Purification device and method for high-purity ethylene carbonate

A ethylene carbonate, high-purity technology, applied in organic chemistry, etc., can solve the problems of difficult purification and achieve the effects of large-scale production, low energy consumption, and low purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

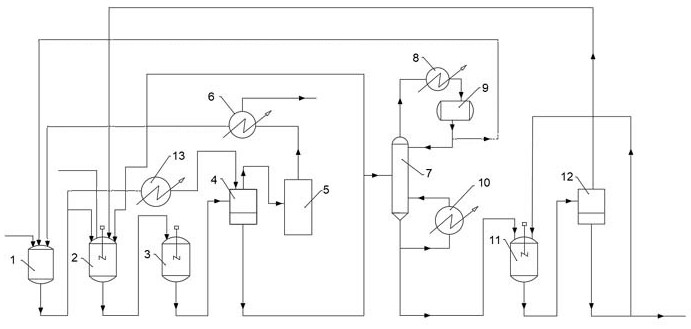

[0031] Such as figure 1As shown, the embodiment of the present invention provides a purification device for high-purity ethylene carbonate, including a purifying agent storage tank 1, a dissolution kettle 2, a purification crystallization kettle 3, a purification filter 4, a purification dryer 5, and a purification and drying gas condenser 6. Filtrate treatment tower 7, filtrate treatment tower overhead condenser 8, filtrate treatment tower condensate tank 9, filtrate treatment tower reboiler 10, recovery crystallization kettle 11, recovery filter 12 and purifying agent cooler 13; The top of the purifying agent storage tank 1 is provided with a fresh purifying agent inlet, a dry condensate inlet and a filtrate treatment tower top production liquid inlet; The liquid inlet at the top is connected with the inlet of the purifying agent cooler 13; the purifying agent cooler 13 is connected with the inlet located at the top of the purifying filter 4; The filter cake inlet of the re...

Embodiment 2

[0043] The purification device and method of embodiment two are the same as embodiment one, and the difference is: the fresh purifying agent is ethyl acetate; The purity of the ethylene carbonate crude product raw material that adds to dissolving kettle 2 is 99.5wt%; Adds to dissolving kettle 2 The quality of the raw material of ethylene carbonate crude product is 0.2 times the quality of the added purifying agent; the temperature of the liquid in the dissolution kettle 2 is 60°C, and it dissolves for 2 hours; the temperature of the purification crystallization kettle 3 is -3°C, and the crystallization time is 10 hours; purification and filtration Carried out at -3°C, the purified filter cake was washed 5 times with the purifying agent cooled to -3°C by the purifying agent cooler 13 from the purifying agent storage tank 1 and then sent to the purifying drier 5 for drying. The quality of the purifying agent used for washing and purifying the filter cake is 1 times of the quality...

Embodiment 3

[0045] The purification device and method of embodiment three are the same as those in embodiment one, except that the fresh purifying agent is a mixture of absolute ethanol and ethyl acetate, wherein the mass ratio of absolute ethanol to ethyl acetate is 99:1; 2 The purity of the ethylene carbonate crude product raw material that adds is 90wt%; The quality of the ethylene carbonate crude product raw material that adds to dissolution kettle 2 is 0.6 times of the ethyl acetate quality that adds; The temperature of liquid in the dissolution kettle 2 is 50 ℃, Dissolved for 1 hour; the temperature of the purification crystallization kettle 3 was 6° C., and the crystallization time was 5 hours; the purification and filtration were carried out at 6° C., and the purification filter cake was cooled to 6° C. by the purification agent cooler 13 from the purification agent storage tank 1 After the purifying agent is washed 3 times, it is sent to the purifying drier 5 for drying, and the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com