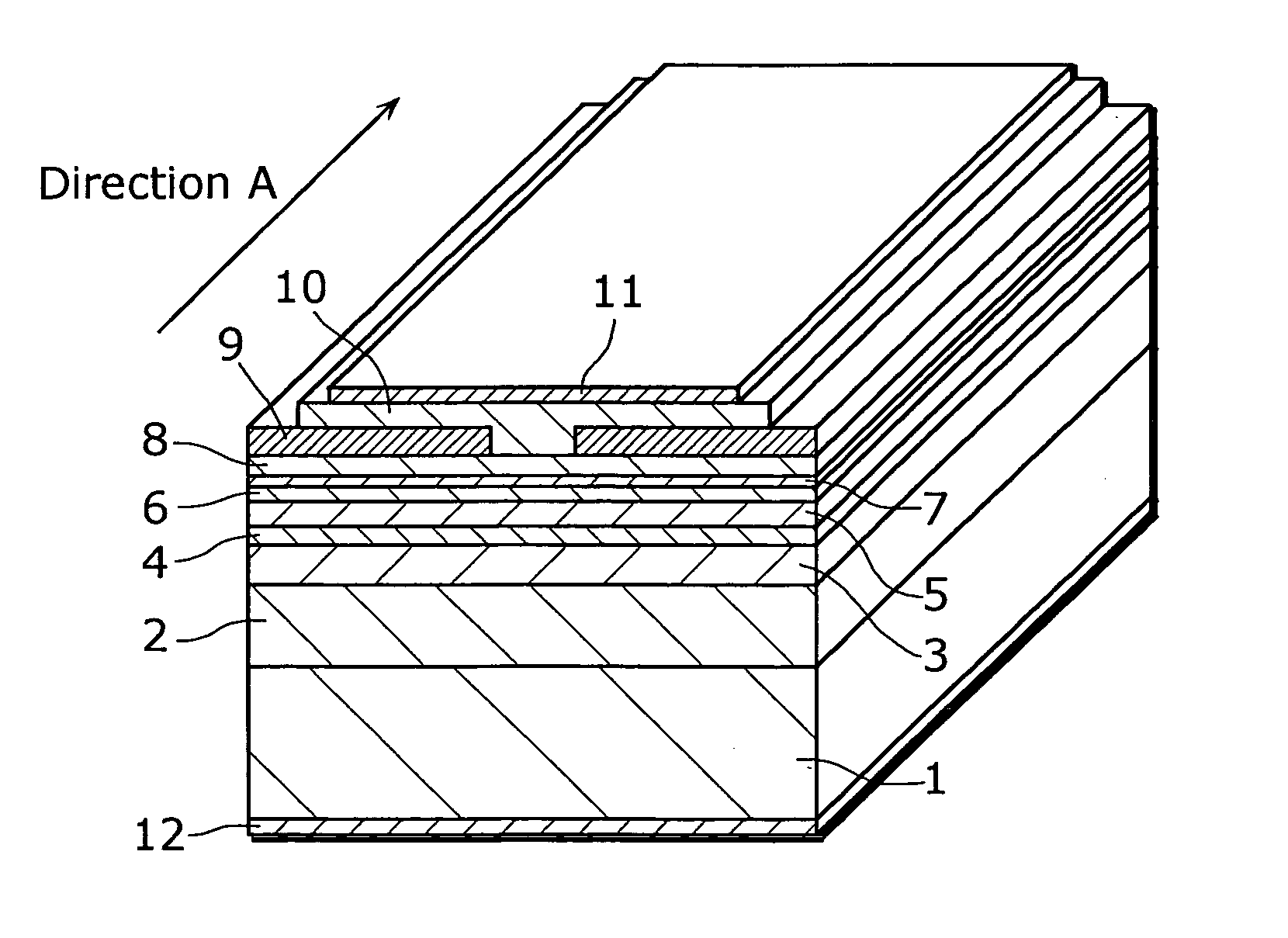

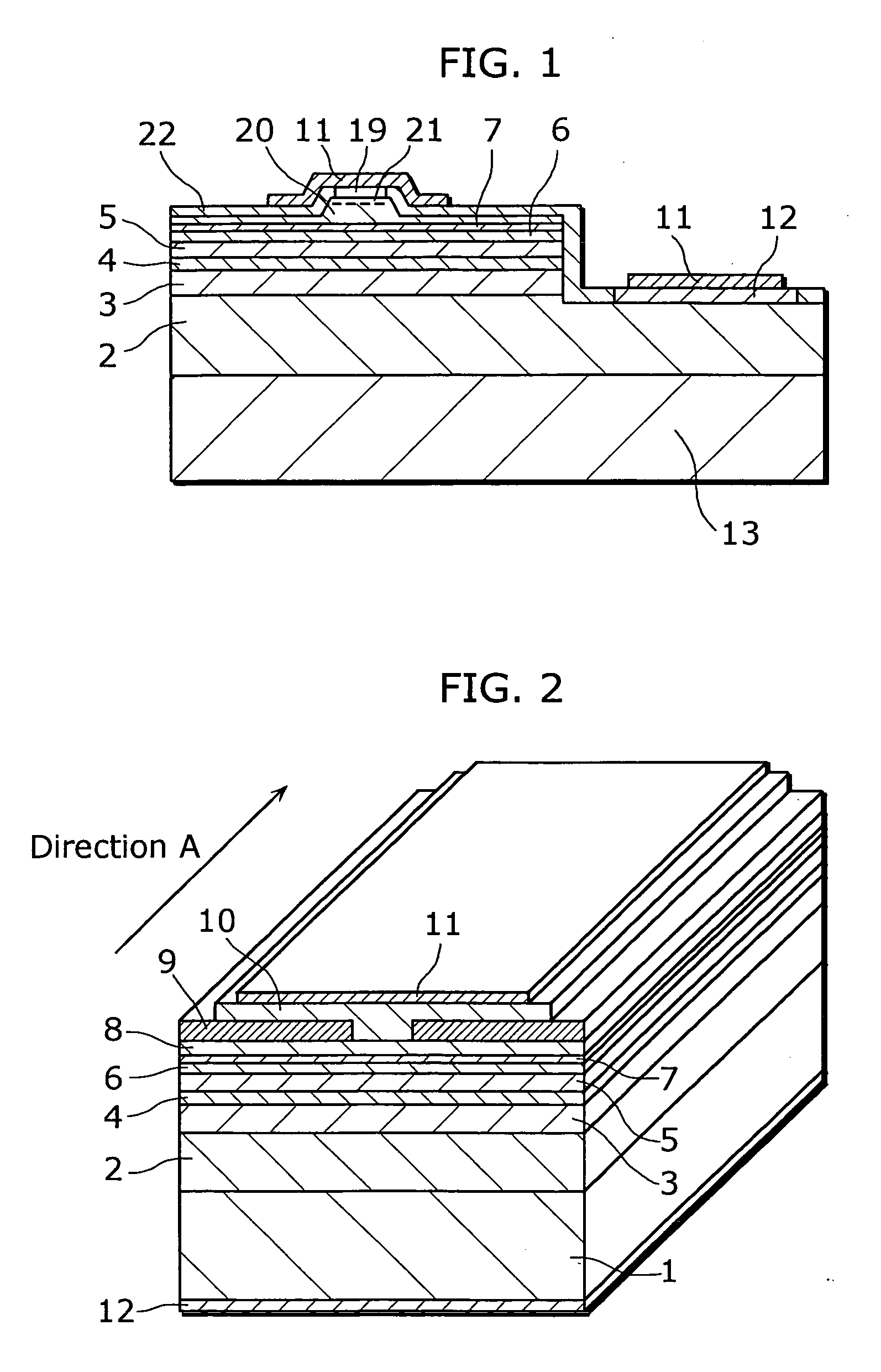

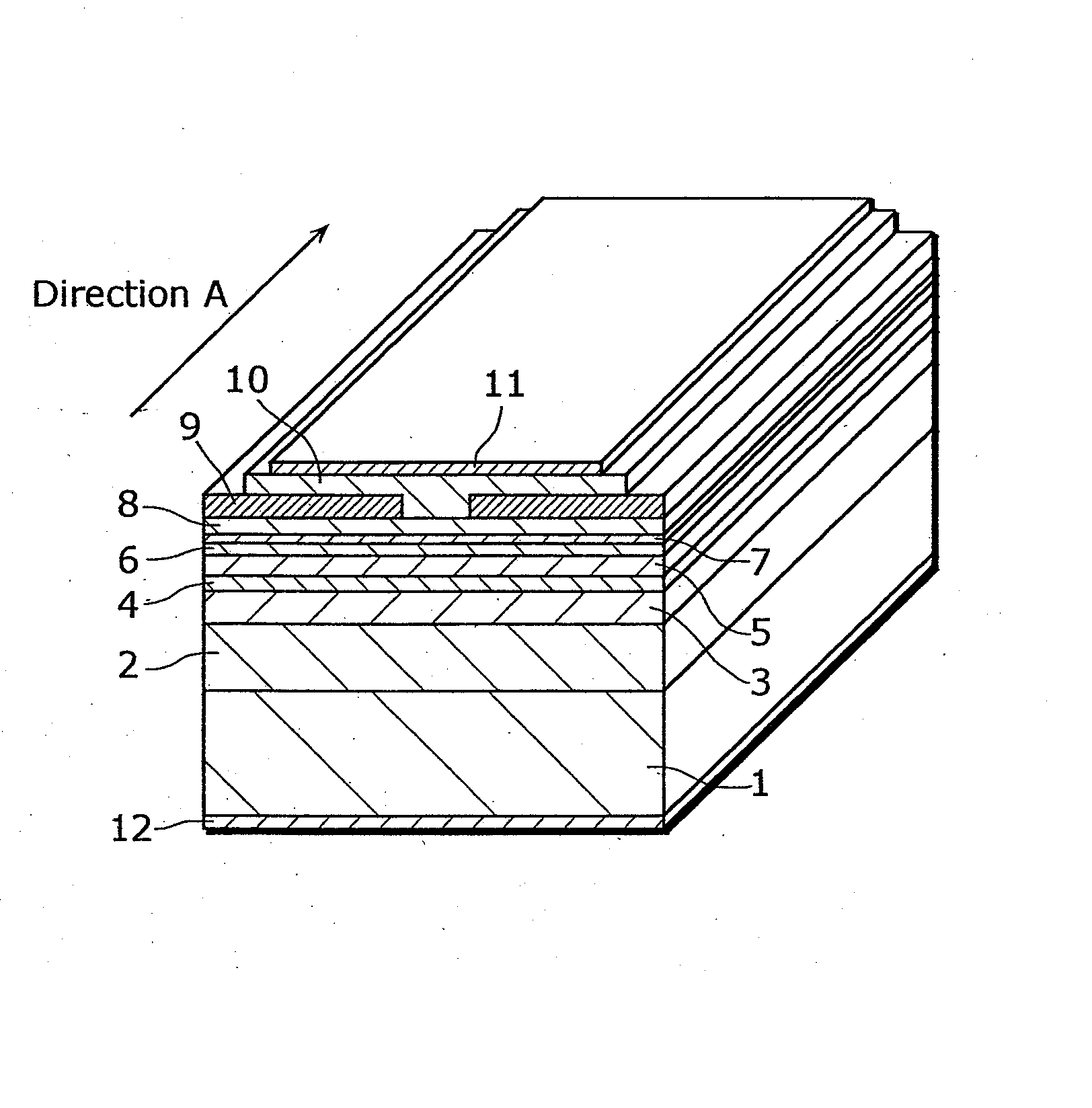

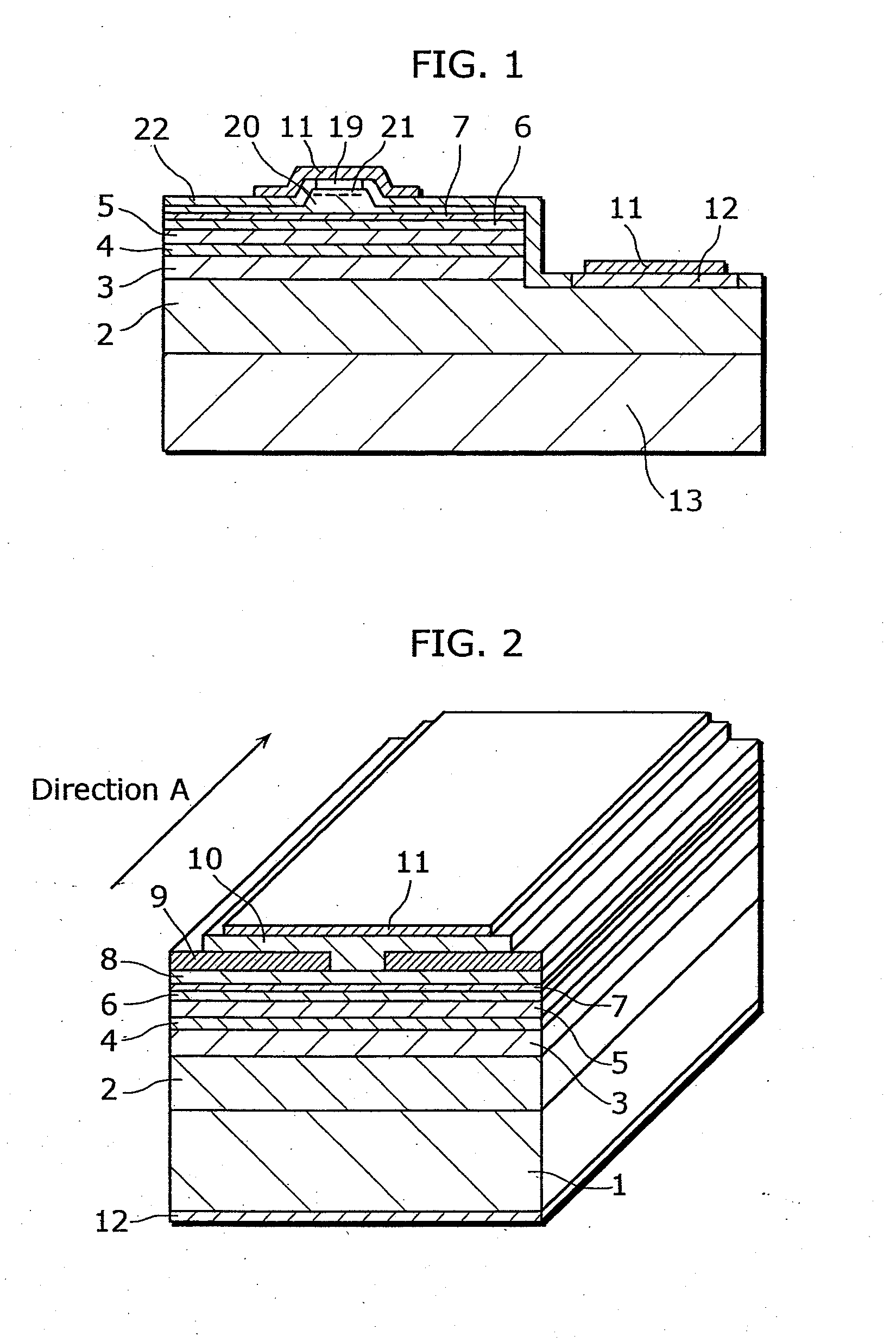

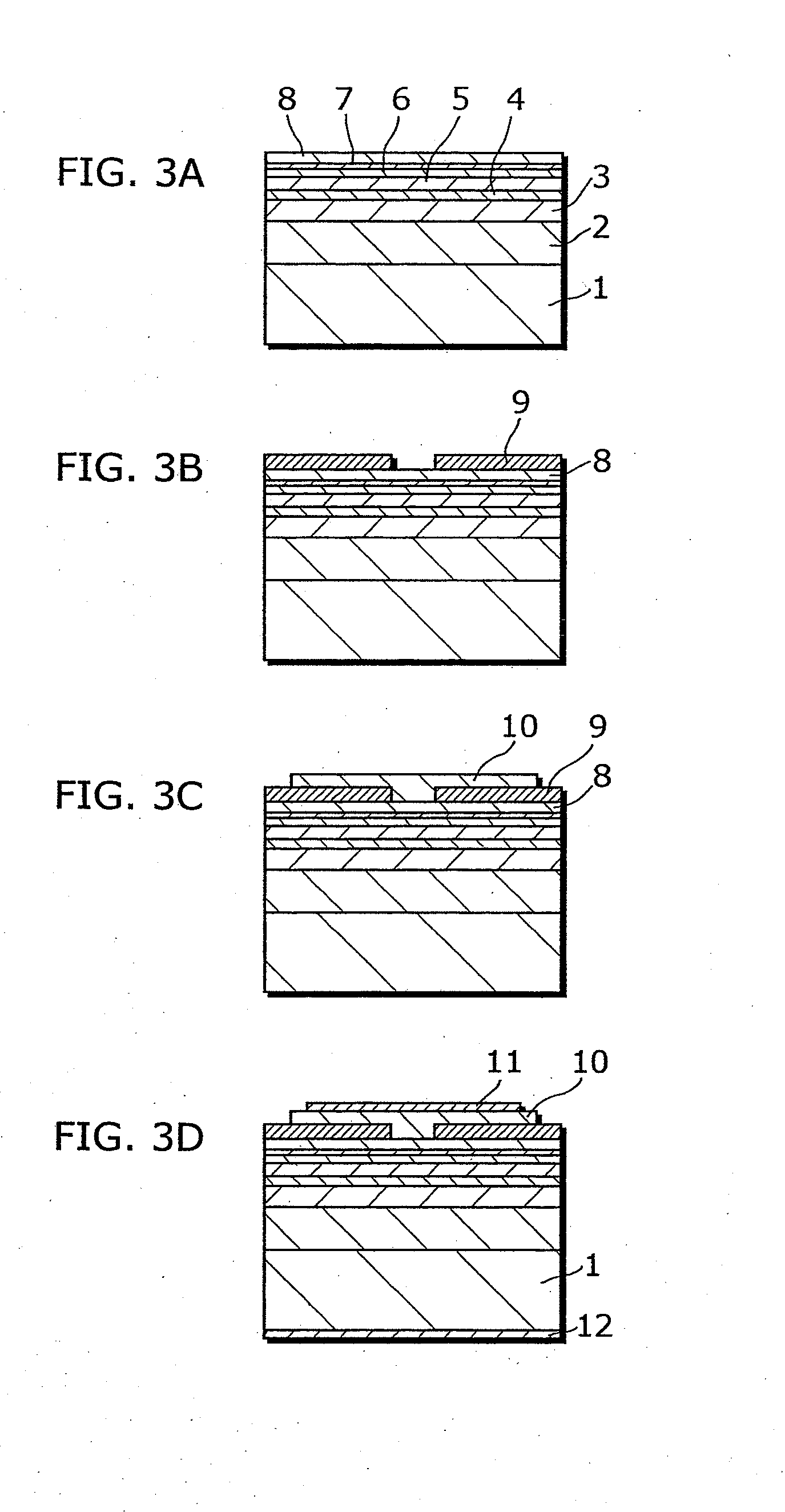

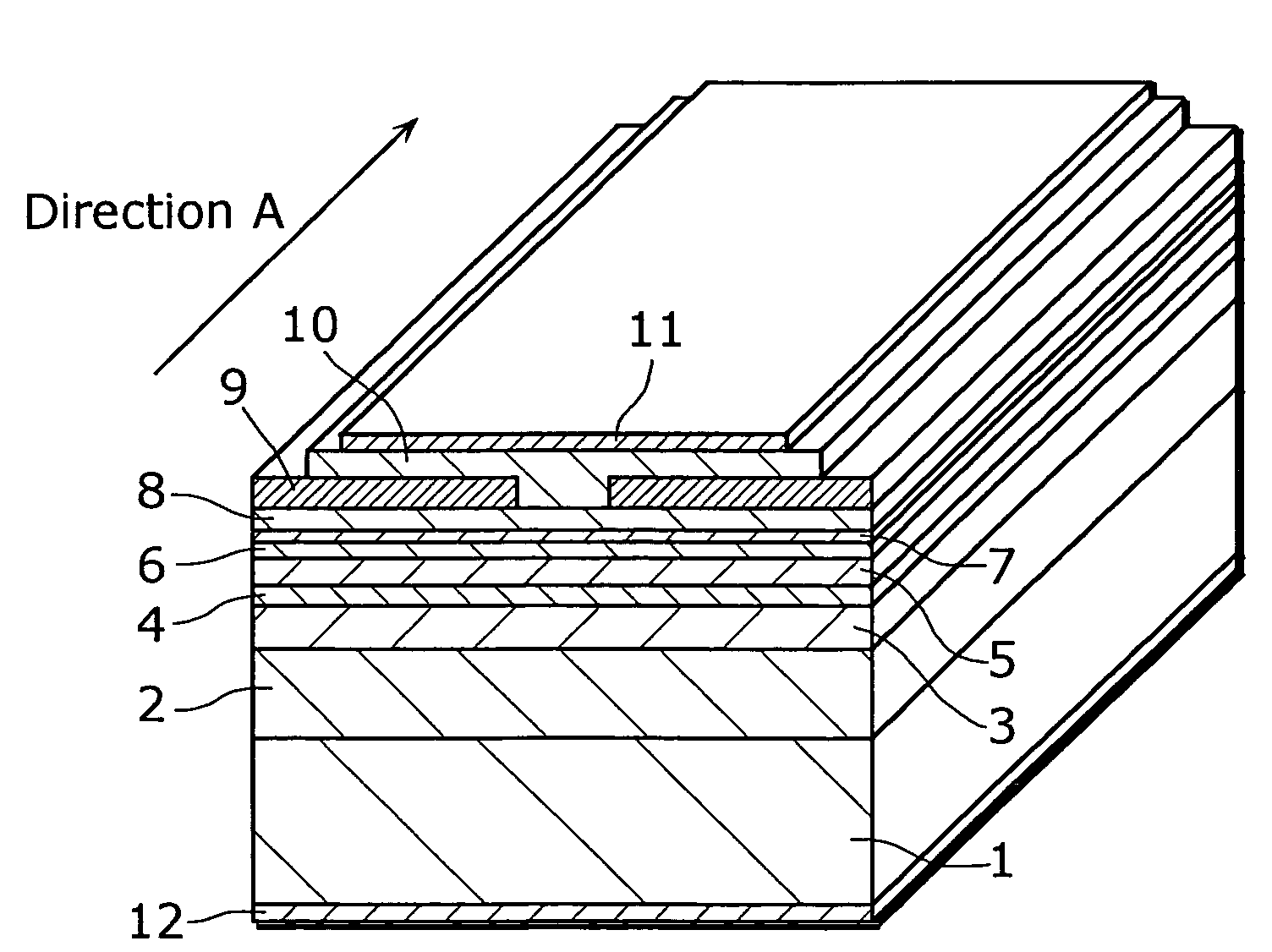

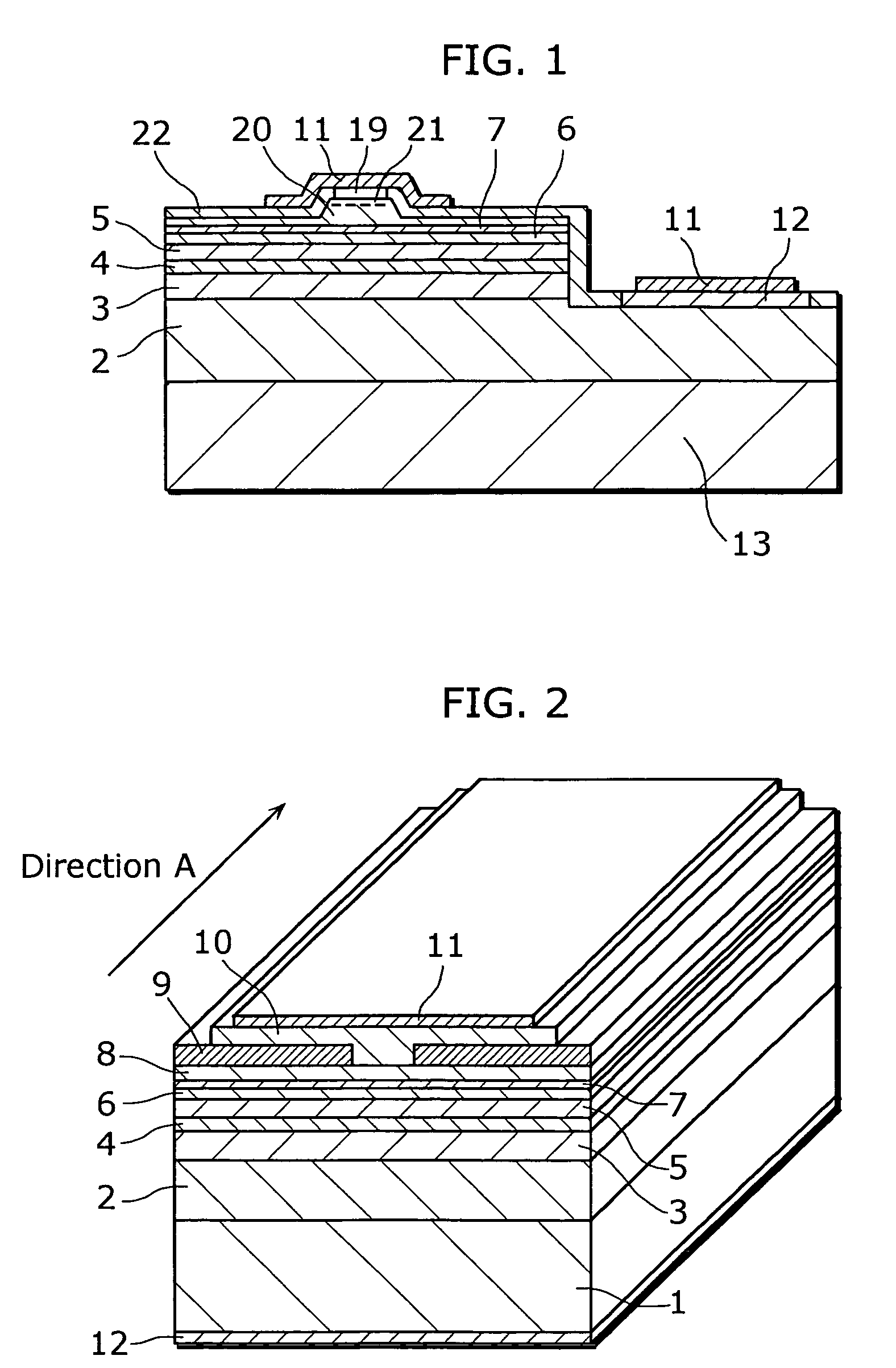

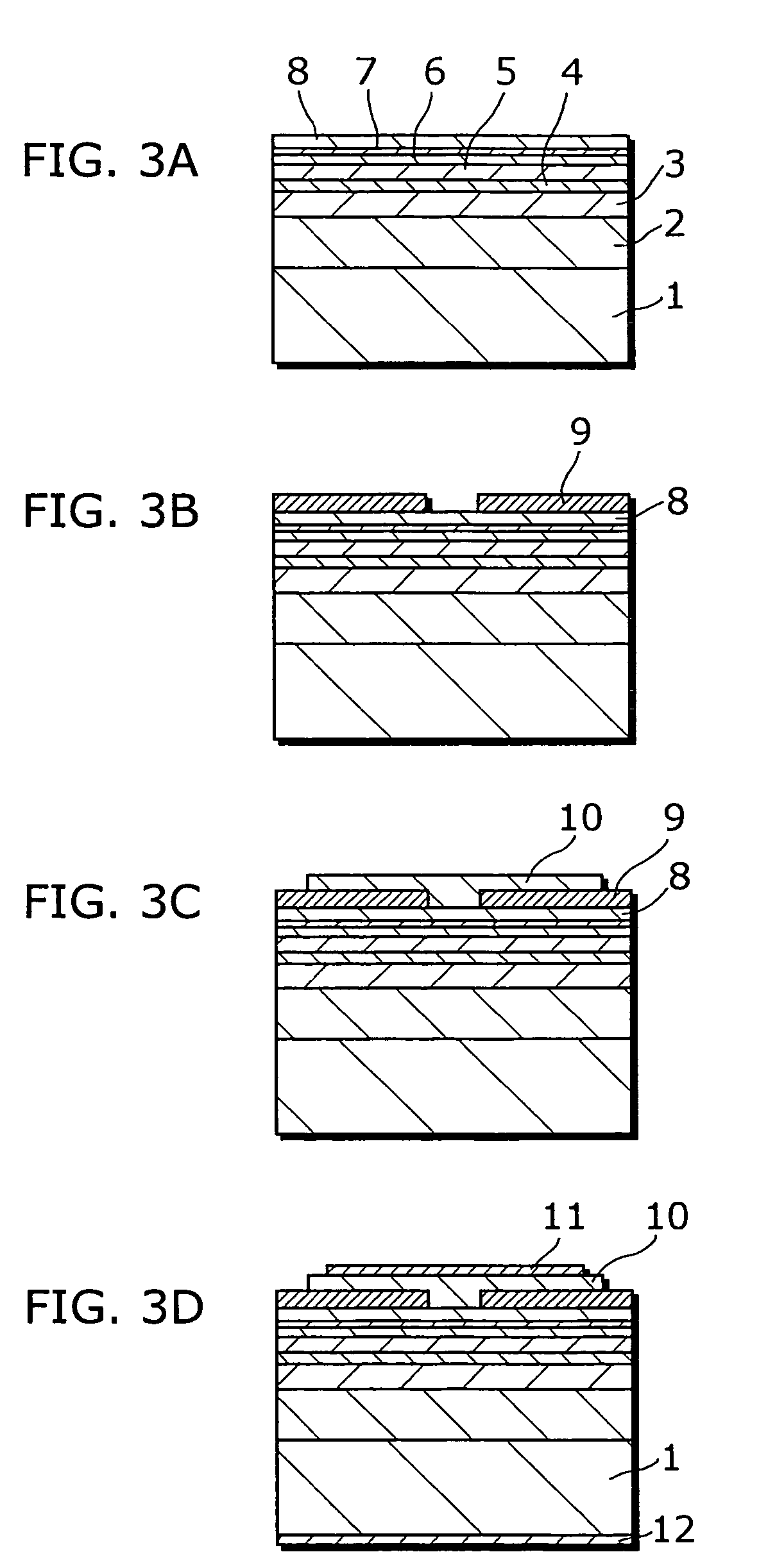

Semiconductor laser device and manufacturing method thereof

ActiveUS20050279994A1High yieldLow costOptical wave guidanceLaser detailsActive layerSilicon dioxide

It is an object of the present invention to provide a semiconductor laser device with high-yielding in which a clack generated in an epitaxial growth layer is restrained and to the manufacturing method thereof, the semiconductor laser device includes a GaN substrate 1, an n-type GaN layer 2, an n-type AlGaN cladding layer 3, a n-type GaN guide layer 4, an InGaN multiple quantum well active layer 5, an undoped-GaN guide layer 6, a p-type AlGaN electron overflow suppression layer 7, a p-type GaN guide layer 8, a SiO2 blocking layer 9, an Ni / ITO cladding layer electrode 10 as a transparent electrode, a Ti / Au pad electrode 11, and a Ti / Al / Ni / Au electrode 12. The SiO2 blocking layer 9 is formed above the InGaN multiple quantum well active layer 5 so as to have an opening. The Ni / ITO cladding layer electrode 10 is formed inside the opening, and which is transparent for the light from the InGaN multiple quantum well active layer, and serves as a cladding layer.

Owner:PANASONIC CORP

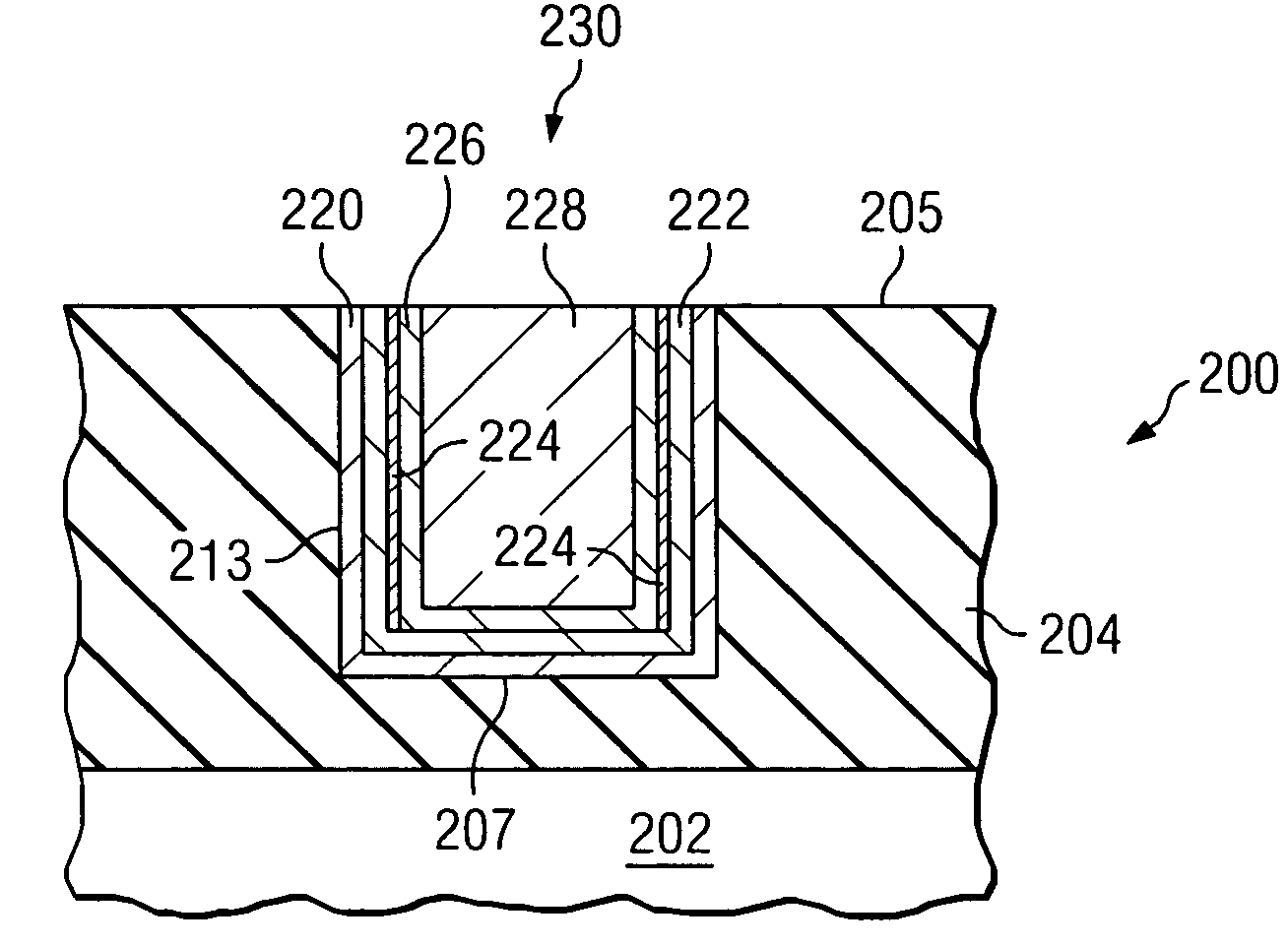

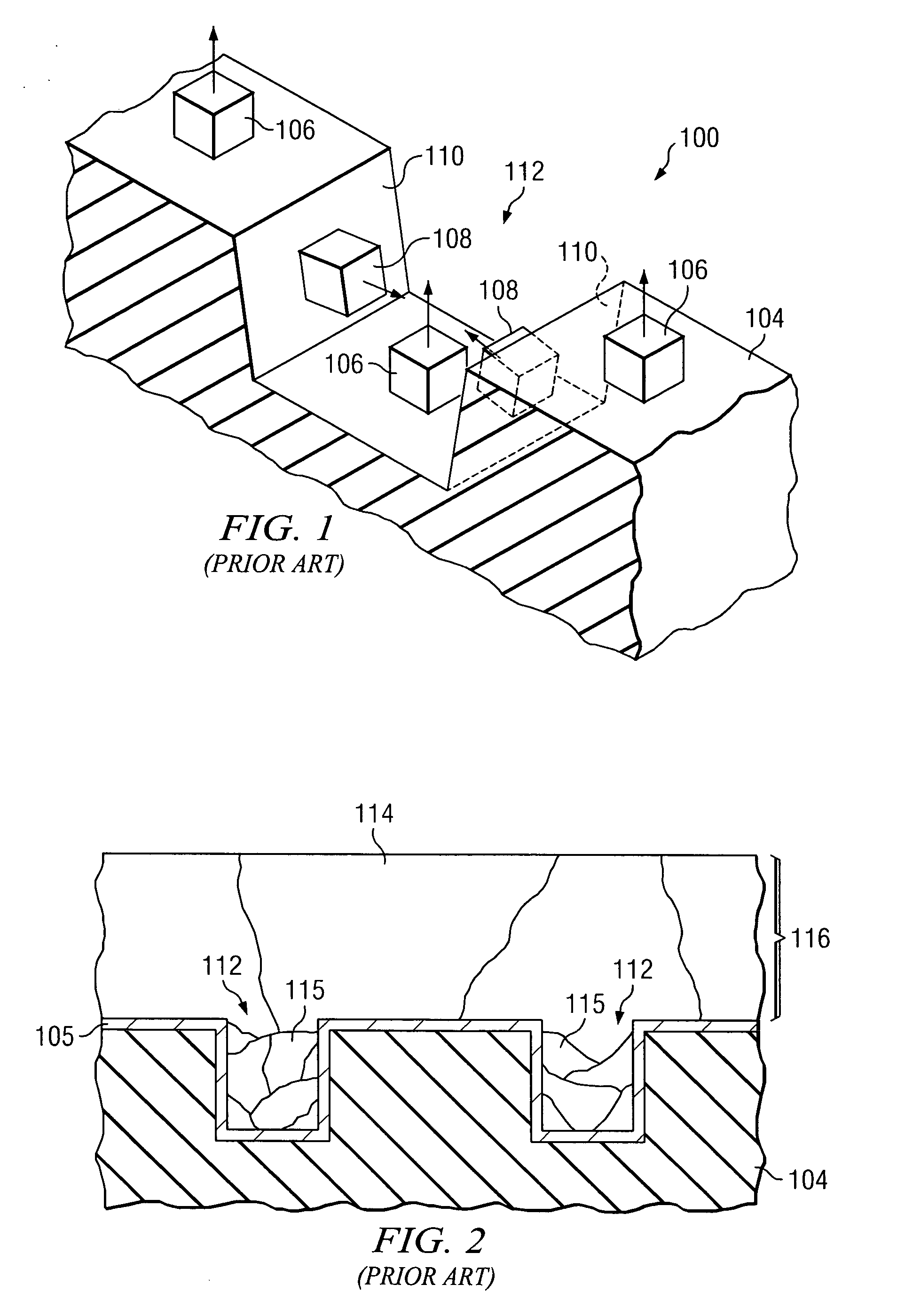

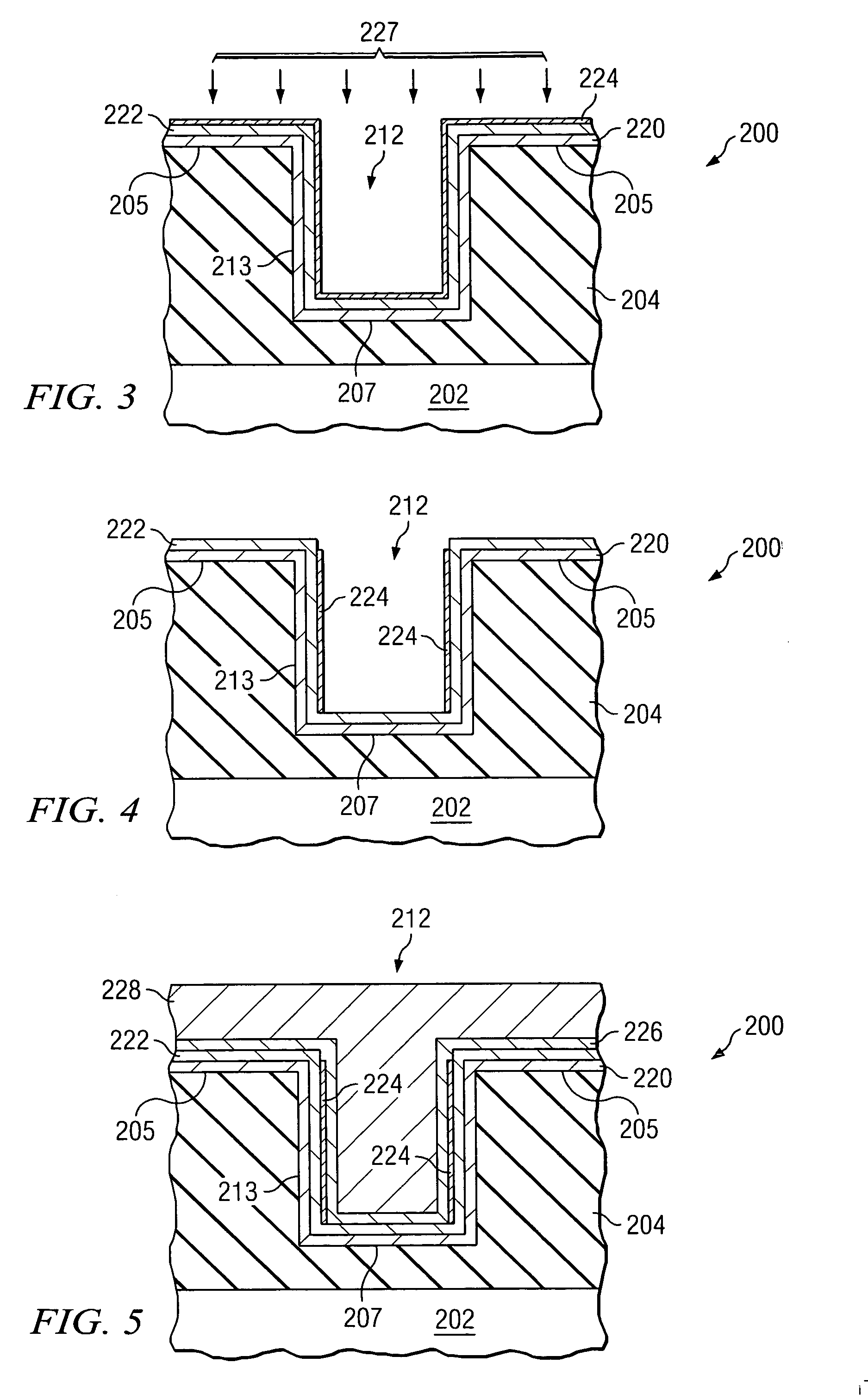

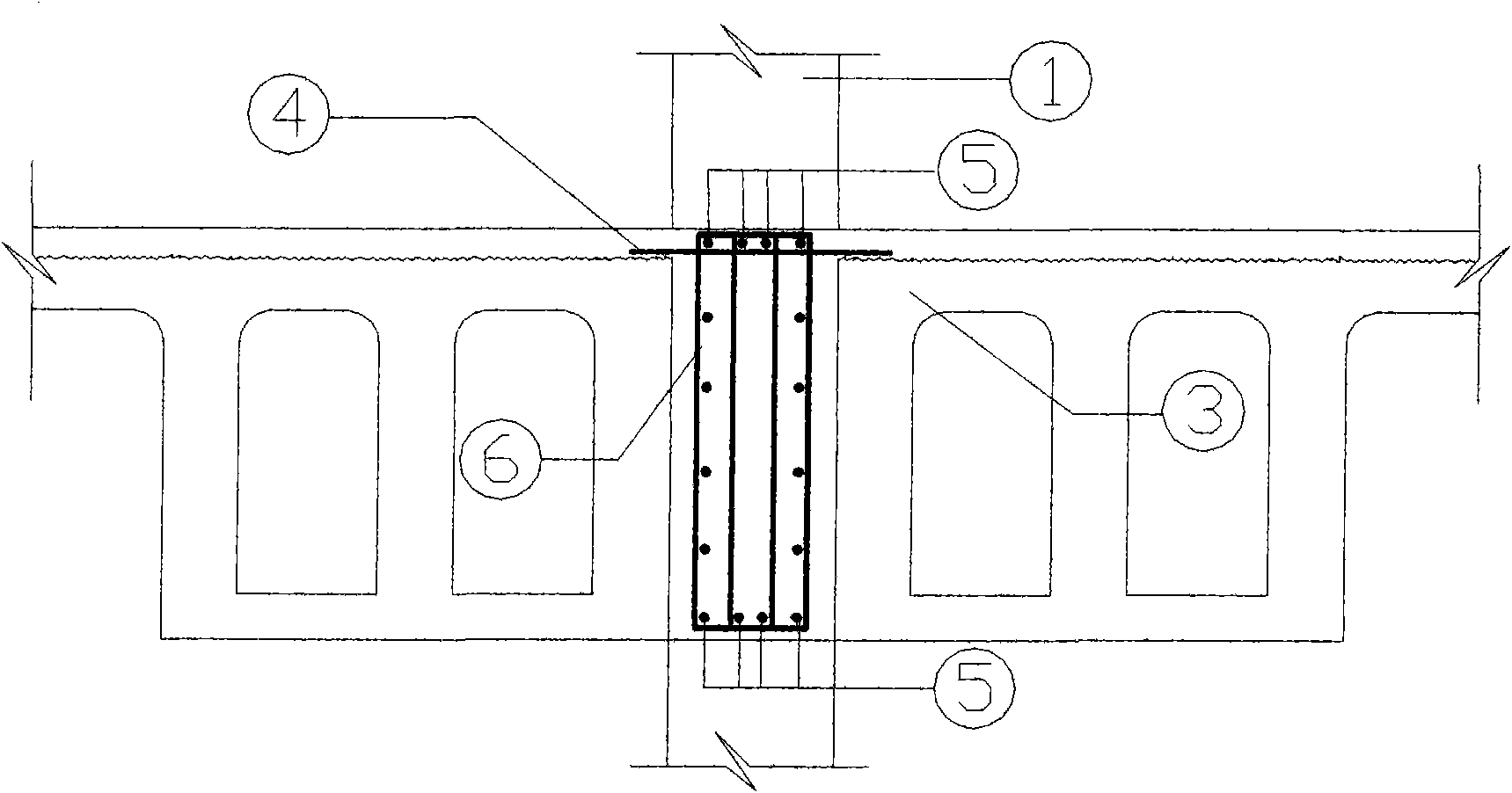

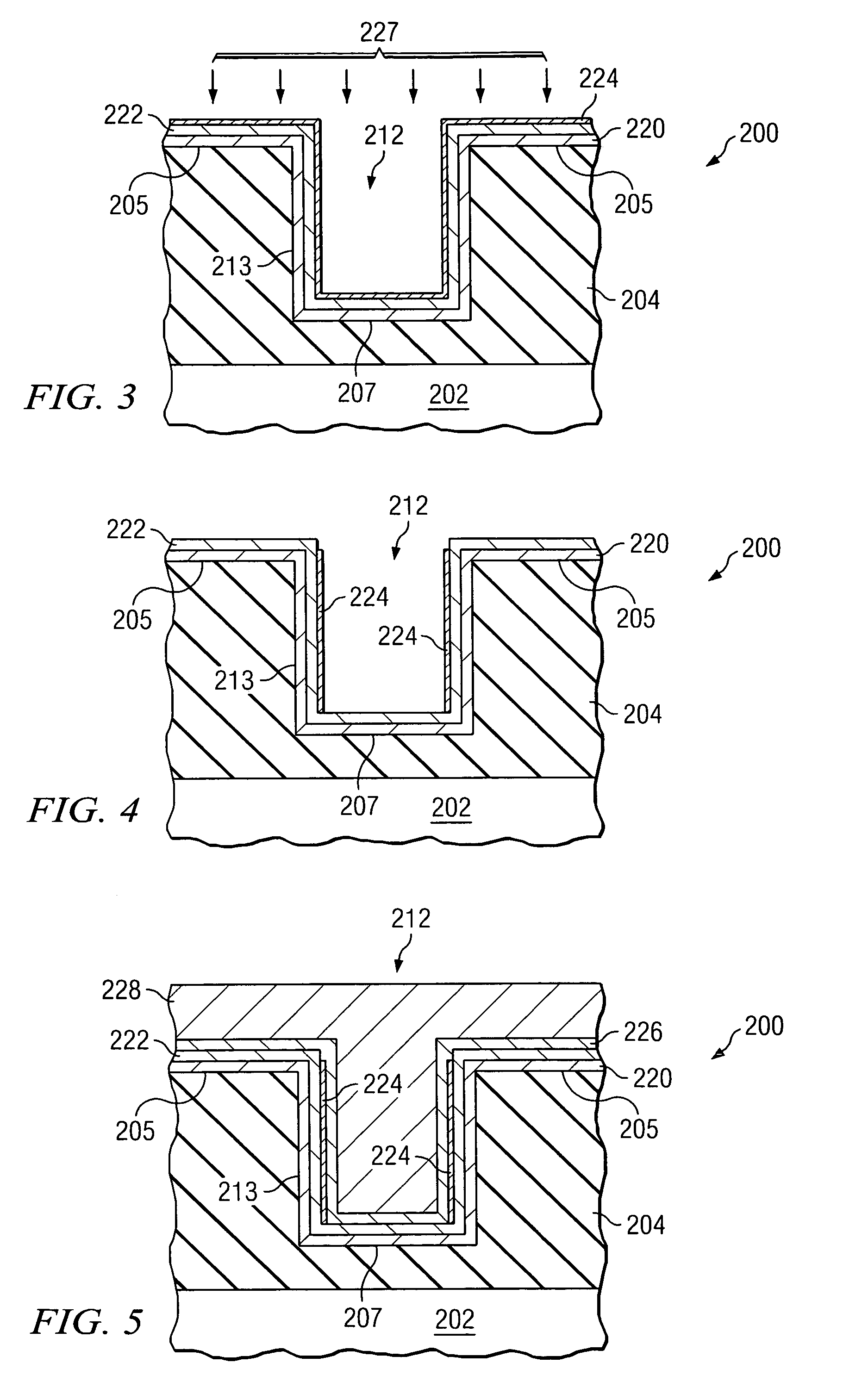

Barrier layers for conductive features

InactiveUS20060202345A1Lower resistanceImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsGrain growth

Barrier layers for conductive features and methods of formation thereof are disclosed. A first barrier material is deposited on top surfaces of an insulating material, and a second barrier material is deposited on sidewalls of the insulating material, wherein the second barrier material is different than the first barrier material. The first barrier material induces grain growth of a subsequently deposited conductive material at a first rate, and the second barrier material induces grain growth of the conductive material at a second rate, wherein the second rate is slower than the first rate.

Owner:INFINEON TECH AG

Semiconductor laser device and manufacturing method thereof

ActiveUS20080008220A1Sufficient epitaxial growth-rateSignificant growthOptical wave guidanceLaser detailsActive layerSilicon dioxide

It is an object of the present invention to provide a semiconductor laser device with high-yielding in which a clack generated in an epitaxial growth layer is restrained and to the manufacturing method thereof, the semiconductor laser device includes a GaN substrate 1, an n-type GaN layer 2, an n-type AlGaN cladding layer 3, a n-type GaN guide layer 4, an InGaN multiple quantum well active layer 5, an undoped-GaN guide layer 6, a p-type AlGaN electron overflow suppression layer 7, a p-type GaN guide layer 8, a SiO2 blocking layer 9, an Ni / ITO cladding layer electrode 10 as a transparent electrode, a Ti / Au pad electrode 11, and a Ti / Al / Ni / Au electrode 12. The SiO2 blocking layer 9 is formed above the InGaN multiple quantum well active layer 5 so as to have an opening. The Ni / ITO cladding layer electrode 10 is formed inside the opening, and which is transparent for the light from the InGaN multiple quantum well active layer, and serves as a cladding layer.

Owner:PANASONIC CORP

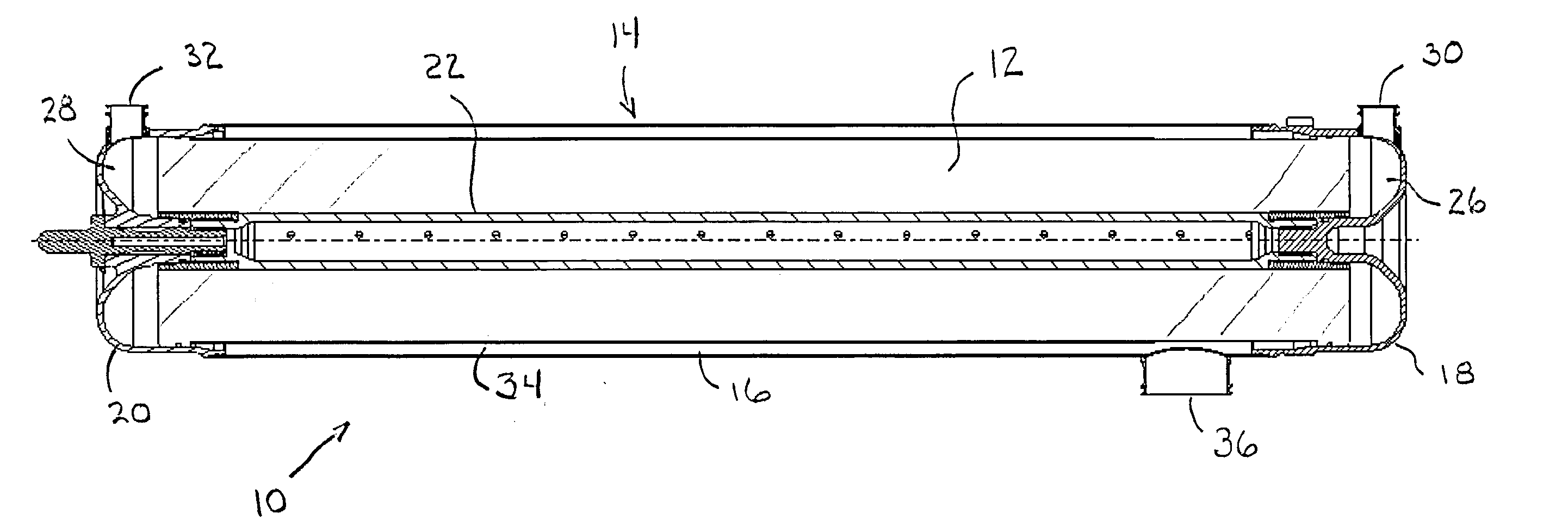

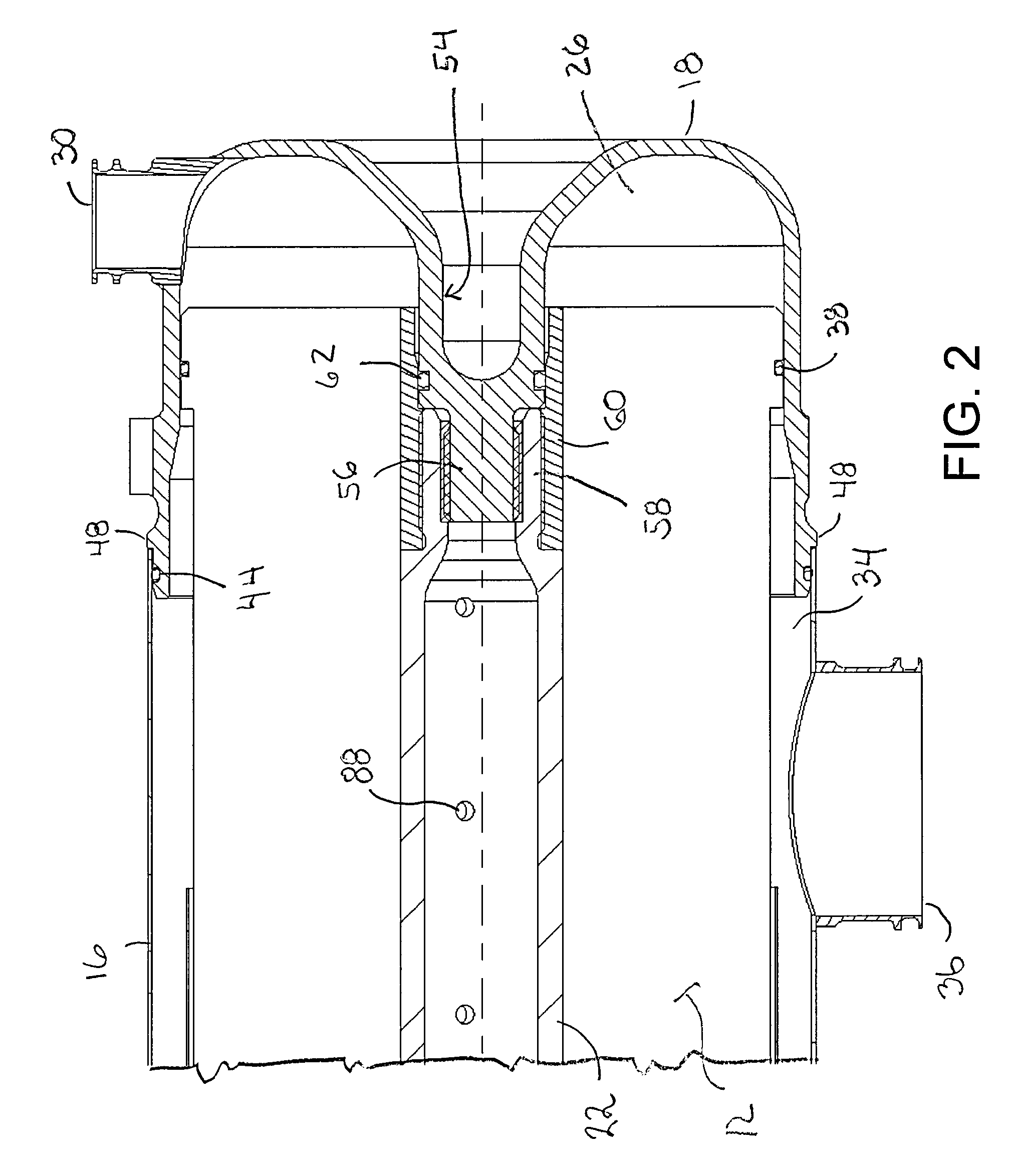

Air separation module with load carrying center tube

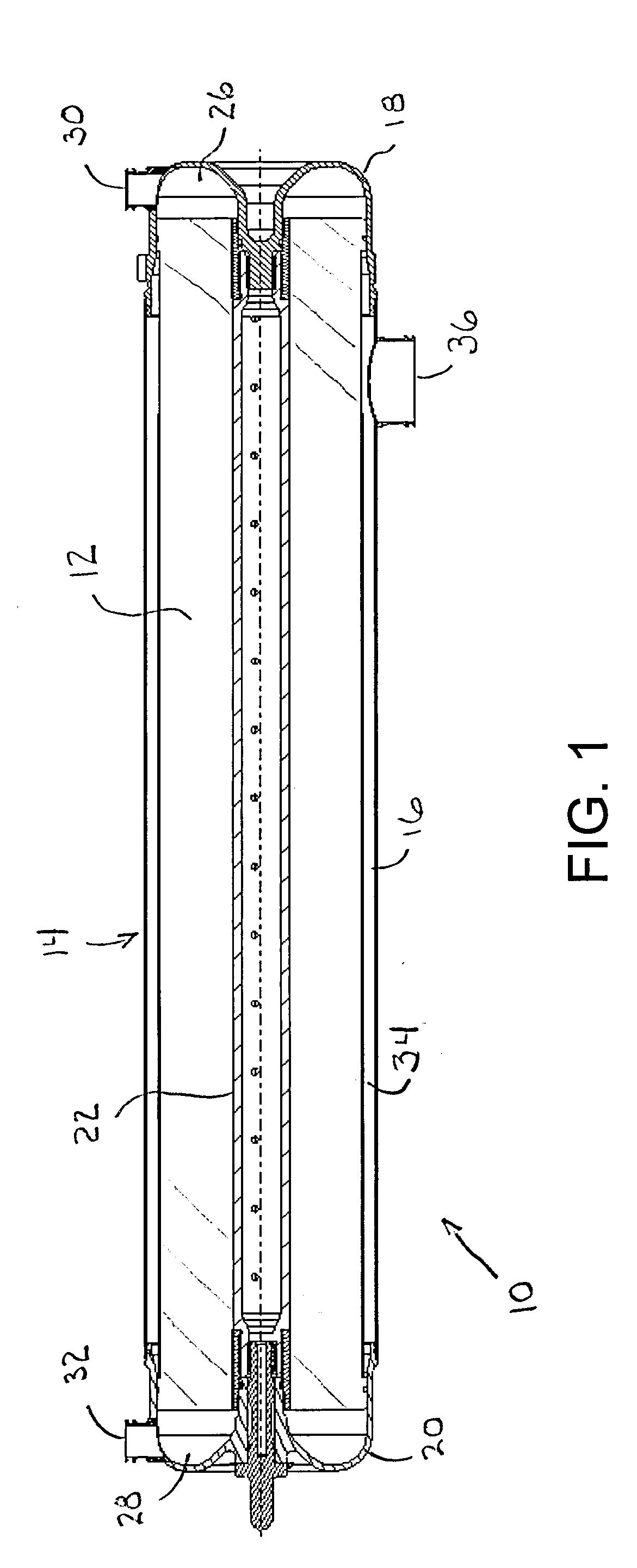

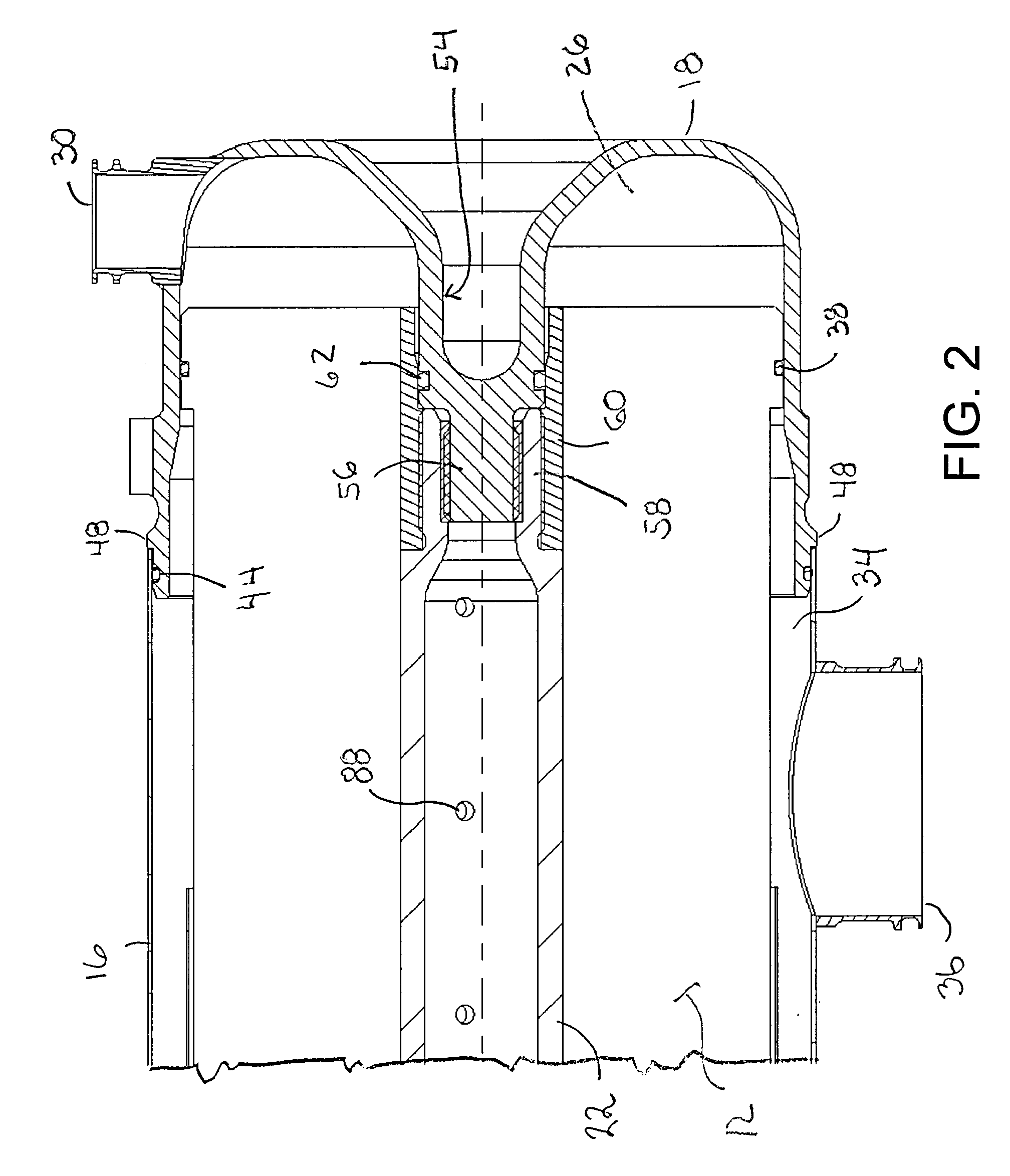

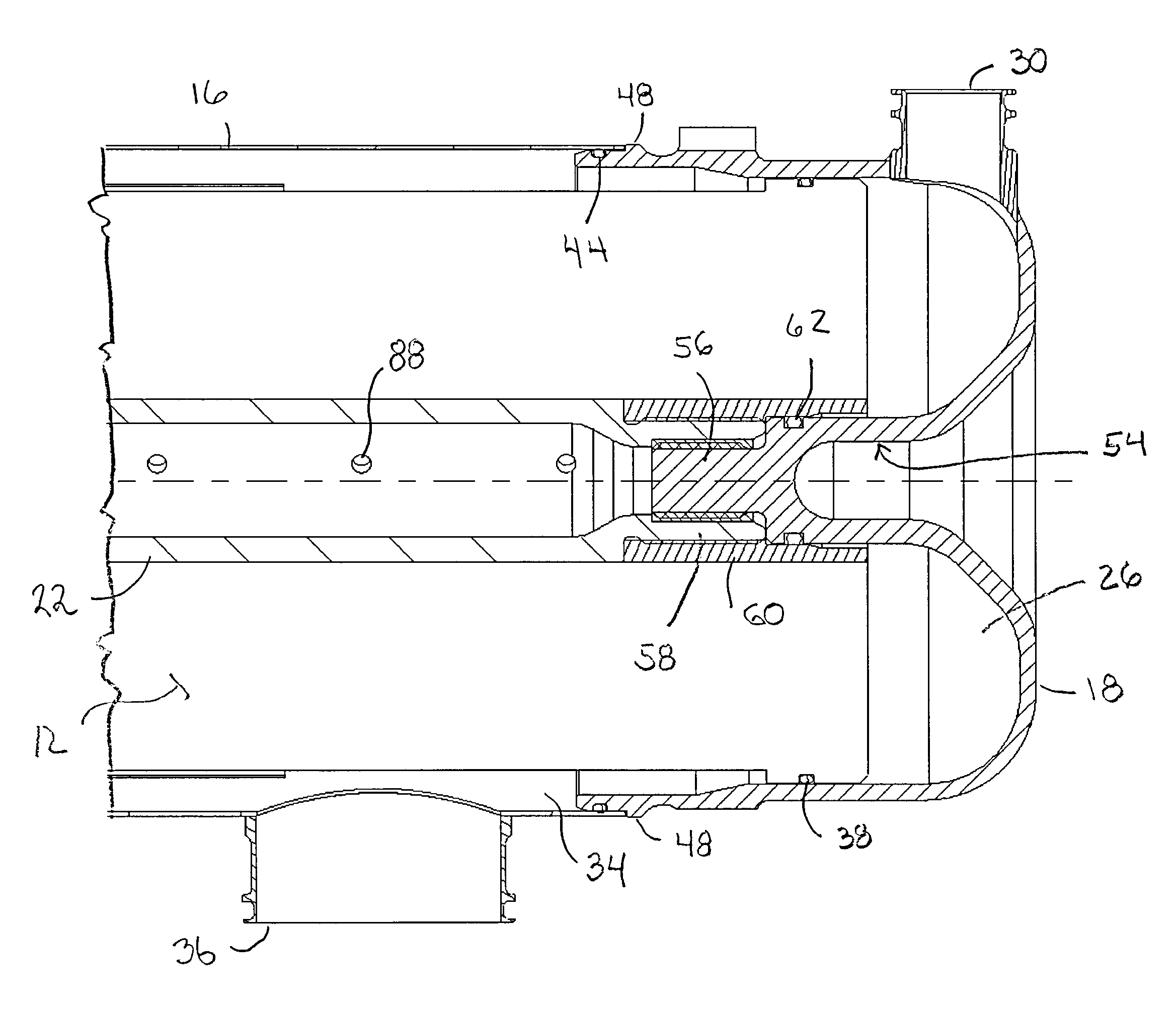

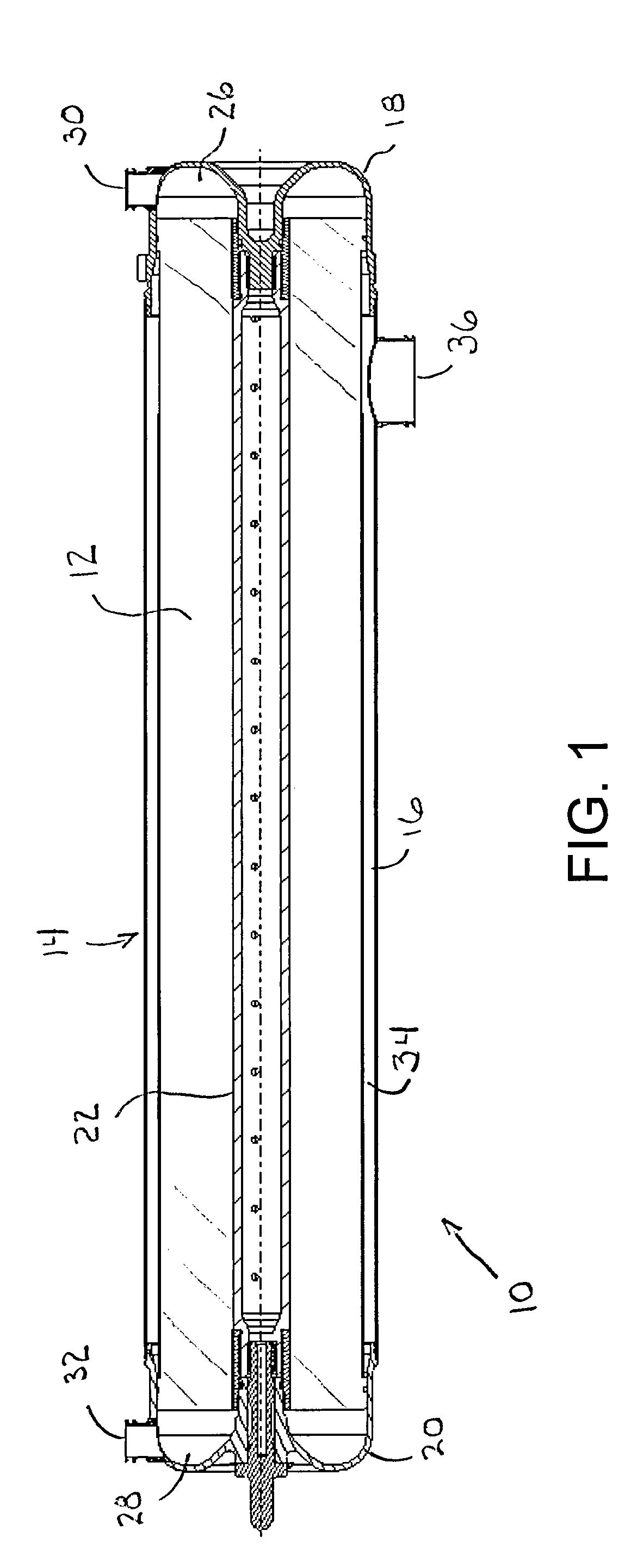

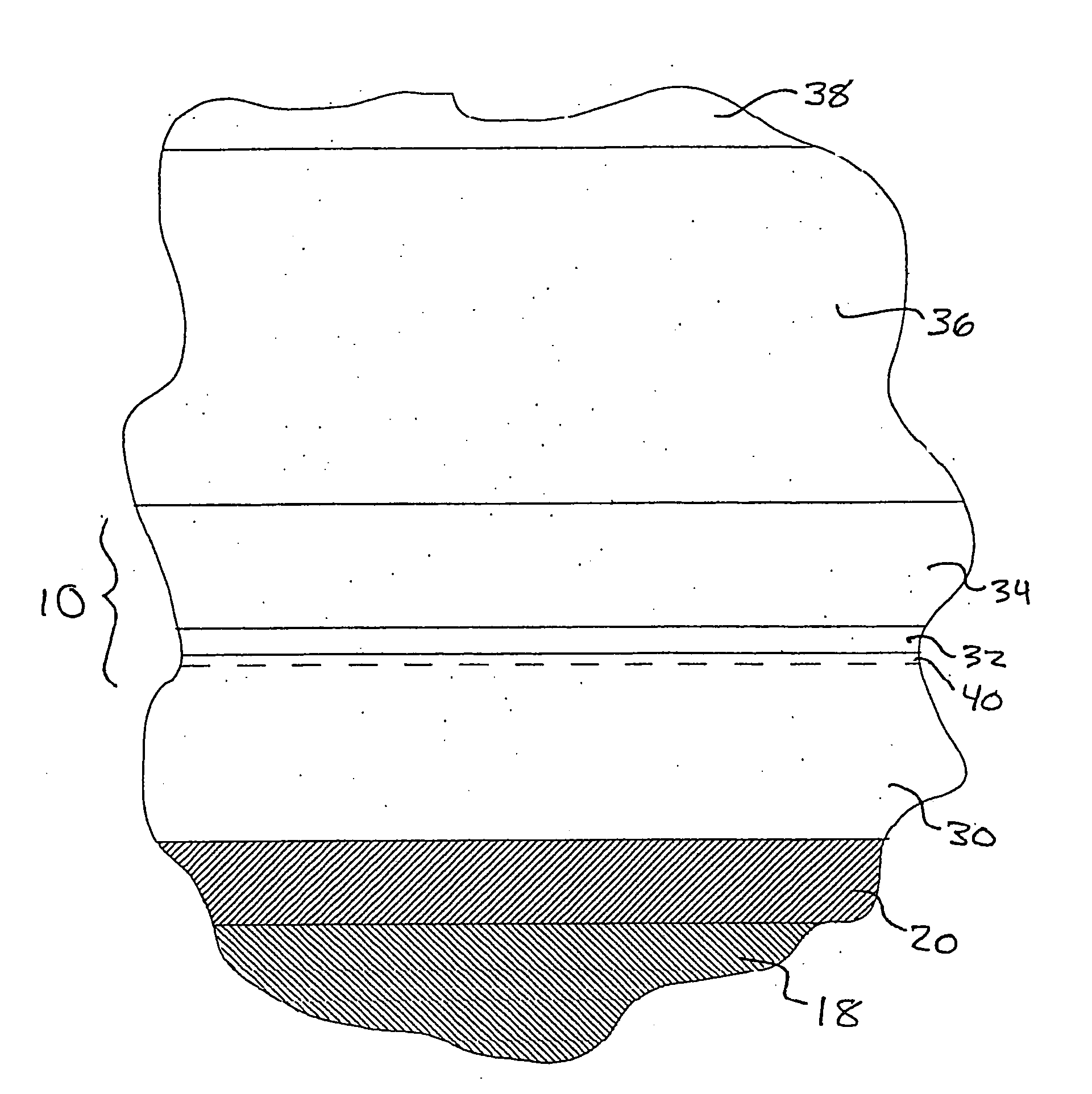

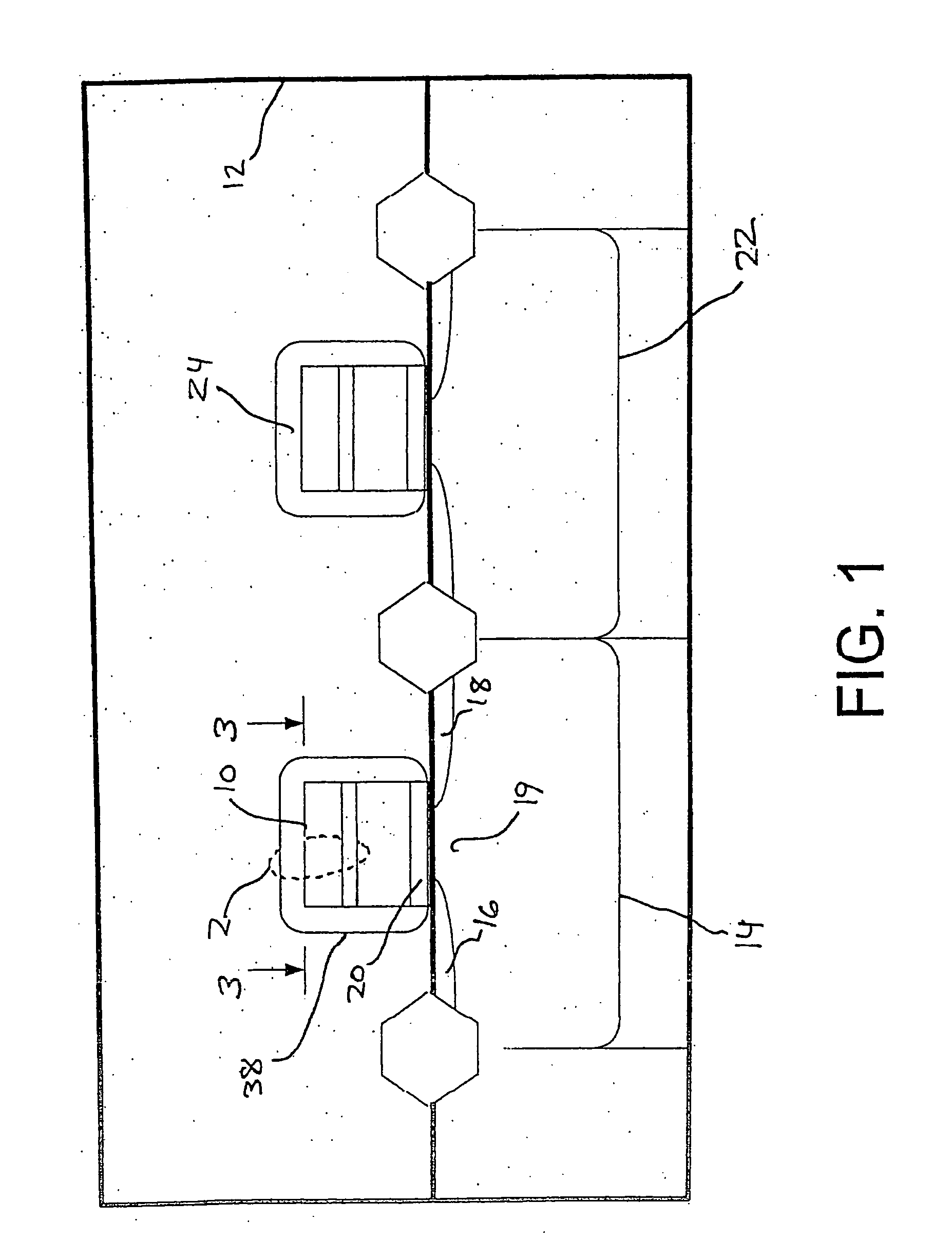

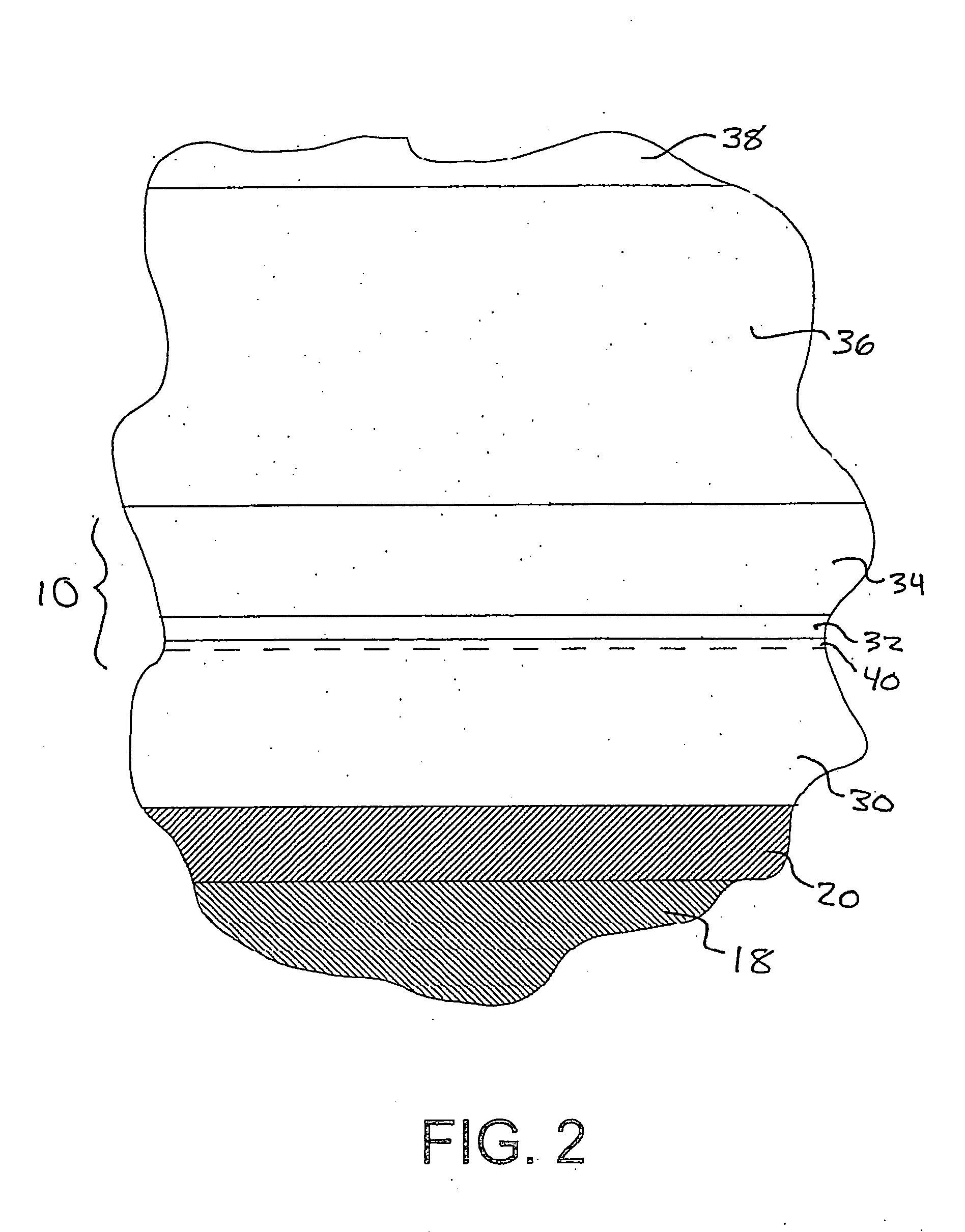

ActiveUS20100024649A1Vibration issuePrevent looseningMembranesSemi-permeable membranesFiber bundleEngineering

An air separation module comprising a bundle of hollow elongated membranes, and a pressure vessel enclosing the bundle. The pressure vessel includes an outer tube, end caps at opposite ends of the tube, and an inner tube located within the fiber bundle. The inner tube is fixedly mechanically connected at opposite ends to the end caps to form a structural spine of the pressure vessel, whereby loads acting on the air separation module are transferred between the end caps primarily by the center tube.

Owner:PARKER INTANGIBLES LLC

Air separation module with load carrying center tube

ActiveUS7717983B2Eliminating the tolerance accumulation issueSignificant growthSemi-permeable membranesMembranesFiber bundleAir separation

An air separation module comprising a bundle of hollow elongated membranes, and a pressure vessel enclosing the bundle. The pressure vessel includes an outer tube, end caps at opposite ends of the tube, and an inner tube located within the fiber bundle. The inner tube is fixedly mechanically connected at opposite ends to the end caps to form a structural spine of the pressure vessel, whereby loads acting on the air separation module are transferred between the end caps primarily by the center tube.

Owner:PARKER INTANGIBLES LLC

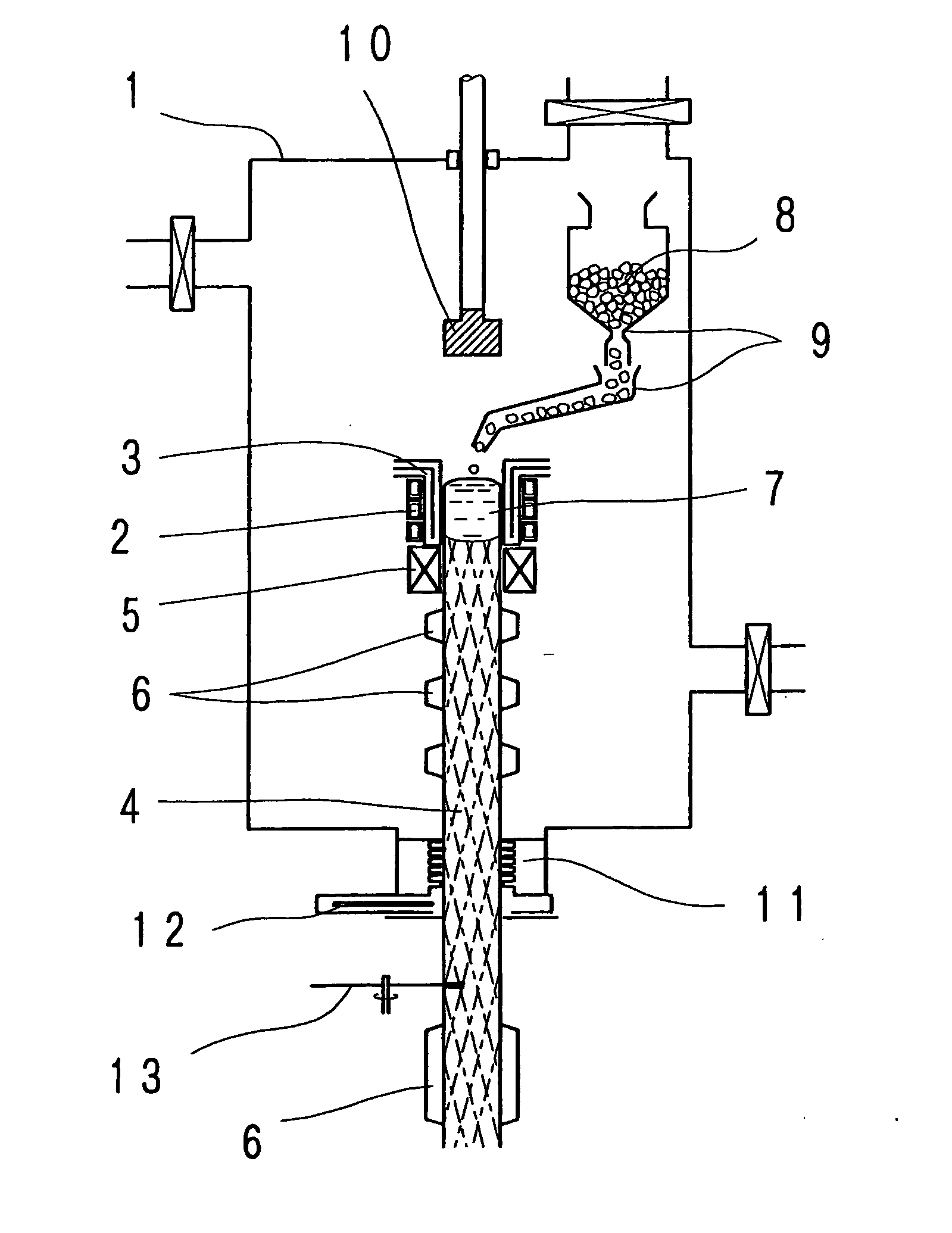

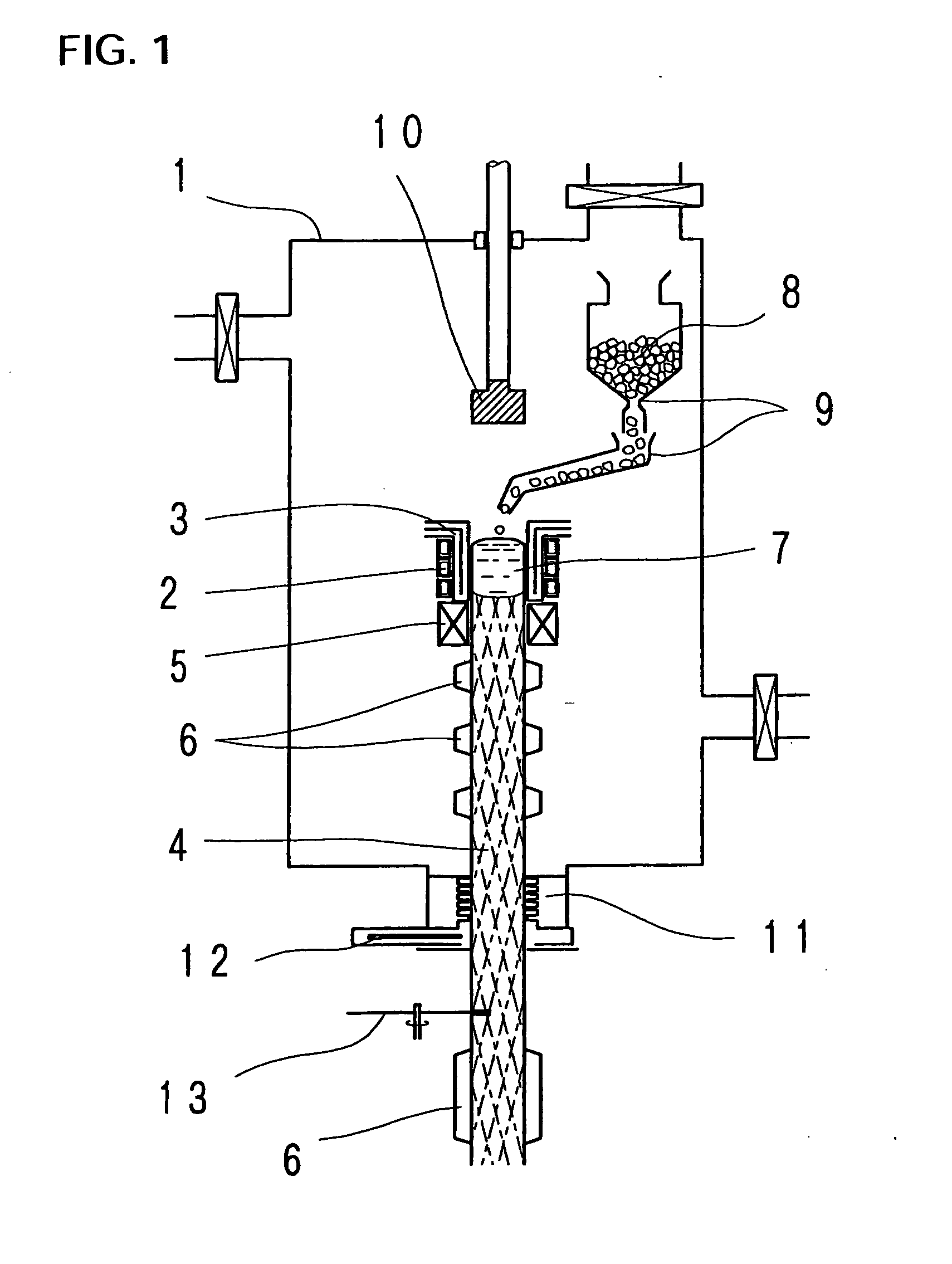

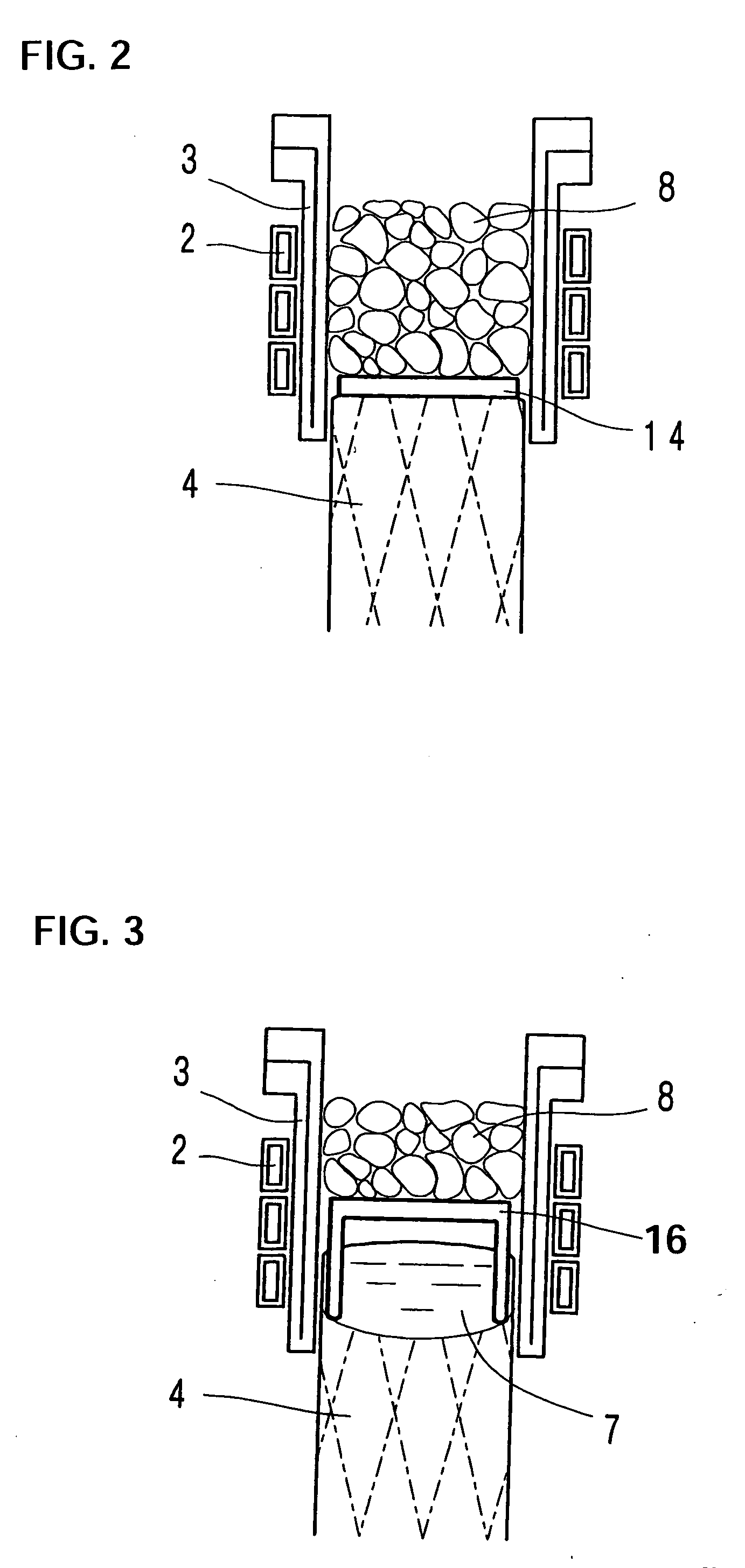

Method for casting polycrystalline silicon

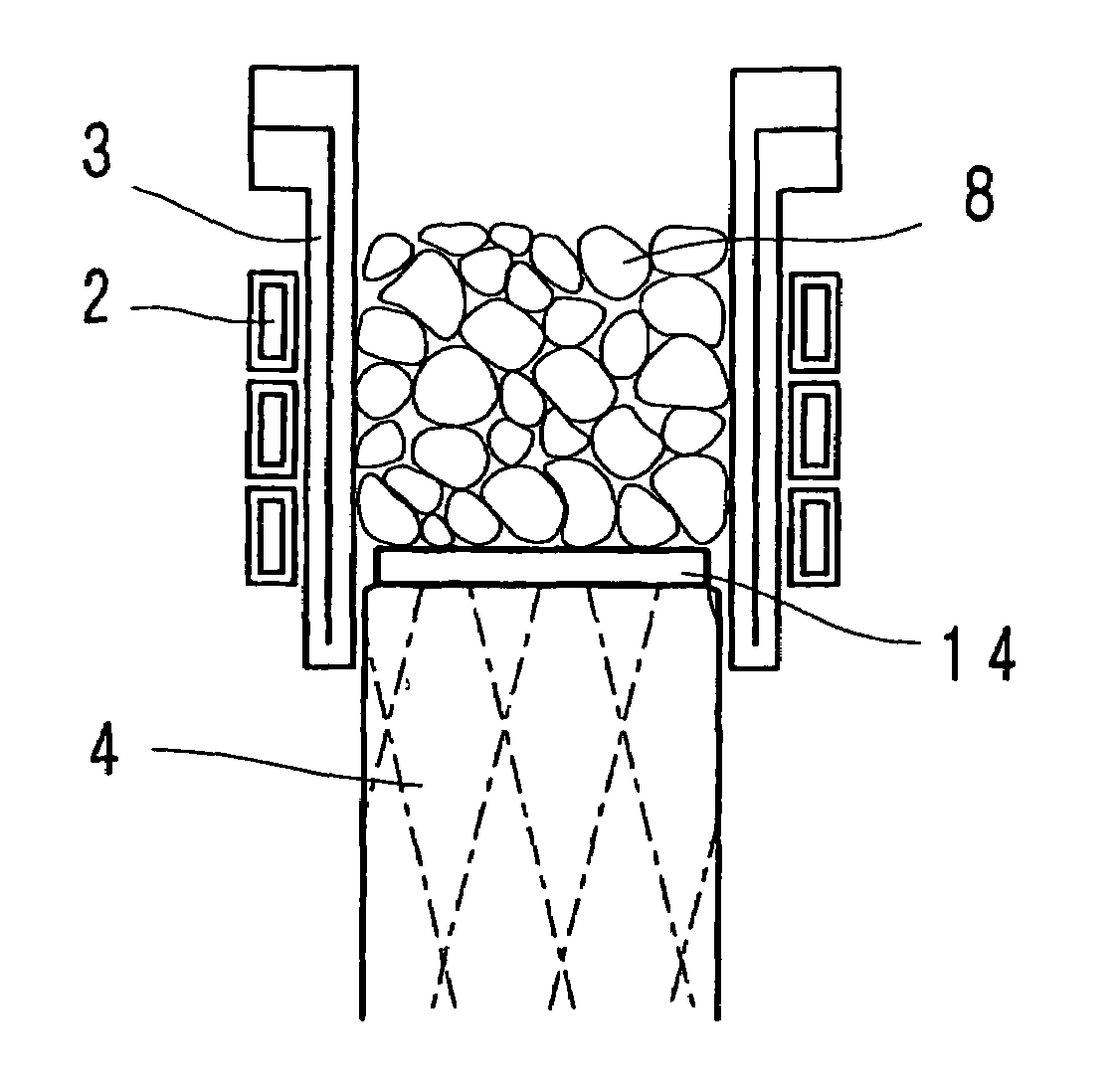

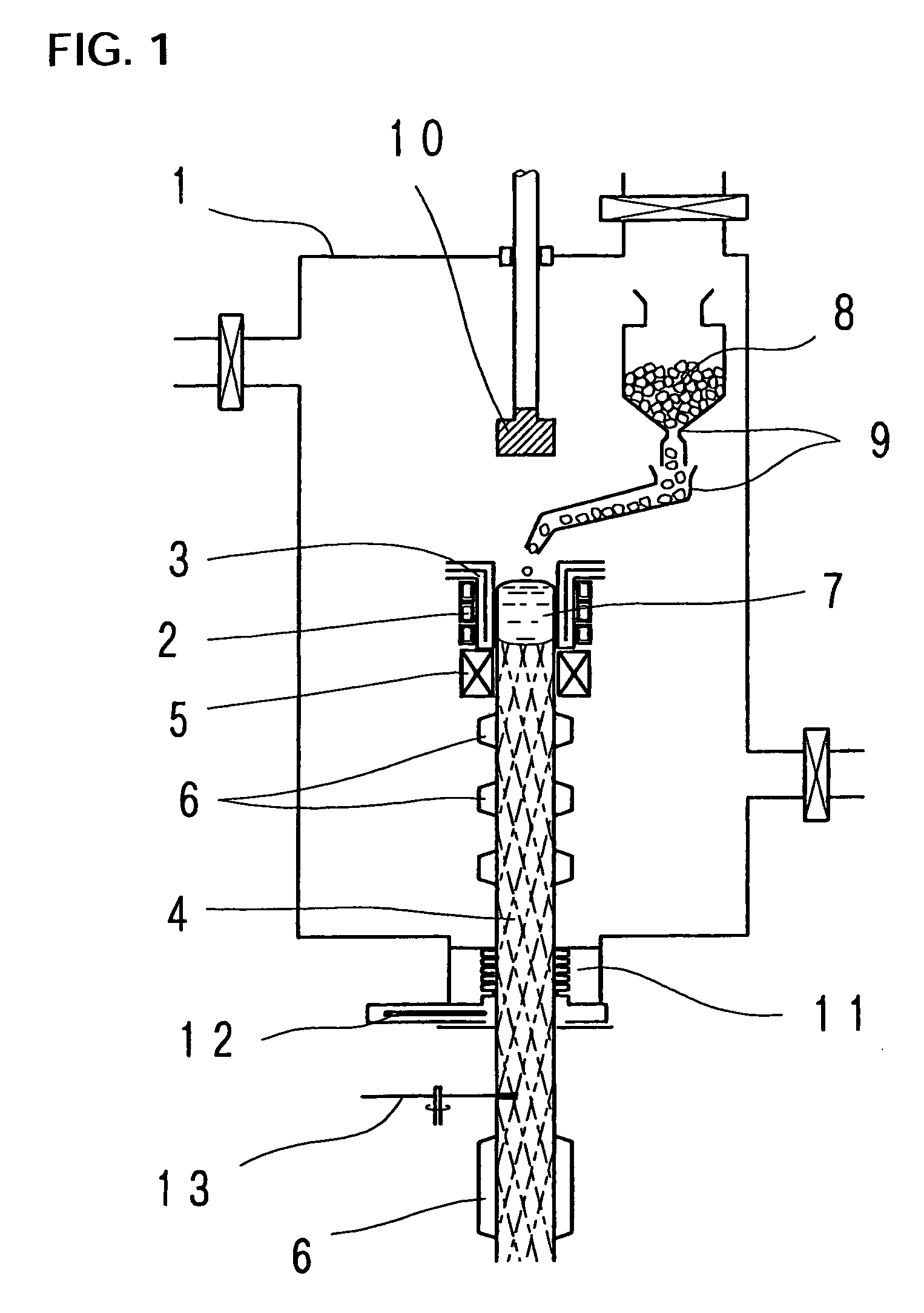

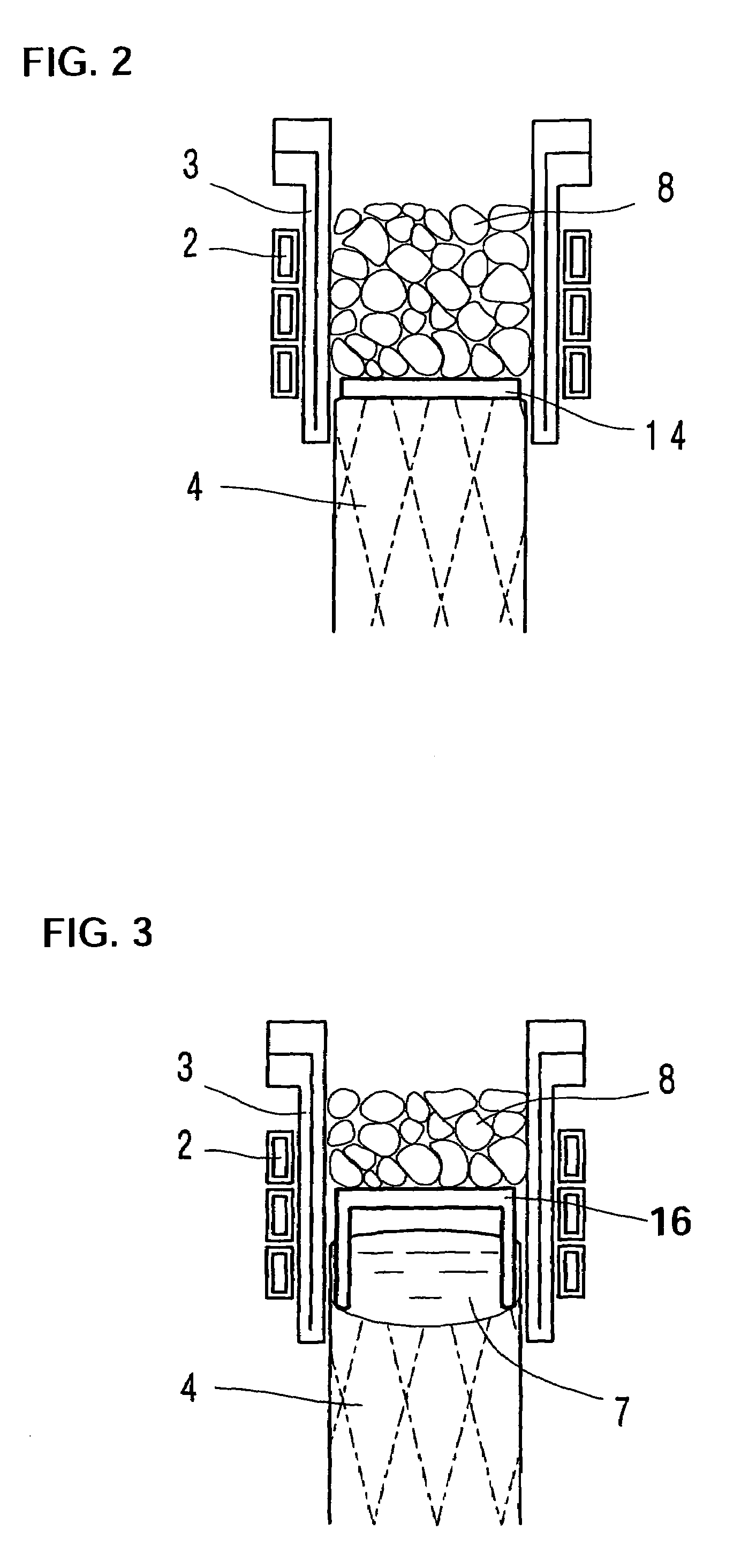

InactiveUS20070039544A1Improve productivityReduce manufacturing costPolycrystalline material growthFrom melt solutionsProduction rateIngot

In melting and casting by a water-cooled crucible induction melting technique, a partition means is inserted on top portion of a melt, and a new raw material for is charged on an upper side of the partition means to continue the melting and casting. Therefore, the continuous casting can be kept while avoiding mixture of the melt on a lower side of with the melt on an upper side of the partition means. A partition plate or a partition plate with legs can be used as the partition means. When the present invention is applied to production of a silicon ingot used for a solar cell and the like, productivity is largely improved, which allows costs to be remarkably reduced in solar energy generation. Therefore, the present invention can widely be utilized as the method for casting a polycrystalline-silicon ingot for a solar cell.

Owner:SUMCO CORP

Method for casting polycrystalline silicon

InactiveUS7682472B2Avoid crackingSignificant growthPolycrystalline material growthFrom melt solutionsProduction rateIngot

In melting and casting by a water-cooled crucible induction melting technique, a partition means is inserted on top portion of a melt, and a new raw material for is charged on an upper side of the partition means to continue the melting and casting. Therefore, the continuous casting can be kept while avoiding mixture of the melt on a lower side of with the melt on an upper side of the partition means. A partition plate or a partition plate with legs can be used as the partition means. When the present invention is applied to production of a silicon ingot used for a solar cell and the like, productivity is largely improved, which allows costs to be remarkably reduced in solar energy generation. Therefore, the present invention can widely be utilized as the method for casting a polycrystalline-silicon ingot for a solar cell.

Owner:SUMCO CORP

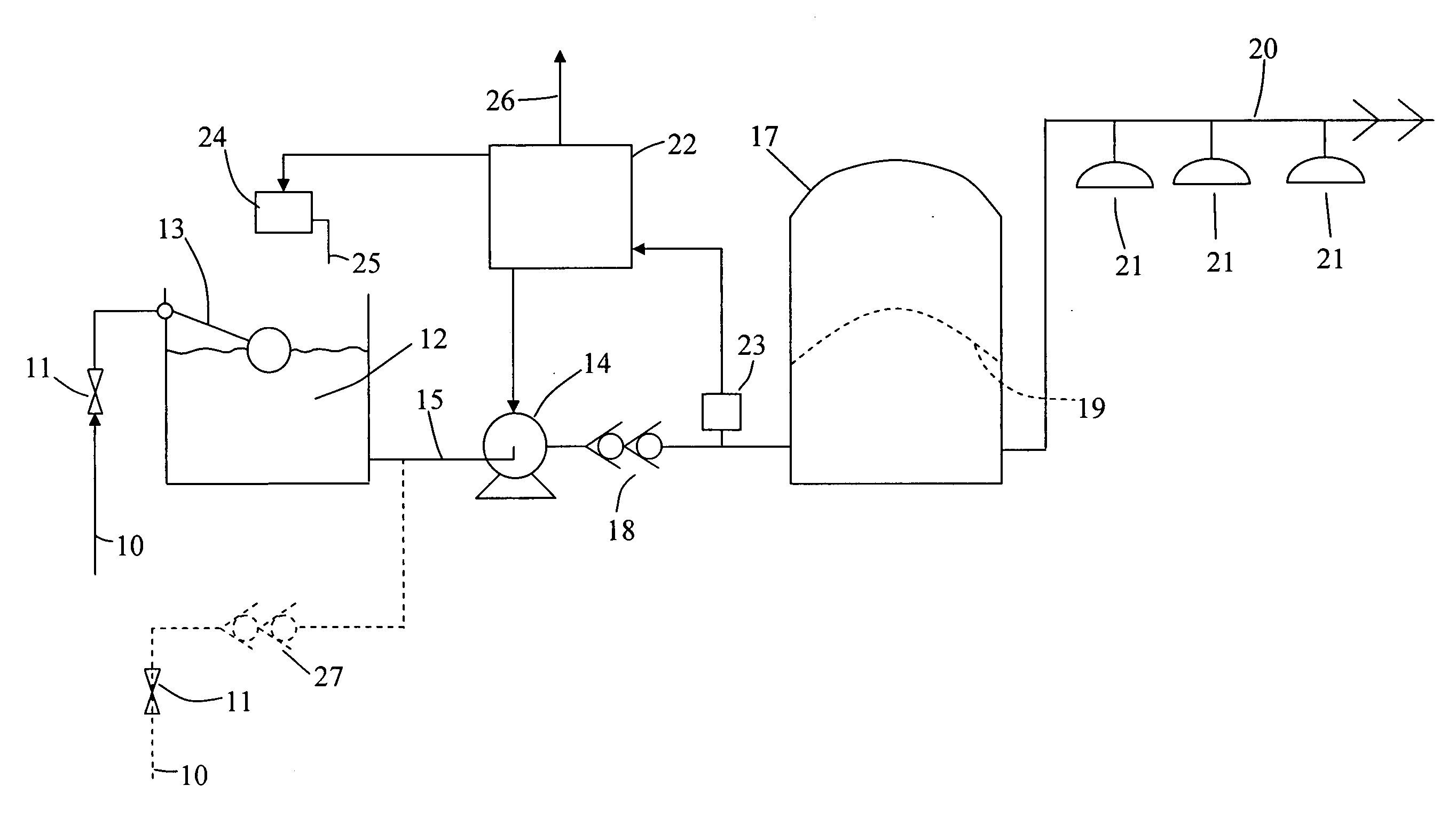

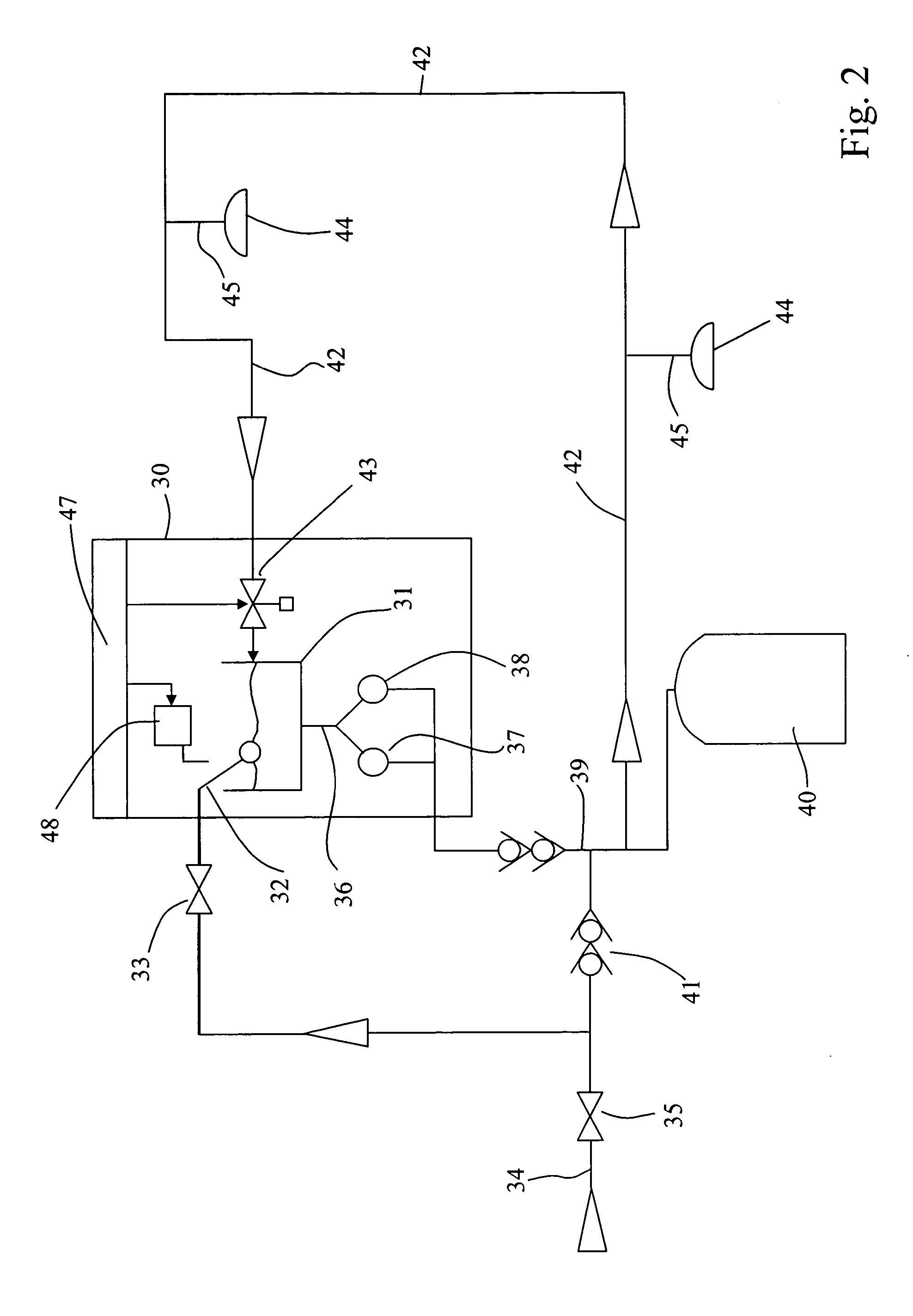

Sprinkler system

InactiveUS20050257938A1Minimize the possibilityEasy to installFire rescueSprinkler systemWaste management

A sprinkler system primarily intended for use in a domestic dwelling to cover an exit route from the dwelling has an accumulator feeding the pipes leading to the sprinkler heads. The accumulator is charged with water under pressure by a pump drawing water from a water main or from a check tank itself fed with water from the water main. A sterilising unit may be provided to allow sterilisation of the water in the pipework.

Owner:ELSEY STEPHEN JOHN

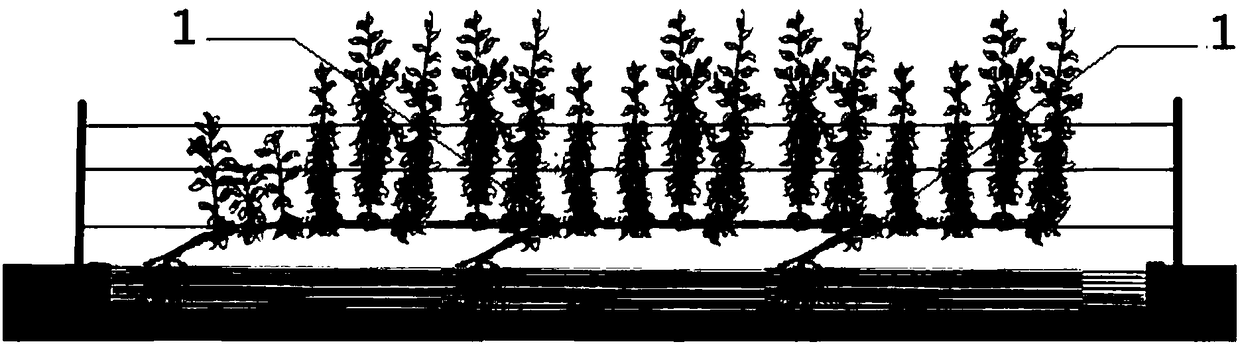

Efficient sweet cherry fence type grafting and symbiotic cultivation technology and application thereof

The invention discloses an efficient sweet cherry fence type grafting and symbiotic cultivation technology. According to the technical scheme, fence type cultivation is utilized. The method comprisesthe steps of large seedling cultivation and transplanting before grafting, trunk grafting and cultivation of lateral branches after grafting. According to structural indexes of trees obtained after symbiotic cultivation, the height of the trees is 2.5-3.0 m, the vertical section of each trunk is 40-50 cm high, the horizontal section of each trunk is 1.8-2.3 m long, 8-12 back branches grow on eachtrunk, the back branch spacing of each trunk is 10-15 cm, the length of the back branches on each trunk is smaller than 2.0 m, the diameter of base parts of the back branches on each trunk is smallerthan 4 cm, and the effect fruit and branch proportion is 98%. The invention further discloses application of the technology in the field of cherry grafting and cultivation field. The problem that in atraditional fence type cultivation technology, back branches of cherries are not balanced in growth is solved, seedling planting is completed within two years, and the technology has the advantages that the number of layers of tree structures is small, growth is balanced, the back branches are strong, the yield is high, harvesting is early, the cherry variety is good, and mechanical harvesting isfacilitated.

Owner:SHANGHAI JIAO TONG UNIV

Semiconductor laser device and manufacturing method thereof

ActiveUS7279751B2Sufficient epitaxial growth-rateSignificant growthOptical wave guidanceLaser detailsOptoelectronicsActive layer

Owner:PANASONIC CORP

Nitride and polysilicon interface with titanium layer

InactiveUS20060001162A1Low resistivityQuick destructionSemiconductor/solid-state device detailsSolid-state devicesMetal silicideTungsten nitride

A conductive structure in an integrated circuit (12), and a method of forming the structure, is provided that includes a polysilicon layer (30), a thin layer containing titanium over the polysilicon, a tungsten nitride layer (34) over the titanium-containing layer and a tungsten layer over the tungsten nitride layer. The structure also includes a silicon nitride interfacial region (38) between the polysilicon layer and the titanium-containing layer. The structure withstands high-temperature processing without substantial formation of metal silicides in the polysilicon layer (30) and the tungsten layer (32), and provides low interface resistance between the tungsten layer and the polysilicon layer.

Owner:INFINEON TECH AG +1

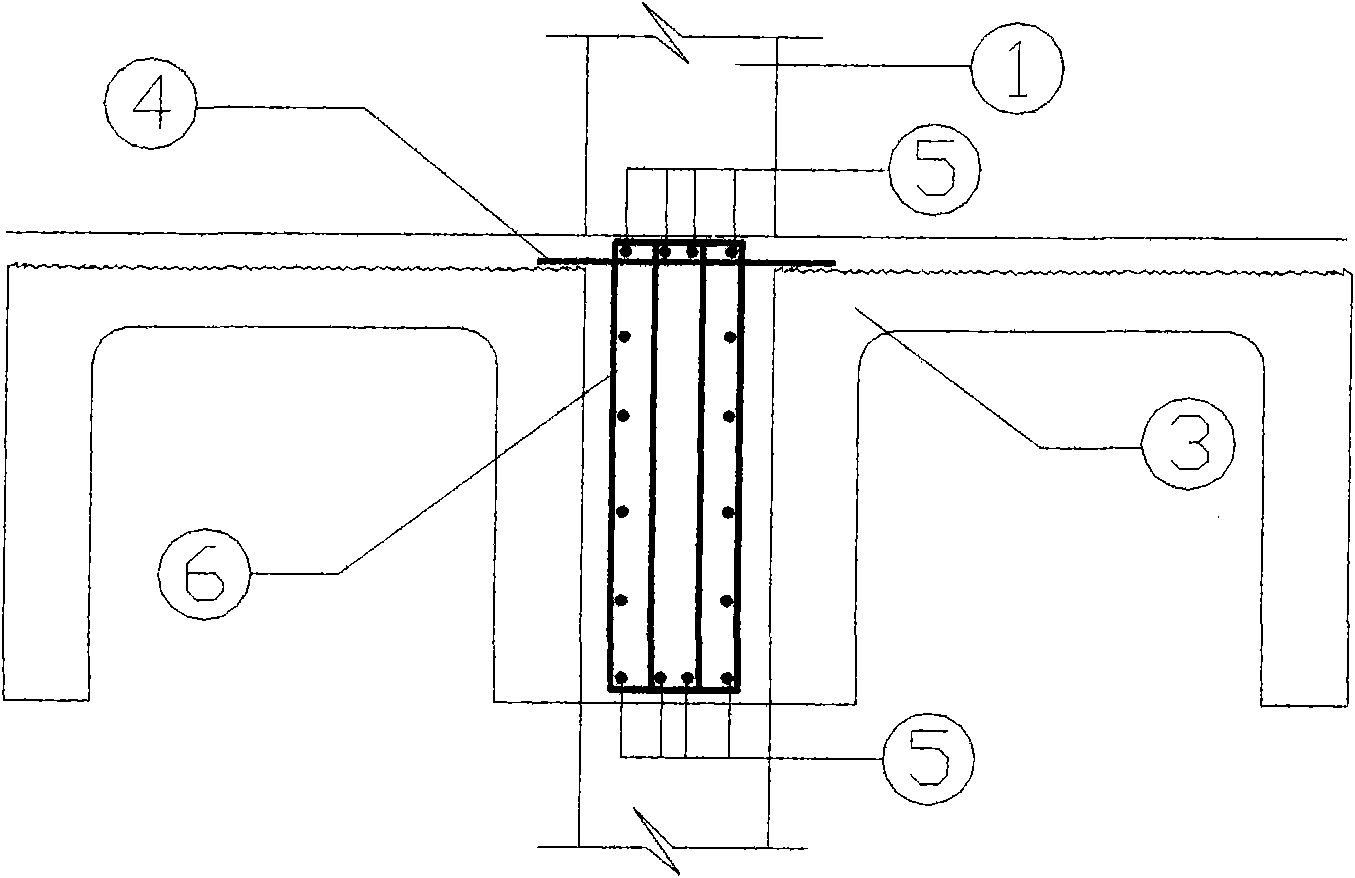

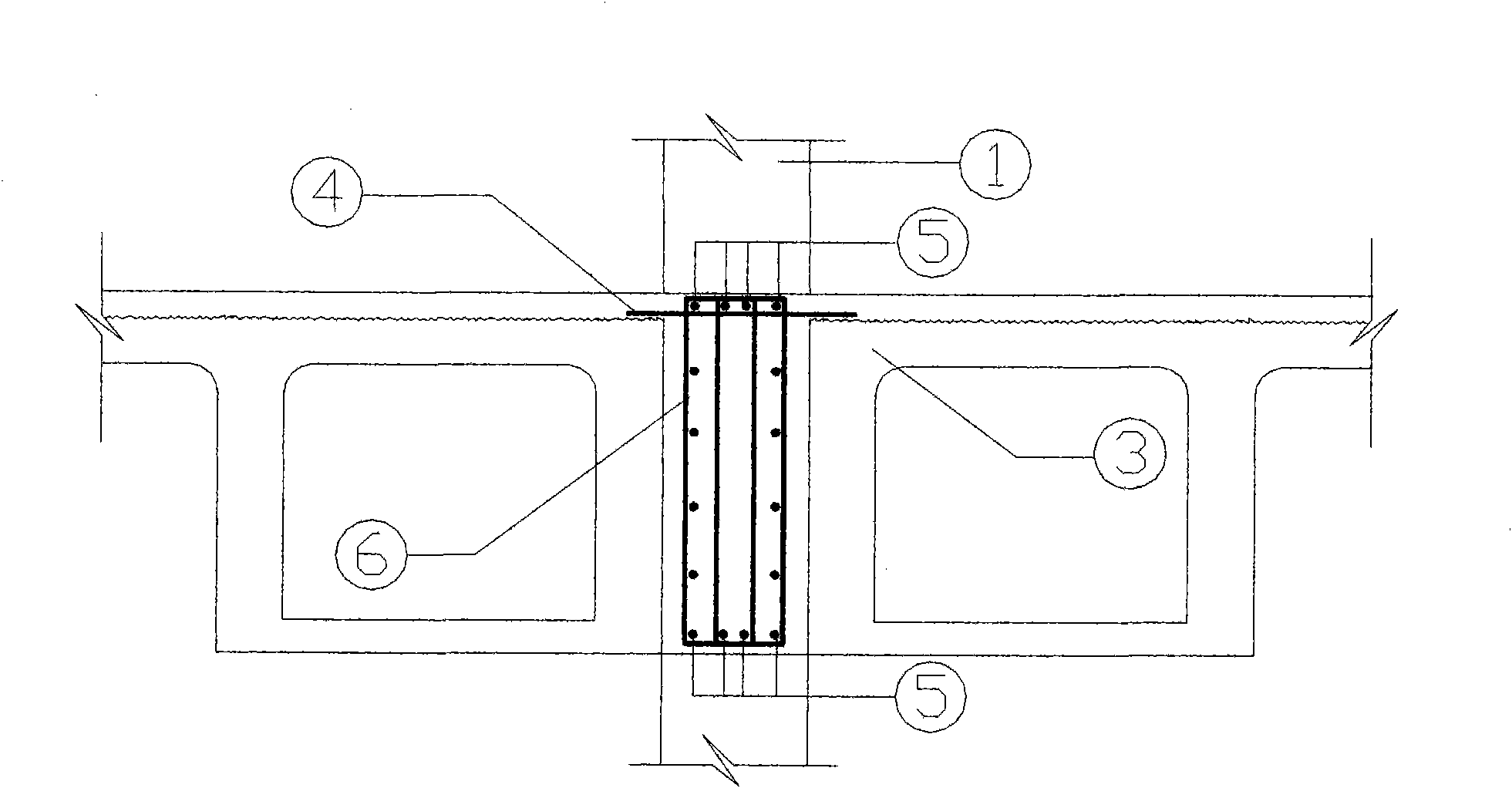

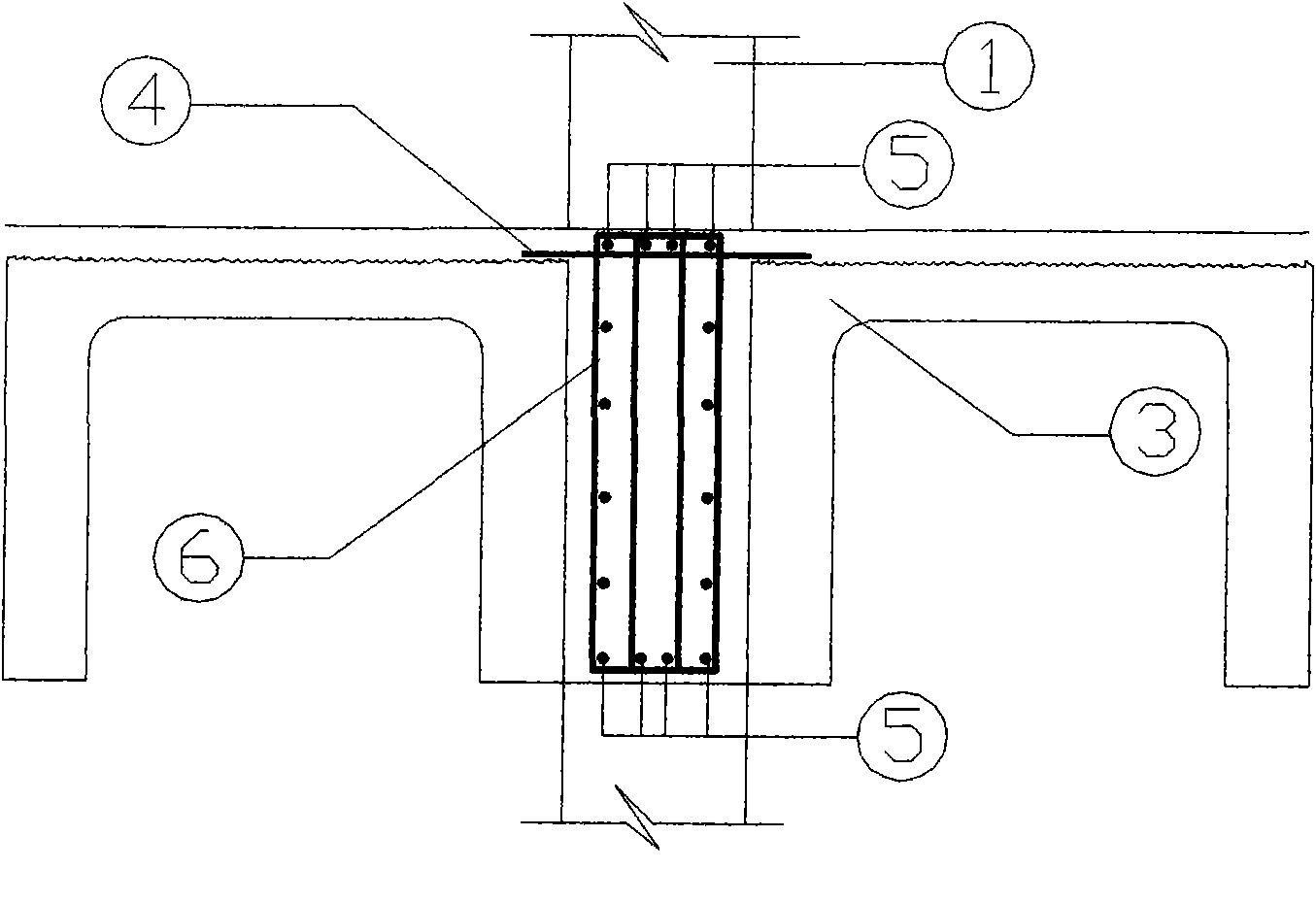

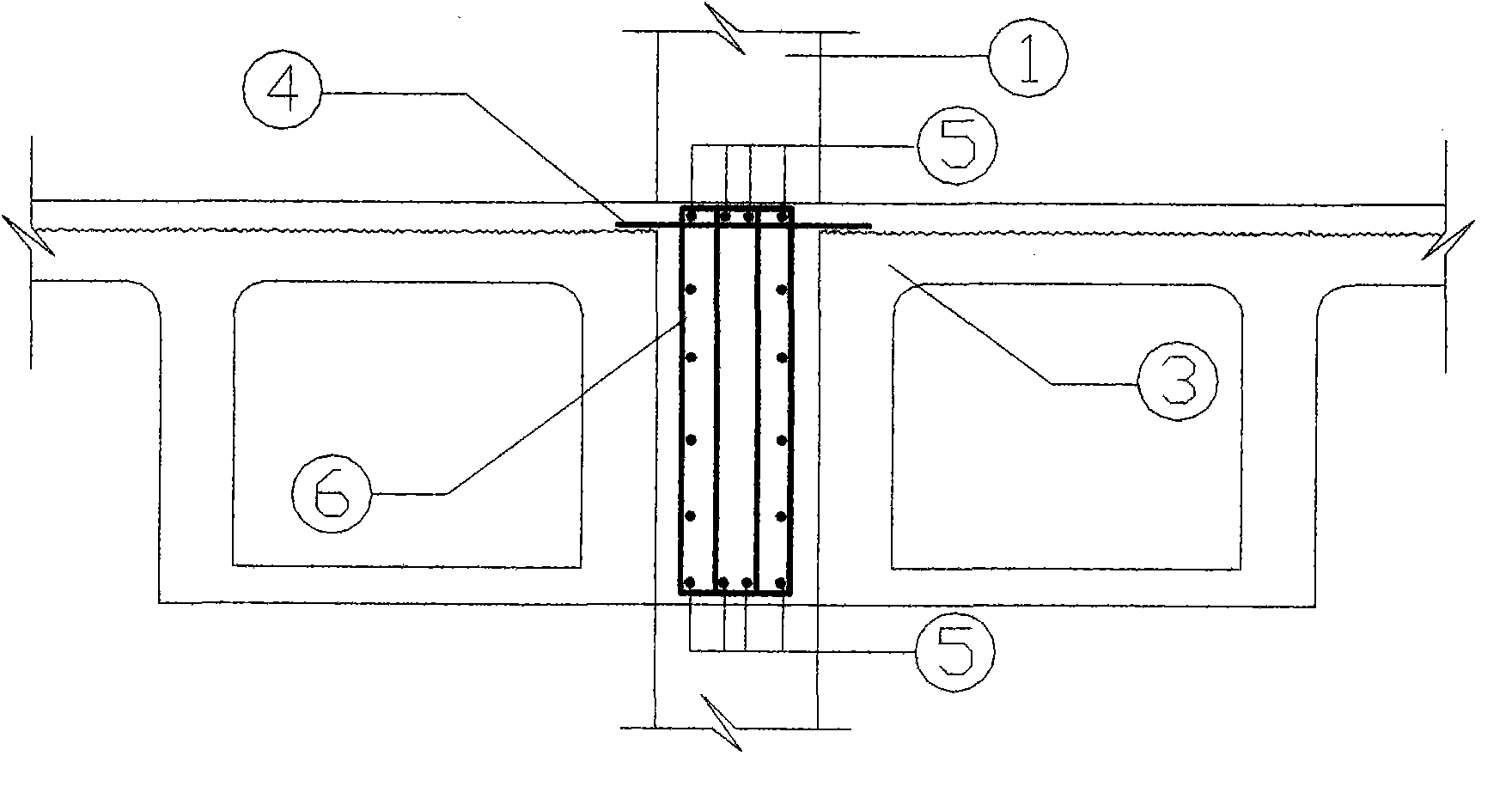

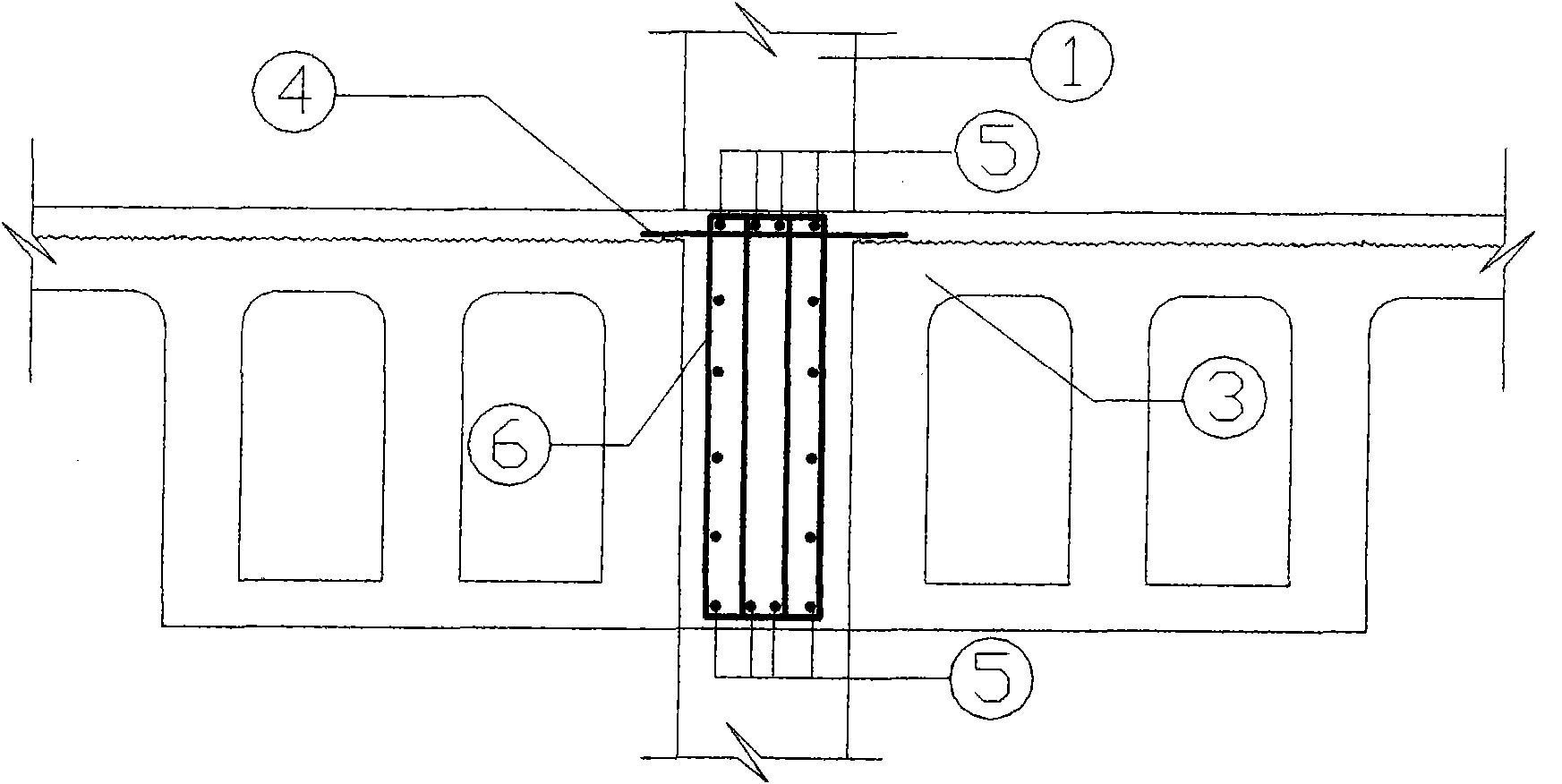

Construction method for imitated frame structure of long-span prestressed concrete beam slab

InactiveCN102061770ASignificant growthReduce dosageFloorsGirdersPrestressed concrete beamShaped beam

The invention relates to a construction method for an imitated frame structure of a long-span prestressed concrete beam slab, belonging to the technical field of constructional engineering structures. The method comprises the following steps of: installing single T-shaped slabs consisting of prestressed hollow single T-shape beam slabs with no flanges or flanges removed, or a plurality of T-shaped box-shaped beams, or trough slabs or rectangular beams at two sides close to a frame column after the frame column and a frame longitudinal beam are installed; arranging transverse constructed erected reinforcing steel bars on the frame column; suspending a bottom template on the deck or erected reinforcing steel bars along a beam slab arris or a side direction; leveling the bottom template with the bottom of the prestressed concrete beam slab; arranging reinforcing steel bars of the beam in a space formed by the template; connecting the reinforcing steel bars with the reinforcing steel bars of the frame column; then connecting the reinforcing steel bars again by hooping; and finally, pouring and tamping concrete as required to form a frame beam, i.e. an imitated frame beam. The method disclosed by the invention has the advantages of reducing the section of the imitated frame beam, not needing to cut off the flanges of the T-shaped slab, lowering the cost and improving construction and precasting benefits.

Owner:柳忠林

Barrier layer for conductive features

InactiveUS7449409B2Small conductiveReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesConductive materialsGrain growth

Barrier layers for conductive features and methods of formation thereof are disclosed. A first barrier material is deposited on top surfaces of an insulating material, and a second barrier material is deposited on sidewalls of the insulating material, wherein the second barrier material is different than the first barrier material. The first barrier material induces grain growth of a subsequently deposited conductive material at a first rate, and the second barrier material induces grain growth of the conductive material at a second rate, wherein the second rate is slower than the first rate.

Owner:INFINEON TECH AG

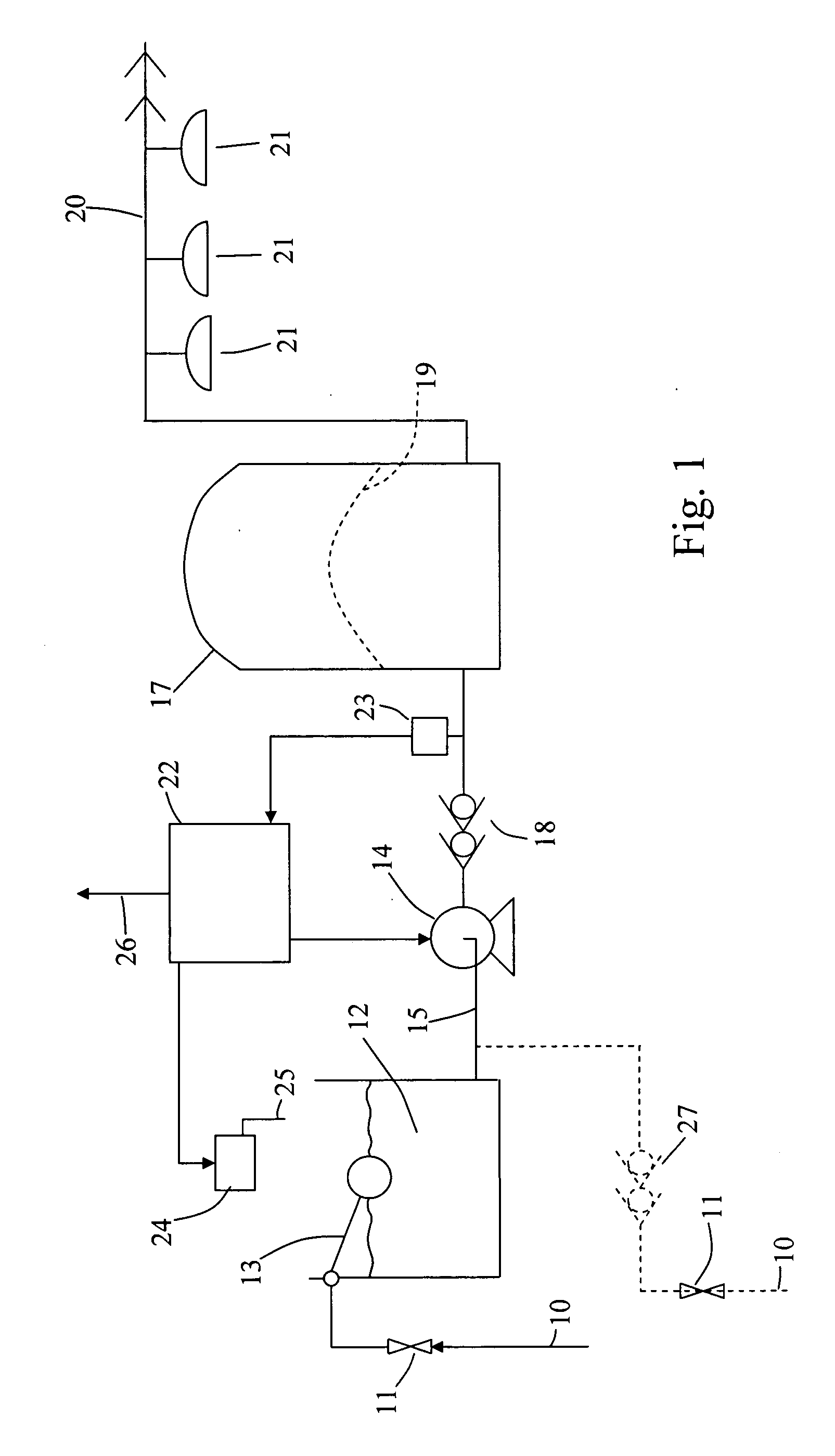

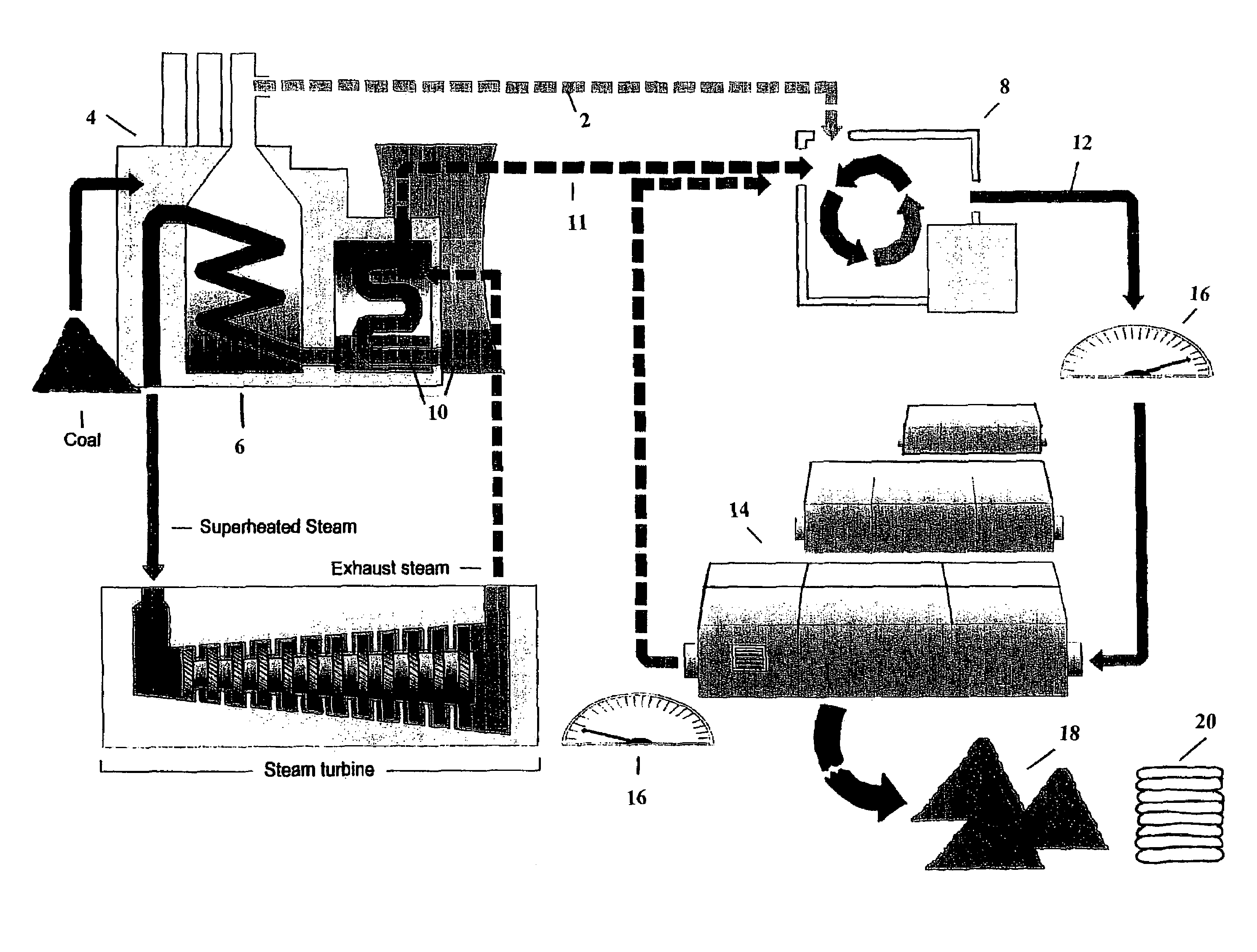

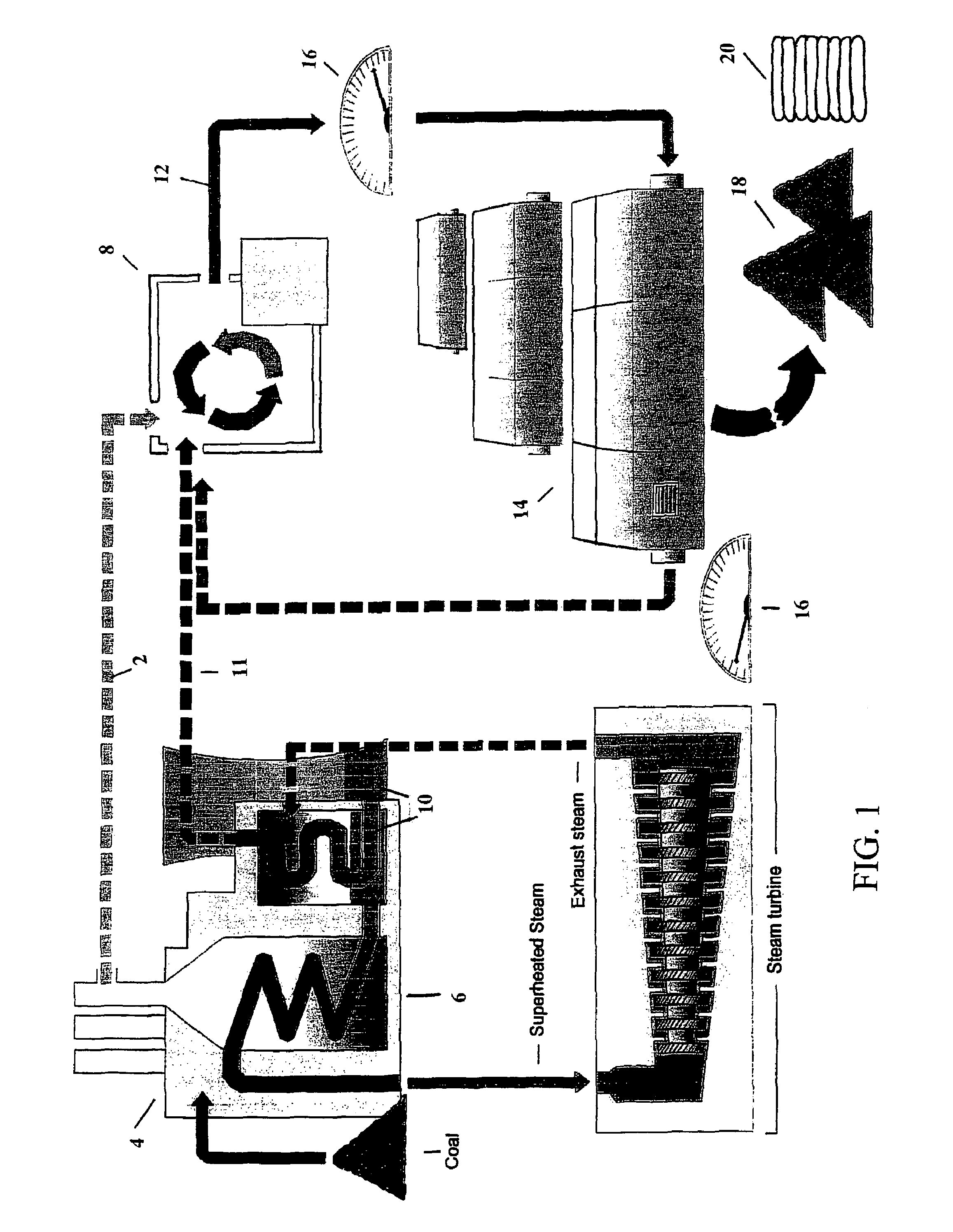

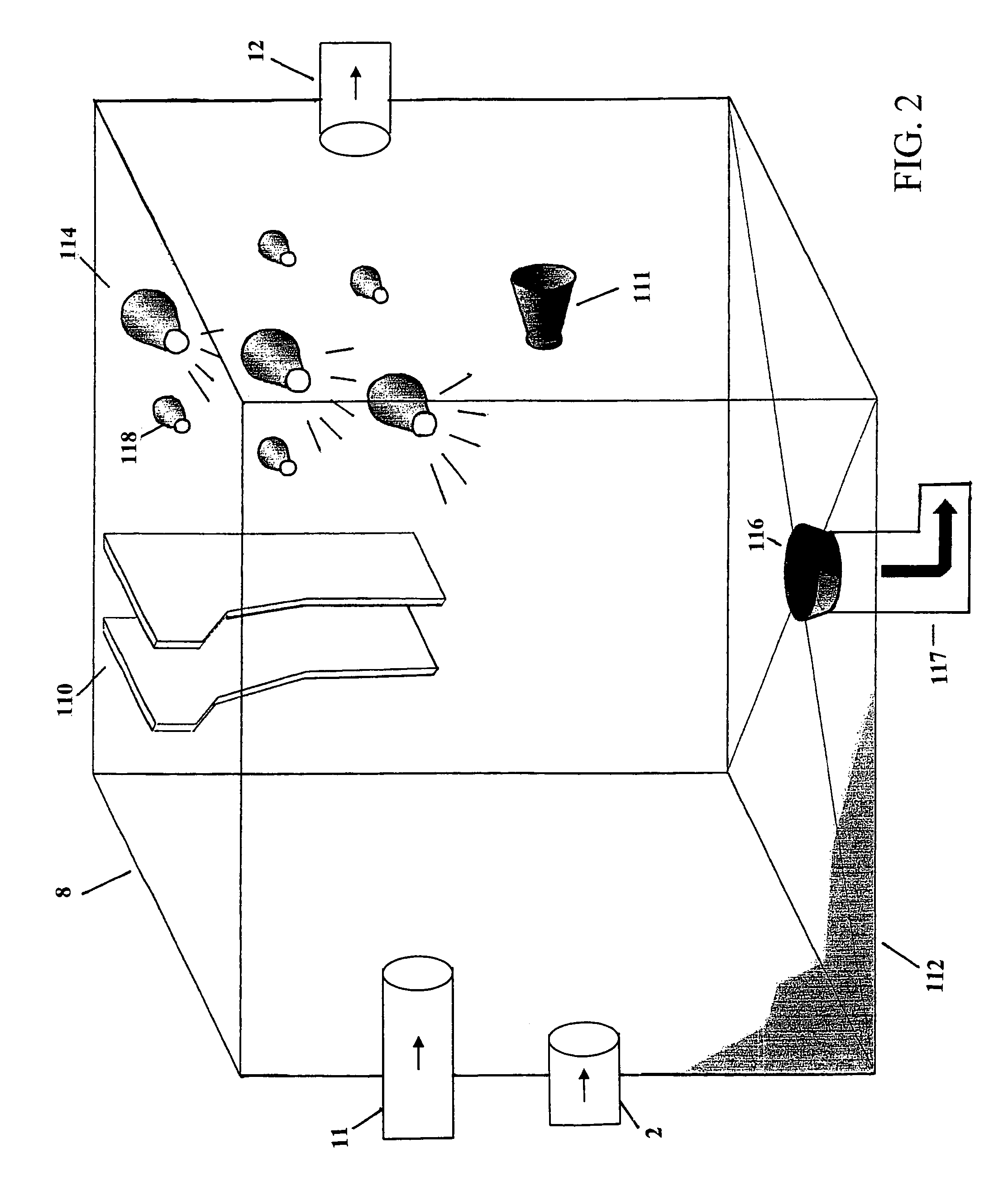

Process to produce a commercial soil additive by extracting waste heat, exhaust gas, and other combustion by-products from a coal power generator

Exhaust gas 2 from a coal power generator 4 may be used to provide a commercial soil additive. The exhaust gas 2 is fed to a growing cell 14 containing bio-mass material. After the bio-mass material matures, the bio-mass material is harvested to produce the commercial soil additive, which is preferably treated to produce mulch 18 and compost 20.

Owner:LEE L COURTLAND

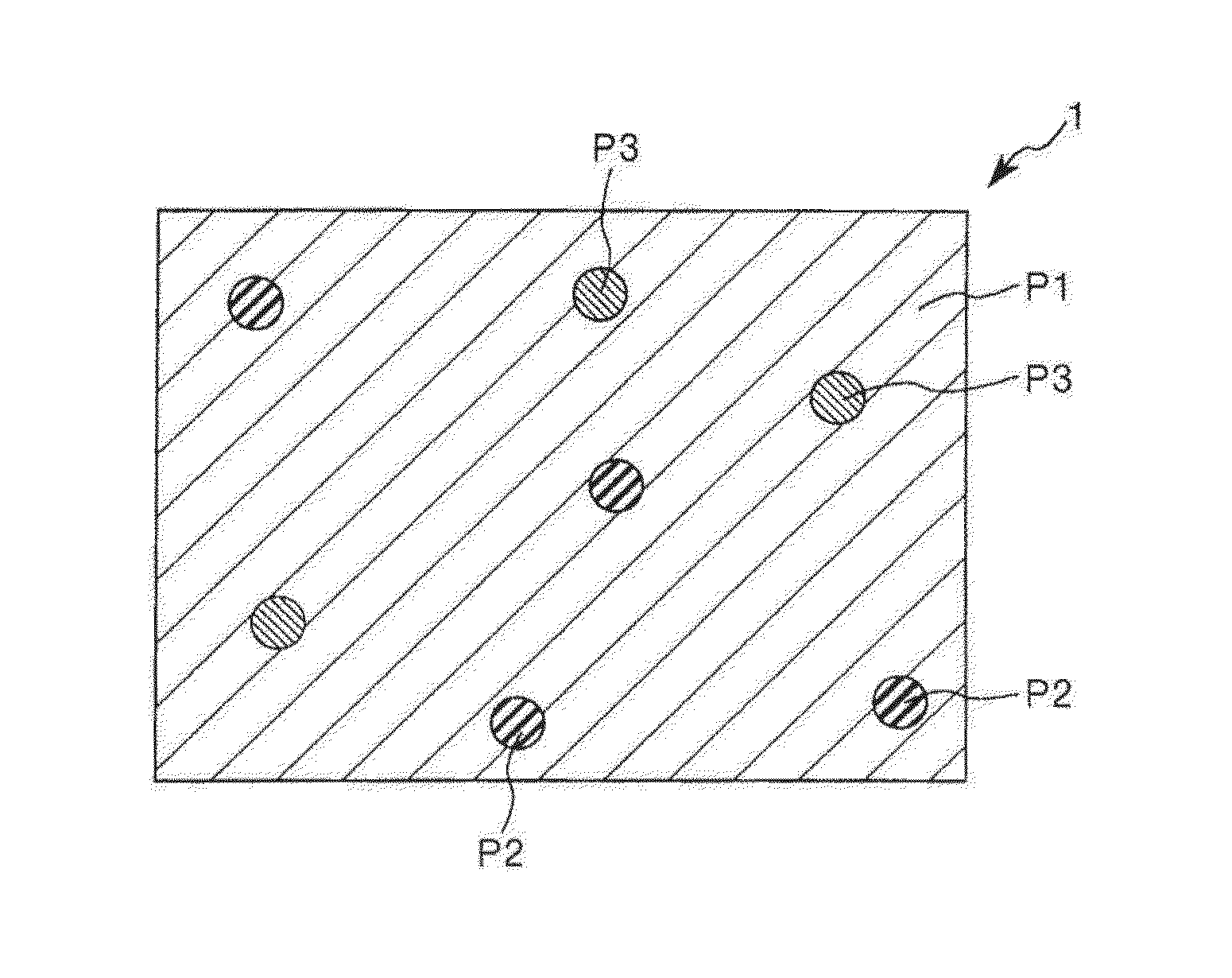

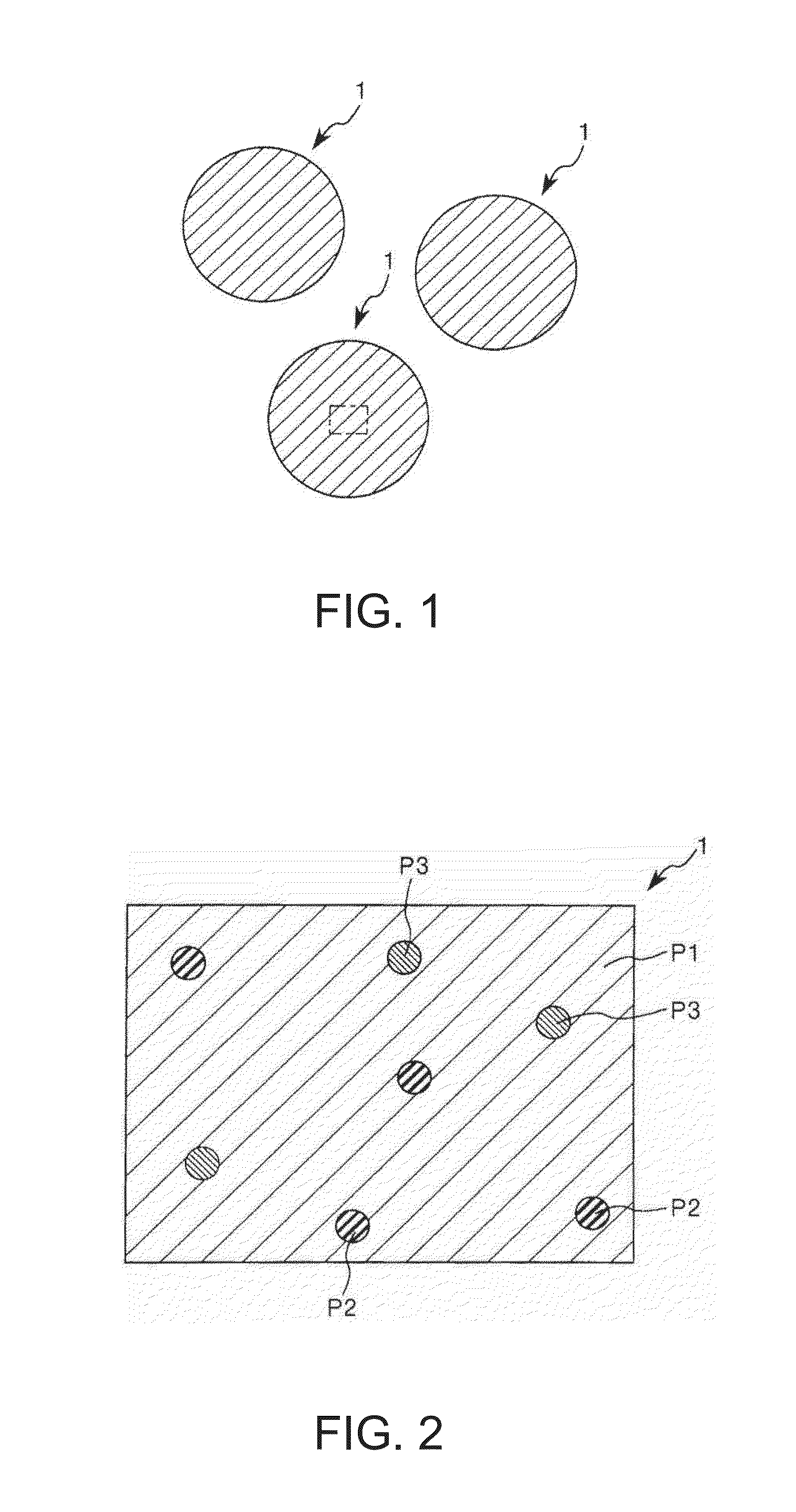

Metal powder for powder metallurgy, compound, granulated powder, sintered body, and method for producing sintered body

InactiveUS20150273581A1High densitySignificant growthTransportation and packagingMetal-working apparatusMetal powderCrystallization

A metal powder for powder metallurgy includes particles each having a first region containing Fe as a principal component, a second region, in which the content of a first element is higher than in the first region, the content of Si is higher than in the first region, and the content of Fe is lower than in the first region, and a third region, in which the content of a second element is higher than in the first region, the content of Si is higher than in the first region, and the content of Fe is lower than in the first region. Further, the first region occupies 50% by volume or more of each of the particles and also is crystalline.

Owner:SEIKO EPSON CORP

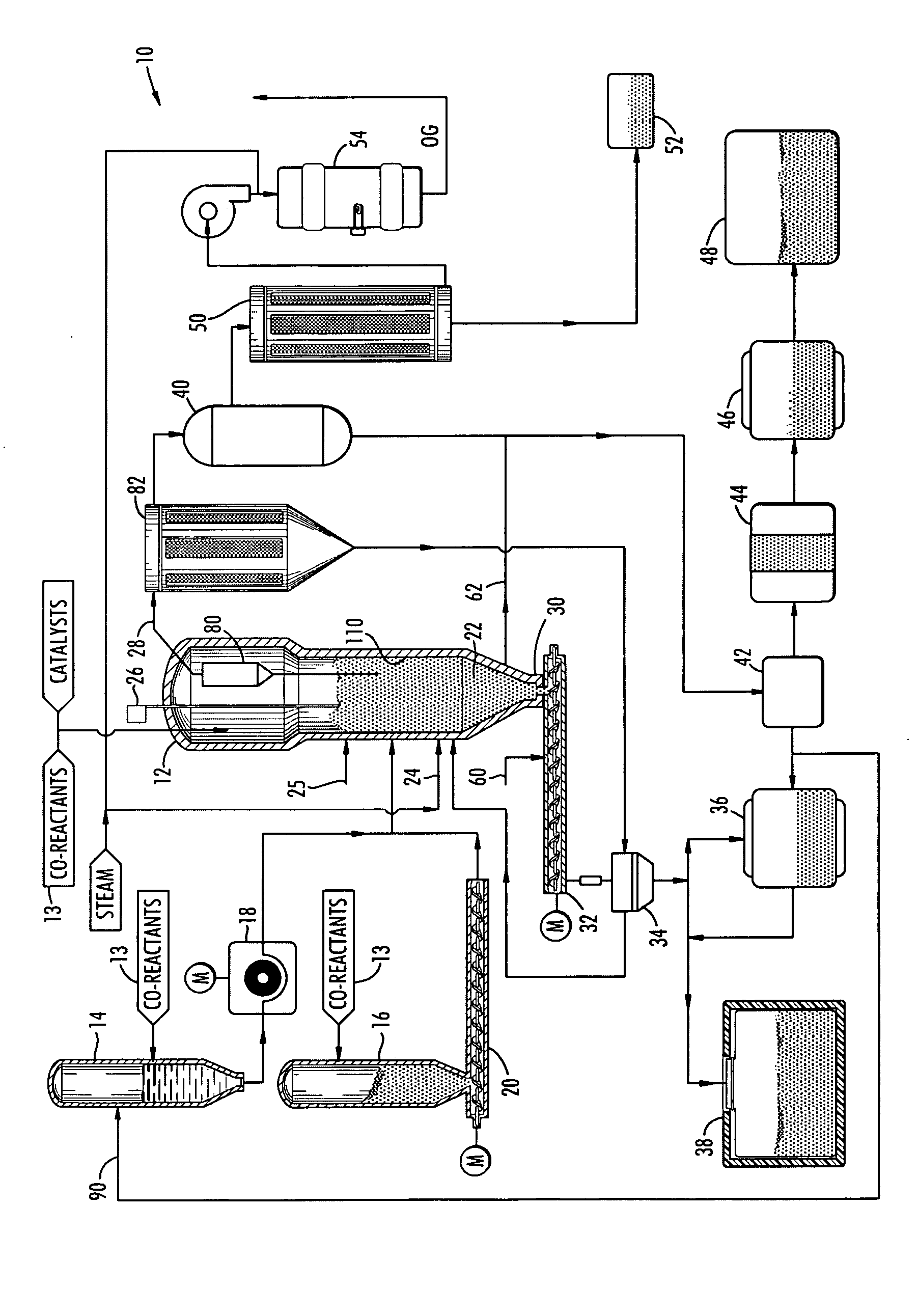

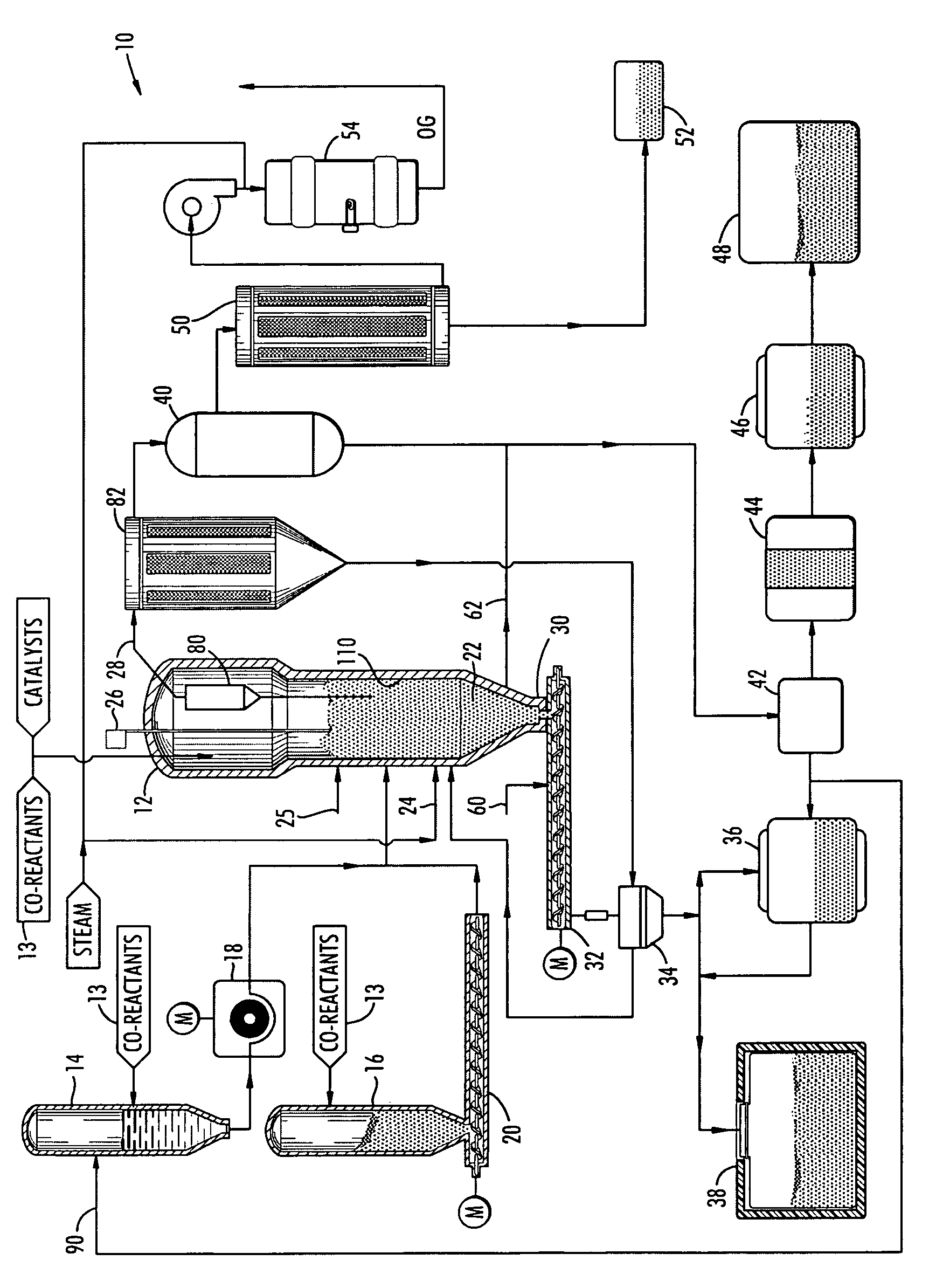

Mineralization of alkali metals, sulfur, and halogens

A system and method for conversion of alkali metals, heavy metals, halogens, and sulfur into mineral products. The system includes a single reaction vessel. To begin the process, co-reactants such as lime and clay are mixed with waste feeds containing alkali metals, heavy metals, halogens, and sulfur. This mixture is then introduced into the reaction vessel. The reaction vessel is operated under reducing conditions. After the mineral products are allowed to form, they are collected from the reaction vessel.

Owner:STUDSVIK INC

Transformation system in camelina sativa

InactiveUS20040031076A1Significant growthOther foreign material introduction processesFermentationTransformation systemsBiotechnology

The present invention relates to plant biotechnology and specifically to a method for genetically transforming Camelina sativa with Agrobacterium-mediated transformation system. It comprises Camelina sativa for producing homologous and heterologous recombinant products including oil and protein products and assessing and screening the efficacy of plant transformation. Also disclosed are transgenic Camelina sativa plants, seeds as well as cells, cell-lines and tissue of Camelina sativa.

Owner:UNICORP +1

Agent for improving activity of root system

InactiveCN1690022AIncrease vitalityVigorousOrganic fertilisersFertilizer mixturesDipotassium hydrogen phosphateChlorine dioxide

The root system activity agent is one kind of powdered product comprising microbial nitrogen, humate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate and chlorine dioxide. It has the main effects of promoting crop's root system growth, raising crop's root system activity, eliminating re-cropping disturbance, raising crop's resistance, raising nutrient utilization, and protecting and repairing soil.

Owner:么向和 +1

Mineralization of alkali metals, sulfur, and halogens

A system and method for conversion of alkali metals, heavy metals, halogens, and sulfur into mineral products. The system includes a single reaction vessel. To begin the process, co-reactants such as lime and clay are mixed with waste feeds containing alkali metals, heavy metals, halogens, and sulfur. This mixture is then introduced into the reaction vessel. The reaction vessel is operated under reducing conditions. After the mineral products are allowed to form, they are collected from the reaction vessel.

Owner:STUDSVIK INC

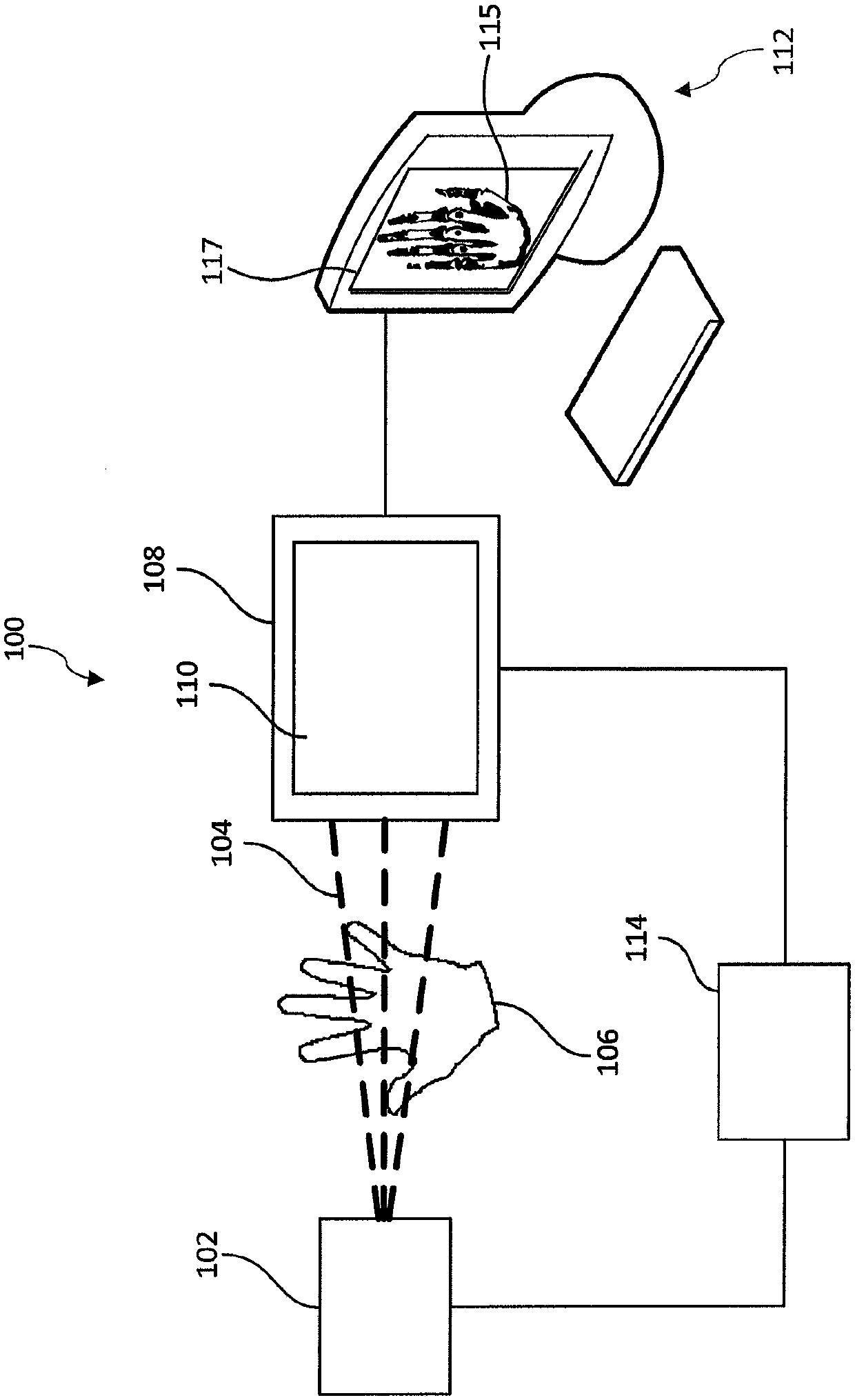

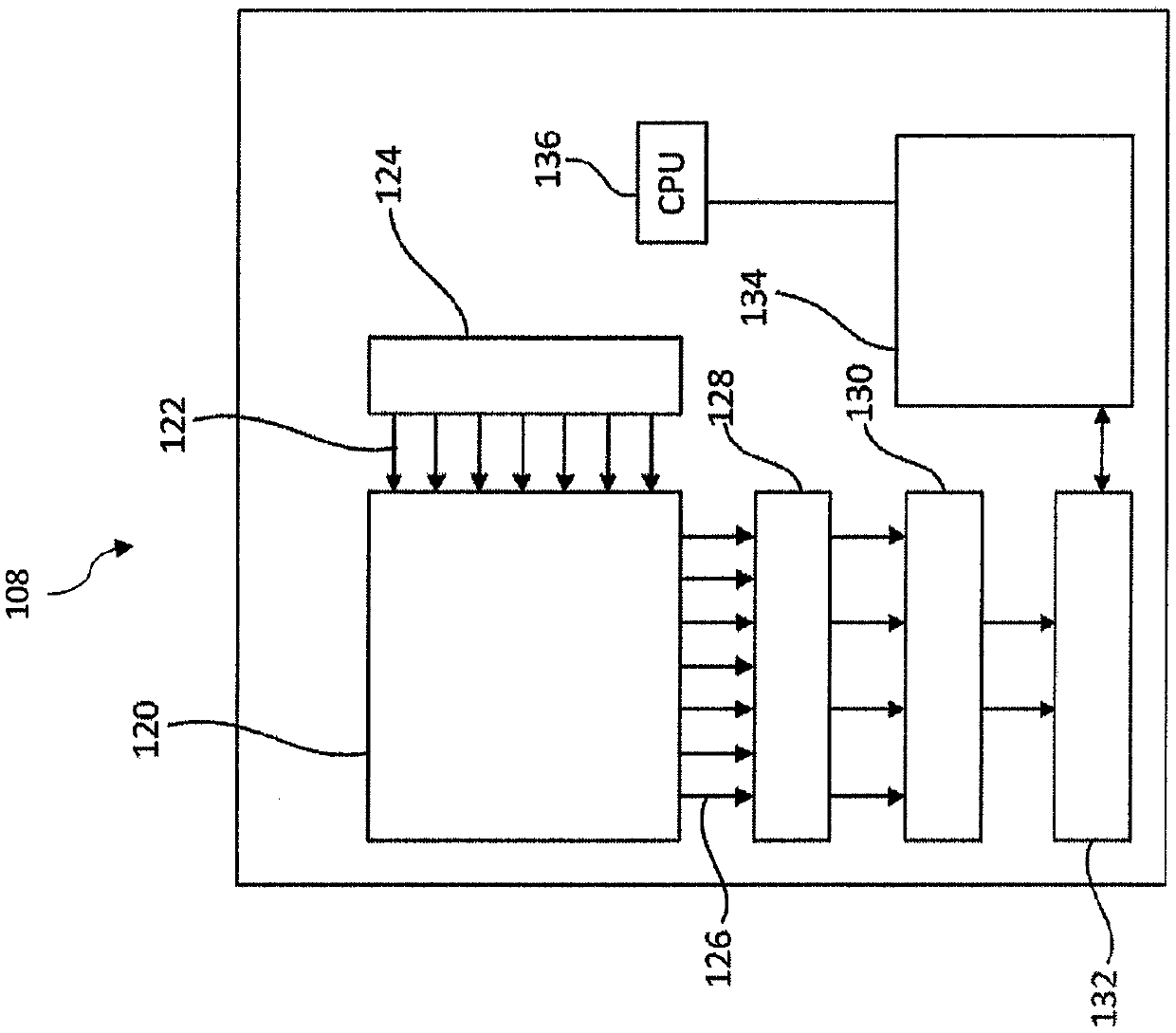

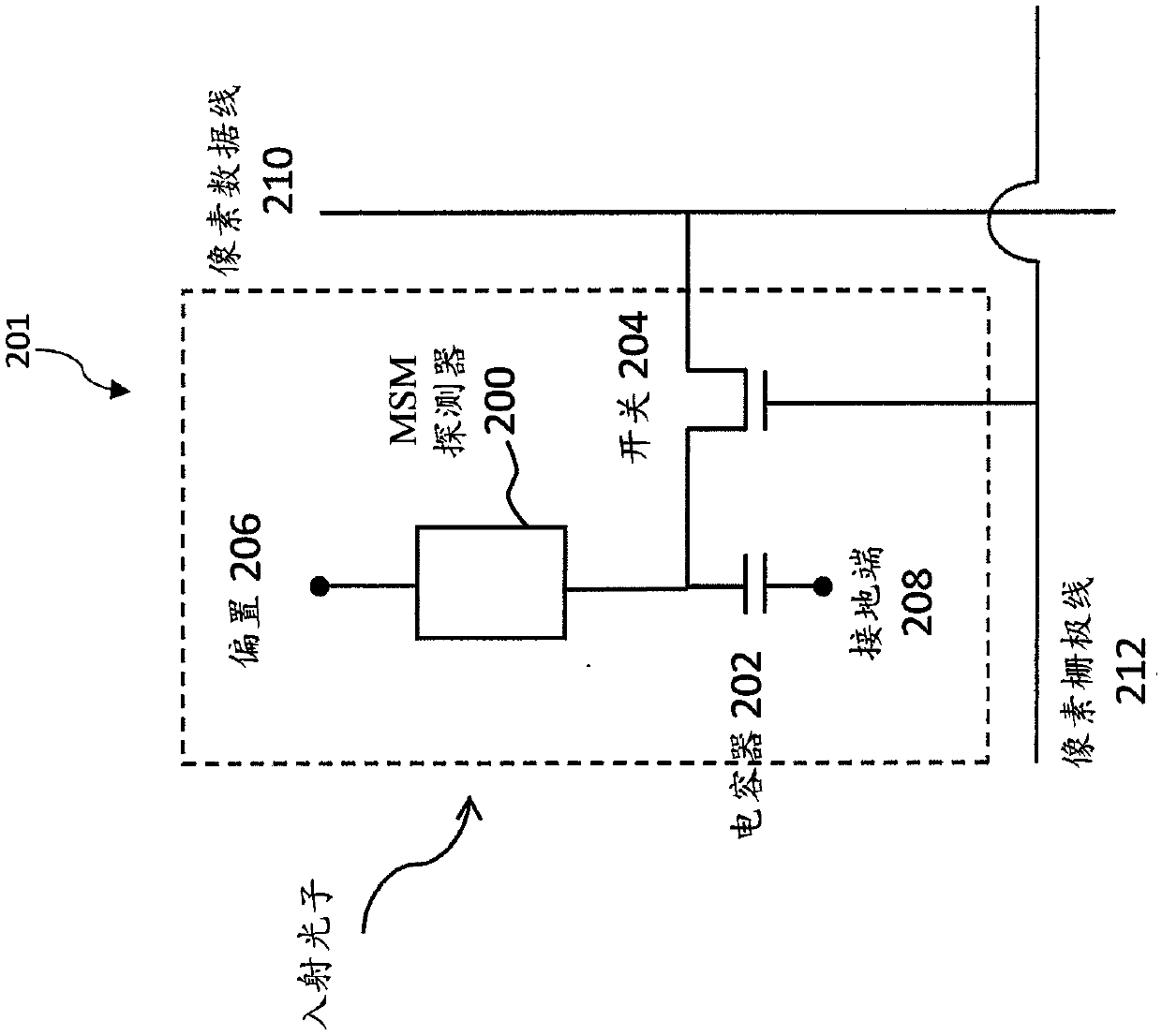

Multi-sensor pixel architecture for use in digital imaging system

PendingCN107831523ASignificant growthSolid-state devicesRadiation diagnosticsDigital imagingVIT signals

A system and method for a multi-sensor pixel architecture for use in a digital imaging system is described. The system includes at least one semiconducting layer for absorbing radiation incident on opposites of the at least one semiconducting layer along with a set of electrodes on one side of the semiconducting layer for transmitting a signal associated with the radiation absorbed by the semiconducting layer.

Owner:KA IMAGING INC

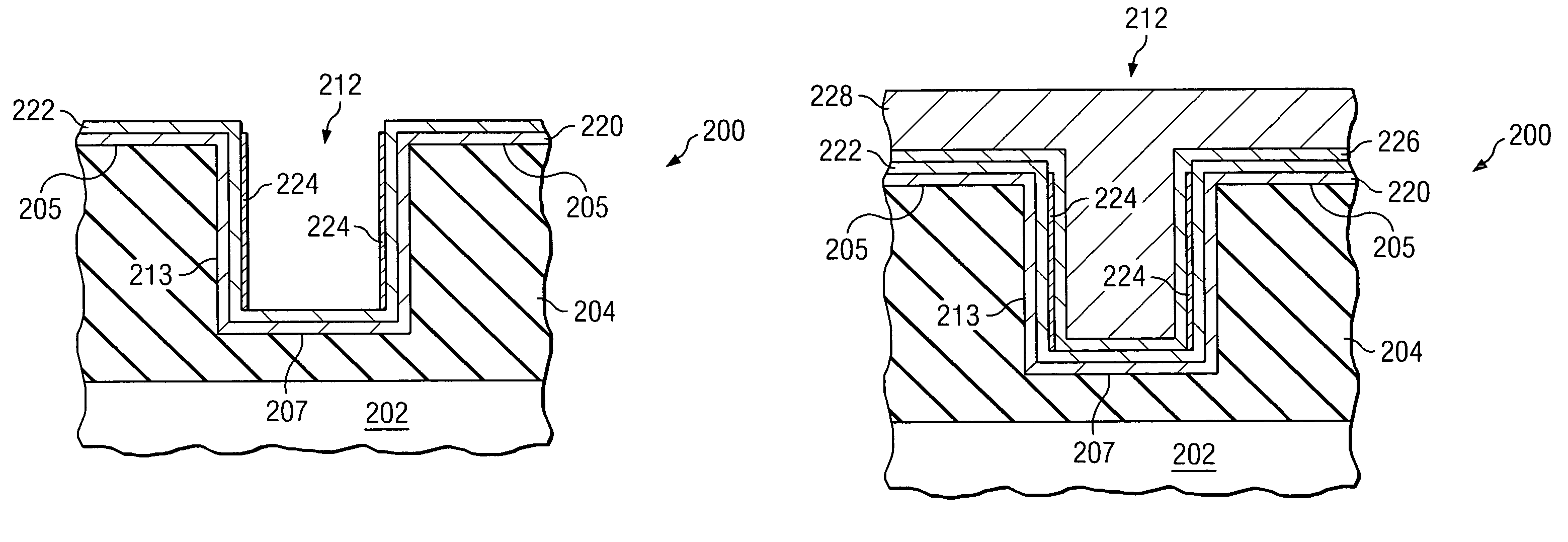

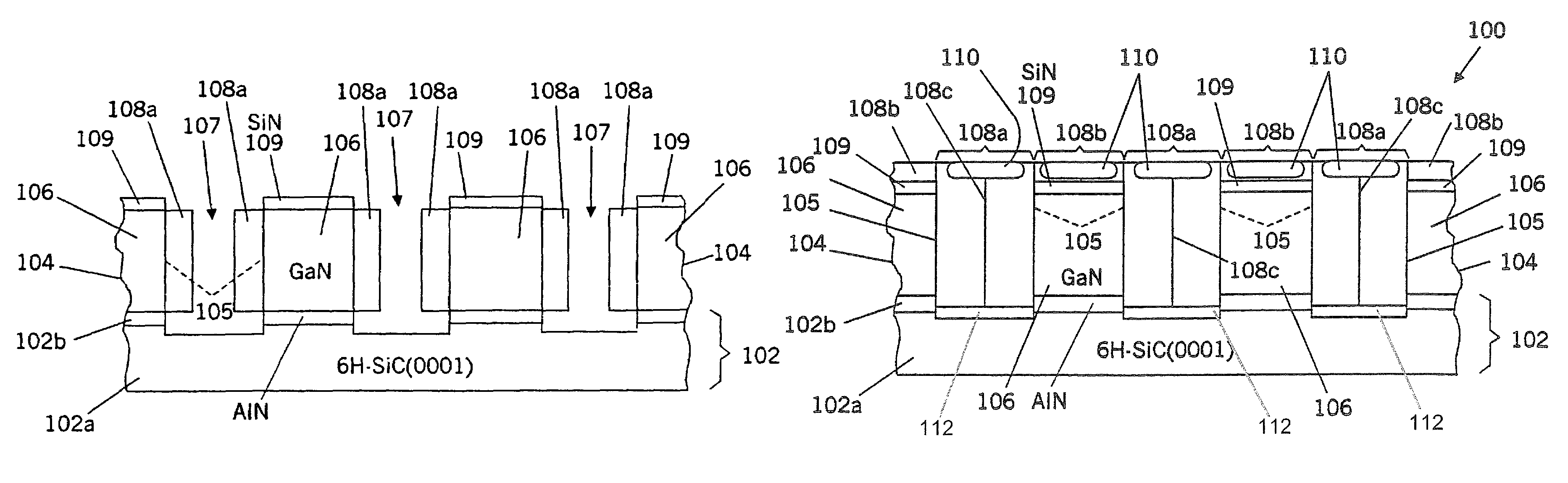

Pendeoepitaxial gallium nitride semiconductor layers on silicon carbide substrates

InactiveUS7378684B2Enhance layeringSignificant growthPolycrystalline material growthLaser detailsLateral overgrowthNucleation

An underlying gallium nitride layer on a silicon carbide substrate is masked with a mask that includes an array of openings therein, and the underlying gallium nitride layer is etched through the array of openings to define posts in the underlying gallium nitride layer and trenches therebetween. The posts each include a sidewall and a top having the mask thereon. The sidewalls of the posts are laterally grown into the trenches to thereby form a gallium nitride semiconductor layer. During this lateral growth, the mask prevents nucleation and vertical growth from the tops of the posts. Accordingly, growth proceeds laterally into the trenches, suspended from the sidewalls of the posts. The sidewalls of the posts may be laterally grown into the trenches until the laterally grown sidewalls coalesce in the trenches to thereby form a gallium nitride semiconductor layer. The lateral growth from the sidewalls of the posts may be continued so that the gallium nitride layer grows vertically through the openings in the mask and laterally overgrows onto the mask on the tops of the posts, to thereby form a gallium nitride semiconductor layer. The lateral overgrowth can be continued until the grown sidewalls coalesce on the mask to thereby form a continuous gallium nitride semiconductor layer. Microelectronic devices may be formed in the continuous gallium nitride semiconductor layer.

Owner:NORTH CAROLINA STATE UNIV

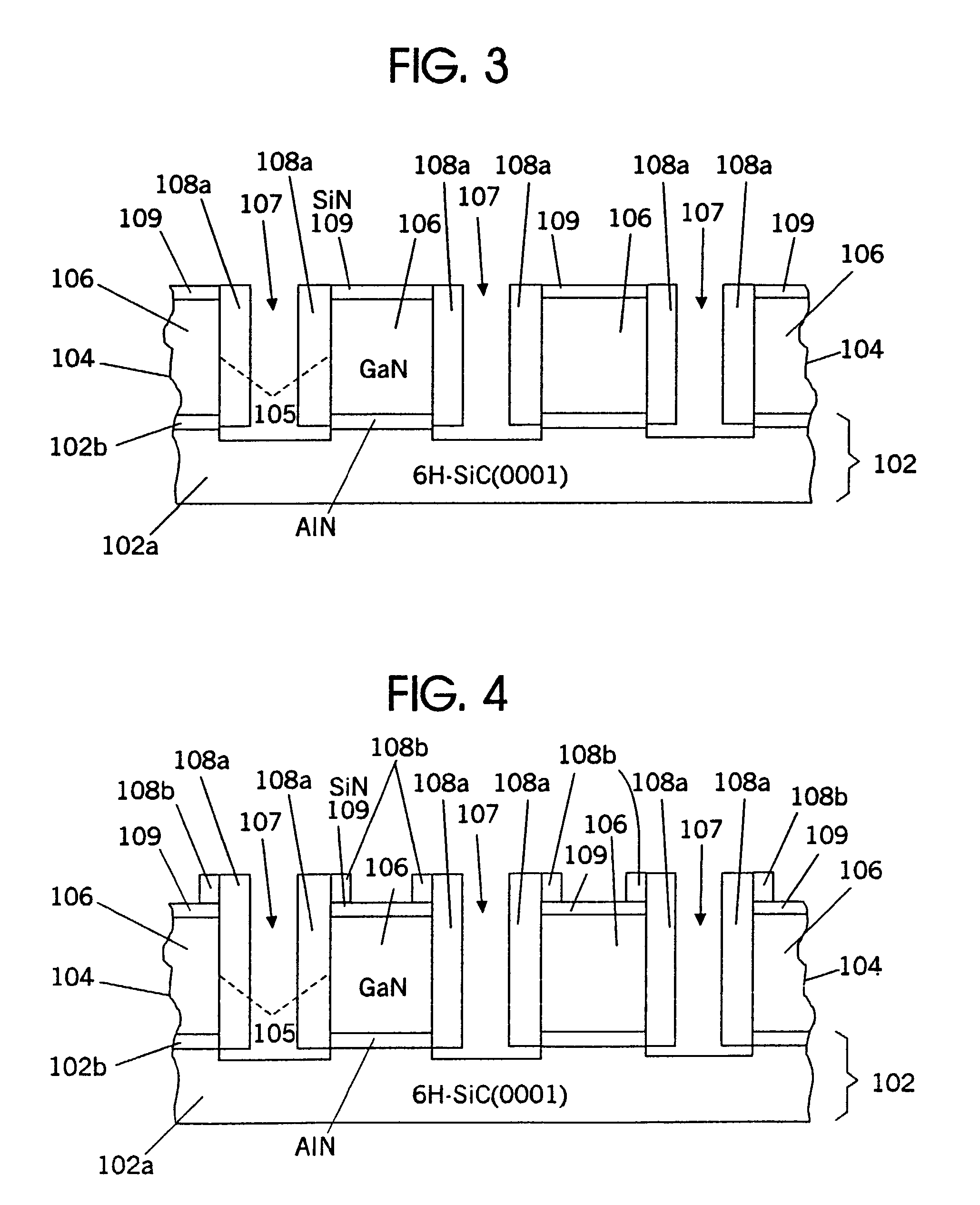

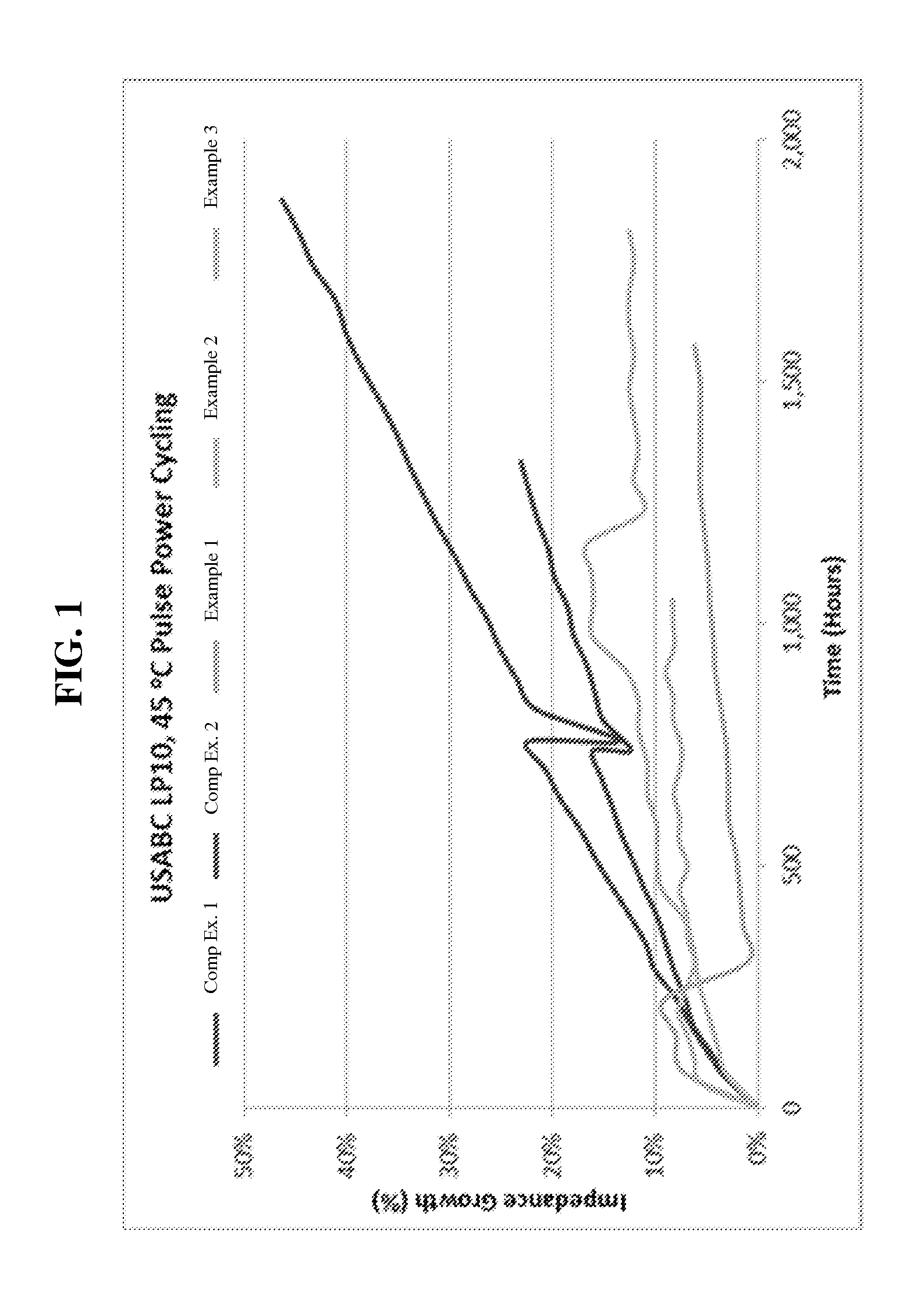

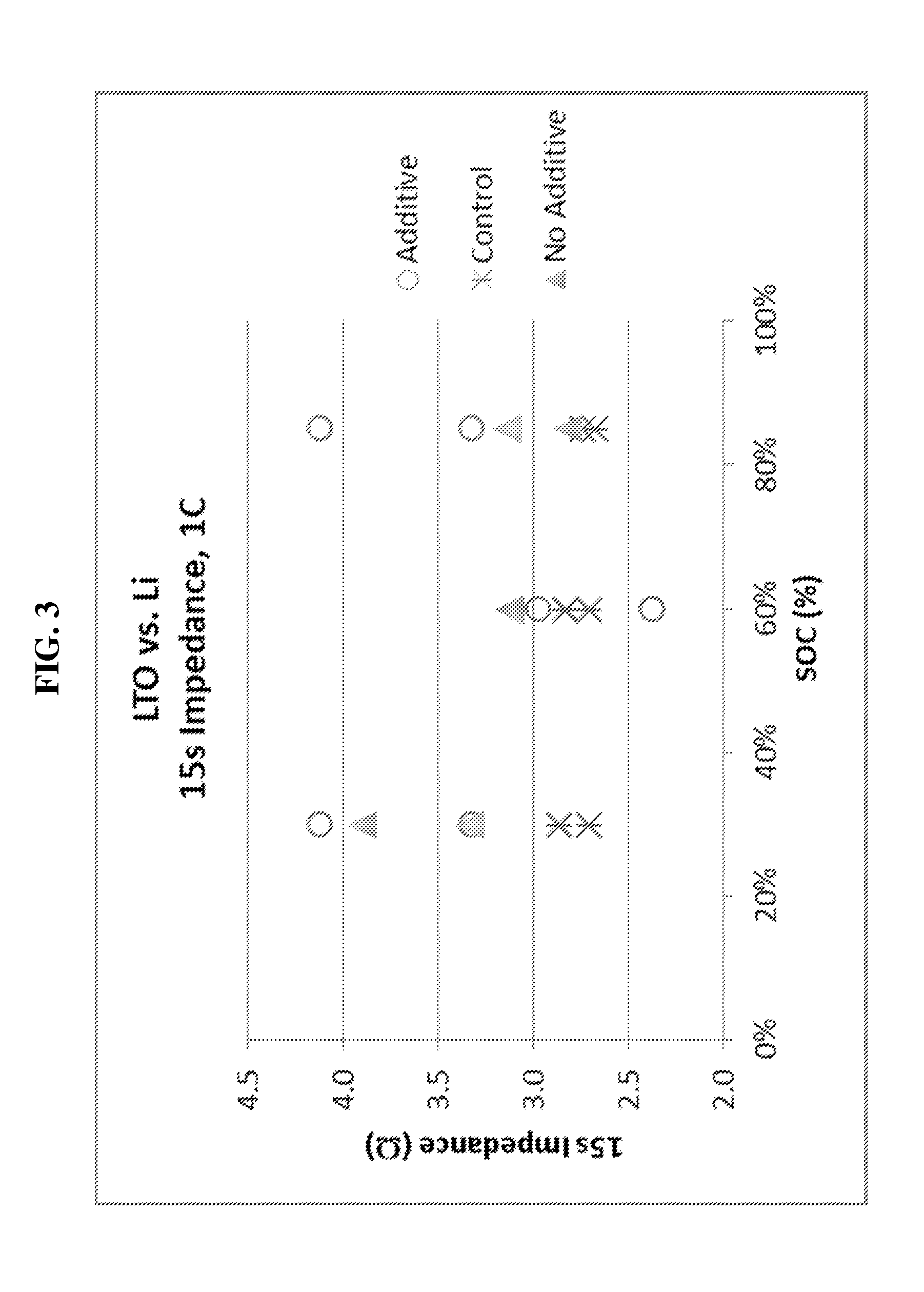

Lithium titanate oxide as negative electrode in li-ion cells

InactiveUS20150333371A1Improve rendering capabilitiesProlong lifeFinal product manufactureElectrode carriers/collectorsInterface layerEngineering

A lithium-ion battery including a negative electrode (anode) containing lithium titanate oxide (Li4Ti5O12) (LTO) as an active material and a stable interface layer disposed on a surface of the electrode; a positive electrode (cathode); an electrolyte containing a solvent and an impedance growth reducing additive; and a separator disposed between the electrodes. The LTO-based cell with the stable interface layer on the negative electrode is formed by holding the potential of the negative electrode below the reduction potential of the impedance growth reducing additive for a sufficient length of time during a first formation cycle. The stable interface layer on the negative electrode mitigates impedance growth on the positive electrode over cycle life. When the impedance growth reducing additive is fluoroethylene carbonate (C3H3FO3), the stable interface layer includes a LiF deposit.

Owner:SAFT GRP SA

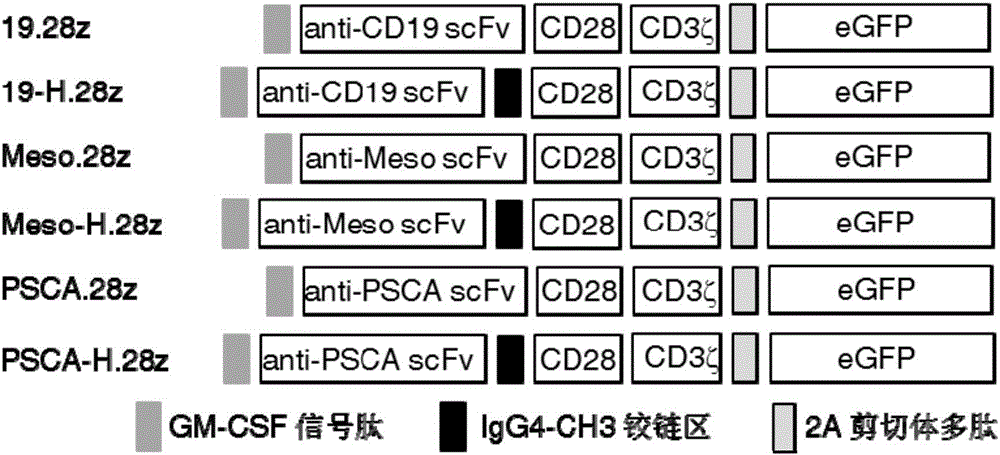

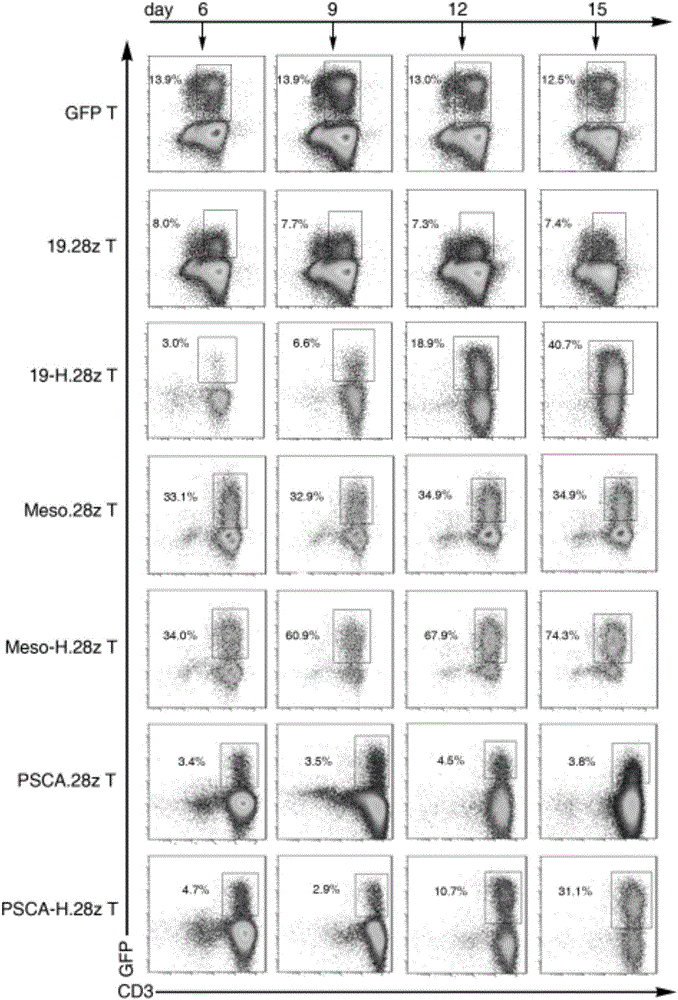

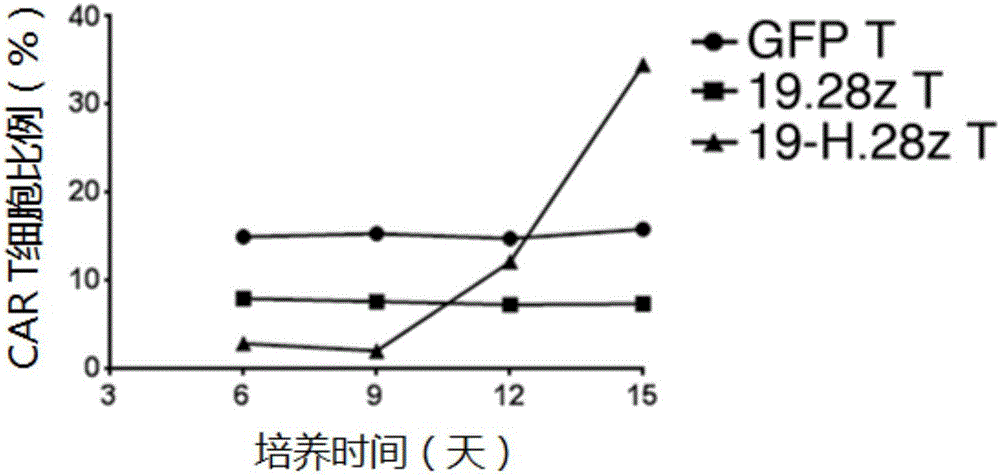

Chimeric antigen receptor (CAR) and application thereof

ActiveCN106800601AImprove efficiencyPromote amplificationPolypeptide with localisation/targeting motifImmunoglobulin superfamilyAntigen receptorsHinge region

The invention relates to the field of tumor cellular immunotherapy, in particular to a chimeric antigen receptor (CAR) and application thereof. The CAR comprises a hinge region, and the hinge region is IgG4-CH3. The IgG4-CH3 hinge region is introduced into a CAR molecular structure, so that the amplification efficiency of CAR T cells can be specifically increased in an in-vitro culture process, the amplification of CD4+CAR T cells is mainly promoted, CD4 cells and CD8 T cells do not need to be cultured in a separated way, the process is completed in a mixing system, and the amplification efficiency of the CD4+CAR T cells is increased.

Owner:广东昭泰细胞生物科技有限公司

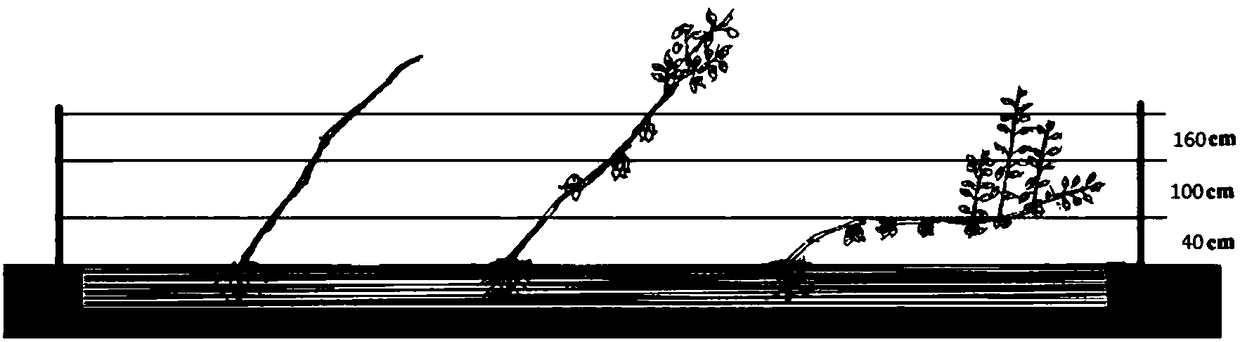

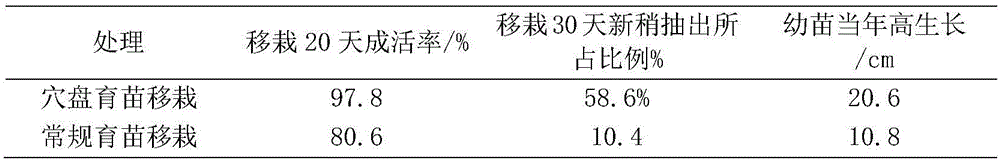

Method for walnut seedling culture and transplantation

InactiveCN106069462ASignificant growthEasy to operateGrowth substratesCulture mediaRootstockObserved Survival

The invention discloses a method for walnut seedling culture and transplantation. Through seedling setting with trays, root cutting transplanting and container culture, the growth process and the transplanting process of seedlings do not affect each other. Soil balls which seedling roots take greatly reduce loss of roots in the transplanting process, the transplanting survival rate is improved, the rejuvenation period is shortened, root systems of the cultured seedlings are flourishing, and the standard of grafting on the same year is met. The method is simple to operate, practical, low in cost and consistent in growth vigor, the transplanting survival rate is 95% or above, the seedling growth amount is obvious on the year of transplantation, nearly a half of rootstocks can reach the grafting standard when autumn is up, the seedling culture time is short, and the method is suitable for large-scale reproduction.

Owner:江苏水木农景股份有限公司

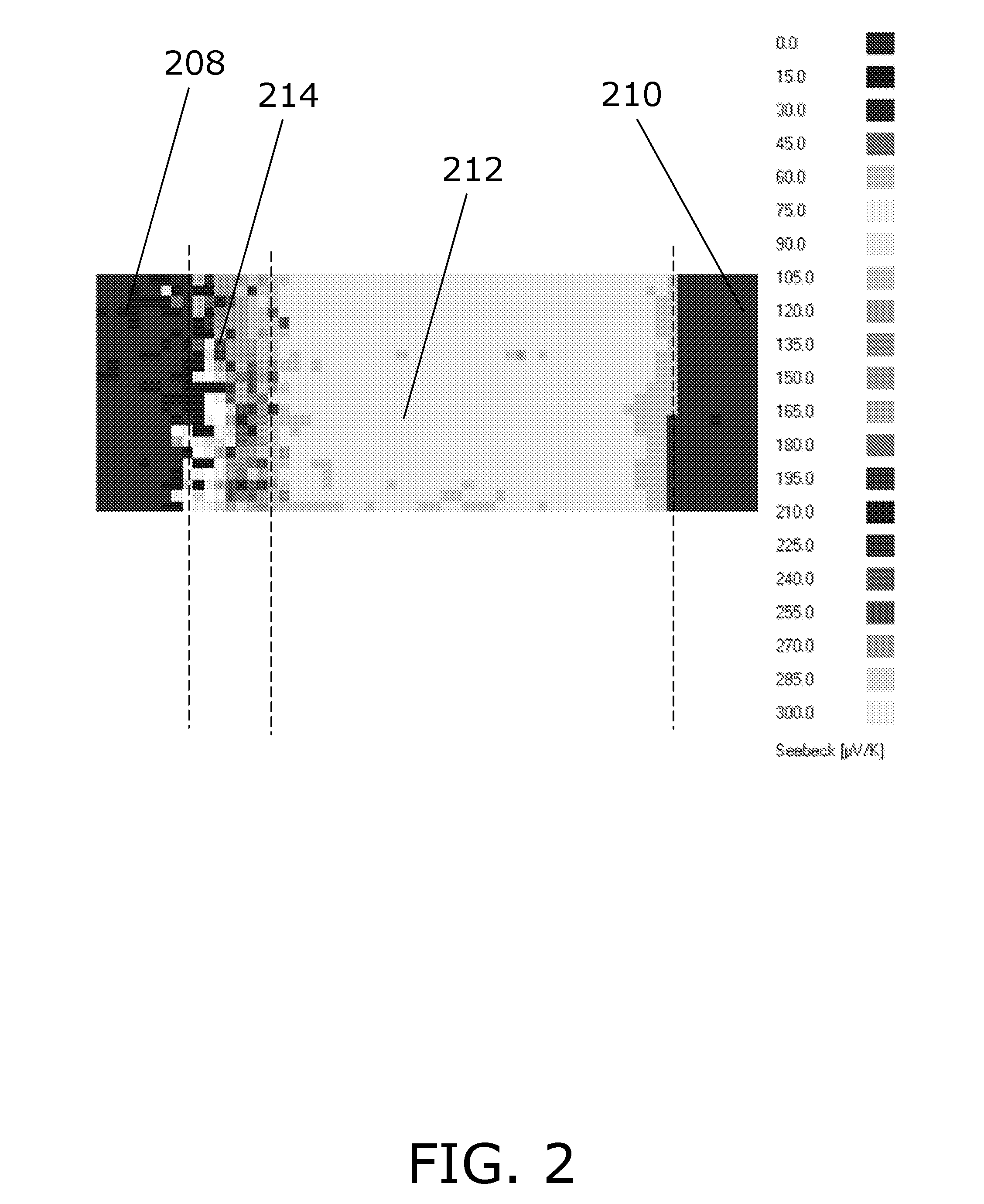

Method for producing a thermoelectric solid element

InactiveUS20140140881A1Reduce energy consumptionReduce time consumptionThermoelectric device manufacture/treatmentPowder mixturePhysical chemistry

The present invention relates to a method 931 for producing a solid element, which comprises the thermoelectrically active material beta-Zn4Sb3. The method utilizes that is possible to directly synthesize and press pellets of Zn4Sb3 starting from powders of Zn and Sb, by mixing 930 powders of Zn and Sb so as to obtain a mixed powder comprising elemental zinc and elemental antimony, placing 932 the mixed powder in a container and simultaneously applying 936 a pulsed current, such as to heat up the powders, and applying 938 a pressure such as to compact the powder mix. The gist of the invention might be seen as exploiting the basic insight, that the cumbersome and time- and energy consuming steps of synthesis and pressing of Zn and Sb, so as to achieve a solid element comprising Zn4Sb3, can be combined into a single step where the synthesis and pressing is effected simultaneously.

Owner:AARHUS UNIV

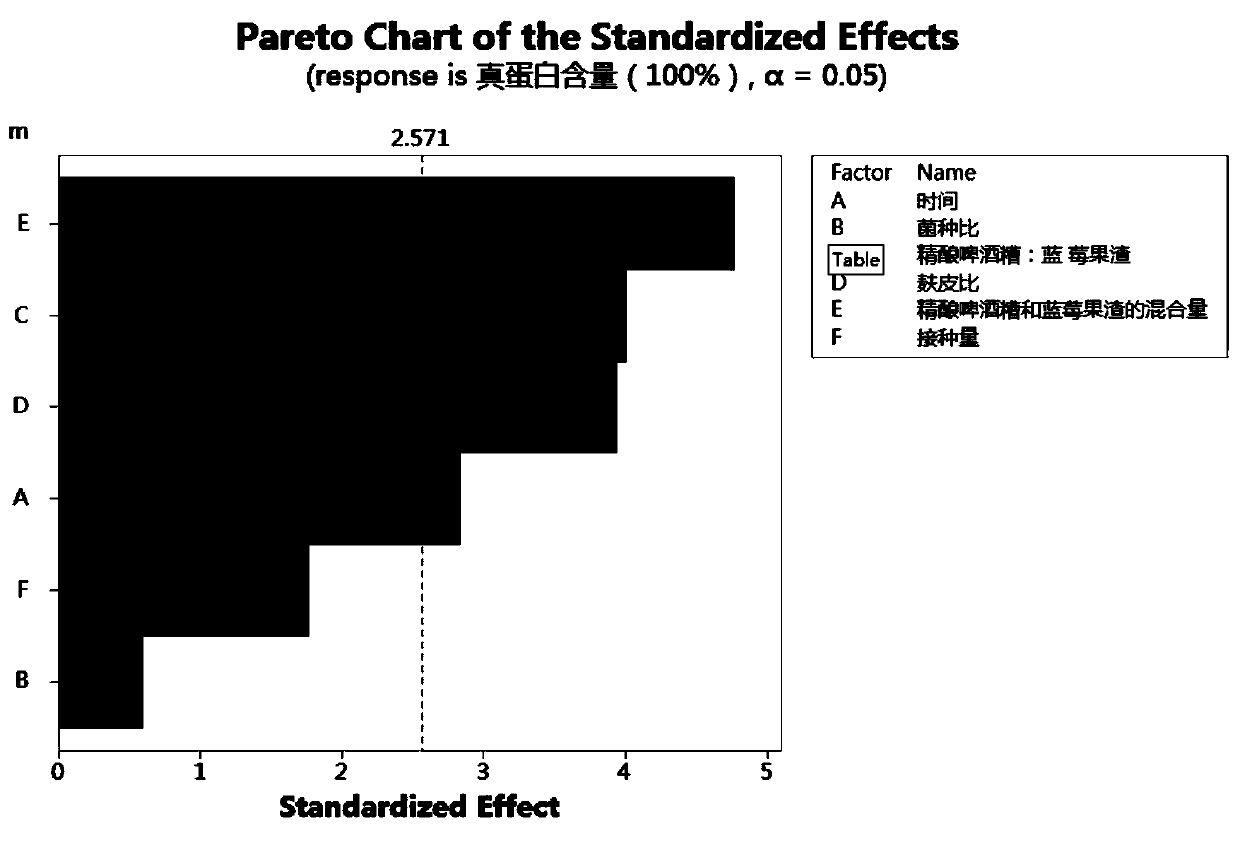

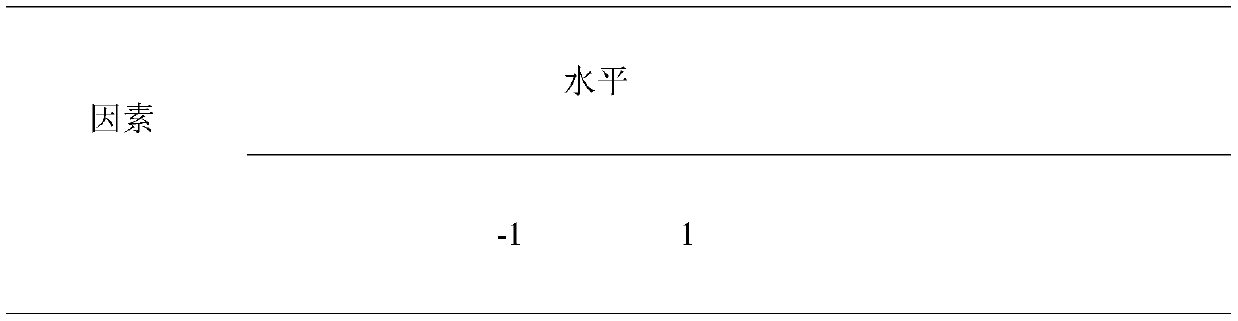

Method for producing protein feed through different mixed fermentation twice of fine-brewed brewer's grains and blueberry fruit residues

PendingCN110583856ASignificant growthReduce pollutionFood processingAnimal feeding stuffBiotechnologyThermoactinomyces

The invention discloses a method for producing a protein feed through different mixed fermentation twice of fine-brewed brewer's grains and blueberry fruit residues, and belongs to the technical fieldof the production of protein feeds. The method specifically comprises the steps of respectively performing protospecies test tube activation, triangular flask enlarged culture and seeding tank culture on ordinary thermoactinomyces, geotrichum candidum and lactobacillus plantarum, enabling a fermenter to be subjected to standing so as to obtain bacterium suspension, and mixing cultured strains inproportion so as to obtain mixed bacteria; preparing fermentation raw materials of the fine-brewed brewer's grains, the blueberry fruit residues and bran; preparing the ordinary thermoactinomyces, thegeotrichum candidum and the lactobacillus plantarum according to a certain inoculum concentration into a solid mixed bacterium agent through sterilized bran; and mixing the prepared solid mixed bacterium agent with the fine-brewed brewer's grains and the blueberry fruit residues, performing solid fermentation, firstly performing inoculation with the ordinary thermoactinomyces, performing culturefermentation at constant temperature of 50 DEG C for the first time for 72h, then performing inoculation with the obtained geotrichum candidum and lactobacillus plantarum mixed bacteria, performing fermentation at 30 DEG C for the second time for 72h, drying fermented products, and performing crushing so as to obtain the protein feed.

Owner:EASTERN LIAONING UNIV

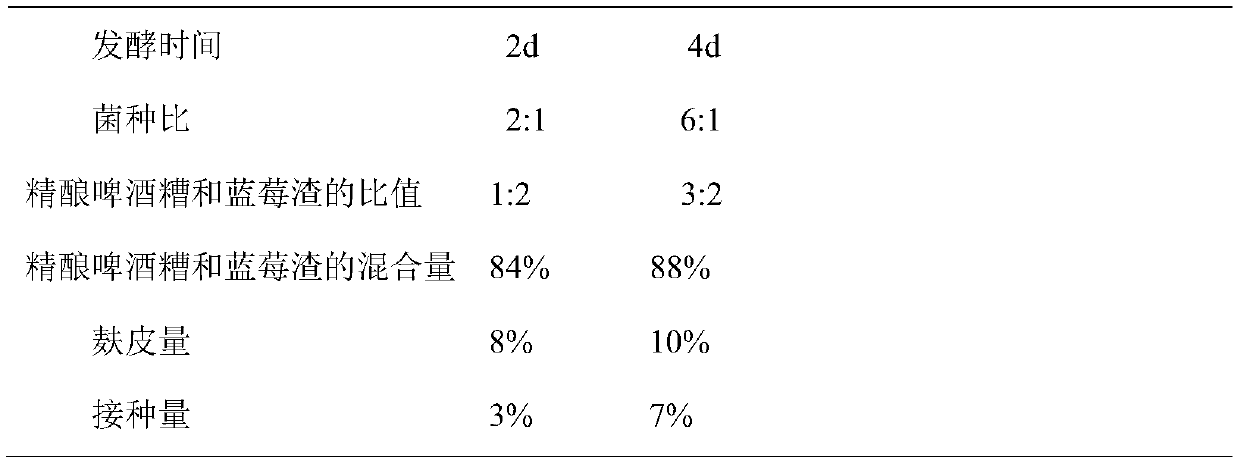

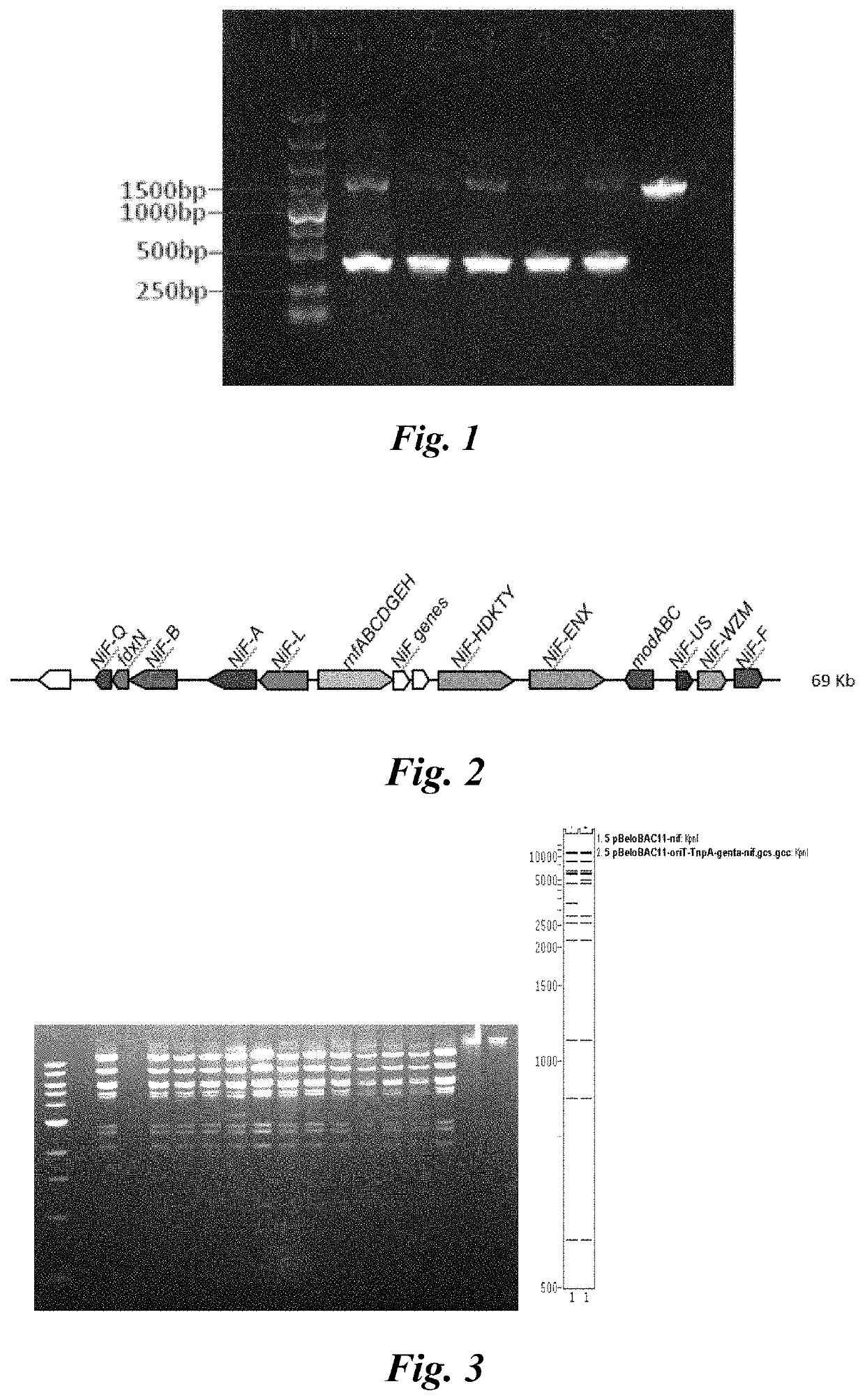

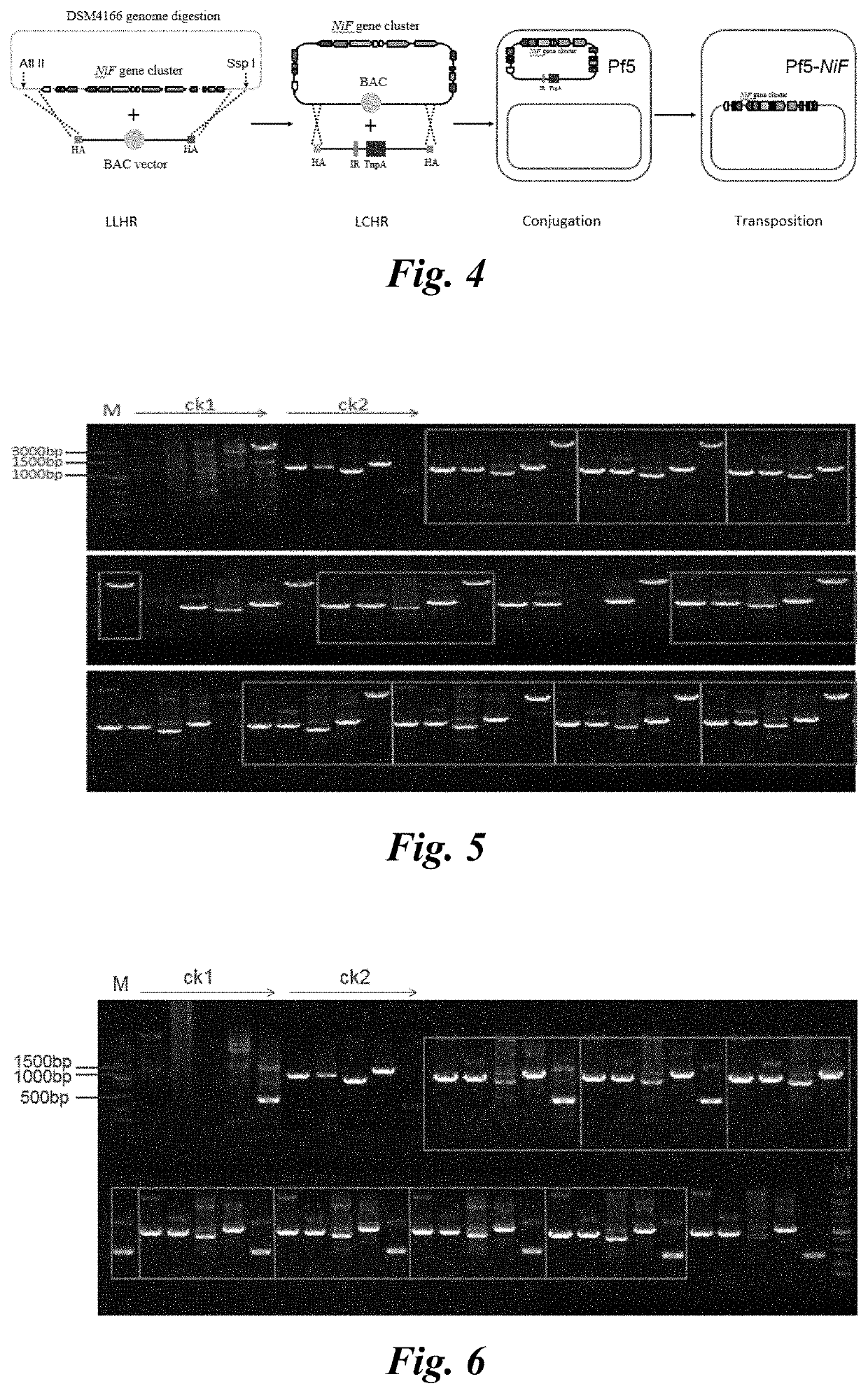

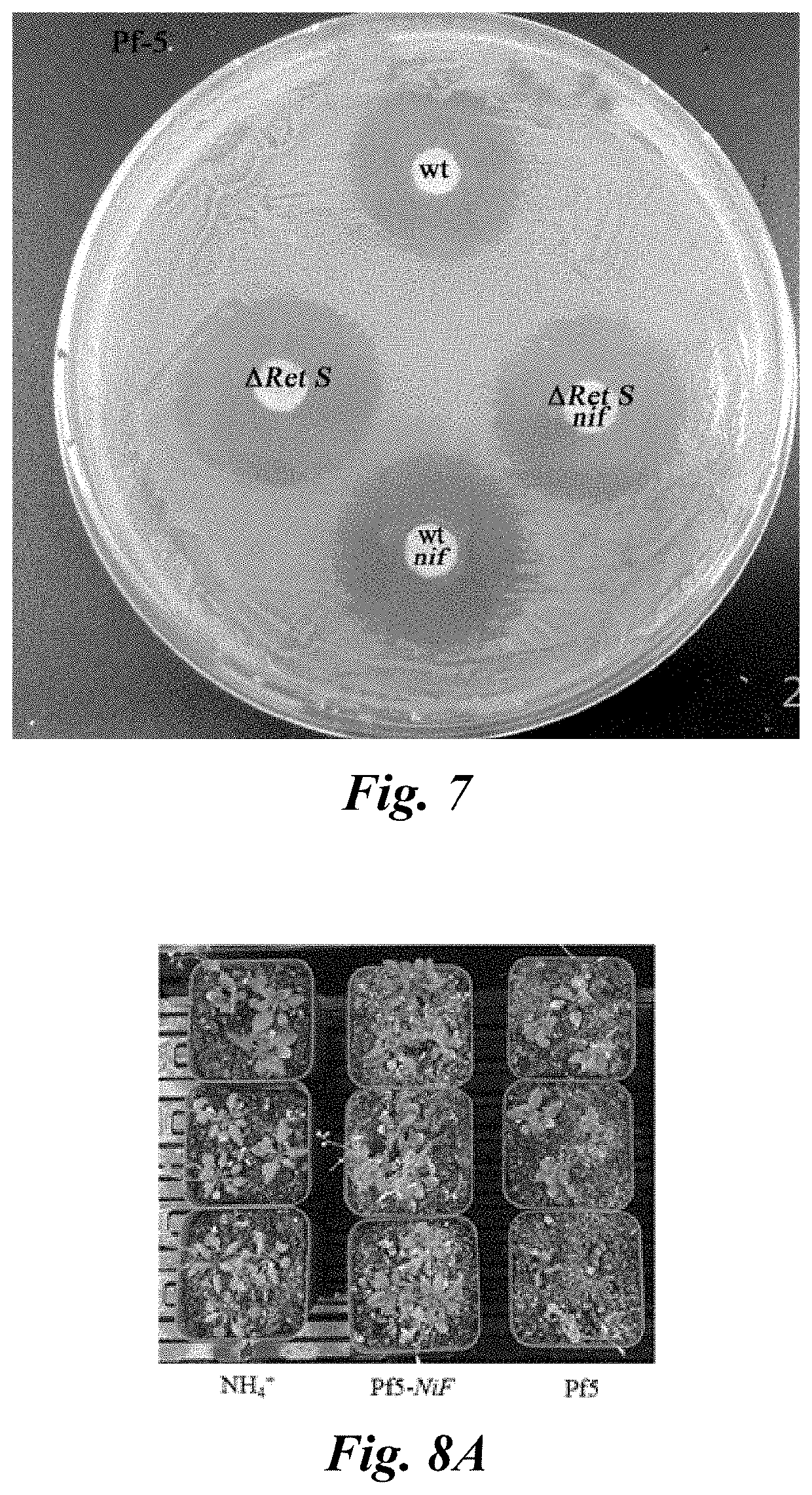

Method For Screening Pseudomonas Protegens Mutant Strain, And Application Thereof In Biological Control

InactiveUS20200120939A1High bactericidal activitySignificant biological nitrogen fixationBiocideMicroorganismsBiotechnologyHeterologous

Provided are Pseudomonas protegens mutant strain Pf5-NiF, Pf5-ΔretS, or Pf5-ΔretS-NiF, and a screening method therefor and an application thereof. By means of Red / ET recombination and direct cloning technologies, the NiF nitrogen fixation gene island in the genome of Pseudomonas stutzeri DSM4166, taken as a whole, is cloned into the genome of Pseudomonas protegens Pf5, so as to heterologously express the same successfully to obtain a genetically engineered strain Pf5-NiF, thereby bringing a biological nitrogen fixation function to Pseudomonas protegens Pf5 which does not own a biological nitrogen fixation function. In addition, gene-directed markerless knockout of retS gene in the genome of Pseudomonas protegens Pf5 is performed to obtain a genetically engineered strain Pf5-ΔretS. Thus, the expression levels of an antibiotic 2,4-diacetylphloroglucinol and red pigment are increased, and a mutant strain of Pseudomonas protegens Pf5 having a stronger bactericidal activity is obtained.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com