Preparation method of cellulose nanofiber biomass gel and aerogel

A nanofiber and cellulose technology, which is applied in the field of preparation of cellulose nanofiber biomass gel and aerogel, can solve the problems of complex preparation process, lack of research and reports, etc., and achieve low preparation cost, good shape, and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of Cellulose 1: Take the pulp and wash it to neutral with distilled water. Prepare a sodium chlorite solution with a mass fraction of 0.5%, and add the pulp into the sodium chlorite solution until the pulp is completely submerged. Add acetic acid solution to the sodium chlorite solution soaked in pulp to adjust the pH of the system to 3. Then the whole system was placed at 70°C for 2 hours, during which intermittent stirring was performed every 15-20 minutes. After completion, the pulp was washed with distilled water until neutral to obtain cellulose 1, which was stored in a refrigerator for later use.

[0043] Preparation of Cellulose 2: Take microcrystalline cellulose and wash it to neutral with distilled water. A sodium chlorite solution with a mass fraction of 0.2% was prepared, and microcrystalline cellulose was added into the sodium chlorite solution until the microcrystalline cellulose was completely submerged. Add acetic acid solution to the sodiu...

specific Embodiment 1

[0054] Preparation of cellulose nanofiber biomass gel 1: take 20mL of the cellulose nanofiber dispersion 1 and place it in a coagulation tank, and use a hydrochloric acid solution with a concentration of 5M to treat it in an acidic coagulation bath. Cellulose nanofiber biogels with high and low cellulose content1.

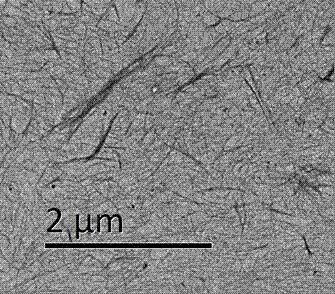

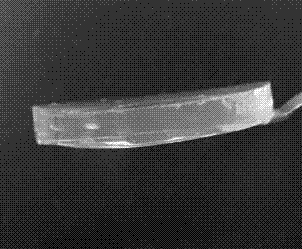

[0055] Preparation of cellulose nanofiber biomass airgel 1: freeze-dry the cellulose nanofiber biomass gel 1 to obtain cellulose nanofiber biomass airgel with good shape, high strength and low cellulose content Glue 1.

specific Embodiment 2

[0057] Preparation of cellulose nanofiber biomass gel 2: take 20mL of the cellulose nanofiber dispersion 2 and place it in a 50mL beaker, and pour 20mL of hydrochloric acid solution with a concentration of 7M into another 250mL beaker, and place the small beaker in the large Put the large beaker in the beaker and seal it with plastic wrap for acidic steam bath treatment, take out the small beaker after 6 hours of treatment, and prepare the cellulose nanofiber biomass gel 2 with good shape, high strength and low cellulose content.

[0058] Preparation of cellulose nanofiber biomass airgel 2: supercritically dry the cellulose nanofiber biomass gel 2 to obtain cellulose nanofiber biomass gas with good shape, high strength and low cellulose content gel2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com