Environment-friendly long-life cutting fluid and preparation method thereof

A long-life, cutting fluid technology, applied in the field of lubrication, to achieve the effect of increasing water solubility and good anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

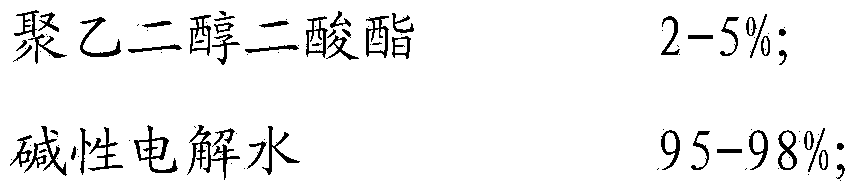

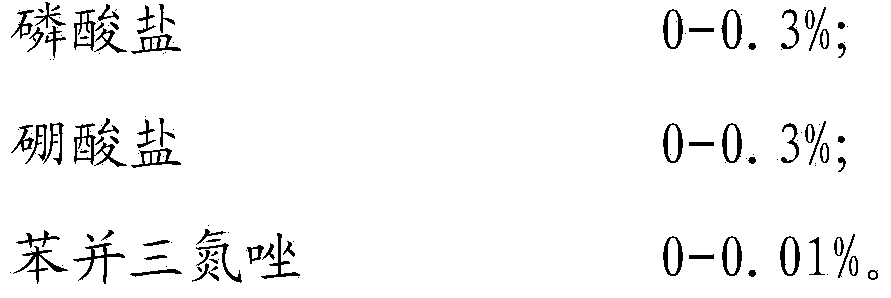

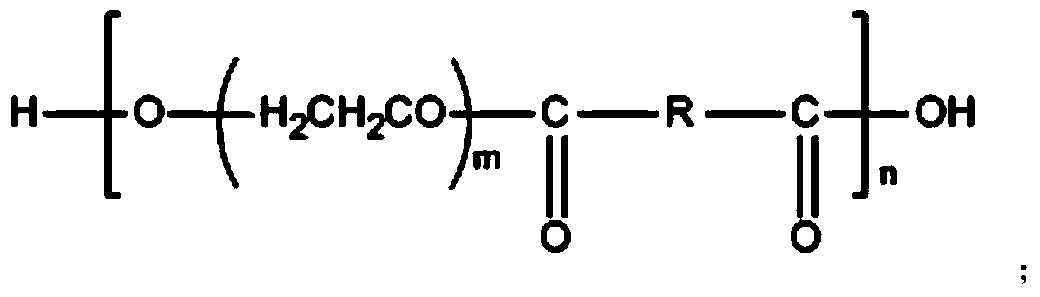

Method used

Image

Examples

Embodiment 1

[0040] 116.07kg (1000mol) of maleic acid and 62.068kg (1000mol) of ethylene glycol are dropped into the polymerization kettle, add 0.89kg of dilute sulfuric acid (5%) and stir, then feed the air in the polymerization kettle into the protective gas conversion kettle, and at the same time Stir and heat up to 180°C. After 24 hours of polymerization, remove part of the water under reduced pressure to obtain polyethylene glycol butenedioate.

[0041] Add 5kg of the above-prepared polyethylene glycol succinate and 0.3kg of potassium tripolyphosphate into 94.7kg of alkaline electrolyzed water, mix and stir, prepare and adjust the solution with potassium hydroxide: an environmentally friendly Type long-life cutting fluid use.

[0042] The model of the electrolyzed water machine used to prepare the above alkaline electrolyzed water is: LF500B, and the pH value of the effluent is 9.30.

[0043] An environment-friendly long-life cutting fluid prepared above was used in BW60HS machining ...

Embodiment 2

[0050] Put 146.14kg (1000mol) of adipic acid and 106.12kg (1000mol) of diethylene glycol into the polymerization kettle by equimolarity, add 0.25kg of dilute sulfuric acid (10%) to stir, and then pass into the polymerization kettle to switch over the protective gas In the air, while stirring, the temperature is raised to 160 ° C. After 18 hours of polymerization, part of the water is removed under reduced pressure to obtain polyethylene glycol adipate.

[0051] Add 2 kg of polyethylene glycol adipate prepared above into 98 kg of alkaline electrolyzed water and mix and stir,

[0052] And use sodium oxide to adjust the solution to a pH value of 9.5, and prepare an environmentally friendly long-life cutting fluid for use.

Embodiment 3

[0054] Put 174.2kg (1000mol) of suberic acid and 150.17kg (1000mol) of triethylene glycol into the polymerization kettle, add 0.65kg of dilute sulfuric acid (6%) to stir, then pass into the polymerization kettle to protect the air in the conversion kettle , while stirring and raising the temperature to 170°C. After 21 hours of polymerization, remove part of the water under reduced pressure to obtain polyethylene glycol suberate.

[0055] Add 3kg of polyethylene glycol suberate prepared above, 0.3kg of potassium tetraborate, and 0.01kg of benzotriazole into 96.69kg of alkaline electrolyzed water, mix and stir, and adjust the solution to pH 9.8 with sodium hydroxide , an environmentally friendly long-life cutting fluid prepared for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com