Method for preparing CaO-MgO-SiO2 series foamed ceramic by utilizing asbestos tailings

A technology for foamed ceramics and asbestos tailings, which is used in the production and application of ceramic products and ceramic materials, can solve the difficulty of selecting the type and amount of pore-forming agent, the reduction of the mechanical properties of the sample, and the difficulty in preparing high porosity and high mechanical properties. problems such as samples, to achieve good performance, high value-added utilization, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

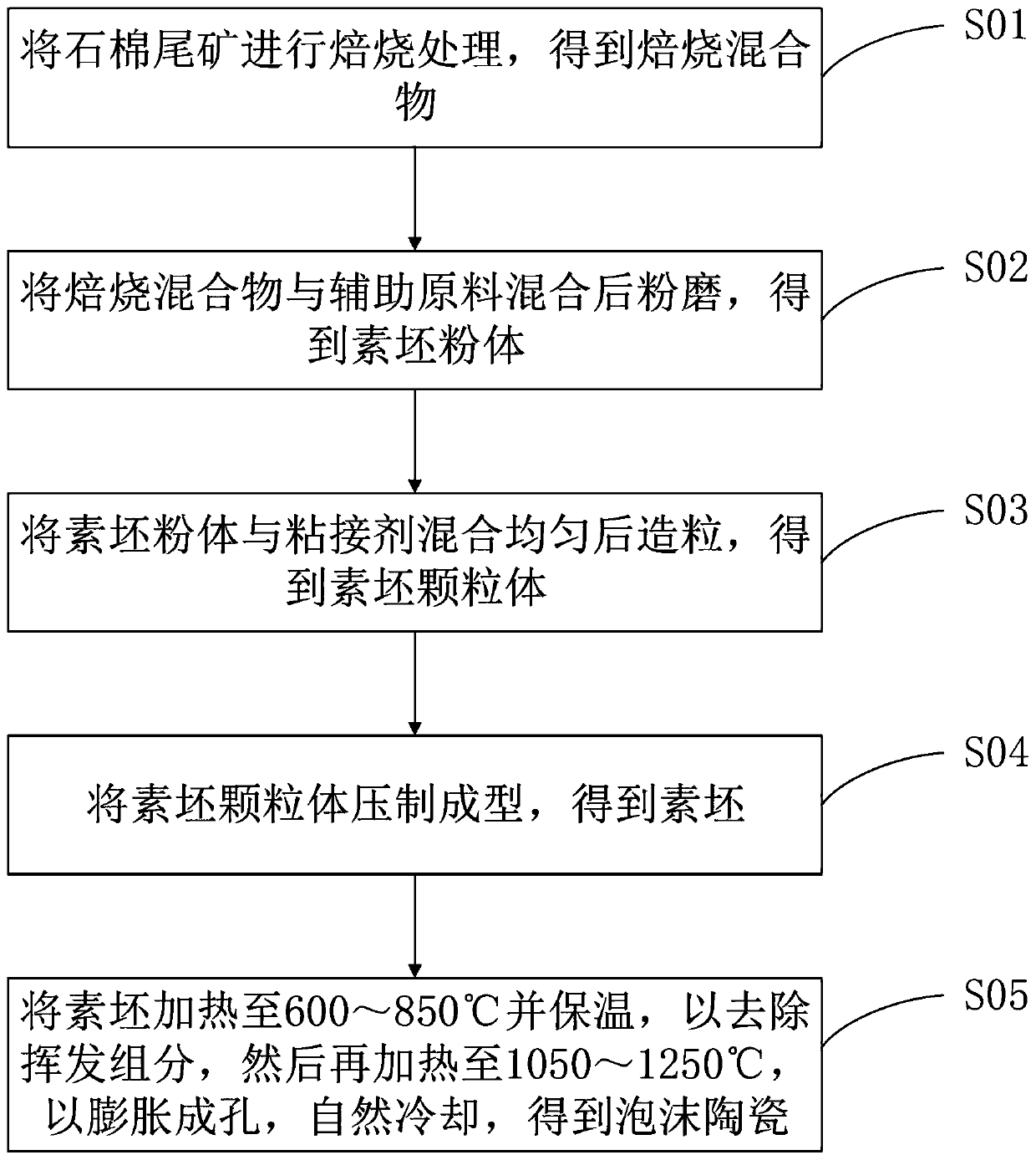

Method used

Image

Examples

preparation example Construction

[0063] The raw materials for the preparation of the foamed ceramics of phase composition (2) can include the following components in terms of mass fraction: 38-55% roasting mixture, 20-40% waste glass, 5-15% kaolin or bentonite, 3-8% potassium Stone or nepheline, 2-6% perlite, 2-5% quartz sand and 1-3% borax.

[0064]The raw materials for the preparation of the foamed ceramics of phase composition (3) can include the following components in terms of mass fraction: 30-48% roasting mixture, 25-40% waste glass, 3-15% kaolin or bentonite, 3-8% potassium Stone or nepheline, 2-6% perlite, 2-5% quartz sand and 1-3% borax.

[0065] The raw materials for the preparation of the foamed ceramics of phase composition (4) can include the following components in terms of mass fraction: 50-70% roasting mixture, 18-35% waste glass, 3-15% kaolin or bentonite, 3-8% potassium Stone or nepheline, 2-6% perlite, 3-5% quartz sand and 1-3% borax.

[0066] In the present embodiment, the prepared cera...

example 1

[0071] Raw material composition: 48% asbestos tailings roasting mixture, 28% waste glass, 8% kaolin or bentonite, 6% potassium feldspar or nepheline, 5% perlite, 3% quartz sand, 2% borax.

[0072] making process:

[0073] (1) Grinding the calcined mixture and auxiliary raw materials to obtain green body powder, the particle size of the green body powder is 75 μm.

[0074] (2) Mix the green body powder and the binder uniformly and then granulate to obtain the green body granules. The binder includes one or both of starch, polyvinyl alcohol and carboxymethyl cellulose in water suspension Cloudy liquid or solution, the granulation method includes dry rotary granulation and slurry spray granulation, and the average particle diameter of the green granules is 1.5mm.

[0075] (3) Spread the green body granules in the forming mold, and dry press them with a green body forming press to obtain the green body. The pressure of the dry pressing is 80 MPa, and the pressure holding time is ...

example 2

[0082] Raw material composition: 45% roasting mixture, 32% waste glass, 10% kaolin or bentonite, 5% potassium feldspar or nepheline, 3% perlite, 3% quartz sand, 2% borax.

[0083] making process:

[0084] (1) Grinding the calcined mixture and auxiliary raw materials to obtain green body powder, the particle size of the green body powder is 75 μm.

[0085] (2) Mix the green body powder and the binder uniformly and then granulate to obtain the green body granules. The binder includes one or both of starch, polyvinyl alcohol and carboxymethyl cellulose in water suspension Cloudy liquid or solution, the granulation method includes dry rotary granulation and slurry spray granulation, and the average particle diameter of the green granules is 1.5mm.

[0086] (3) Spread the green body granules in the forming mold, and dry press them with a green body forming press to obtain the green body. The pressure of the dry pressing is 80 MPa, and the pressure holding time is 10 s.

[0087] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com