Three-dimensional crosslinked network polymer gel electrolyte membrane, preparation method and lithium-ion battery

A gel electrolyte, three-dimensional cross-linking technology, used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolyte immobilization/gelation, etc. Low problems, to achieve the effects of good interface compatibility, avoidance of leakage, and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

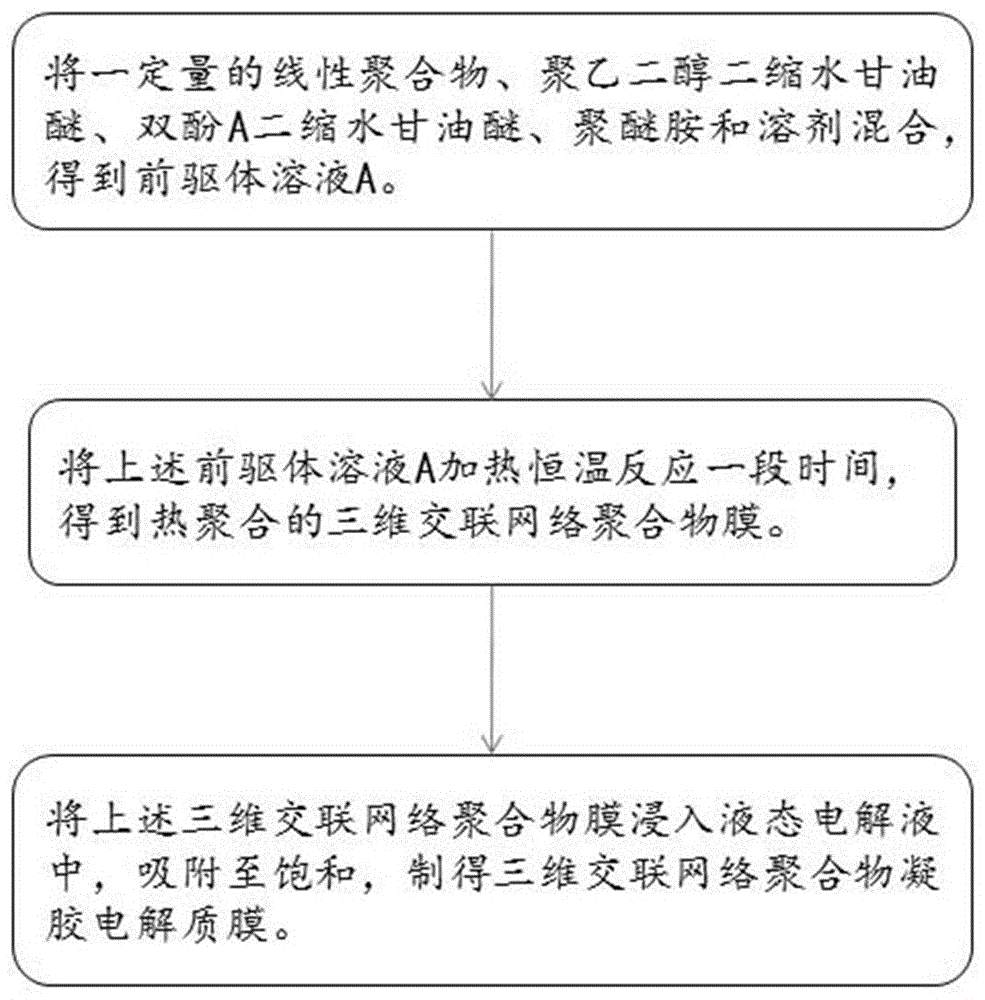

[0037] See figure 1 The present invention provides a method for preparing a three-dimensional cross-linked network gel polymer electrolyte membrane. The three-dimensional cross-linked network gel polymer electrolyte membrane is mainly used in a lithium ion battery (not shown), which includes the following steps:

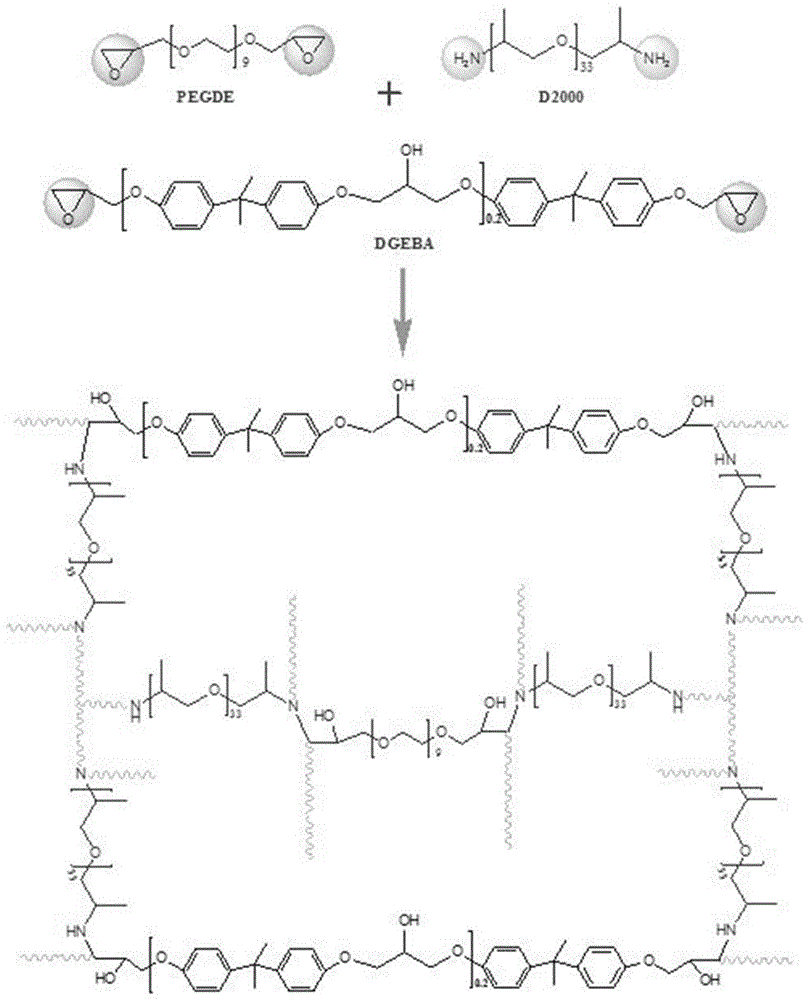

[0038] Step S1, mixing a certain amount of linear polymer, polyethylene glycol diglycidyl ether, bisphenol A diglycidyl ether, polyether amine and a solvent to obtain a precursor solution A.

[0039] Specifically, the linear polymer is first added to the solvent, heated and stirred to dissolve the linear polymer to obtain a linear polymer solution, and then polyethylene glycol diglycidyl ether and bisphenol A diglycidyl are added to the linear polymer solution Ether and polyetheramine are stirred and mixed uniformly to obtain a colorless and transparent precursor solution A.

[0040] Among them, the linear polymer accounts for 5-30% of the mass of the solution. The linear ...

Embodiment 1

[0052] This embodiment relates to a method for preparing a three-dimensional cross-linked network gel polymer electrolyte membrane. The method includes the following steps:

[0053] (1) Add 0.12g of polyvinylidene fluoride-hexafluoropropylene into a 25ml beaker, then add 5.0g of N,N-dimethylformamide dropwise, stir to make it completely dissolved, and then weigh 0.3g of polyethylene Glycol diglycidyl ether (Mn=500), 0.1g of bisphenol A diglycidyl ether (epoxy value of 186) and 0.8g of polyetheramine (Mn=2000) were added to the beaker, and stirred for 6h to mix evenly. And pour the above solution into a clean polytetrafluoroethylene mold, put it in a constant temperature blast oven for a period of time, and perform ring-opening polymerization at a constant temperature of 80°C for 24 hours to obtain a heat-cured three-dimensional crosslinked network polymer film;

[0054] (2) The prepared three-dimensional cross-linked network polymer membrane was washed three times with absolute eth...

Embodiment 2

[0067] This embodiment relates to a method for preparing a three-dimensional cross-linked network polymer gel electrolyte membrane. The method includes the following steps:

[0068] (1) Add 0.12g of polymethyl methacrylate into a 25ml beaker, then add 5.0g of N,N-dimethylformamide dropwise, stir to completely dissolve, and then weigh out 0.1g of polyethylene glycol Diglycidyl ether (Mn=1000), 0.1g of bisphenol A diglycidyl ether (epoxy value of 290) and 0.8g of polyetheramine (Mn=1000) were added to the beaker, and stirred for 6 hours to mix evenly. And pour the above solution into a clean polytetrafluoroethylene mold, and place it in a constant temperature blast oven for a period of time after ring-opening polymerization at a constant temperature of 120°C for 8 hours to obtain a heat-cured three-dimensional crosslinked network polymer film;

[0069] (2) The prepared three-dimensional cross-linked network polymer membrane was washed three times with absolute ethanol to remove resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com