Preparation method of long-term stable amphiphilic antifouling coating based on mussel bionics

An antifouling coating and amphiphilic technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as weak adhesion, achieve good results, simple synthesis conditions, Excellent anti-protein adsorption and seaweed adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of phosphate buffer saline (PBS): add potassium dihydrogen phosphate, dodecahydrate · disodium hydrogen phosphate, sodium chloride (NaCl, potassium chloride (KCl) according to the weight ratio of 1.38:18:40:1 into deionized water and configured as phosphate buffered saline (PBS) at pH 7.4.

[0054] Prepare fluorescein isothiocyanate FITC-labeled bovine serum albumin BSA solution (concentration is 0.01mol / L, pH=7.4) and phosphate buffer saline (PBS) of pH7.4, then soak the membrane sample in it after 24 hours Take it out, wash the surface of the membrane with deionized water several times, wipe off the liquid remaining on the surface with test paper, and observe the qualitative adsorption of protein on the membrane surface with a fluorescence microscope (BX-51, Japan Olympus); for quantitative testing, use the BCA kit for bovine serum The protein solution was used for standard curve determination, and then the samples were soaked in PBS buffer solu...

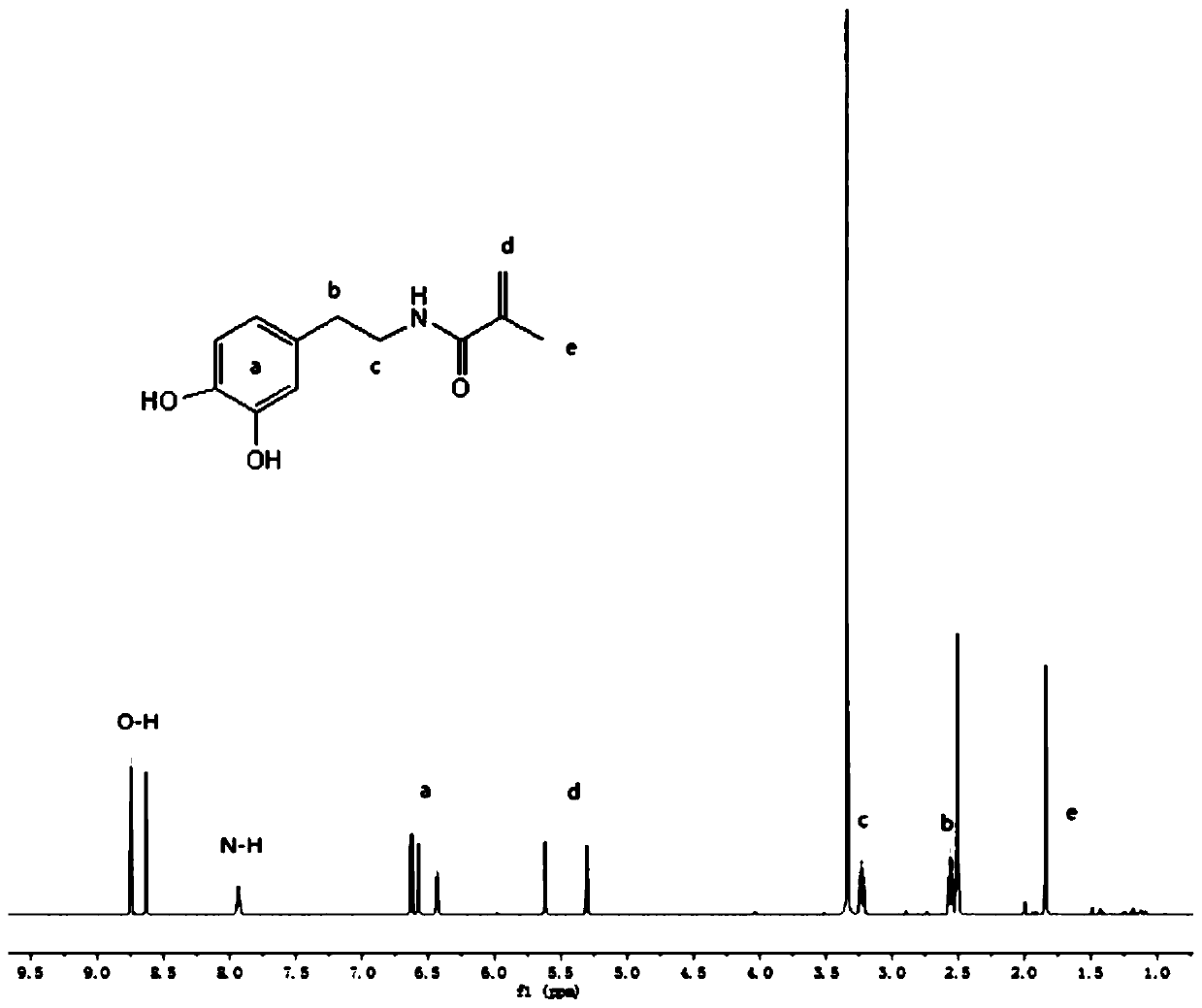

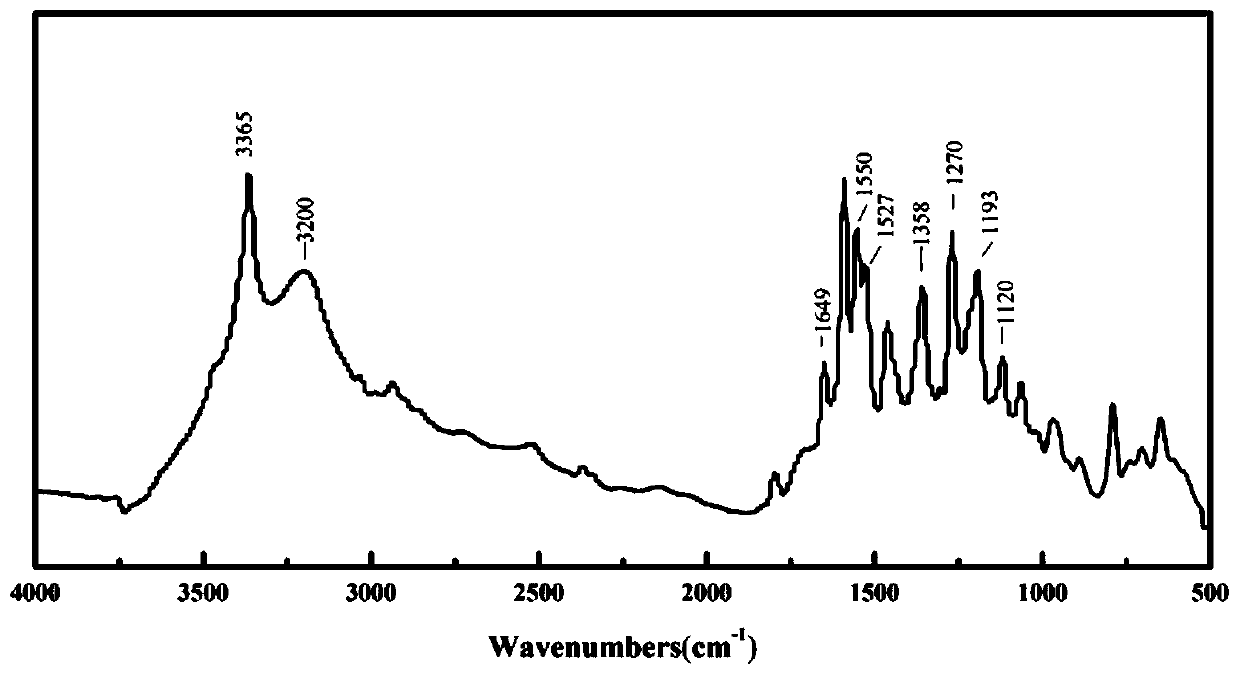

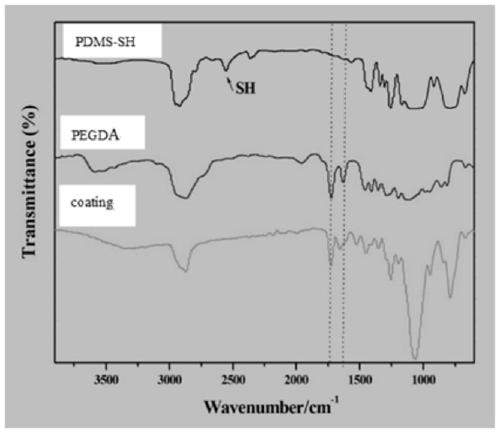

Embodiment 1

[0059] (1) Get 10 parts of sodium borate (the specific weight is 10 g), and dissolve 2 parts of sodium carbonate in 100 parts of deionized water, and get rid of the air therein. Take 3 parts of dopamine hydrochloride, dissolve in 15 parts of deionized water, dissolve 3 parts of methacrylic anhydride in 4.5 parts of tetrahydrofuran, add dropwise to the reaction solution, and then add 0.1mol / L sodium hydroxide solution to adjust the pH value to 8.5, react at 25°C for 36 hours. The reaction mixture was dissolved in 50 parts of ethyl acetate, and the solution was filtered to adjust the pH of the filtrate to 2.0. Extract three times with ethyl acetate, add 2 parts of anhydrous magnesium sulfate to the extracted mixed solution, concentrate the mixed solution after removing water for 12 hours, quickly pour 20 parts of n-hexane and ethyl acetate mixed solution (volume ratio 0.25) , freeze crystallization to obtain a white crystalline powder, dry it in a vacuum oven, and store it in a...

Embodiment 2

[0063] (1) Get 15 parts of sodium borate (the specific weight is 15g), dissolve 2 parts of sodium carbonate in 100 parts of deionized water, and get rid of the air therein. Take 3 parts of dopamine hydrochloride, dissolve in 15 parts of deionized water, dissolve 4 parts of methacrylic anhydride in 6 parts of tetrahydrofuran, add dropwise to the reaction solution, and adjust the pH value to 8.5, react at 30°C for 24 hours. The reaction mixture was dissolved in 50 parts of ethyl acetate, then the solution was filtered off, and the pH of the filtrate was adjusted to 2.0. Extract three times with ethyl acetate, add 2 parts of anhydrous magnesium sulfate to the extracted mixture, and remove water for 12 hours. Finally, the mixed solution is concentrated, quickly poured into a mixed solution of 25 parts of n-hexane and ethyl acetate (volume ratio 0.3), frozen and crystallized to obtain a white crystal powder, which is dried in a vacuum oven and stored in a vacuum. amides.

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com