Method for producing protein feed through different mixed fermentation twice of fine-brewed brewer's grains and blueberry fruit residues

A blueberry pomace, protein feed technology, applied in animal feed, animal feed, application and other directions, can solve the problems of insufficient cellulose degradation, affecting the protein production rate, etc., to reduce resource waste and environmental pollution, increase significantly, reproduce strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

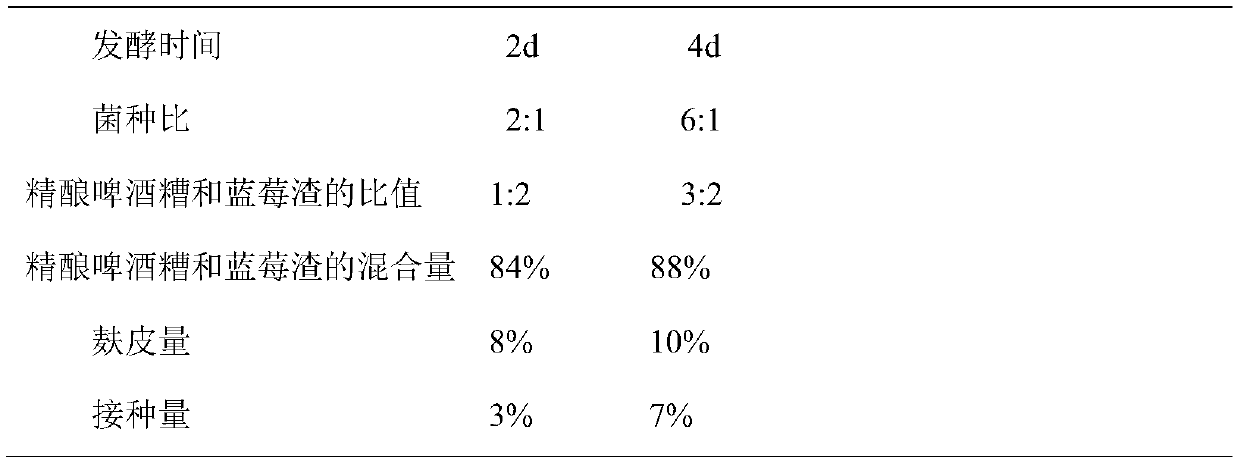

[0043] 1. First test the crude fiber content of the mixture of craft brewer's grains, blueberry pomace and bran (the ratio of craft brewer's grains to blueberry pomace is 1:1, and the ratio of the mixture to bran is 4:1)

[0044] Test method: Weigh 2g of the sample, degrease it with ether, put it into a digester, add 200ml of boiling sulfuric acid solution with an accurate concentration of 0.255N and 1 drop of n-octanol, heat immediately, and make it boil within 2min. And continue to slightly boil for 30±1min, pay attention to keep the concentration of sulfuric acid unchanged, then filter, wash with boiling distilled water until no acid is present, remove the insoluble matter, put it into the original container, add 200ml of boiling sodium hydroxide solution with accurate concentration, Also accurately boil for 30 minutes. Immediately filter with asbestos on a Gooch's crucible, first wash with 25ml of sulfuric acid solution, then use boiling distilled water, wash until the lot...

Embodiment 2

[0081] (1) Strains and sources

[0082] Common high-temperature actinomycetes (strain preservation number: CICC 10672, Latin name: Thermoactinomycesvulgaris), Geotrichum candidum (strain preservation number: CICC 1443 Latin name: Geotrichum candidum) and Lactobacillus plantarum (strain preservation number: CICC 21794 Latin name: Lactobacillus plantarum ) were purchased from the China Industrial Microbiology Culture Collection Management Center.

[0083] (2) Activation and preparation of strains

[0084] Original seed test tube activation-triangular flask expansion-seed tank culture-fermenter tank culture

[0085] Ordinary actinomycetes culture medium is glucose 4.0g, yeast extract 4.0g, malt extract 10.0g, CaCO 3 2.0g, 12.0g agar, 1.0L distilled water, pH7.2, the prepared slant medium should be sterilized at 121°C for 20min before use; just remove the agar when making liquid medium.

[0086] Geotrichum candidum medium is 5°Bé malt juice agar medium, and its preparation ste...

Embodiment 3

[0098] (1) strain and source: same as embodiment 2

[0099] (2) Activation and preparation of strains

[0100] Geotrichum candidum and Lactobacillus plantarum are mixed in 4:1 ratio, and others are identical with embodiment 2.

[0101] (3) Preparation of fermentation raw materials: 51.4% of fine brewer's grains, 36.2% of blueberry pomace, 9.9% of bran, and the inoculation amount of mixed bacteria of Geotrichum candidum and Lactobacillus plantarum was 5%.

[0102] (4) Strain inoculation and preparation process

[0103] Firstly, the inoculum amount of ordinary high-temperature actinomycetes is 10% of the weight of the fermentation raw material, and the sterilized bran is carried out by conventional carrier technology to make solid mixed bacterial agent II, and then Geotrichum candidum and plant milk with a volume ratio of 4:1 The inoculum amount of bacilli according to the weight of 5% of the fermentation raw material is sterilized bran and carried by conventional carrier tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com