Polyimide/polytetrafluoroethylene composite membrane for insulation of electric wire and cable and preparation method thereof

A technology of polytetrafluoroethylene and polyimide, applied in the direction of insulated conductors, insulated cables, chemical instruments and methods, etc., can solve the problems of high equipment requirements, complicated process, and inability to cure at room temperature, and achieve good insulation performance, The effect of excellent mechanical properties and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

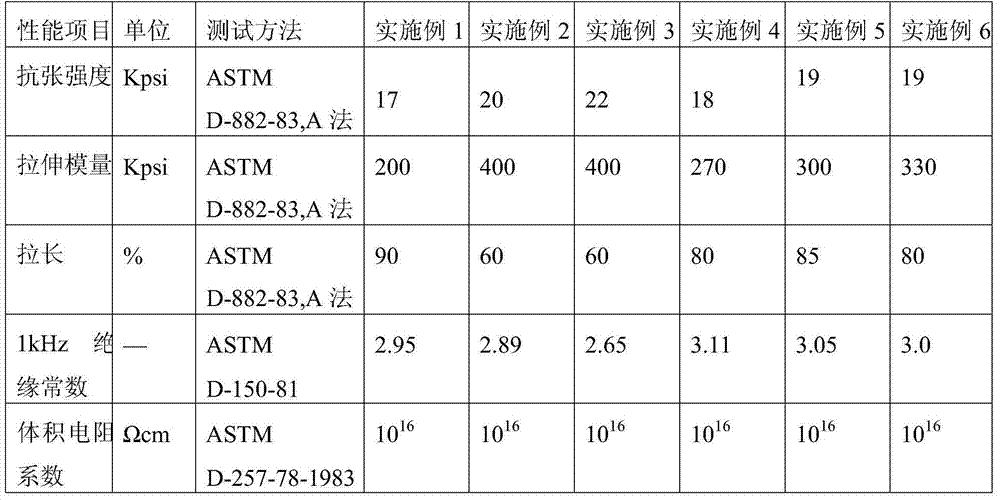

Examples

Embodiment 1

[0053] (1) 20g of 13X molecular sieve with a particle size of 20nm was washed with 0.1mol / L acetic acid solution and distilled water until the pH value was 6-7, and then dried in an oven at 180°C for 4h.

[0054] (2) Dissolve 0.02g of isopropyl triisostearate titanate coupling agent in 100ml of ethyl acetate solvent, add the 13X molecular sieve treated in step (1) while stirring, raise the temperature to 50°C, and react 1h, filter out molecular sieves. Next, the filtered 13X molecular sieve was first dried at 100° C. for 1 hour, and then further dried at 150° C. for 4 hours to obtain a 13X molecular sieve surface-modified by a coupling agent.

[0055] (3) Dissolve 0.008g of 13X molecular sieve surface-modified by coupling agent in 23.5g of DMF, then add 3.96g of 4,4'-diaminodiphenyl ether (ODA), after it is completely dissolved, add 4.36g of phenylene Tetraformic dianhydride (PMDA), stirred for 3 hours, and added 23.5 g of solvent toluene, and continued to stir for 0.5 hours ...

Embodiment 2

[0060] (1) 20g of 4A molecular sieve with a particle size of 30nm was washed with 0.1mol / L acetic acid solution and distilled water until the pH value was 6-7, and then dried in an oven at 180°C for 4h.

[0061] (2) Dissolve 0.2g of isopropyl triisostearate titanate coupling agent in 100ml of ethyl acetate solvent, add the 4A molecular sieve treated in step (1) while stirring, heat up to 54°C, and react 1h, filter out molecular sieves. Next, the filtered 4A molecular sieve was first dried at 100° C. for 1 hour, and then further dried at 150° C. for 4 hours to obtain a 4A molecular sieve surface-modified by the coupling agent.

[0062] (3) Dissolve 0.08g of 4A molecular sieve surface-modified by the coupling agent in 23.5g of NMP, then add 3.96g of 4,4'-diaminodiphenyl ether (ODA), after it is completely dissolved, add 4.36g of pyromellitic tetra Formic acid dianhydride (PMDA), stirred for 3 hours, and 23.5 g of solvent ethanol was added, and stirred for 0.5 hours to prepare p...

Embodiment 3

[0067] (1) 20g of 5A molecular sieve with a particle size of 50nm was washed with 0.1mol / L acetic acid solution and distilled water until the pH value was 6-7, and then dried in an oven at 180°C for 4h.

[0068] (2) Dissolve 0.4g of isopropyl tris(dioctylpyrophosphate acyloxy) titanate coupling agent in 100ml of ethyl acetate solvent, and add the 5A molecular sieve treated in step (1) while stirring , heated up to 50°C, reacted for 1h, and filtered out molecular sieves. Next, the filtered 5A molecular sieve was first dried at 100° C. for 1 hour, and then further dried at 150° C. for 4 hours to obtain a 5A molecular sieve surface-modified by the coupling agent.

[0069] (3) Dissolve 0.4g of 5A molecular sieve surface-modified by the coupling agent in 23.5g of NMP, then add 3.64g of 4,4'-diaminodiphenyl ether (ODA), after it is completely dissolved, add 4.36g of pyromellitic tetra Formic acid dianhydride (PMDA), stirred for 3 hours, and 23.5 g of solvent ethanol was added, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com