Construction method for imitated frame structure of long-span prestressed concrete beam slab

A concrete beam and frame structure technology, which is applied to truss structures, girders, formwork/formwork/work frames, etc., can solve the problems of increased labor and materials, large cross-section of frame beams, and difficult construction sequence of beams and slabs. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

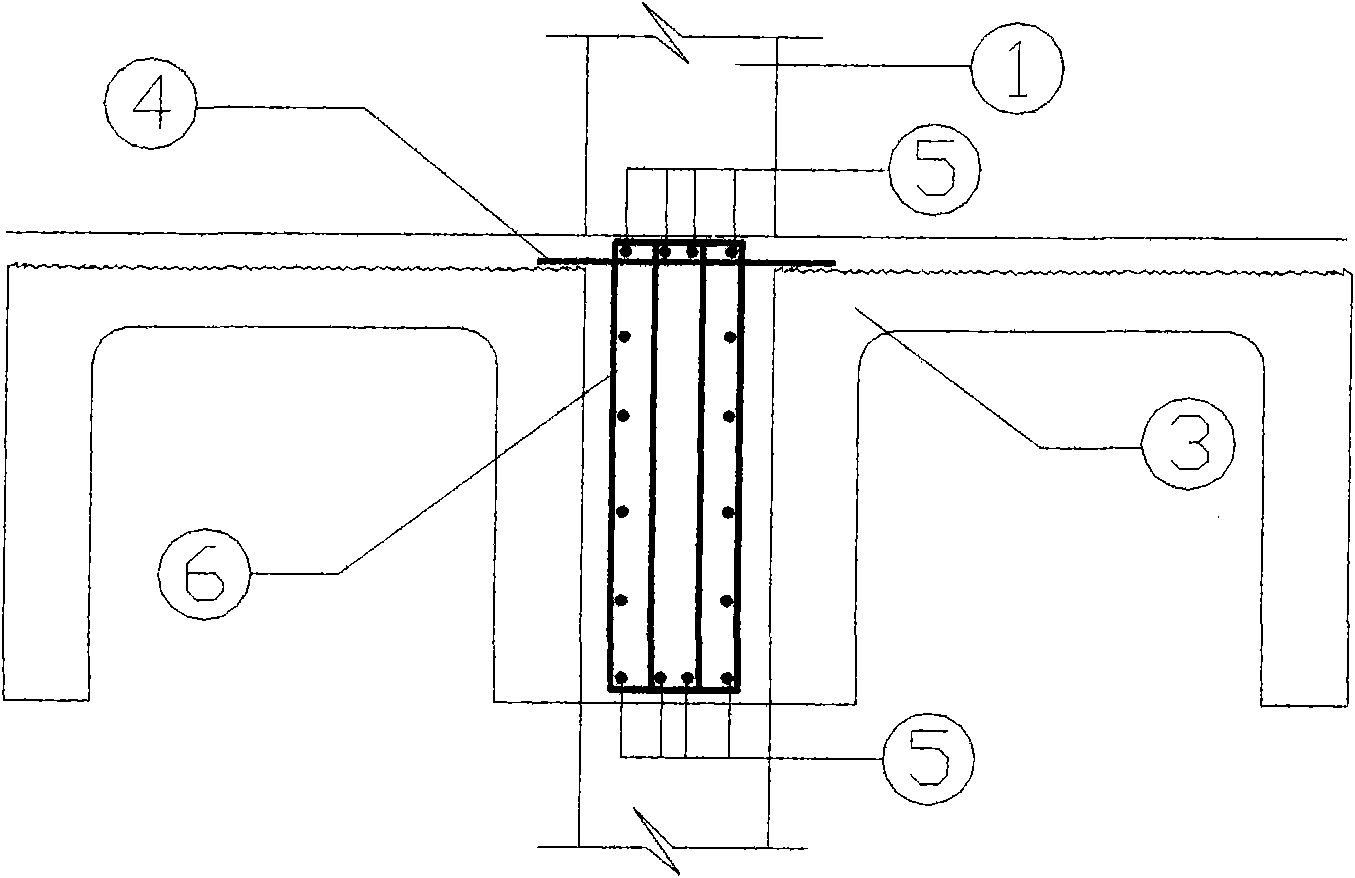

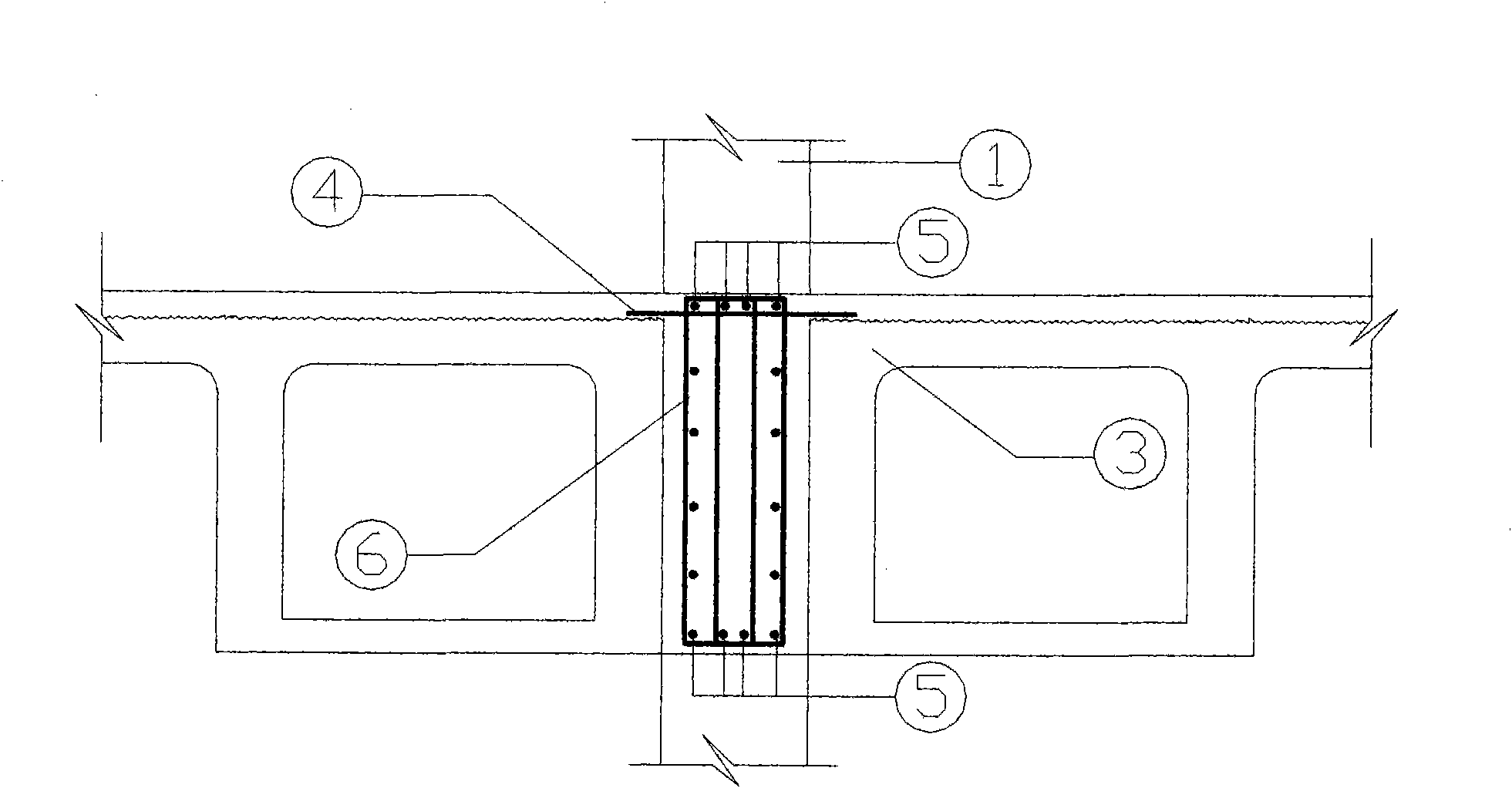

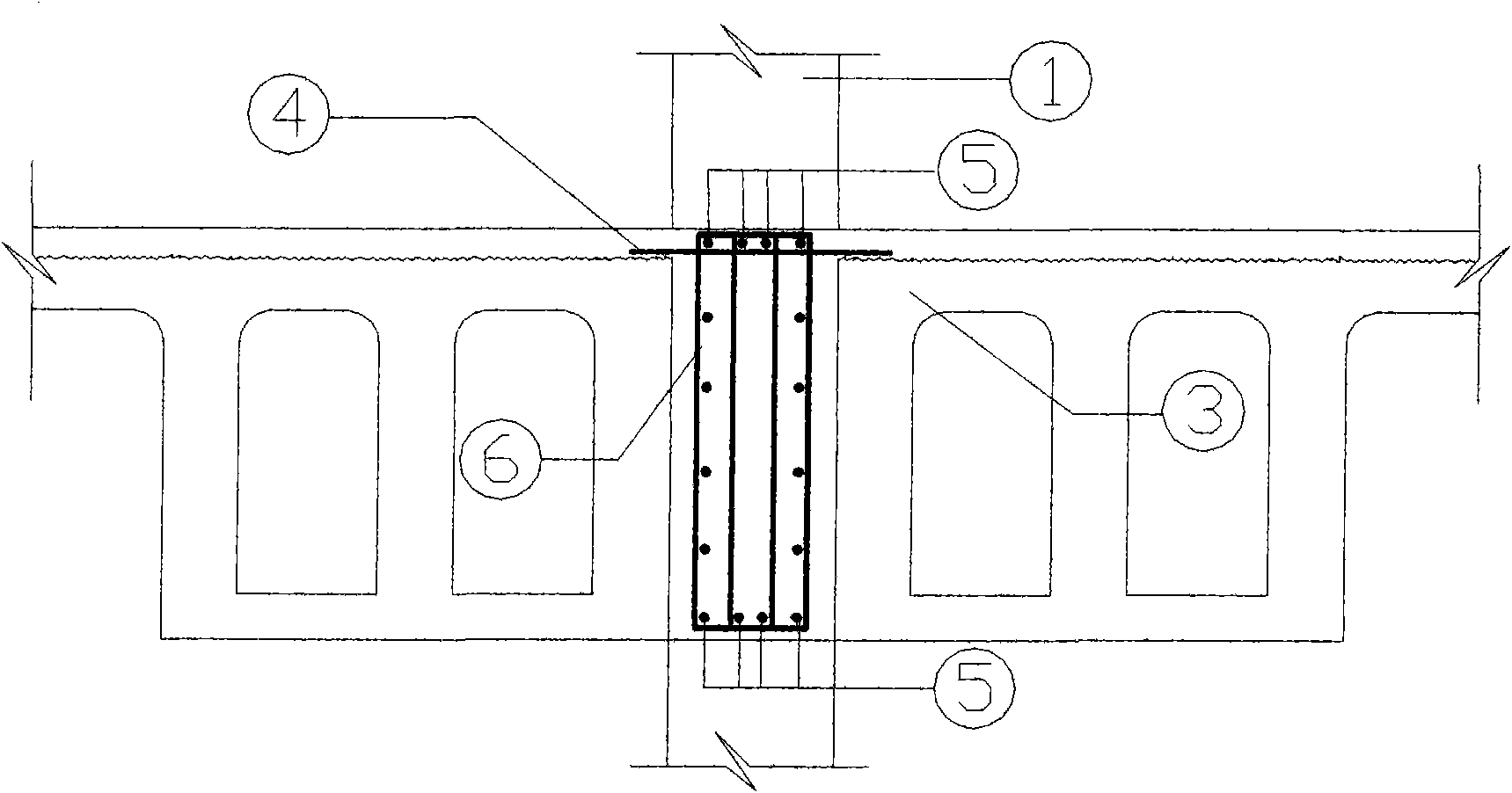

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 5 As shown in the flow chart, the frame columns and frame stringers are first installed using the conventional process. After the frame columns and frame stringers are installed, a large-span prestressed bridge with no flange or no partial flange on one side is installed on both sides of the frame column. The concrete beam slab forms the side formwork of the beam, and the suspended beam bottom formwork is erected along the side formwork, and the steel bars (non-prestressed steel bars) of the beam are arranged slightly upward in the space formed by the bottom formwork, including the connection between the vertical steel bars on the top of the slab and the frame column steel bars longitudinal ribs and stirrups. Use EPS board to fill the part outside the concrete protective layer inside the steel bar in the beam, and then pour the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com