Metal powder for powder metallurgy, compound, granulated powder, sintered body, and method for producing sintered body

a technology of metal powder and powder metallurgy, which is applied in the direction of metal-working apparatus, transportation and packaging, etc., can solve the problems of significant increase in work load and inability to avoid the increase in cost, and achieve high density, high density, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0300]Next, Examples of the invention will be described.

1. Production of Sintered Body (Zr—Nb Based)

Sample No. 1

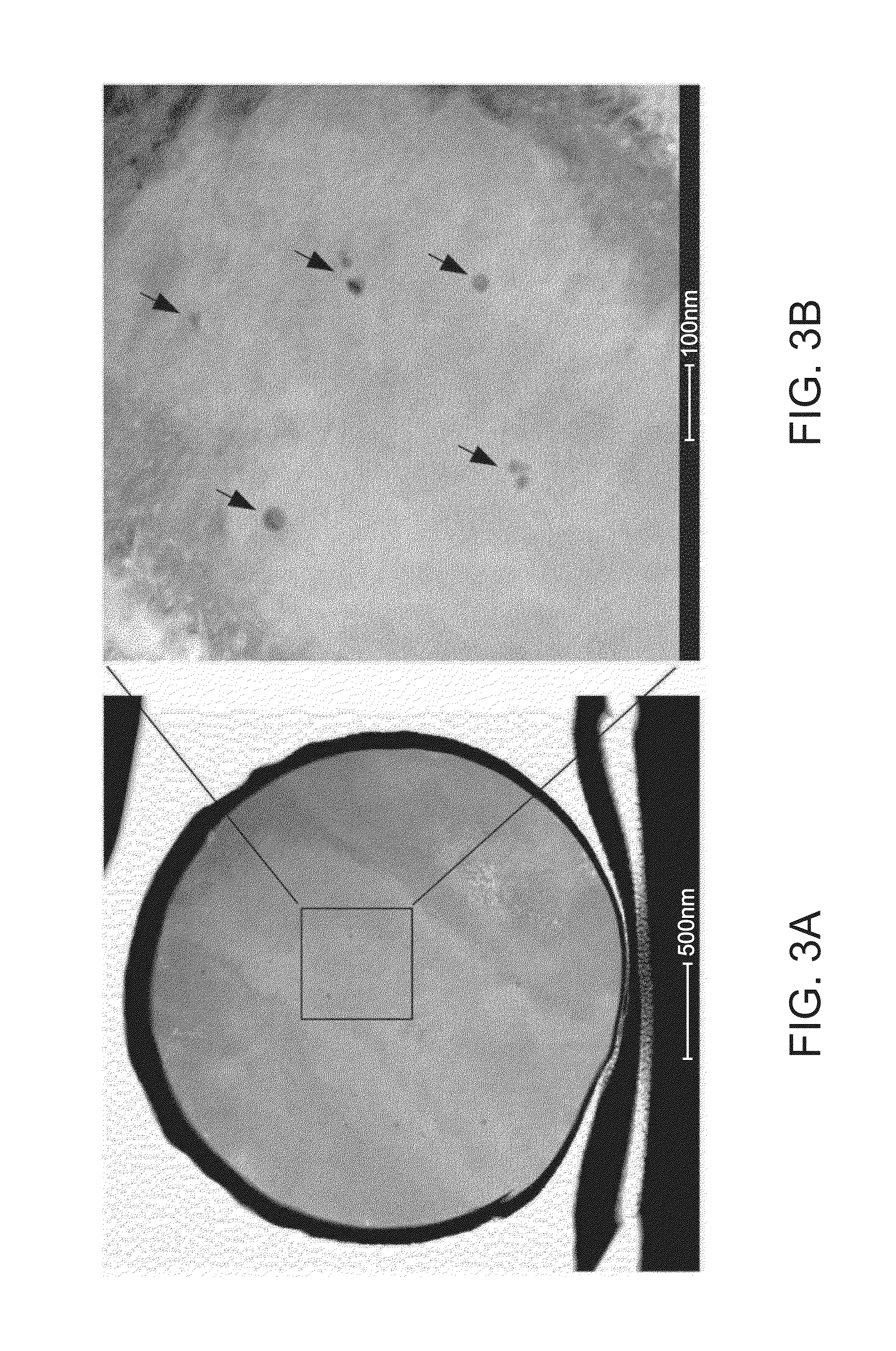

[0301](1) First, a metal powder having a composition shown in Table 1 produced by a water atomization method was prepared. This metal powder had an average particle diameter of 4.05 μm, a tap density of 4.20 g / cm3, and a specific surface area of 0.23 m2 / g.

[0302]The composition of the powder shown in Table 1 was identified and determined by an inductively coupled high-frequency plasma optical emission spectrometry (ICP method). In the ICP analysis, an ICP device (model: CIROS-120) manufactured by Rigaku Corporation was used. Further, in the identification and determination of C, a carbon-sulfur analyzer (CS-200) manufactured by LECO Corporation was used. Further, in the identification and determination of O, an oxygen-nitrogen analyzer (TC-300 / EF-300) manufactured by LECO Corporation was used.

[0303](2) Subsequently, the metal powder and a mixture (an organic binder) of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com