High-strength conductive hydrogel based on polyethyleneglycol diacrylate crosslinking and preparation method thereof

A polyethylene glycol diacrylate and conductive hydrogel technology, applied in the biological field, can solve the problems of difficult processing, uneven distribution of conductive components, cumbersome preparation methods of conductive hydrogels, etc., and achieves a simple and easy preparation method. performance, good biocompatibility, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

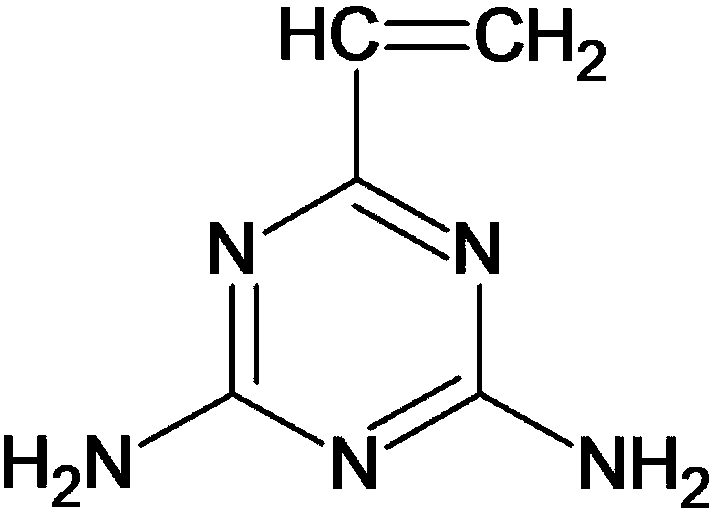

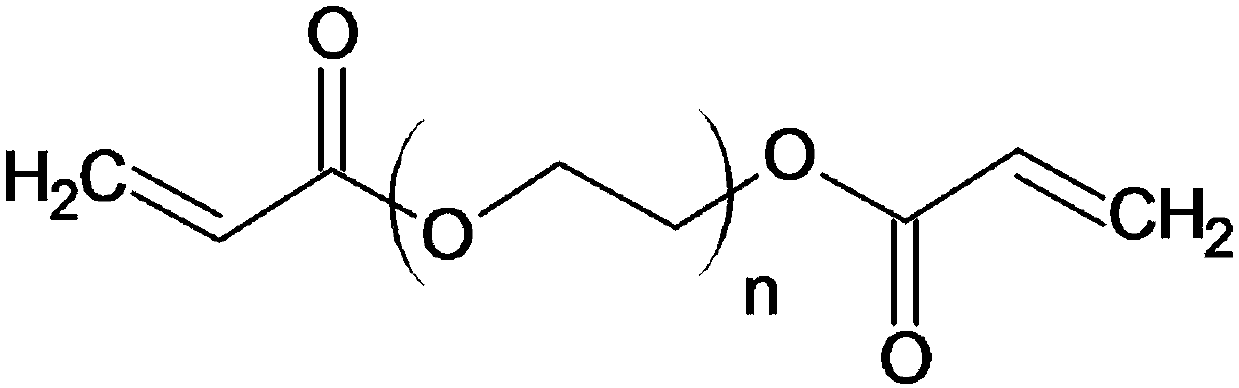

[0023]Example 1 Preparation of undoped 2-vinyl-4,6-diamino-1,3,5-triazine / polyethylene glycol diacrylate conductive hydrogel

[0024] Dissolve 320 mg of 2-vinyl-4,6-diamino-1,3,5-triazine and 160 mg of polyethylene glycol diacrylate in 2400 μL of dimethylsulfoxide. Then 7.2 mg of dibenzoyl peroxide was added and dissolved, and finally 7.2 μL of N,N-dimethylaniline was added. The mixture was injected into a closed mold and maintained for 24 hours to ensure sufficient initiation of polymerization. Then open the mold and take out the gel, soak it in deionized water to make it reach the swelling balance (such as soaking for 7 days, change the water every 12h to reach the swelling balance), and the obtained prepared undoped 2-vinyl-4 , 6-diamino-1,3,5-triazine / polyethylene glycol diacrylate conductive hydrogel, denoted as PVDT-PEGDA / PEDOT / PSS-0.

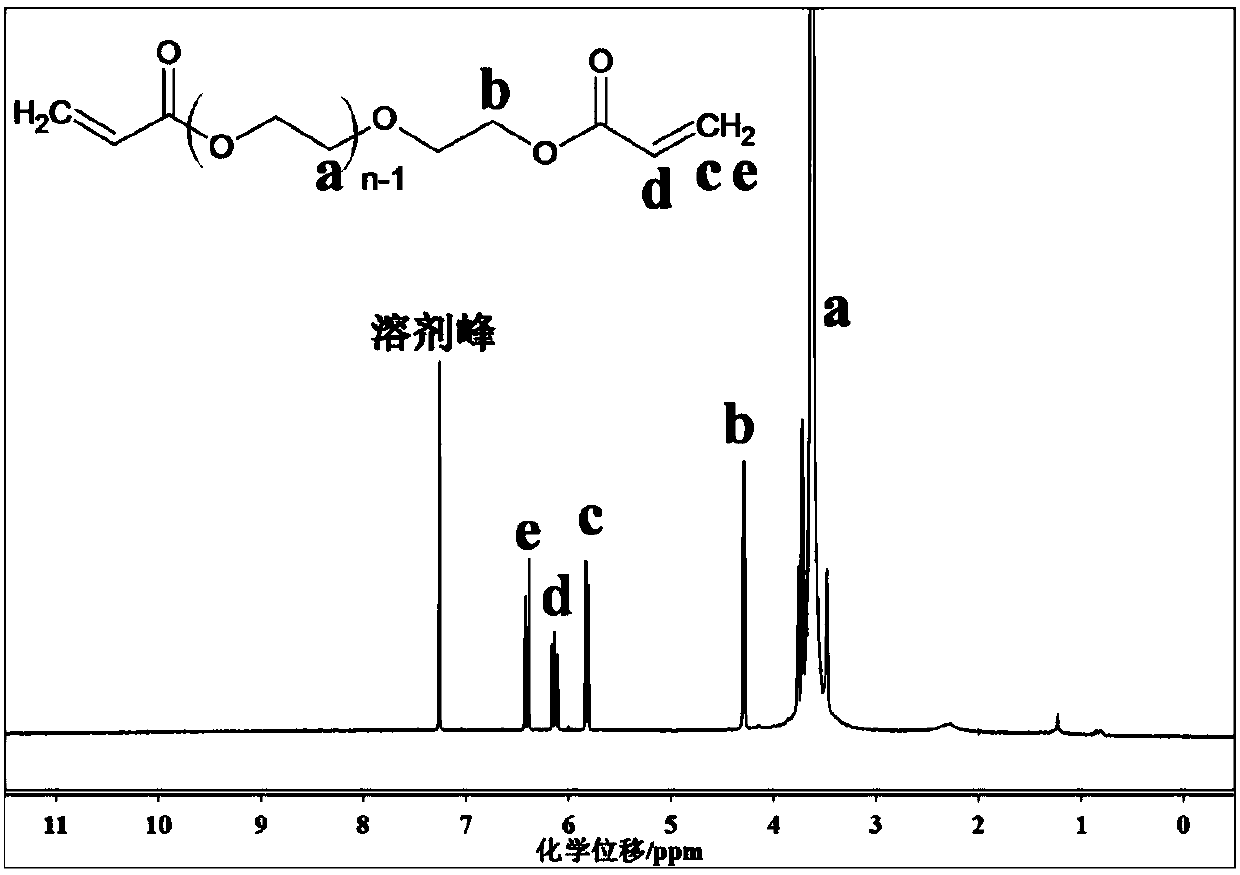

[0025] Utilize Fourier transform infrared spectrometer (English name: Attenuated total reflection Fouriertransform infrared spectrosco...

Embodiment 2

[0026] Example 2 Preparation of doped 2-vinyl-4,6-diamino-1,3,5-triazine / polyethylene glycol diacrylate conductive hydrogel

[0027] Dissolve 320 mg of 2-vinyl-4,6-diamino-1,3,5-triazine and 160 mg of polyethylene glycol diacrylate in 2400 μL of dimethyl sulfoxide, and add 120 μL of poly(3, 4-ethylenedioxythiophene)-poly(styrenesulfonic acid). Then 7.2 mg of dibenzoyl peroxide was added and dissolved, and finally 7.2 μL of N,N-dimethylaniline was added. The mixture was injected into a closed mold and maintained for 24 hours to ensure sufficient initiation of polymerization. Then open the mold and take out the gel, soak it in deionized water to make it reach the swelling balance (such as soaking for 7 days, change the water every 12h to reach the swelling balance), the obtained doped 2-vinyl-4, 6-diamino-1,3,5-triazine / polyethylene glycol diacrylate conductive hydrogel, denoted as PVDT-PEGDA / PEDOT / PSS-5.

[0028] 2-Vinyl-4,6-diamino-1,3,5-triazine is a monomer with amino gro...

Embodiment 3

[0030] The mechanical properties of the two hydrogels prepared above were tested by the following methods. The mechanical performance test was carried out on an electronic universal testing machine (Jinan Times Co., Ltd.), and the hydrogel before the test reached a swelling equilibrium in deionized water. The sample size of the tensile mechanical property test is 20mm×10mm, the thickness is 500μm, and the tensile rate is 50mm / min; the sample size of the compressive mechanical property test is a cylinder with a diameter of 10mm and a height of 8mm, and the compression rate is 10mm / min. The tensile and compressive strengths of the hydrogels before and after doping can reach the level of MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com