Two-dimensional transition metal chalcogenide crystal, and preparation method and application thereof

A transition metal chalcogenide, transition metal technology, applied in the fields of electronics and optoelectronics, can solve the problems of difficult control of nucleation and growth, complex process, poor product uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of two-dimensional transition metal chalcogenide crystals

[0069] (1) In a tube furnace with a single temperature zone, a quartz crucible filled with 60 mg of Te elemental powder with a particle size of 100 mesh is placed on the upstream of 15 cm from the center, and a layer of Te elemental powder with an effective aperture of The particle size of 3mg of molecular sieve is 300 mesh MoO 3 The powdered cubic ceramic crucible will have a layer of 280nm SiO on the surface 2 The silicon substrate is placed on the top of the cubic ceramic crucible, and retains a slit accounting for 15% of the cubic ceramic crucible mouth area for the entry and exit of airflow;

[0070] (2) Into the tube furnace with a flow rate of 20 sccm and hydrogen of 10 sccm, and the tube furnace is heated to 800 ° C at a rate of 30 ° C / min, so that the precursor Te elemental powder is placed The temperature at the place is 450°C, keep the temperature for 10min, and carry out chemical va...

Embodiment 2

[0074] The difference from Example 1 is that the temperature of the tube furnace was raised to 750°C.

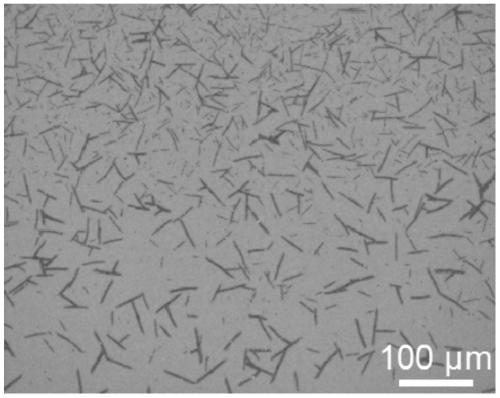

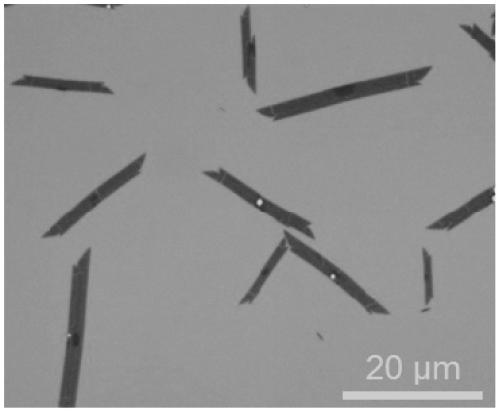

[0075] Figure 4 It is the 1T'MoTe obtained in Example 2 2 The optical photo of the crystal, it can be seen from the figure that the 1T'MoTe 2 The crystals are polycrystalline with a maximum dimension of about 18 μm.

Embodiment 3

[0077] The difference from Example 1 is that the temperature of the tube furnace was raised to 650°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com