Steel slag and cement stabilized base material

A technology for water-stabilized base material and steel slag, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high brittleness, reduced pavement strength and service performance, and strong temperature and humidity sensitivity, etc. Achieve the effect of good board body, improve water permeability, and improve road service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

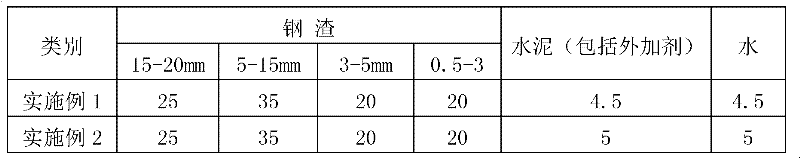

[0025] Table 1 Material example formula (material weight ratio)

[0026]

[0027]

[0028] Additives are added at 5% by weight of cement.

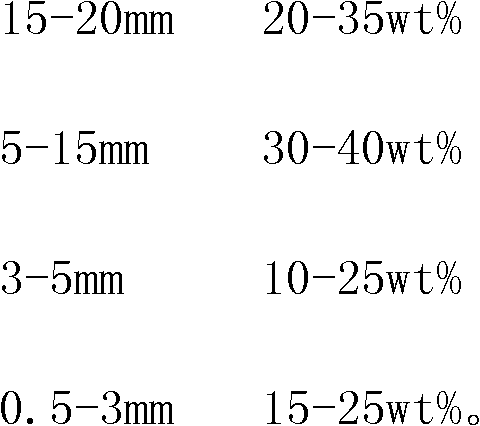

[0029] Among them, the performance parameters of the steel slag aggregate in each embodiment are as follows:

[0030] Table 2

[0031] Steel slag aggregate process parameters

Example 1

Example 2

Example 3

f-CaO,%

3.81

3.15

2.97

f-MgO,%

2.76

2.03

1.88

SO 3 ,%

0.05

0.07

0.03

[0032] Among them, the type parameters of the components in each embodiment are as follows:

[0033] table 3

[0034]

[0035] The preparation of steel slag water-stable base layer includes the following steps:

[0036] a) Cushion treatment;

[0037] b) Weigh each raw material according to weight percentage;

[0038] c) Put the weighed raw materials in a forced mixer, add water and stir, about 10-15 minutes;

[0039] d) Paving, the thickness is 25-35cm;

[0040] e) Vibration compaction, repeated rolling;

[0041] f) Cover the film and spray water regular...

Embodiment 4-6

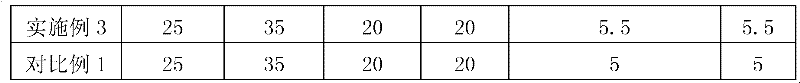

[0046] Table 5 Material example formula (material weight ratio)

[0047]

[0048] Additives are added at 5% by weight of cement. The types and performance parameters of other components are the same as in Example 1. The test results are as follows:

[0049] Table 6 Test results

[0050]

Embodiment 7-8

[0052] Table 7 Material example formula (material weight ratio)

[0053]

[0054] The types and performance parameters of each component are the same as in Example 1. The test results are as follows:

[0055] Table 8 Test results

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com