Light reinforced composite floating plate for preventing water level from evaporating

A waterproof surface and floating board technology, which is applied in the direction of hydraulic layered products, river regulation, layered products, etc., can solve difficult water-saving effects, anti-wind and waves, anti-collision, anti-freezing and thawing, impermeability and anti-ultraviolet rays and poor water erosion resistance, damage and other problems, to achieve the effect of solving the problem of anti-corrosion, reducing cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

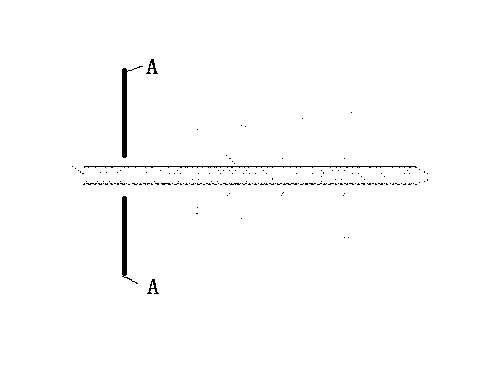

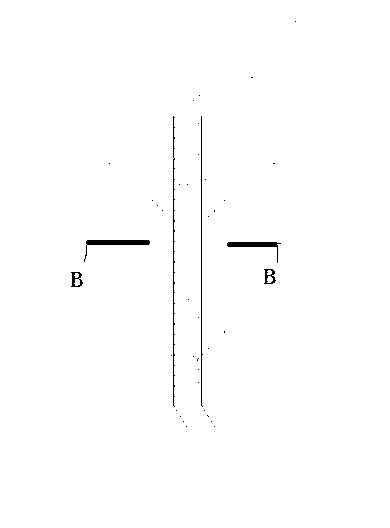

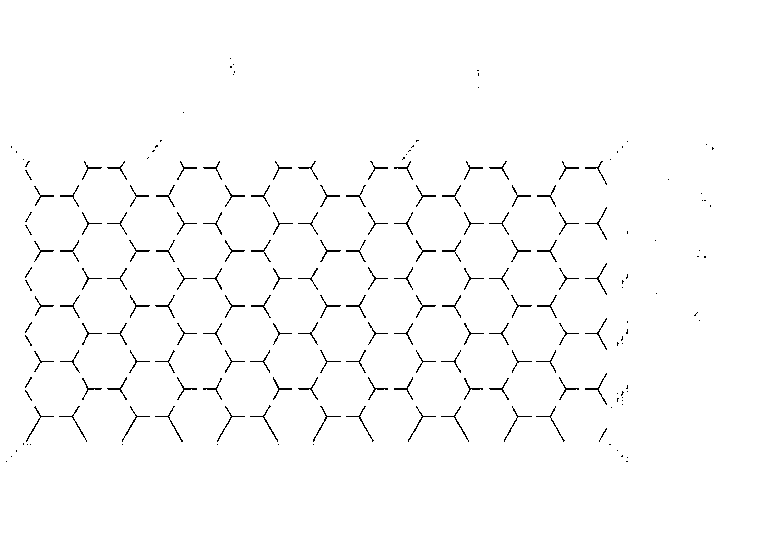

[0027] Step 1 Production of plastic geogrid: cut the two-way plastic geogrid mesh that meets the national standard of 25-50KN into length 1x width 0.6m or length 1.5x width 1.5m or length 2x width 2m (rather than each side of the prefabricated floating plate The length is 1cm, and the upper and lower meshes are cut to the same size) for spare;

[0028] Step 2 Preparation of prefabricated materials:

[0029] Cement fly ash cementitious material mixing slurry:

[0030] 1) The amount of water used is 50.3Kg / m 3 , 425R cement dosage is 81.2Kg / m 3 , the dosage of Class I fly ash is 52.2Kg / m 3 , the addition amount of CC-2 superplasticizer is 1.067Kg / m 3 ; Place them in a blender and mix evenly, that is, set aside;

[0031] 2) The amount of water used is 49Kg / m 3 , 425R cement dosage is 80Kg / m 3 , the dosage of Class I fly ash is 51Kg / m 3 , the addition amount of CC-2 superplasticizer is 1.065Kg / m 3 ; Place them in a blender and mix evenly, that is, set aside;

[0032] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com