Patents

Literature

208 results about "Ethyleneglycol bis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

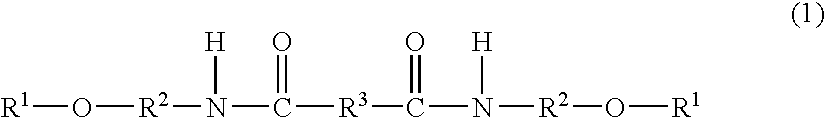

Response type medical gel as well as preparation method and application thereof

ActiveCN107626002AAdhesion can be regulatedSurgical adhesivesBandagesSurgical operationPolymer science

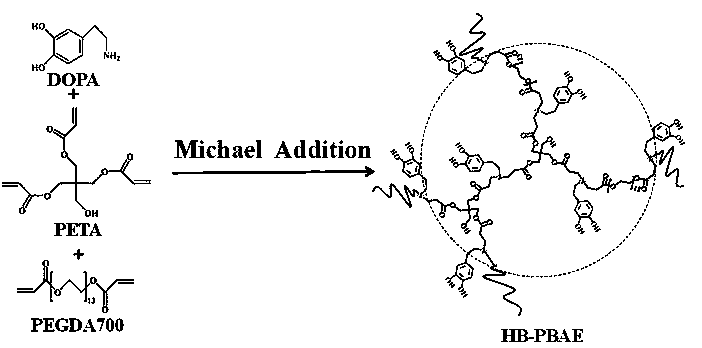

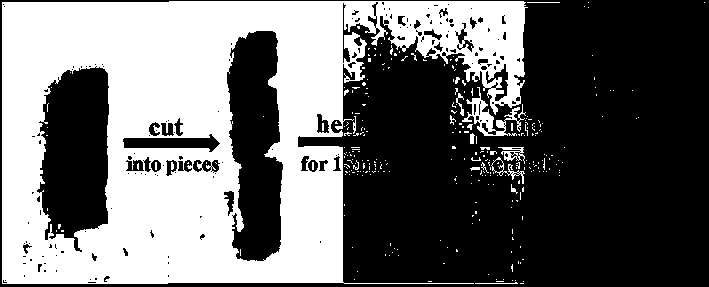

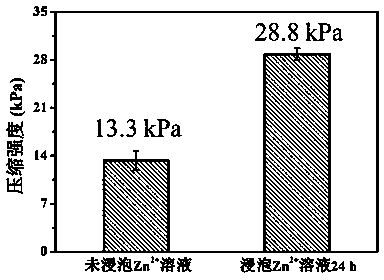

The invention provides response type medical gel. Particularly, a functional hyperbranched polymer monomer (HB-PBAE) is synthesized by virtue of Michael addition reaction of dopamine (DOPA), polyethylene glycol diacrylate (PEGDA700) and pentaerythritol triacrylate (PETA); and gel is formed by virtue of a mixed solution of HB-PBAE, polyvinyl imidazol (PVI) and gelatin (Geln) under the action of aniron ion (Fe<3+> solution). The gel has the properties of softness and viscidity in the primary formation period, and the viscidity is obviously reduced after the gel is soaked in a zinc ion (Zn<2+> solution). Hydrogel provided by the invention has syringeability, can be taken as a sealing agent or a wound surface dressing for surgical operations and is used for smearing the wound surface of a tissue, so that the adverse leakage of liquid or gas is avoided; and the viscidity of the gel has ion responsitivity, so that the secondary injury in a dressing change process can be reduced, and the pain of the wound surface can be alleviated.

Owner:HANGZHOU YAHUI BIOTECH CO LTD

Environment-friendly long-life cutting fluid and preparation method thereof

ActiveCN104017638AImprove the lubrication effectGood extreme pressure and anti-wear propertiesLubricant compositionElectrolysed waterActive agent

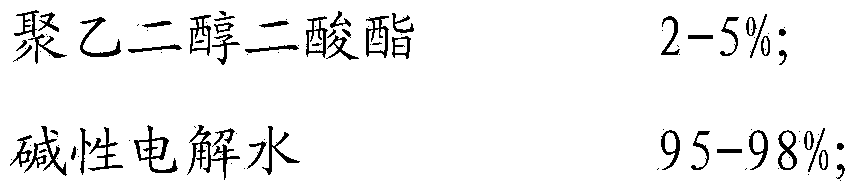

The invention provides an environment-friendly long-life cutting fluid, which is characterized by consisting of the following components by weight percentage: 2-5% of polyethylene glycol succinate, 95-98% of alkaline electrolysis water, 0-0.3% of phosphate, 0-0.3% of borate and 0-0.01% of benzotriazol. The major component polyethylene glycol succinate salt of the cutting fluid system provided by the invention is an anionic and non-ionic surface active agent, so even if a small amount of some other lubricating oil is introduced into a workpiece or a guide in the machining process, polyethylene glycol succinate salt can emulsify the lubricating oil into cutting fluid for usage, without reducing the usage performance.

Owner:株洲开元润滑材料股份有限公司

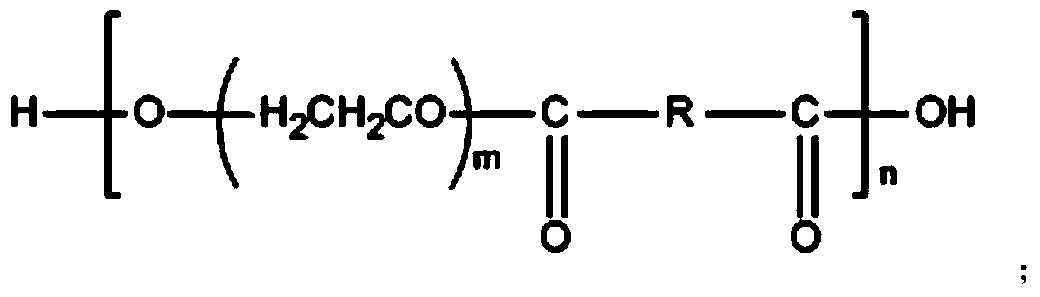

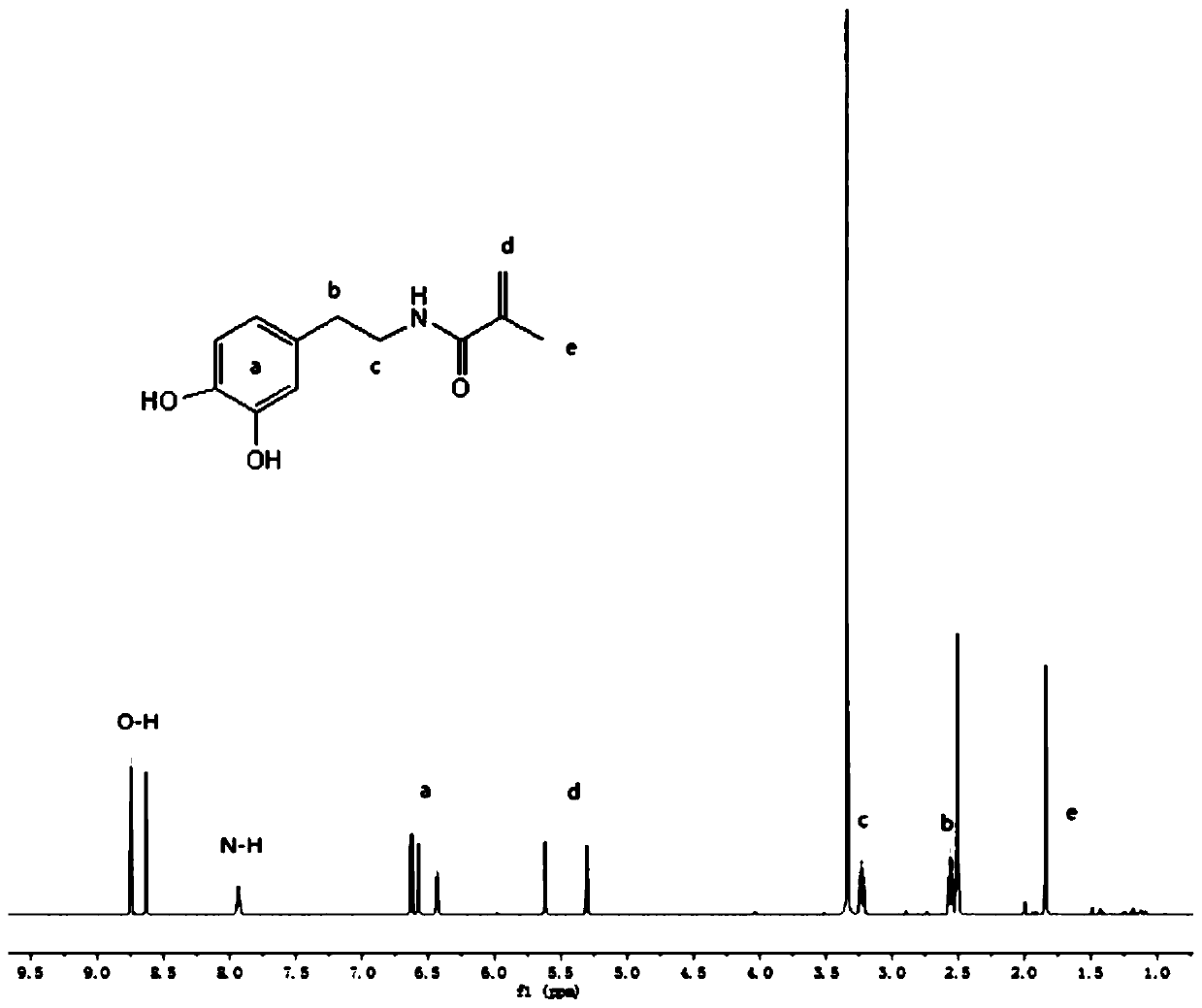

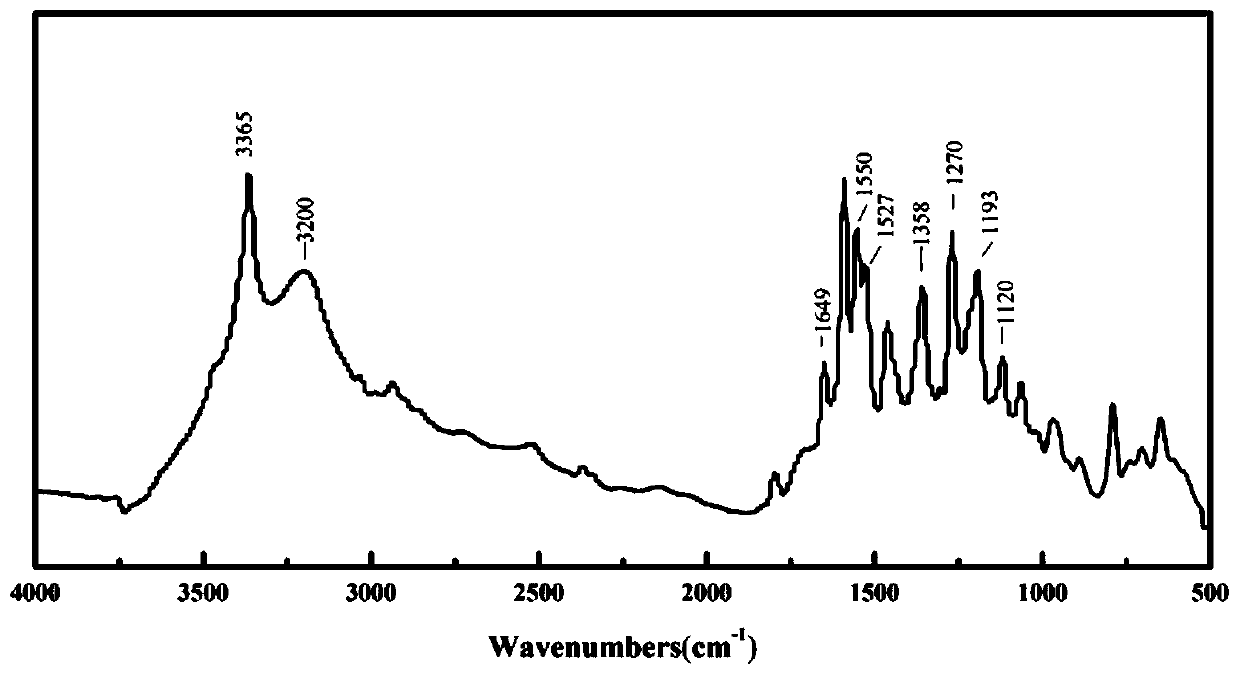

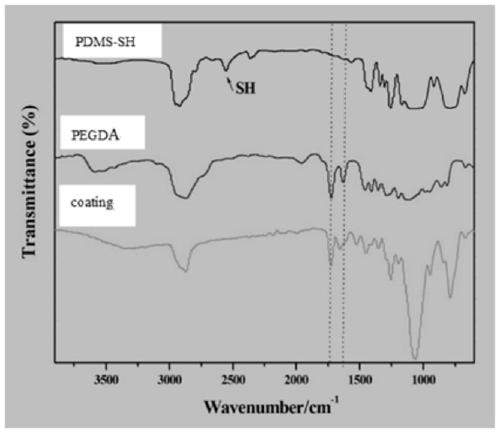

Preparation method of long-term stable amphiphilic antifouling coating based on mussel bionics

ActiveCN111440519ASolve the problem of weak adhesionGood for fighting pollutionAntifouling/underwater paintsPaints with biocidesMeth-Polyethylene glycol

The invention relates to a preparation method of a long-term stable amphiphilic antifouling coating based on mussel bionics. The method comprises the following steps: mixing dopamine hydrochloride, sodium borate, sodium carbonate and deionized water, dropwise adding a methacrylic anhydride solution, mixing the obtained dopamine methacrylamide with mercaptopolydimethylsiloxane, polyethylene glycoldiacrylate, a photoinitiator and a solvent, coating a base material with the mixture, and curing under ultraviolet irradiation. The method has the advantages of simple process synthesis conditions, cleanness, environmental protection, rapid ultraviolet-induced cross-linking reaction and good effect; the prepared coating has good mechanical properties and stability, has a very small swelling degreein a seawater environment, has an excellent anti-algae adhesion effect and has potential application in the aspect of marine antifouling materials.

Owner:DONGHUA UNIV

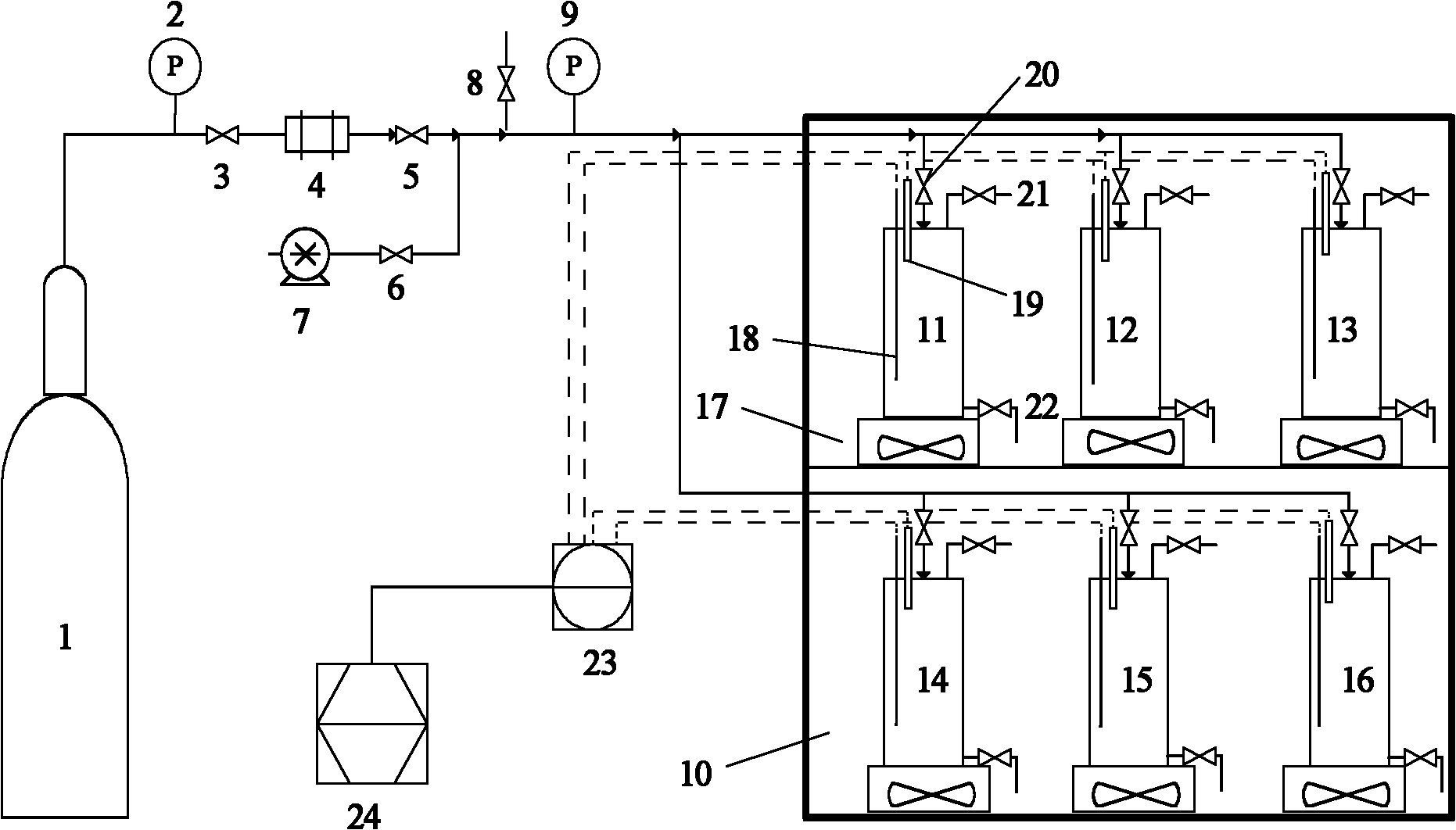

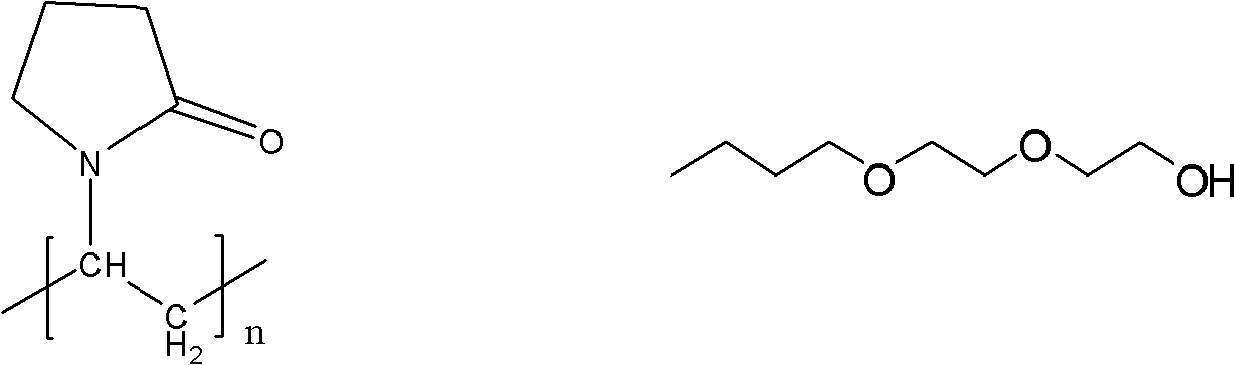

High-efficiency composite hydrate inhibitor as well as preparation method and application thereof

ActiveCN102161720ANo pollutionLow toxicity and good biocompatibilityPipeline systemsPolymer scienceBenzoyl peroxide

The invention discloses a high-efficiency composite hydrate inhibitor as well as a preparation method and an application thereof. The preparation method of the high-efficiency composite hydrate inhibitor comprises the following steps: taking N-vinyl pyrrolidone as a monomer and azodiisobutyronitrile or benzoyl peroxide as an initiator; and carrying out a polymerization reaction of a free-radical solution in a solvent to obtain the composite hydrate inhibitor, wherein the solvent is selected from at least one of the following components: carbinol, ethylene glycol, diethylene glycol, isopropanol, diethylene glycol, ethylene glycol monobutyl ether and Di(ethylene glycol) butyl ether, the volume ratio of the monomer to the solvent is (1:2)-(1:5), and the use amount of the initiator is 0.3-1.5wt% of the monomer. Compared with the method for industrially synthesizing the initiator, the method disclosed by the invention saves energy and is convenient and economic. The inhibitor synthesized by the invention can be applied to hydrate prevention and treatment in the processes of producing and transporting petroleum fluid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

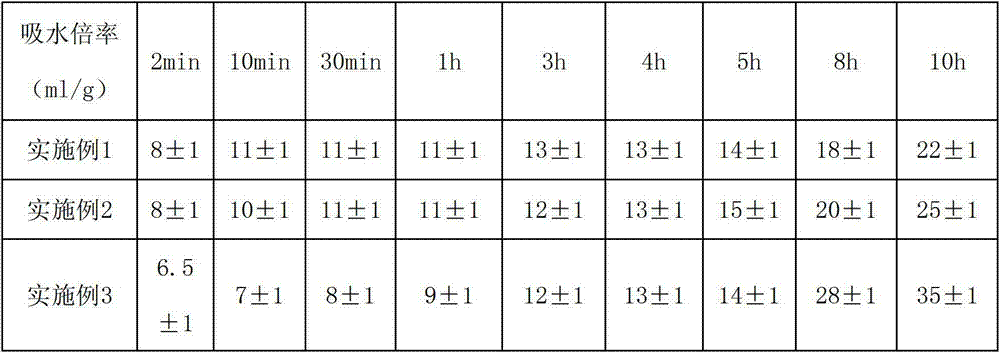

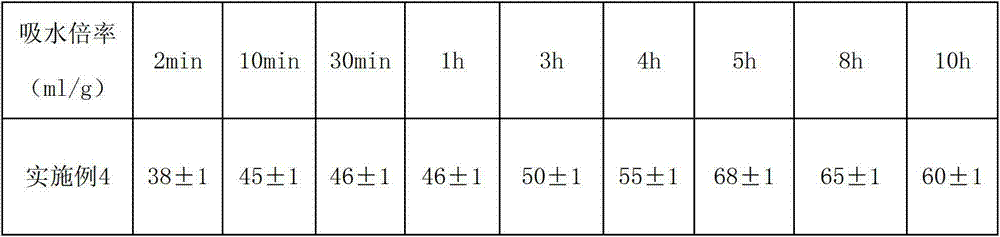

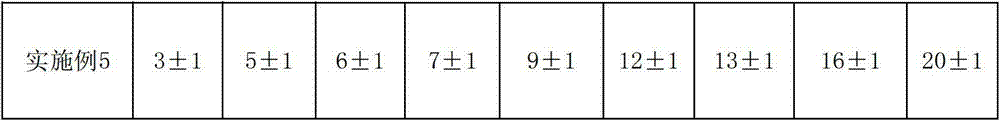

Super absorbent resin with lower liquid absorbing rate, and preparation method and application thereof

The invention discloses super absorbent resin with lower liquid absorbing rate. The resin comprises the raw materials of monomer aqueous solution, an initiator and a crosslinking agent, wherein the crosslinking agent comprises an ester crosslinking agent which is one of ethylene glycol diacrylate, ethylene glycol dimethacrylate, polyethylene glycol diacrylate, polyethylene glycol dimethacrylate, propylene glycol diacrylate, propylene glycol dimethacrylate, polypropylene glycol diacrylate, polypropylene glycol dimethacrylate, 1, 4-butanediol diacrylate, 1, 4-butanediol dimethacrylate, 1, 3-butanediol diacrylate or 1, 3-butanediol dimethacrylate or a mixture of more than two thereof. The super absorbent resin with slowly increased liquid absorbing capability disclosed by the invention absorbs little water in an early stage to reduce influence to workability of concrete, while has a certain water absorbing capacity in a later stage so as to ensure that concrete is maintained by enough water.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

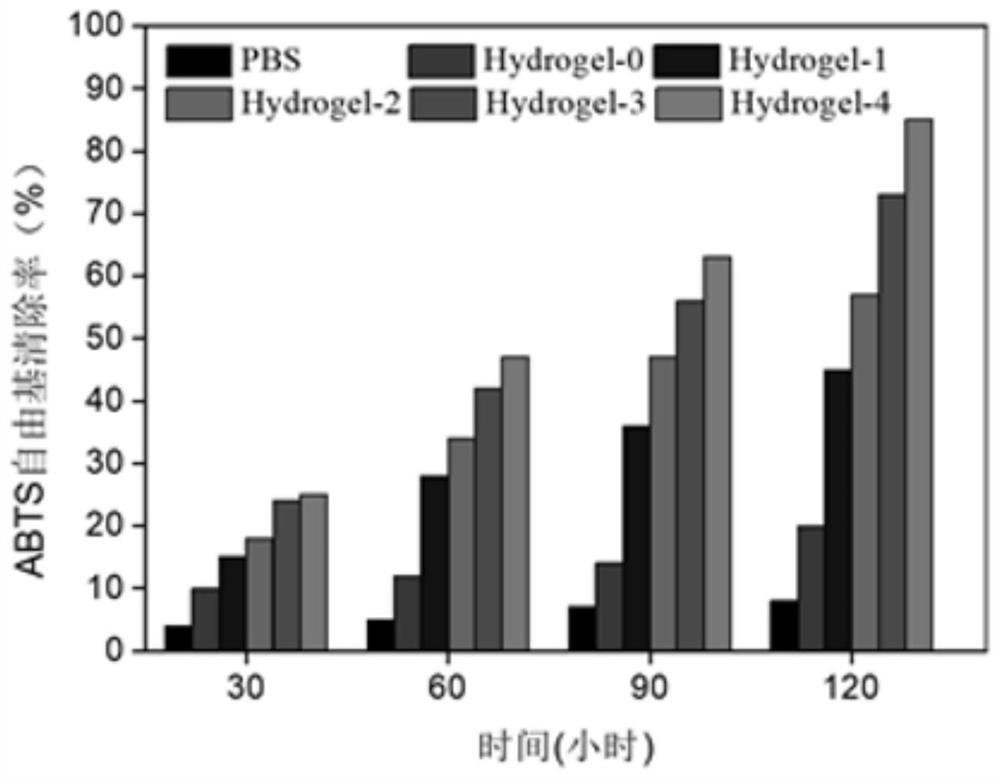

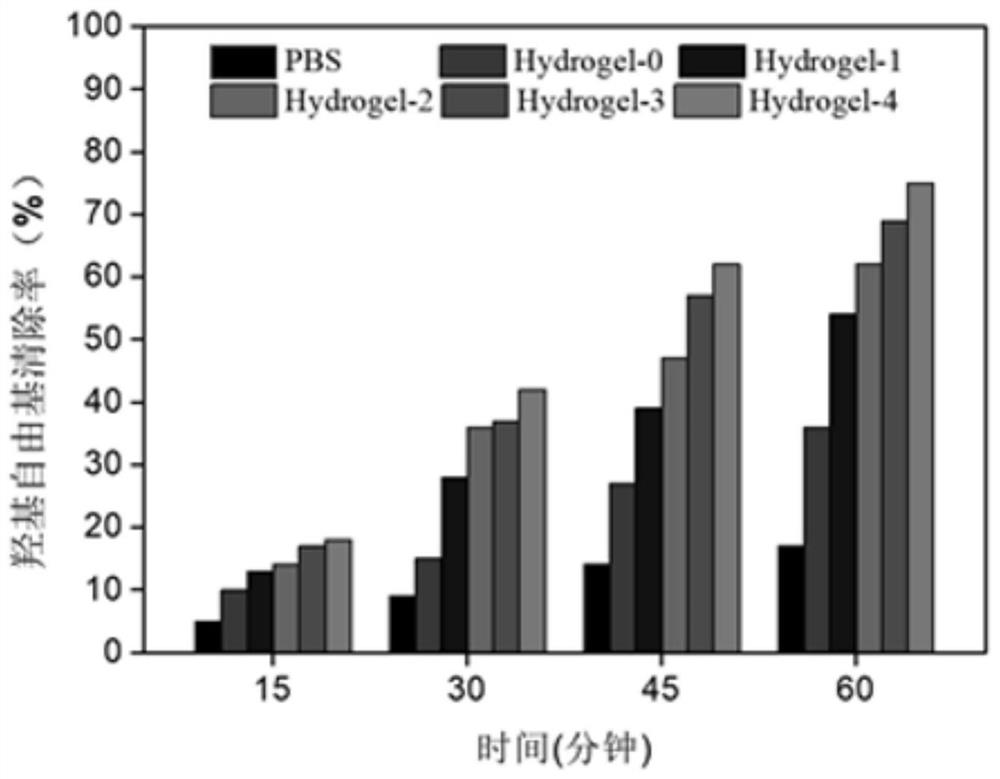

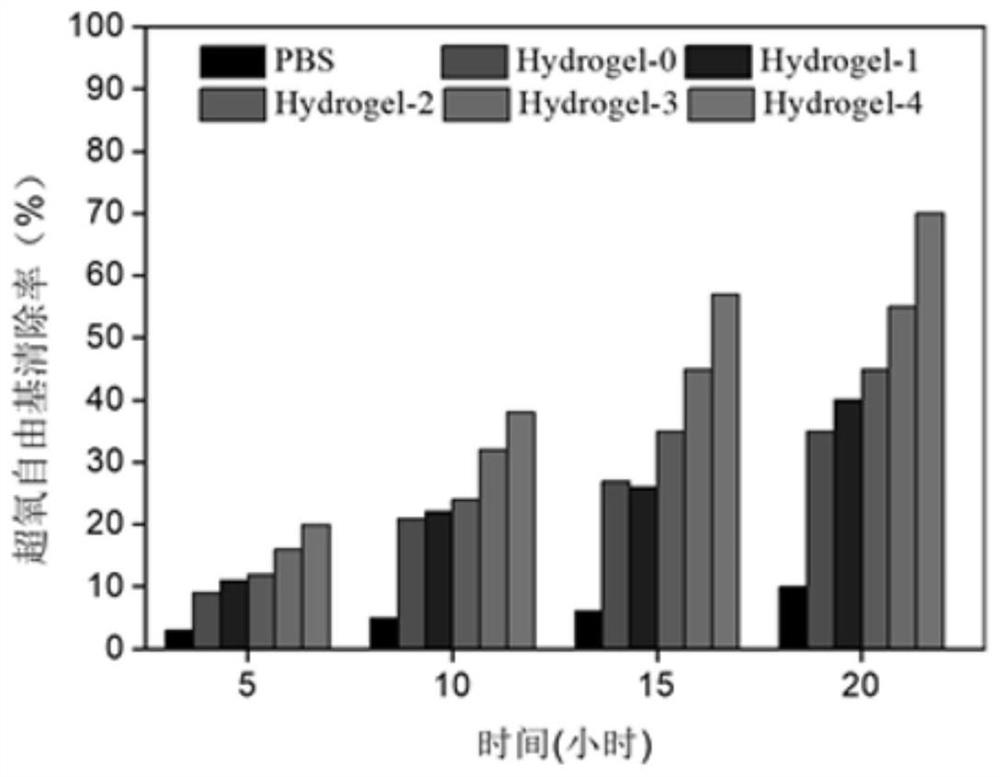

Copper metal organic framework nanoparticle functionalized hydrogel, preparation method and application thereof

ActiveCN112250887AGood mechanical propertiesLow cytotoxicityBandagesPolyethylene glycolMetal-organic framework

The invention discloses a copper metal organic framework nanoparticle functionalized hydrogel, a preparation method and application thereof. The preparation method comprises the following steps: dissolving carboxymethyl chitosan, and adding reduced glutathione and N-hydroxysuccinimide which are mixed and dissolved in deionized water; adding 1-(3-dimethylaminopropyl)-3-ethyl carbodiimide hydrochloride to prepare glutathione modified carboxymethyl chitosan; preparing copper metal organic framework nanoparticles; then mixing the copper metal organic framework nanoparticles with deionized water; and adding the glutathione modified carboxymethyl chitosan, acrylamide, polyethylene glycol diacrylate, polyethylene glycol diglycidyl ether and an initiator to prepare the copper metal organic framework functionalized hydrogel. According to the invention, the obtained hydrogel has the capabilities of slowly and controllably releasing copper ions, removing active oxygen of a wound surface, always keeping the wound surface free of hydrops and a wet 3D microenvironment, protecting the wound from external injury and promoting wound healing.

Owner:SOUTH CHINA UNIV OF TECH

Vinyl acetate production process

Owner:LYONDELL CHEM TECH LP

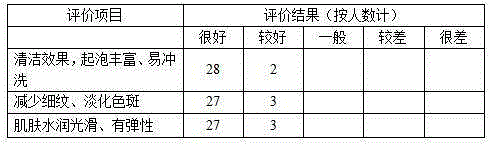

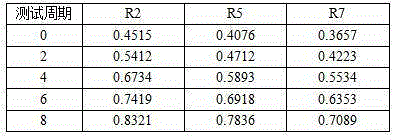

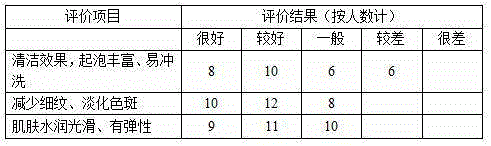

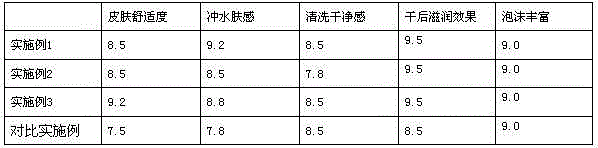

Anti-wrinkle cleansing lotion and preparation method thereof

ActiveCN105287331AStay hydratedGood skin affinityCosmetic preparationsToilet preparationsCellulosePunica

The invention belongs to the technical field of cosmetics, and in particular relates to an anti-wrinkle cleansing lotion and a preparation method thereof. The anti-wrinkle cleansing lotion consists of myristic acid, palmitic acid, stearic acid, glycerol, potassium hydroxide, sodium taurine laurate, sodium cocoyl glycinate, sodium lauroyl glutamate, C12-14 secondary-chain alkanol polyether-20, glycol distearate, propanediol, lactobacillus / punica granatum fruit fermentation product extract, arctic chlamydomonas essence, starfish essence, cortex acanthopanacis essence, a pearl extract, EDTA-Na2, hydroxypropyl methyl cellulose, methyl hydroxybenzoate, propyl hydroxybenzoate, methylisothiazolinone, essence and water. The anti-wrinkle cleansing lotion disclosed by the invention is gentle and skin-friendly, safe and non-irritant; and the cleansing lotion is capable of deeply cleansing skin, and meanwhile the cleansing lotion is capable of moisturizing and resisting wrinkles.

Owner:广州科玛生物科技股份有限公司

UV (ultraviolet) fire retardant coating and preparation method thereof

ActiveCN107652875AAvoid pollutionImprove protectionFireproof paintsAntifouling/underwater paintsWeather resistanceDiacrylate ester

The invention belongs to the field of coating and particularly relates to UV (ultraviolet) fire retardant coating and a preparation method thereof. The UV fire retardant coating comprises the following raw materials in parts by weight: 30-40 parts of 1, 6-ethylene glycol diacrylate, 30-40 parts of flame retardant modified hyperbranched acrylic resin, 15-20 parts of polyesteracrylate, 0.5-2 parts of a photoinitiator, 1-3 parts of an adhesion promoter and 0.5-1 part of a flatting agent. The coating is excellent in flame retardant property and comparatively strong in weather resistance and belongs to environment-friendly coating.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

Wool anti-pilling finishing agent

InactiveCN102995419AReduce or eliminate sliding frictionPrevent mobile bondingAnimal fibresPolymer scienceDiethylene glycol

Owner:广东爱华毛织工艺有限公司

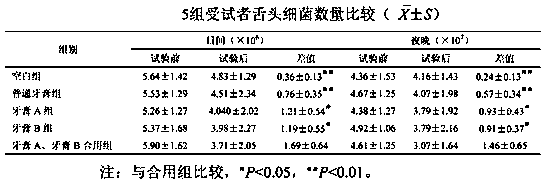

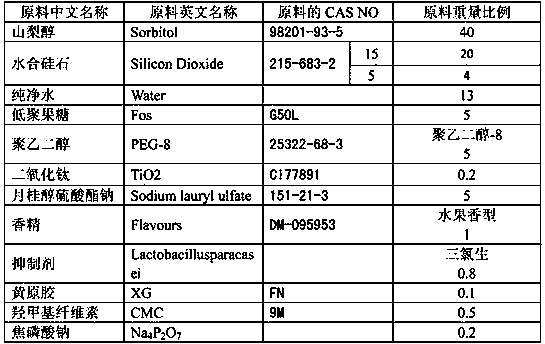

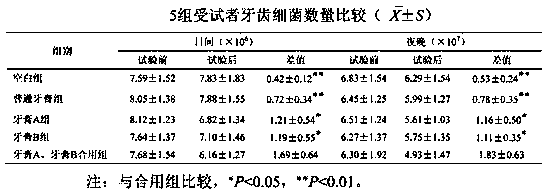

Oral caring method and application thereof

PendingCN109692138AGrowth inhibitionInhibition of reproductionAntibacterial agentsCosmetic preparationsBacteriostatic agentFlavor

The invention provides an oral caring joint product, in particular to a combined use method of two toothpastes and an application thereof. The combination product consists of a toothpaste A and a toothpaste B, which consists of a traditional Chinese medicine composition or an active ingredient of the traditional Chinese medicine composition, a friction agent, a wetting agent, a binder, a foaming agent, a sweetener, a fragrance, and deionized water; the toothpaste B is composed of sorbitol, hydrated silica, purified water, fructo-oligosaccharide, polyethylene glycol, titanium dioxide, sodium lauryl sulfate, a flavor, a bacteriostatic agent, xanthan gum, hydroxymethyl cellulose, and sodium pyrophosphate. The invention provides the toothpaste for preventing or treating oral diseases, teeth brushing is carried out in the morning by using the toothpaste A, and the teeth brushing is carried out by using the toothpaste B before going to bed. The oral diseases are periodontitis, gingivitis, oral ulcers, and oral mucositis.

Owner:SHIJIAZHUANG YILING PHARMA

Photocurable photochromic material and preparation method thereof

ActiveCN105670602AShorten production timeImprove impact resistanceTenebresent compositionsOptical partsWeather resistanceDiacrylate ester

The invention discloses a photocurable photochromic material and a preparation method thereof. The photocurable photochromic material is composed of 30%-70% of bisphenol A dimethacrylate, 10%-60% of poly(ethylene glycol) diacrylate, 10%-30% of polyfunctional acrylate monomer and the balance modifying additives, wherein the sum of weight percentages is 100%. The photocurable photochromic material and the preparation method thereof have the advantages that lens production time is shortened from 20 hours to 15 minutes, impact resistance of lenses is improved to prevent breakage in use, and weather resistance of the lenses can be improved as well to avoid cracks in a fierce cold-hot change process.

Owner:JIANGSU MAAT OPTICAL CO LTD

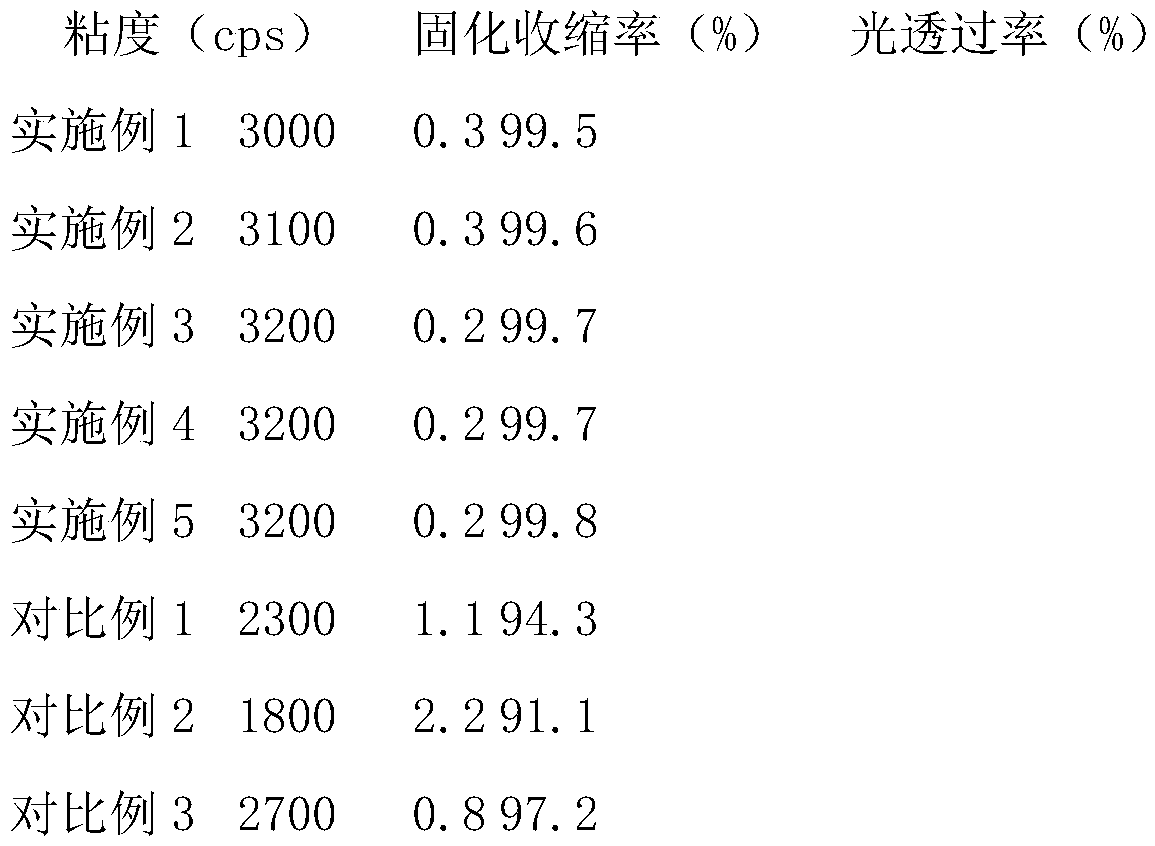

Optical cement for repairing touch screen cracks and application thereof

ActiveCN110016295AHigh viscosityCuring shrinkage is smallNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceGlycidyl methacrylate

The invention provides optical cement for repairing touch screen cracks and application thereof. Firstly, an ultraviolet light initiating agent and monomer of glycidyl methacrylate, ethoxylated trimethylolpropane triacrylate and the like are mixed to produce a first mixture, an emulgator is added into deionized water to obtain mixed liquid, then acrylate, toluene diisocynate, triethylene glycol diacrylate, polyether acrylate, tetrahydrofurfuryl acrylate, isobornyl methacrylate and the like are used as raw materials, the raw materials and the mixed liquid are mixed to produce prepolymer emulsion, then copolymer of ethylene glycol dimethacrylate, polypropylenglycol glycidyl ether, dibutyltin dilaurate, 2-methyl methacrylate and butyl acrylate is added to produce a second mixture, and finally, under a dark condition, the first mixture is slowly added into the second mixture to obtain the optical cement for repairing the touch screen cracks. After the touch screen cracks are repaired, theoriginal appearance of a touch screen is recovered, no crack traces are seen visually, the light transmittence is 99.5% or above, the viscosity is high, and a cure shrinkage rate is low.

Owner:浙江国能科技有限公司

Cell freezing liquid not containing protein and serum and preparation method thereof

InactiveCN106993606AAvoid pollutionReduce batch variabilityCulture processCell culture mediaPolyvinyl alcoholHigh activity

The invention relates to cell freezing liquid not containing protein and serum and a preparation method thereof. The cell freezing liquid comprises polyvinyl alcohol, glucose, sodium chloride, sodium dihydrogen phosphate, disodium hydrogen phosphate, 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid, ethyleneglycol bis(2-aminoethylether)tetraacetic acid, dimethyl sulfoxide, and the balance of double distilled water. The cell freezing liquid has the advantages that the cell freezing liquid with single component and clear chemical components is established, the traditional serum is replaced, the possibility of pollution by viruses, bacteria, mycoplasma and the like is avoided, and the batch difference due to serum is reduced; a method of direct refrigerating in a -80 DEG C refrigerator is established, the freezing time is longer than or equal to 3 years, the procedure cooling step is not needed, and the freezing box is not used; compared with the traditional method, the operation is simple and convenient, and the safety is high; the survival rate and high activity of the frozen cells are guaranteed, the effect is better in comparison with the traditional serum, the serum is replaced, and the price is lower.

Owner:SUZHOU NEW CELL & MOLECULAR BIOTECH CO LTD

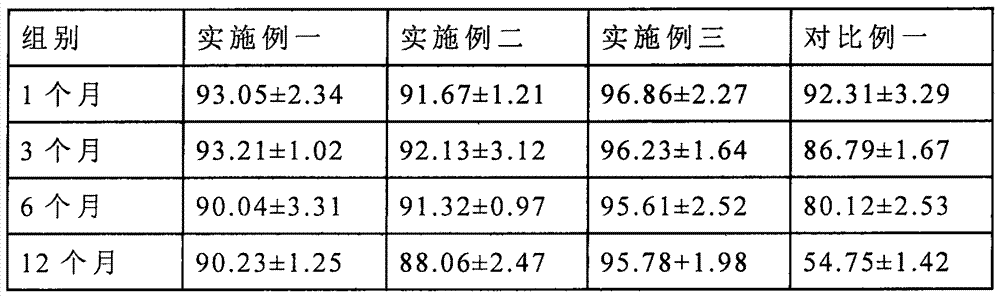

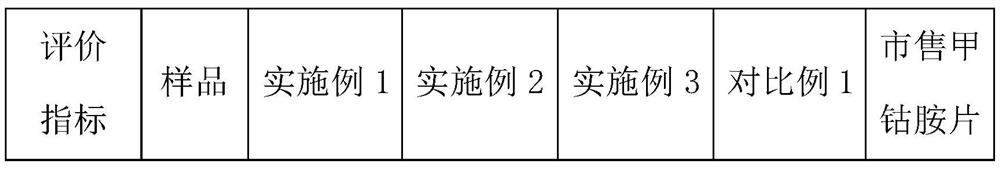

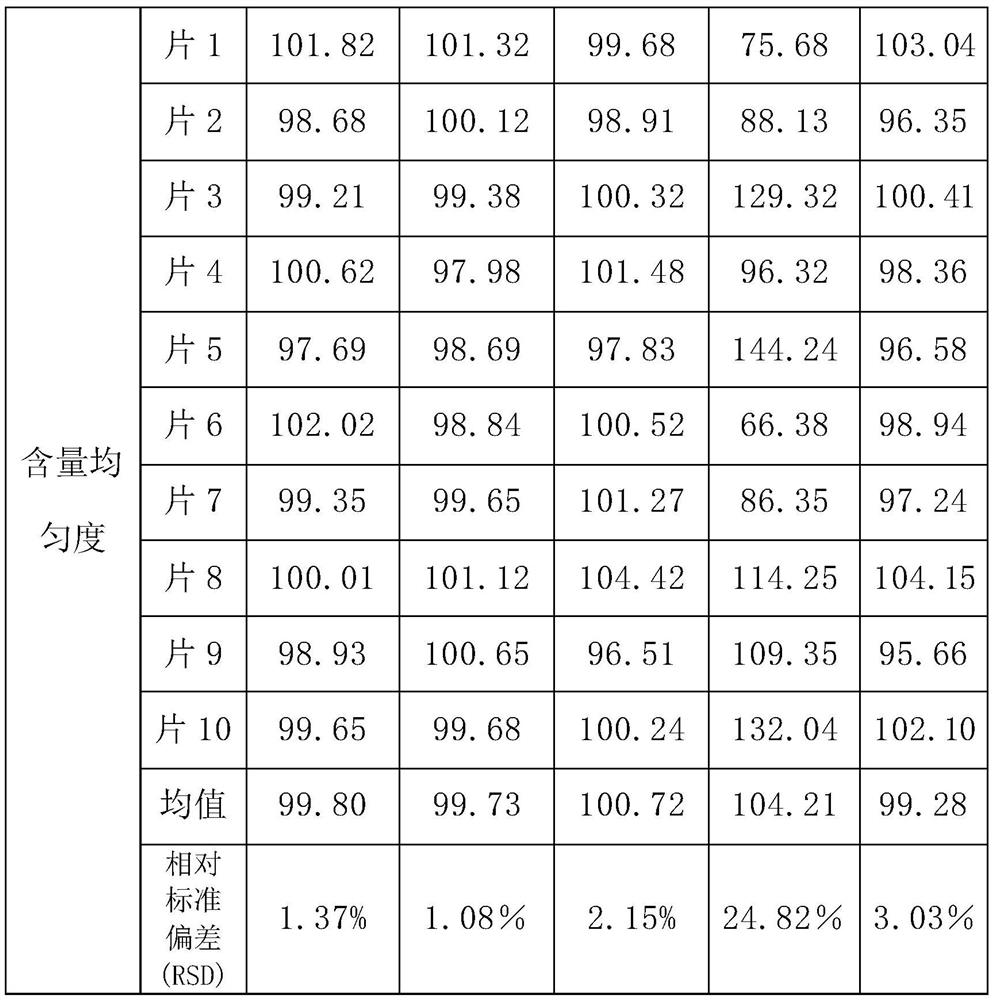

Mecobalamin tablet and preparation method thereof

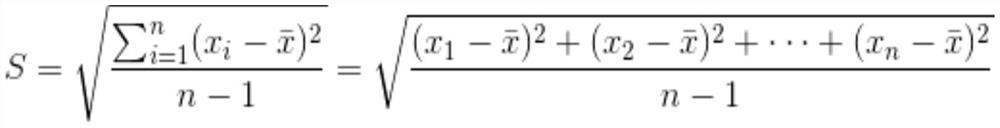

PendingCN112022826AGood content uniformityImprove stabilityOrganic active ingredientsNervous disorderCelluloseFiber

The invention discloses a mecobalamin tablet and a preparation method thereof. The mecobalamin tablet comprises a plain tablet and a film coating layer; the mass ratio of the plain tablet to the filmcoating layer is 100:510; the plain tablet comprises the following components in percentage by weight: 0.5% of mecobalamin, 40% to 70% of directly-compressed lactose, 15% to 45% of micro-crystalline fiber, 0 to 15% of corn starch, 0 to 15% of pregelatinized starch, 0 to 2% of stearic acid and 0 to 2% of a lubricant; the film coating layer comprises the following components in percentage by weight:20% to 40% of hydroxypropyl methyl cellulose, 20% to 50% of polyethylene glycol; 10% to 35% of titanium dioxide; 1% to 15% of yellow iron oxide; and 1% to 15% of red iron oxide. The preparation method of the mecobalamin tablet disclosed by the invention is simple; a mecobalamin raw material medicine can be uniformly dispersed in a manner of sieving and mixing the mecobalamin raw material medicineand proper auxiliary materials; the phenomenon of aggregation of the raw material medicine is prevented by a mechanical force, the raw material medicine is fully adsorbed on the auxiliary materials,and then the raw material medicine is mixed with other auxiliary materials step by step to improve the content uniformity; The preparation method disclosed by the invention reduces the stability riskby adopting a powder direct-compression process, and further improves the stability of the preparation by adopting a high-shading-performance film coating material for coating.

Owner:湖北欣泽霏药业有限公司

Efficient corrosion and scale inhibitor

ActiveCN104528960AComponent safety and environmental protectionSimple production processSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsMeth-Ethylene glycol toxicity

The invention discloses an efficient corrosion and scale inhibitor and belongs to the field of water treatment. The corrosion and scale inhibitor consists of polyaspartic acid, sodium silicate, phthalandione diethylene glycol acrylate, polydiallyl dimethyl ammonium chloride, hexamethylene tetramine, di(hydroxymethyl) imidazolidinyl urea, methylisothiazolinone, mycose, trihydroxymethyl aminomethane and water. The corrosion and scale inhibitor prepared by appropriate technological processes has the advantages of good corrosion inhibiting effect, storage resistance, safe and environment-friendly components, no pollution to the environment and the like, and has a very good application prospect.

Owner:WUHU XIECHENG METAL PROD

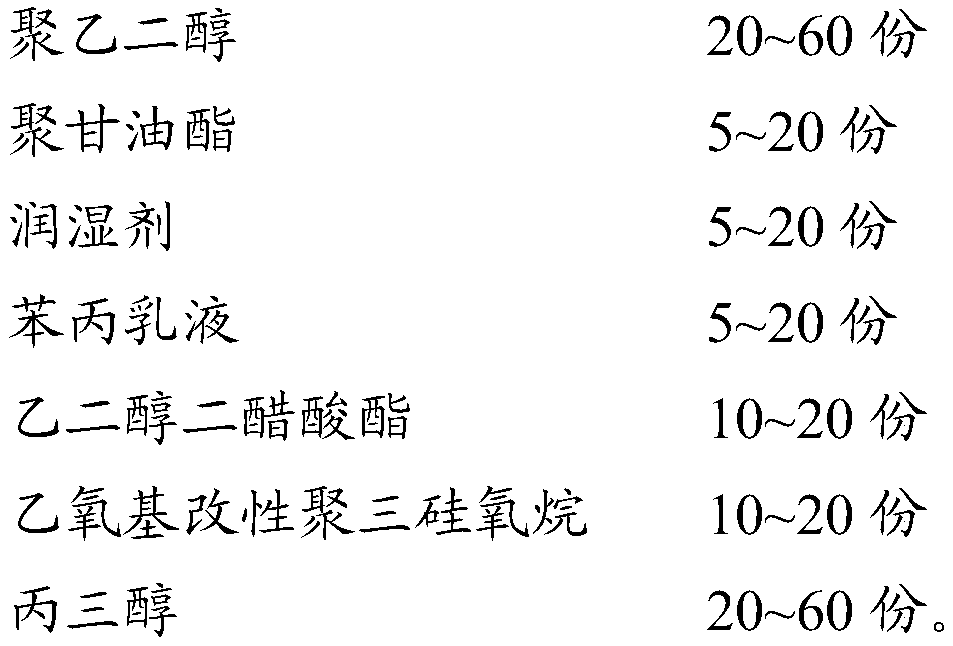

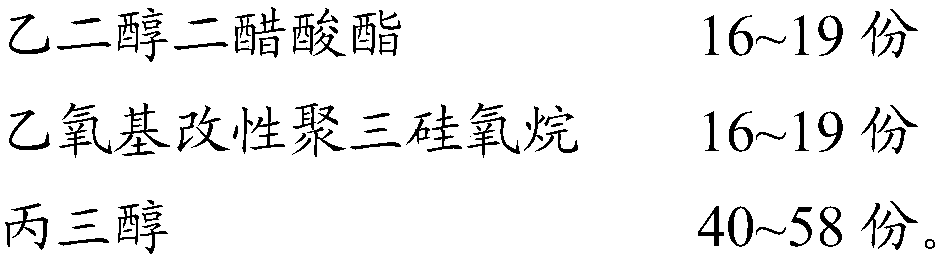

Multifunctional flying prevention adjuvant and preparation method and application thereof

ActiveCN109601531AGood anti-drift performanceExcellent volatility resistanceBiocideAnimal repellantsPESTICIDE ADJUVANTSVegetable oil

The invention relates to the technical field of pesticide adjuvants, in particular to a flying prevention adjuvant and a preparation method and application thereof. The flying prevention adjuvant provided by the invention comprises the following components in parts by weight: 20-60 parts of polyethylene glycol, 5-20 parts of polyglycerol ester, 5-20 parts of wetting agent, 5-20 parts of styrene-acrylic emulsion, 10-20 parts of ethylene glycol diacetate, 10-20 parts of ethoxy modified polytrisiloxane and 20-60 parts of glycerol. According to the embodiment of the invention, the flying prevention adjuvant has better anti-drift performance, and the drift inhibition rate is more than 70%, so that different liquid medicines all have better anti-transpiration performance, the evaporation time ismore than 149s, and the anti-drift performance and the anti-volatility performance of the flying prevention adjuvant are improved compared with the flying prevention adjuvant added with vegetable oil.

Owner:中化化工科学技术研究总院有限公司 +1

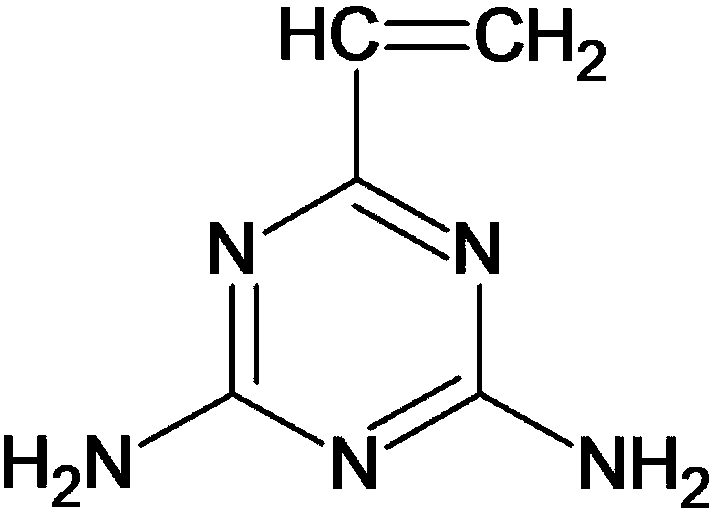

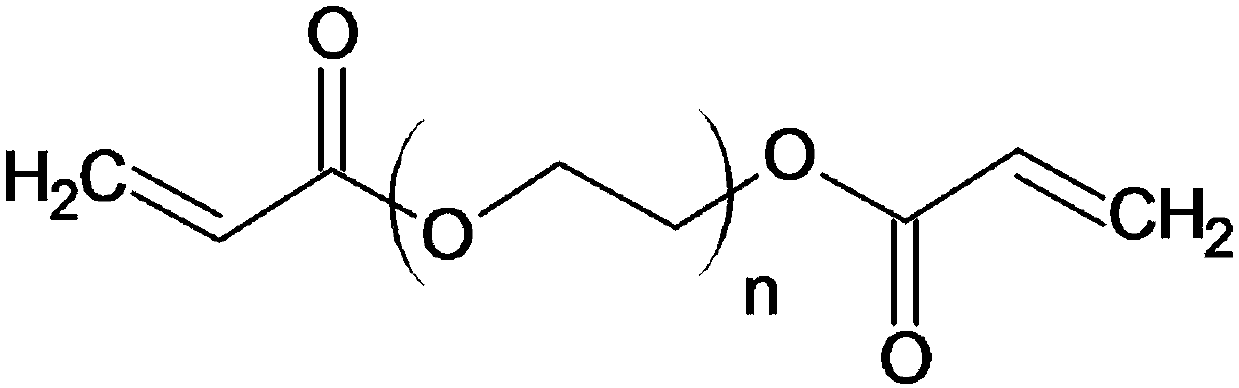

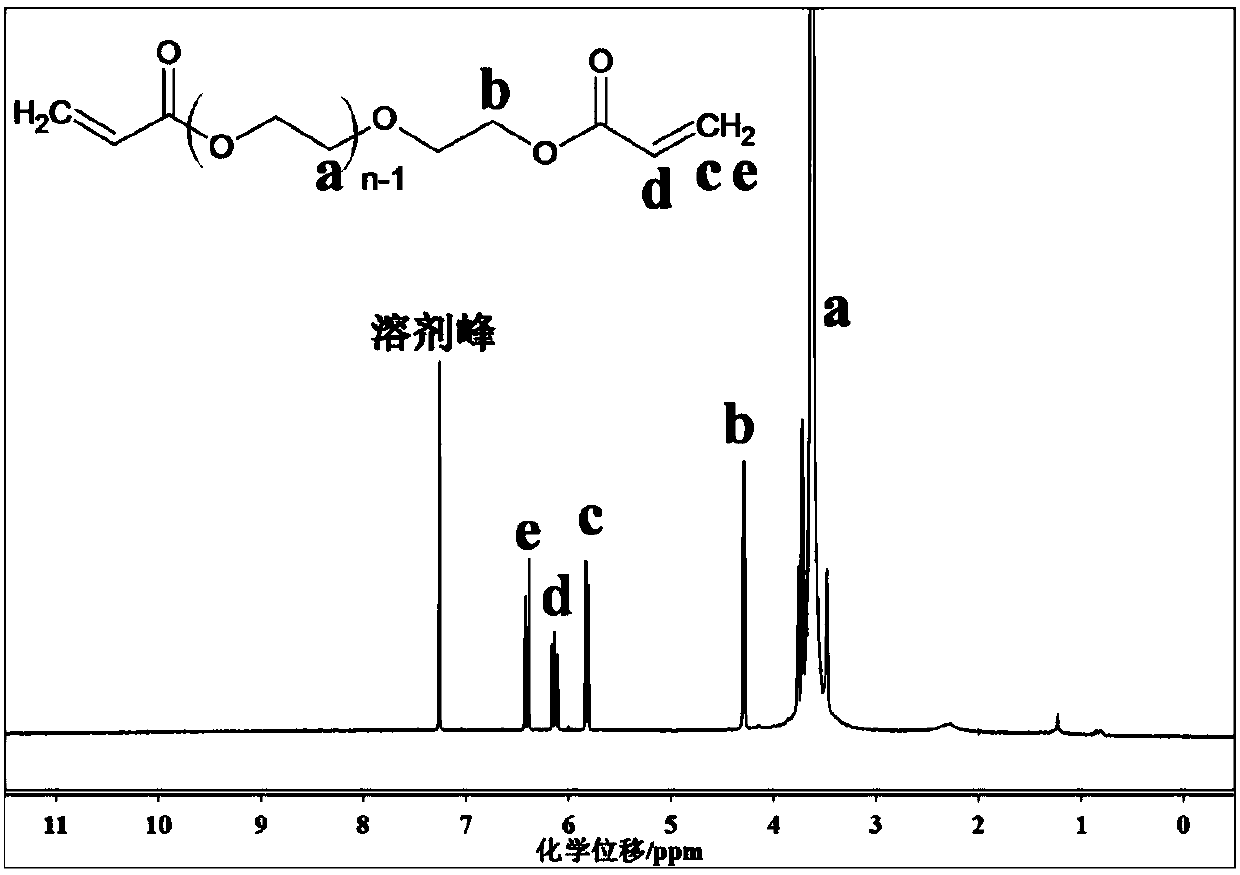

High-strength conductive hydrogel based on polyethyleneglycol diacrylate crosslinking and preparation method thereof

InactiveCN107805310AImprove compression performanceSimple manufacturing methodCross-linkEthylenedioxy

The invention discloses a high-strength conductive hydrogel based on polyethyleneglycol diacrylate crosslinking and a preparation method thereof. According to the invention, 2-vinyl-4,6-diamino-1,3,5-triazine is taken as a monomer, polyethyleneglycol diacrylate is taken as a cross-linking agent, poly(3,4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) is taken as a blending component, a free radical polymerization is carried out on a monomer initiated through an initiator and carbon-carbon double bonds on the cross-linking agent to form a hydrogel network having physical crosslinking and chemical crosslinking, and the poly(3,4-ethylenedioxy group thiophene)-poly (styrene sulfoacid) is doped in a gel network structure. The hydrogel has the advantages of simple process, strong stretching and compression performance, good conductivity, and good biocompatibility.

Owner:TIANJIN UNIV

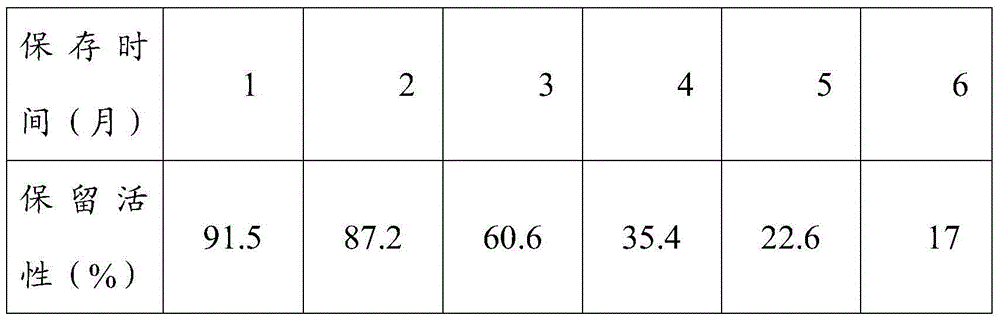

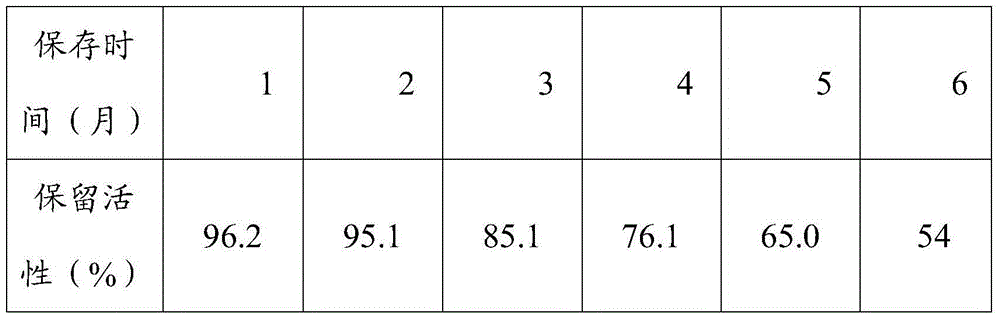

Method for immobilizing escherichia coli glutamate decarboxylase through entrapping method

InactiveCN104531662AIncrease enzyme activityUniform particlesOn/in organic carrierEscherichia coliGlutamate decarboxylase

The invention discloses a method for immobilizing escherichia coli glutamate decarboxylase through an entrapping method, wherein the method comprises the following steps: (1) preparing a sodium alginate carrier: infiltrating sodium alginate with glycerol, then adding deionized water, stirring to dissolve, then adding polyoxyethylene octyl phenyl ether, polyethylene glycol and dithiothreitol, stirring to dissolve, and thus obtaining a homogeneous sodium alginate solution; (2) adding a glutamate decarboxylase enzyme solution into the sodium alginate solution prepared in the step (1), mixing the two solutions uniformly, and thus obtaining a sodium alginate enzyme solution; (3) dropwise adding the sodium alginate enzyme solution into a CaCl2 solution with a needle of a constant-flow pump externally-connected injector at a uniform velocity, stirring and immobilizing; and (4) filtering, repeatedly washing a gel precipitate with a PBS buffer solution, drying, and thus obtaining granular immobilized glutamate decarboxylase. Glycerol, polyoxyethylene octyl phenyl ether, polyethylene glycol and dithiothreitol are added in the sodium alginate solution, and the enzyme activity of the glutamate decarboxylase after immobilization is effectively improved.

Owner:SOOCHOW KH BIO SCI & TECH CO LTD KHB

Flame retardant for computer mainboard

The invention relates to a flame retardant for a computer mainboard, belonging to the technical field of flame retardant articles. The flame retardant for the computer mainboard is prepared from the following raw materials: water, 2-acrylic acid-2, 2-dimethyl-1, 3-dipropyl ester, 3, 6-dioxa-1, 8-diaminooctane tetraacetic acid, diethyl-amino-ethylmethacrylate, (6-methoxyl-4-quinolyl) (5-vinyl-1-aza bicycle[2.2.2] octane-2-yl) methanol, diethylene glycol divinyl ether and the like. The flame retardant for the computer mainboard is prepared by mutual reaction of the chemical components of the substances, so that the flame retardant effect is effectively realized. The flame retardant is stable in chemical property and is not decomposed at high temperature. The flame retardant is attached to inner and outer walls of the computer mainboard and not only cannot influence the work of the computer mainboard, but also can be used for effectively resisting flame spread and preventing fire of a computer case, so that the flame retardant has an extremely good flame retardant effect.

Owner:安徽斯迈特新材料股份有限公司

Flame-retardant and anti-rusting anti-adhesion epoxy paint and preparation method thereof

InactiveCN104293090AImprove flame retardant performanceLow costFireproof paintsAnti-corrosive paintsXylyleneBenzoic acid

The invention discloses flame-retardant and anti-rusting anti-adhesion epoxy paint which is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of E-51 epoxy resin, 12-17 parts of fluorosilicone resin, 8-12 parts of polybutadiene epoxy resin, 3-5 parts of vinyl triamine, 2-3 parts of urotropine, 0.4-0.8 part of bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, 12-15 parts of modified asphalt, 2-4 parts of asbestos, 1-2 parts of sodium silicate, 3-6 parts of modified waste clay sand, 3-4 parts of hexachlorocyclopentadiene, 1-3 parts of p-nitrobenzoic acid, 3-4 parts of single methyl phosphinic acid calcium, 0.5-1.0 part of phenethyl naphthol polyoxyethylene ether, 2-4 parts of nano calcium carbonate, 5-7 parts of diethylene glycol, 7-9 parts of xylene and 9-13 parts of acetic ether. The fluorosilicone resin added into the paint disclosed by the invention is excellent in temperature resistance, adhesion prevention, chemical resistance, antifouling property and rain corrosion resistance; the mutual synergistic effects of pentaerythritol phosphate, single methyl phosphinic acid calcium and hexachlorocyclopentadiene added into the paint are brought into play, so that the flame retardancy of the paint is improved; as the waste clay sand is modified and added into the paint, both the cost of the paint is lowered, the weather resistance and corrosion resistance of the paint are improved, and the environment pollution is also alleviated.

Owner:TIANCHANG YINHU PAINT

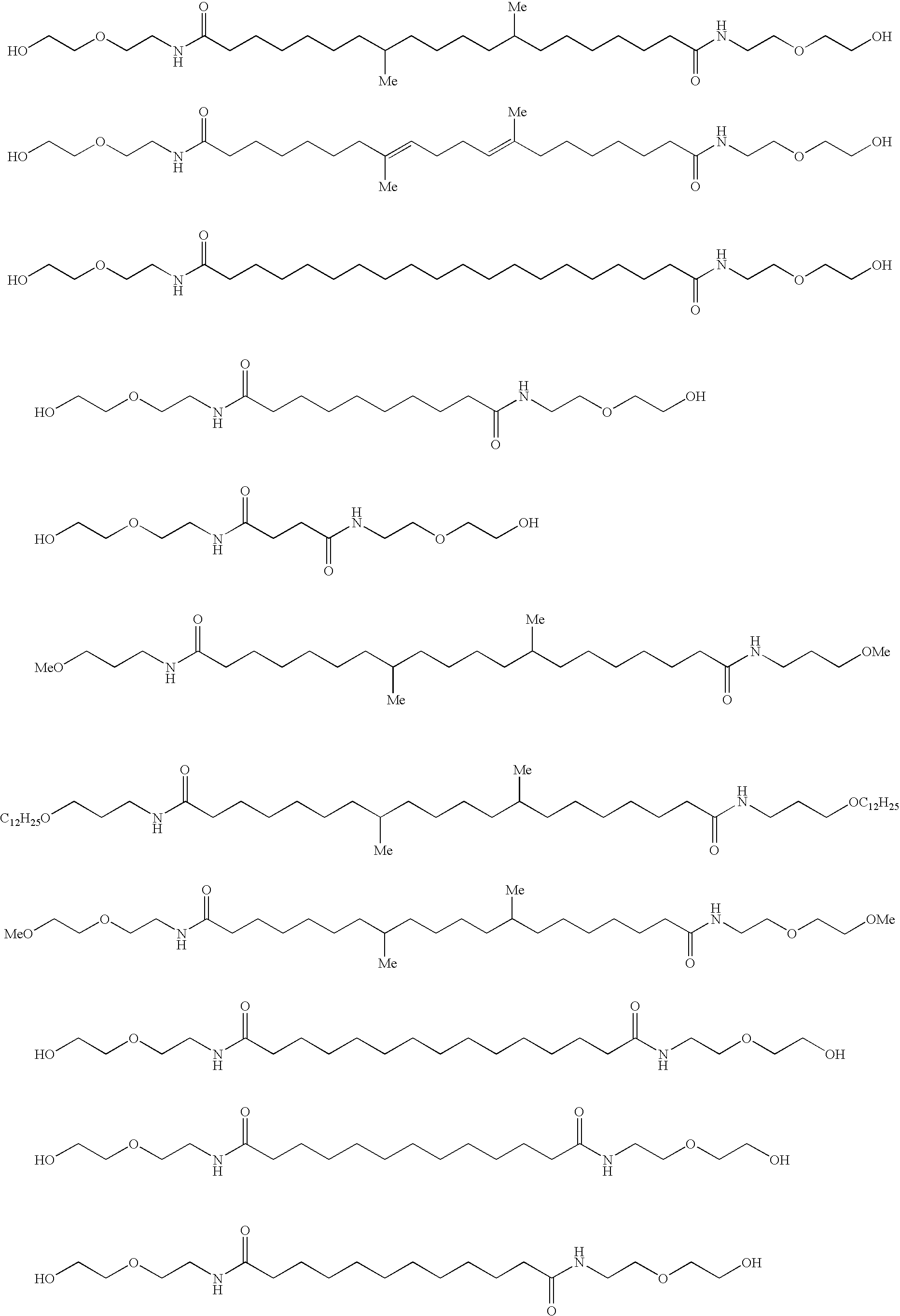

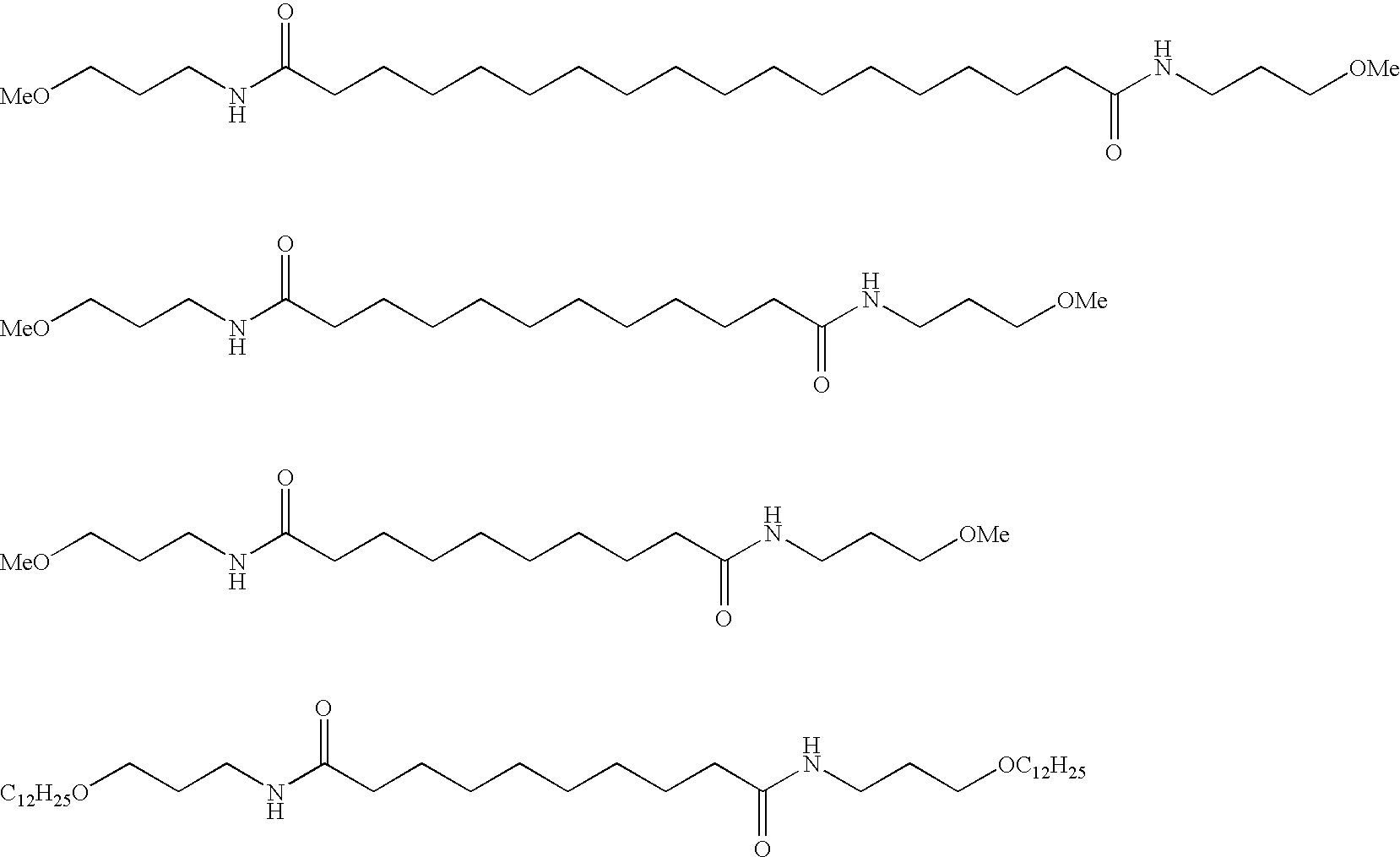

Hair cosmetic composition

Provided is a hair cosmetic composition containing (A) from 0.001 to 10 wt. % of an amphipathic amide lipid, and (B): from 0.05 to 10 wt. % of a dialkyl ether or ethylene glycol dialkyl ether with an alkyl group having from 18 to 22 carbon atoms, or an ethylene glycol monofatty acid ester, ethylene glycol difatty acid ester, fatty acid monoethanolamide or acylated beta-alanine with an acyl group having from 18 to 22 carbon atoms. The hair cosmetic composition of the present invention for example, protects the hair from physical or chemical stimulation, prevents appearance of split ends and broken hair, imparts natural smoothness, moist feeling, resilience and strength, and moisture retention property to the hair after treatment (shampooing), and at the same time has excellent storage stability.

Owner:KAO CORP

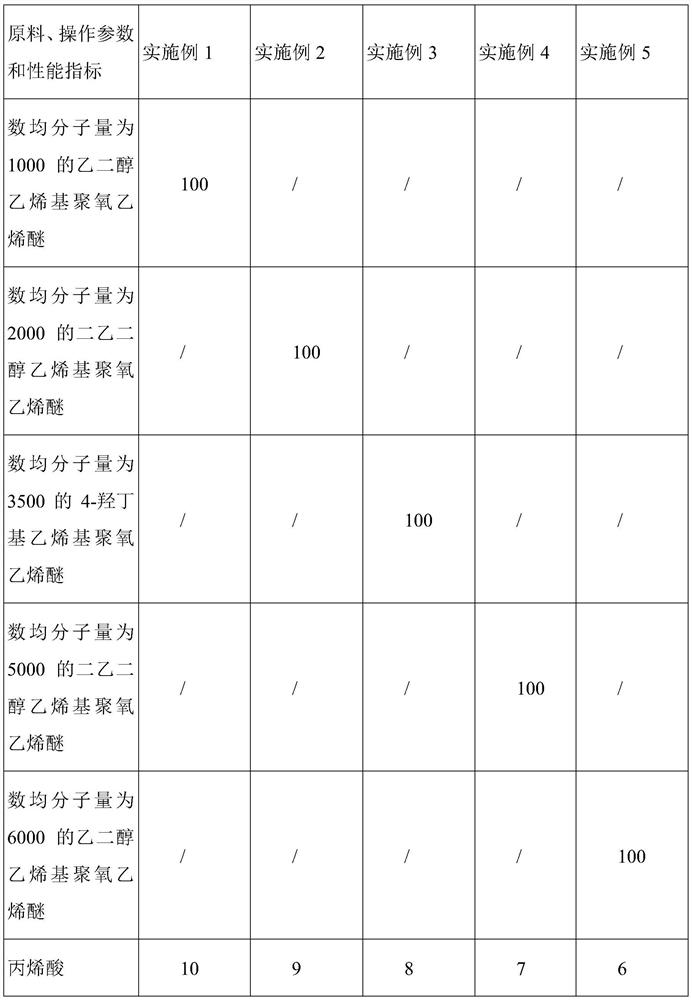

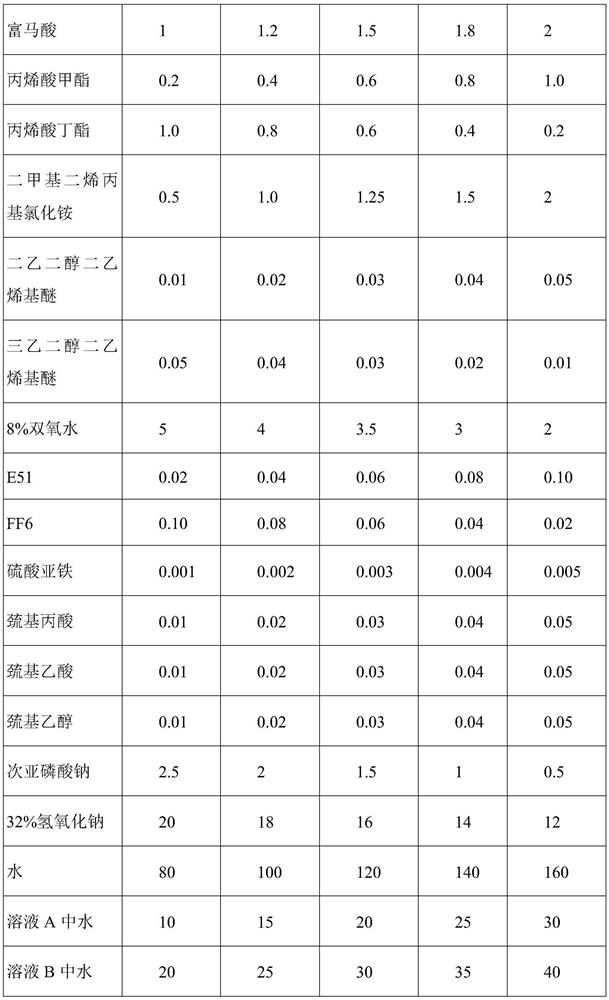

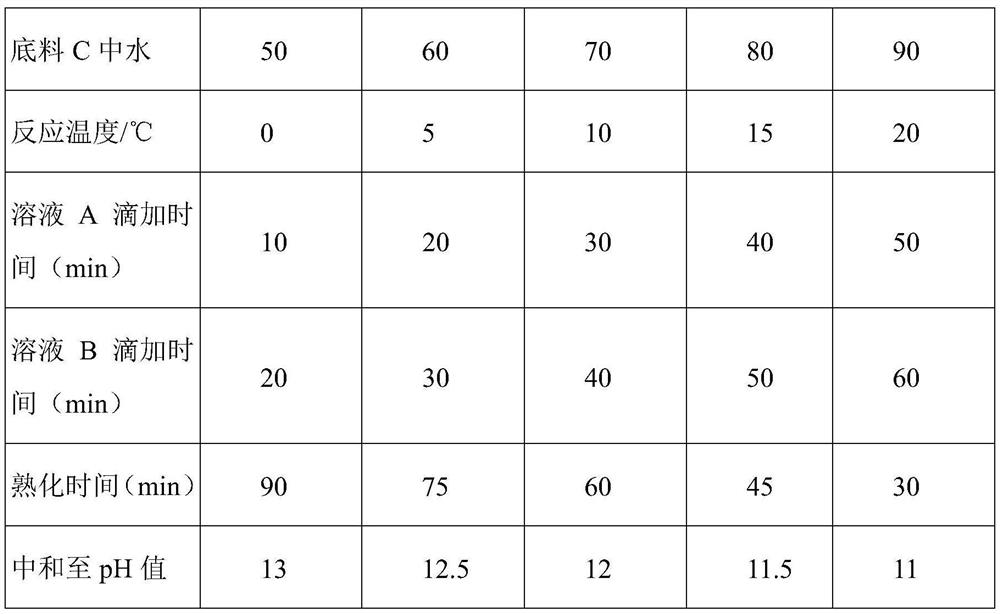

Polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and preparation method and use method thereof

ActiveCN113527592AReduced molecular weight distribution widthIncrease the length of the main chainVinyl etherPhosphorous acid

The invention discloses a polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and a preparation method and a use method thereof. The polycarboxylate-type water reducing agent is prepared from the following components in parts by weight: 100 parts of polyether, 6 to 10 parts of acrylic acid, 1 to 2 parts of fumaric acid, 0.2 to 1 part of methyl acrylate, 0.2 to 1 part of butyl acrylate, 0.5 to 2 parts of dimethyl diallyl ammonium chloride, 0.01 to 0.05 part of diethylene glycol divinyl ether, 0.01 to 0.05 part of triethylene glycol divinyl ether, 2 to 5 parts of hydrogen peroxide, 0.02 to 0.1 part of a reducing agent E51, 0.02 to 0.1 part of a reducing agent FF6, 0.001 to 0.005 part of ferrous sulfate, 0.01 to 0.05 part of mercaptopropionic acid, 0.01 to 0.05 part of mercaptoacetic acid, 0.01 to 0.05 part of mercaptoethanol, 0.5 to 2.5 parts of sodium hypophosphite, 12 to 20 parts of sodium hydroxide and 80 to 160 parts of water. The invention provides polycarboxylate-type water reducing agent for the gypsum-based self-leveling mortar and the preparation method and the use method thereof. The polycarboxylate-type water reducing agent is good in adaptability to byproduct gypsum, high in water reducing rate, good in slump retaining effect, fast in coagulation, small in shrinkage and high in strength, and can be widely applied to the field of gypsum-based self-leveling mortar.

Owner:连云港石化有限公司

Mild and moist facial cleanser

InactiveCN104644525AStrong water absorption capacityFacilitates water supply mobilityCosmetic preparationsToilet preparationsGlycerolCocamidopropyl betaine

The invention discloses a mild and moist facial cleanser which is prepared from the following components in parts by weight: 0.1-15 parts of glycerinum, 0.1-20 parts of butanediol, 0.05-1 part of PCA sodium, 1-5 parts of glycol distearate, 2-5 parts of cocamidopropyl betaine, 5-10 parts of lauramidopropyl betaine, 0.5-1 part of papain, 5-10 parts of hydrolyzed collagen, 5-9 parts of a milk protein extract, 1-3 parts of a pansy extract, 1-3 parts of a honey extract, 1-5 parts of EDTA disodium, 0.5-1 part of citric acid, 0.5-1 part of sodium citrate, 1-3 parts of tocopherol, 0.5-1 part of phenoxyethanol, 0.5-1 part of hyaluronic acid, 0.5-3 parts of an essence and the balance of water.

Owner:安婕妤化妆品科技股份有限公司

Silk fibroin shampoo

InactiveCN105326673ANo toxicityNo stimulationCosmetic preparationsHair cosmeticsAmmonium dodecyl sulfatePolymer science

The invention discloses a silk fibroin shampoo, characterized by comprising the following components by weight: 15% silk fibroin solution 12-15 parts, coco-glucoside 4-6 parts, coco-hydroxypropyl betaine 4-6 parts, ammonium laureth sulfate 5-7 parts, tea tree oil 2-3 parts, guar gum 0.2-0.4 part, ethylene glycol distearate 1-2 parts, ammonium lauryl sulfate 1.2-1.5 parts, vitamin E 0.6-0.8 part, citric acid 1-2 parts, a plant additive 6-8 parts, propylene glycol 15-20 parts, and deionized water 30-40 parts. The silk fibroin is free of toxicity, stimulation and allergy to the human body and is crucial to moisturizing and balancing of a hair growth environment, small-molecular silk fibroin can deepen in the core of hair for internal restoration, required moisture is supplemented, nutrition is given to the hair, and the tea tree oil can improve oil-water balance, effectively preventing the occurrence of dandruff, and can also avoid the hair yellowing and withering.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

High-molecule slip casting plugging material

The invention relates to a high-molecule slip casting plugging material. Particularly the material is suitable for being applied to water plugging and leakage prevention for fine cracks of buildings at the normal temperature. According to the material, a mixture of two or more of N,N'-dimethylacrylamide, N-methylol acrylamide, N,N'-methylene bisacrylamide, polyethylene glycol (200) diacrylate, poly ethyleneglycol (200) dimethacrylate, sodium hydrogen sulfite, sodium sulfite, sodium dithionite and sodium thiosulfate is used as a main raw material (a material A); a mixture of two or more of ammonium persulfate, potassium persulfate, trismetyl aminomethane and ethylenediamine tetraacetic acid disodium salt is used as a curing agent (a material B); after the material A and the material B are mixed, the slurry viscosity is extremely low, the groutability is excellent, the gelation time can be adjusted according to the demand, the high-molecule gel formed through curing has good adhesivity and compression strength and has a leakage prevention and plugging function, and the material has wide application prospects in the field of leakage prevention and plugging of the buildings.

Owner:山东省建筑科学研究院有限公司 +1

Preservation method of hilsa herring sperm

InactiveCN109122668AShorten the timeLower metabolic rateDead animal preservationSodium bicarbonateChlorogenic acid

The invention discloses a preservation method of a hilsa herring sperm. The preservation method comprises mixing an antifreeze agent, the hilsa herring sperm and a diluent at the volume ratio of 1:1:5, and preserving at the temperature of 5 DEG C, wherein the diluent comprises the ingredients in percent by volume: 50% of sodium chloride injection, 15-20% of pure water, 7-14% of potassium chloride,5-10% of calcium chloride, 5-10% of sodium bicarbonate, 1-2% of chlorogenic acid, 1-3% of glycerinum, 3-5% of glucose, 8-15% of lecithin, 1-3% of sodium citrate, 1-2% of streptomycin, 1-3% of poly-sodium glutamate, 1-3% of bifidobacterium, and the balance of lactic acid bacteria by volume; and the antifreeze agent comprises the ingredients in percent by volume: 30% of dimethyl sulfoxide, 20% of glycerinum, 30% of ethylene glycol, and 20% of dimethylacetamide. The preservation method effectively inhibits the growth and propagation of harmful microbes, reduces the metabolic rate of the sperm, effectively keeps the preservation quality of the hilsa herring sperm, and saves the production cost, and operation steps are convenient.

Owner:镇江市绿色农业科技有限公司

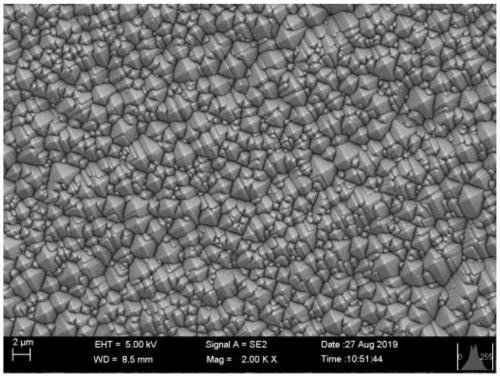

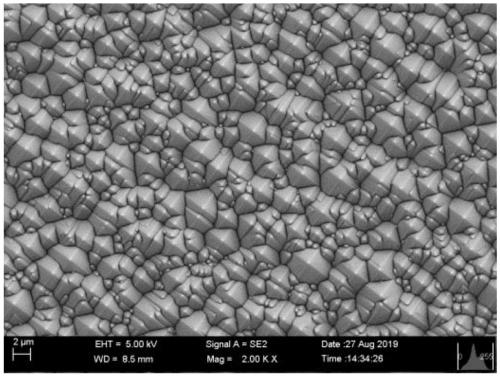

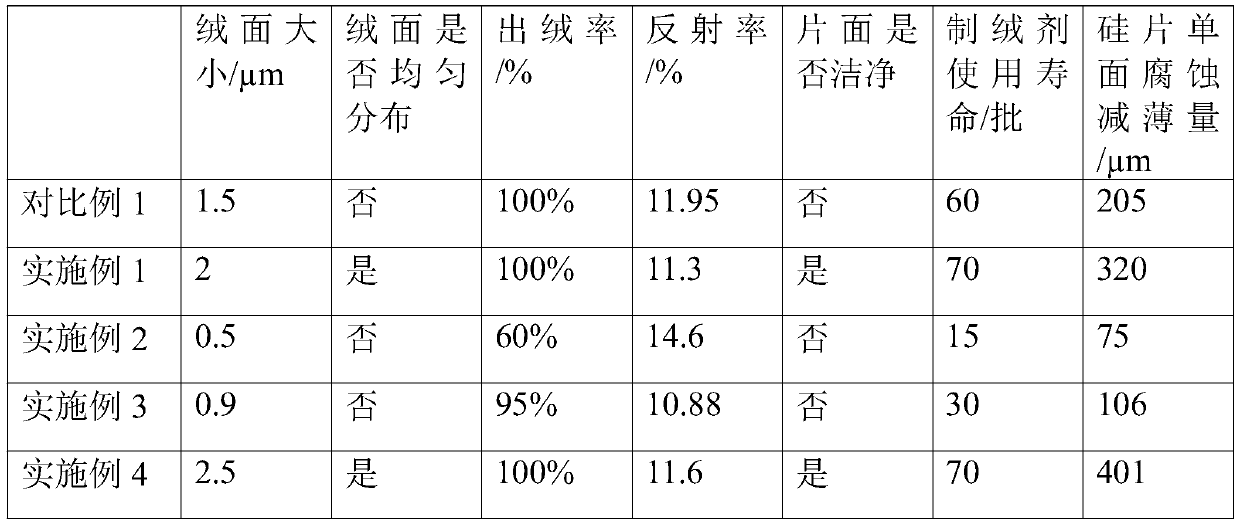

Texturing additive for monocrystalline silicon surface treatment, texturing agent and monocrystalline silicon surface texturing method

ActiveCN111485290AChange sizeSuede increasePolycrystalline material growthAfter-treatment detailsMetallurgyPolyethylene glycol

The invention relates to the technical field of monocrystalline silicon wafer texturing agents. The invention discloses a texturing additive for monocrystalline silicon surface treatment. The texturing additive is prepared from the following components in percentage by weight: 0.01 to 1.0 percent of sodium lignin sulfonate, 0.0001 to 0.01 percent of sodium polynaphthaldehyde sulfonate, 0.2 to 4 percent of polyethylene glycol, 1.5 to 5 percent of diethylene glycol butyl ether, 1.5 to 2.5 percent of potassium perfluorohexylsulfonate, 0.1 to 5 percent of sodium diethylcaprylate and 82 to 96 percent of water. The invention further discloses a texturing agent for monocrystalline silicon surface treatment, the texturing additive is added into a 1%-2% sodium hydroxide or potassium hydroxide solution, the mixture is mixed to be uniform at the temperature of 20-80 DEG C, and the mass ratio of the texturing additive to the alkaline solution is (1-5): 100. The invention also discloses the monocrystalline silicon surface texturing method. The method comprises the following steps: a monocrystalline silicon wafer is pretreated; and the pretreated monocrystalline silicon wafer is immersed in thetexturing agent for texturing, the texturing temperature is 70-90 DEG C, and the texturing time is 300-1200 s. The monocrystalline silicon surface treated by the texturing additive and the texturing agent achieves a good texturing effect, the textured surface size is controllable, the texturing rate is high, the reflectivity is low, one side is clean, and the service life of the texturing agent islong.

Owner:杭州聚力氢能科技有限公司

Thermal insulation waterproof decoration material

InactiveCN107265919AGood flame retardant effectGood waterproof effectPolyvinyl alcoholThermoplastic polyurethane

The invention discloses a thermal insulation waterproof decoration material. The thermal insulation waterproof decoration material comprises the following raw materials in percent by mass: 8-15% of polyvinyl alcohol, 6-15% of fly ash ceramsite, 2-4% of limestone, 3-5% of a medical stone powder, 0.4-2% of tetrakis hydroxymethyl phosphonium sulfate, 2-7% of rosolic acid, 2-5% of titanium tetraisopropoxide, 1-3% of calcium cyanamide, 3-6% of 2,2'-ethylenedioxydiethyl bis(2-ethylhexanoate), 1-2% of alumen, 1-3% of molybdenum selenide, 0.1-1% of an iron powder, and the balance of thermoplastic polyurethane. The thermal insulation waterproof decoration material has a better flame retardance effect, and meets the related requirements of the B1-level flame resistant material; a better waterproof effect is achieved on the basis of efficient thermal insulation, the water absorption is lower than 4%, and the compressive strength is relatively high.

Owner:长沙鼎成新材料科技有限公司

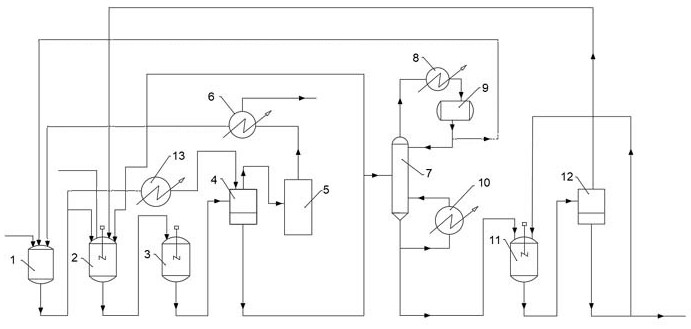

Purification device and method for high-purity ethylene carbonate

ActiveCN113979987AReduce solubilityLow purity requirementOrganic chemistryDiethylene glycolProcess engineering

The invention provides a purification device and method for high-purity ethylene carbonate, and relates to the field of purification devices. The purification device for the high-purity ethylene carbonate comprises a purifying agent storage tank, a dissolving kettle, a purification crystallization kettle, a purification filter, a purification dryer, a purified dry gas condenser, a filtrate treatment tower, a filtrate treatment tower overhead condenser, a filtrate treatment tower condensate tank, a filtrate treatment tower kettle reboiler, a recovery crystallization kettle, a recovery filter and a purifying agent cooler. By utilizing the characteristics that the solubility of ethylene carbonate in a purifying agent is reduced along with the reduction of the temperature, and substances such as ethylene glycol and diethylene glycol can be mixed and dissolved with the purifying agent in any ratio, the substances such as the ethylene glycol and the diethylene glycol are dissolved in the purifying agent by adopting a dissolving and cooling crystallization method, and the ethylene carbonate is crystallized and separated out, so that the high-purity ethylene carbonate can be obtained; and as long as the purity of the raw material ethylene carbonate is greater than or equal to 85wt%, the high-purity ethylene carbonate product with the purity greater than or equal to 99.97 wt% can be obtained.

Owner:DONGYING HI TECH SPRING CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com