Copper metal organic framework nanoparticle functionalized hydrogel, preparation method and application thereof

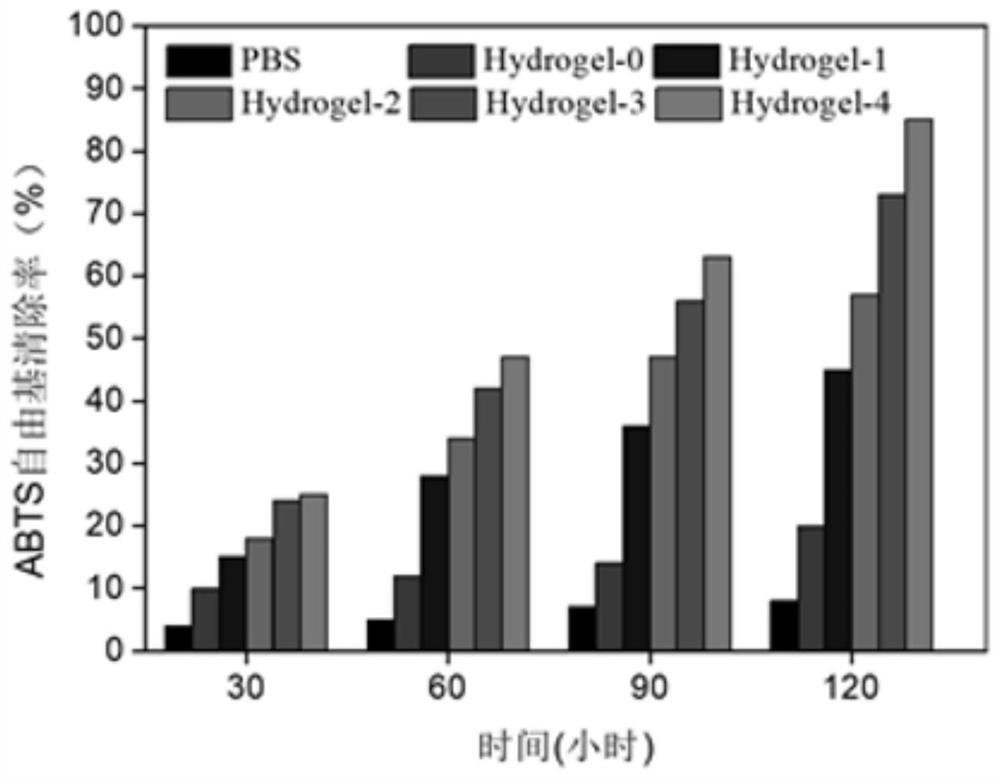

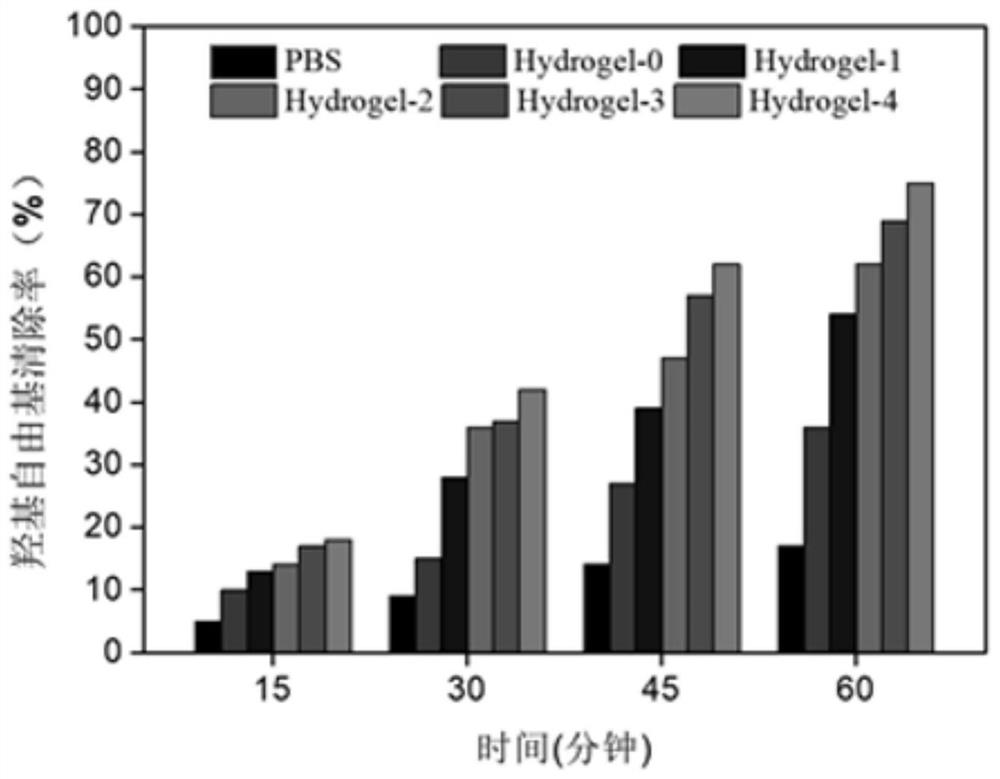

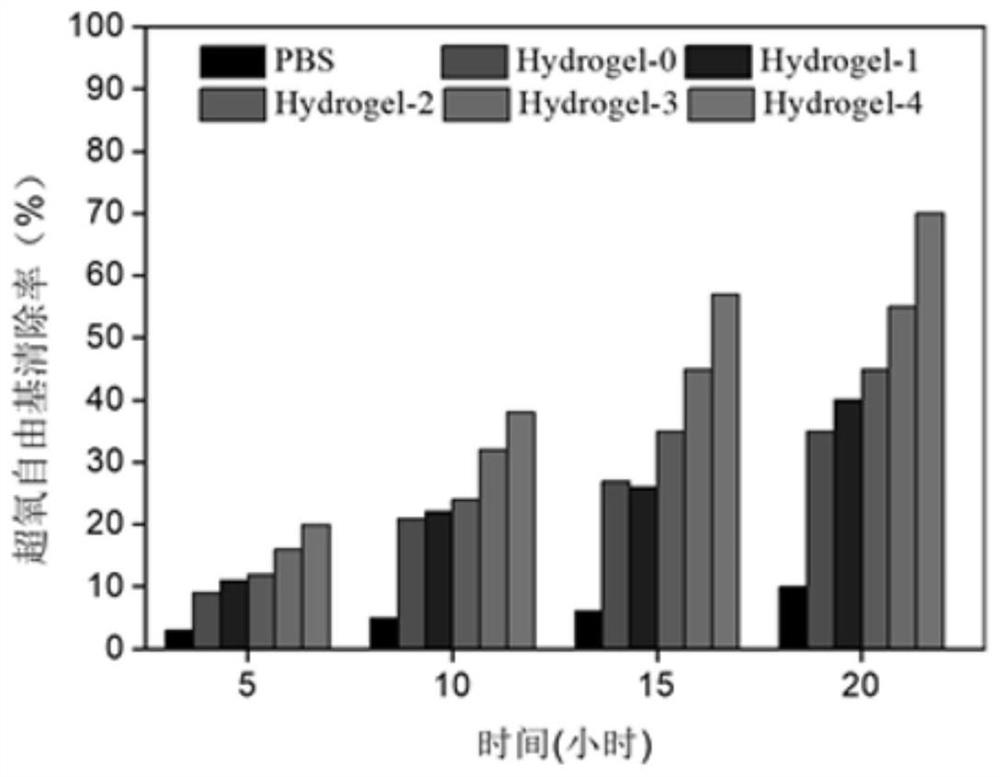

An organic framework and nanoparticle technology, applied in the field of medical devices, can solve the problems of unfavorable wound healing, low hydrogel strength and water swelling rate, and easy breakage, so as to protect from external damage, promote wound healing, and have good anti-aging properties. Oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Preparation of glutathione-modified carboxymethyl chitosan (CMCS-GSH): Dissolve 0.5 g carboxymethyl chitosan ( CMCS) to make a homogeneous solution; 0g reduced glutathione (GSH) and 0.0006g N-hydroxysuccinimide (NHS) were dissolved in 10mL deionized water, stirred evenly at 250rpm for 30min, and GSH and NHS The mixed solution was added into the flask; 0.048g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) was dissolved in 10mL of deionized water, after stirring evenly, it was Add in the flask; at room temperature, adjust the reaction mixture in the flask to pH 4.0-5.8 with 0.5mol / mL HCl solution, and react for 6 hours under uniform stirring at a speed of 300rpm; then the product is placed in a dialysis bag (molecular weight cut-off value : 8~12kD), soaked in deionized water for 3 days (changing deionized water twice every day), to eliminate unreacted reagents; finally, the mixture solution was freeze-dried at -80°C to obtain the degree of graftin...

Embodiment 2

[0044]1) Preparation of glutathione-modified carboxymethyl chitosan (CMCS-GSH): Dissolve 0.5 g carboxymethyl chitosan ( CMCS) was made into a homogeneous solution; 0.10 g of reduced glutathione (GSH) and 0.011 g of N-hydroxysuccinimide (NHS) were dissolved in 10 mL of deionized water, stirred evenly at 250 rpm for 30 min, and GSH and The mixed solution of NHS was added in the flask; 0.096g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) was dissolved in 10mL deionized water, after stirring evenly, the It is added in the flask; at room temperature, adjust the reaction mixture in the flask to pH 4.0-5.8 with 0.6mol / mL HCl solution, and react for 4 hours under uniform stirring at a speed of 300rpm; then the product is placed in a dialysis bag (molecular weight cut-off Value: 8-12kD), soaked in deionized water for 3 days (change the deionized water twice a day) to eliminate unreacted reagents; finally, the mixture solution was freeze-dried at -80°C to obtain the ...

Embodiment 3

[0047] 1) Preparation of glutathione-modified carboxymethyl chitosan (CMCS-GSH): Dissolve 0.5 g carboxymethyl chitosan ( CMCS) to make a homogeneous solution; 0.19g reduced glutathione (GSH) and 0.011g N-hydroxysuccinimide (NHS) were dissolved in 10mL deionized water, stirred evenly at 250rpm for 30min, and GSH and The mixed solution of NHS was added in the flask; 0.096g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) was dissolved in 10mL deionized water, after stirring evenly, the It is added in the flask; at room temperature, adjust the reaction mixture in the flask to pH 4.0-5.8 with 0.5mol / mL HCl solution, and react for 5 hours under uniform stirring at a speed of 300rpm; then the product is placed in a dialysis bag (molecular weight cutoff Value: 8-12kD), soaked in deionized water for 3 days (change the deionized water twice a day) to eliminate unreacted reagents; finally, the mixture solution was freeze-dried at -80°C to obtain the degree of grafting (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com