Texturing additive for monocrystalline silicon surface treatment, texturing agent and monocrystalline silicon surface texturing method

A surface treatment, single crystal silicon technology, applied in the direction of post treatment, single crystal growth, single crystal growth, etc., can solve the problems of strong solution corrosion and poor suede formation, so as to achieve one-sided cleanliness and controllable suede size. , the effect of high cashmere rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

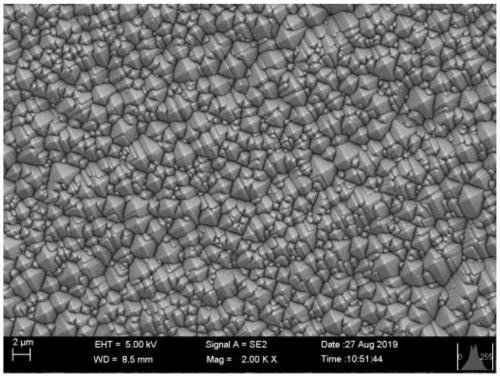

Image

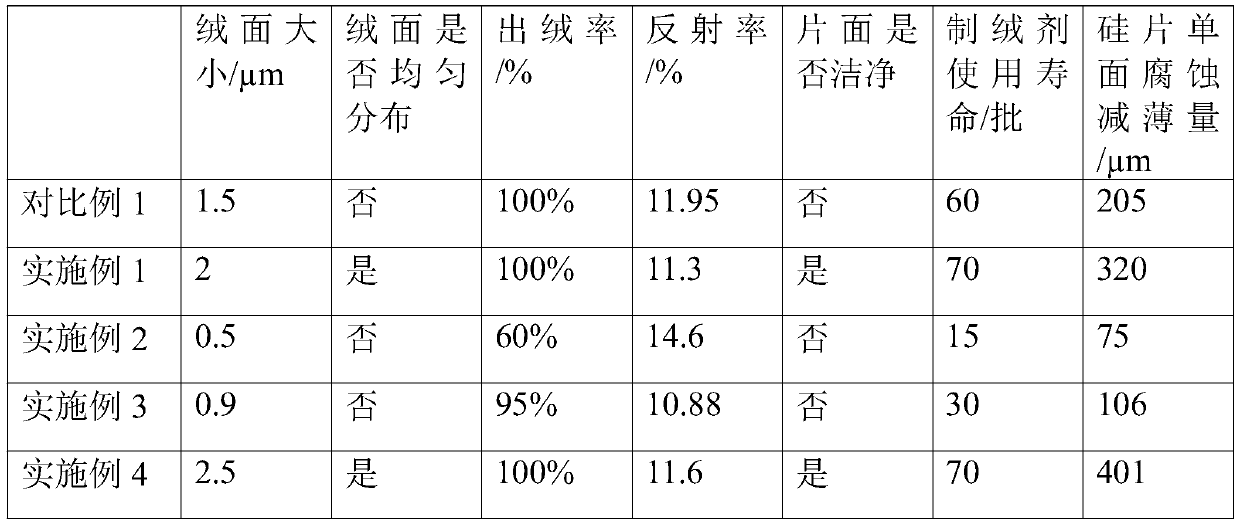

Examples

Embodiment 1

[0031] The texturizing additive for the surface treatment of monocrystalline silicon is made up of the following percentages by weight: sodium lignosulfonate 0.05%, polynaphthalene sodium sulfonate 0.0001%, polyethylene glycol 1.3%, diethylene glycol butyl ether 3.5%, Potassium perfluorohexylsulfonate 1.5%, sodium diethyloctanoate 0.26%, and the balance is water.

[0032] Add the above-mentioned texturizing additive to 1.5% sodium hydroxide or potassium hydroxide solution, and mix evenly at a temperature of 20°C, wherein the mass ratio of the texturizing additive to the alkali solution is 1:100 to obtain a single crystal silicon surface treatment The velvet used.

[0033] The method for making texture on the surface of monocrystalline silicon comprises the following steps:

[0034] Step 1: Pre-treat the monocrystalline silicon wafer. The pretreatment process is as follows: the first step, put the monocrystalline silicon wafer in absolute ethanol for 8 minutes, and clean it wi...

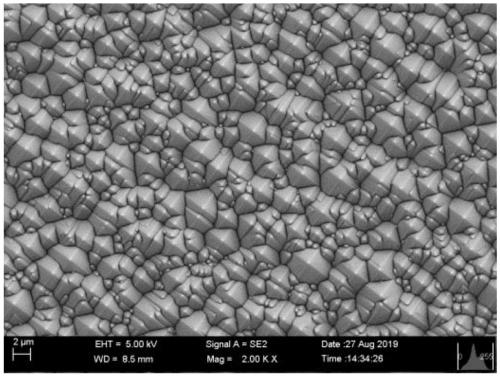

Embodiment 2

[0037] In Example 2, the surface texturing temperature of the monocrystalline silicon is 78° C., the texturing time is 300 s, and other parameters are the same as those in Example 1.

Embodiment 3

[0039] In Example 3, the surface texturing temperature of monocrystalline silicon is 78° C., the texturing time is 600 s, and other parameters are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com