Preparation method of high-performance PP fiber

A high-performance, fiber-based technology, applied in the field of materials, can solve the problems of poor compatibility, difficult to prepare high-performance, and difficult to evenly disperse graphene oxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Prepare piranha solution, prepare piranha solution with 98wt% concentrated sulfuric acid and 30wt% hydrogen peroxide at a volume ratio of 3:1, add graphene oxide raw material provided by Hangzhou Gaoxene Technology Co., Ltd., stir at room temperature for half an hour, filter , rinsed with pure water and dried, added 1g of graphene oxide treated with piranha solution into 50.0mL of isopropanol, added dropwise 0.01g of silane coupling agent KH570, stirred at 40°C for 4h, and spray-dried to obtain modified oxide Graphene raw material.

[0016] (2) Weigh 100g of propylene monomer and 0.5g of modified graphene oxide, mix them evenly, and carry out prepolymerization under the catalysis of polypropylene catalyst under normal temperature conditions, then carry out polymerization at about 70°C, polymerize and then pelletize to prepare Raw material for spinning. Usually, the polypropylene catalyst includes a cocatalyst, an electron donor and a Z-N catalyst. The prepolymeriza...

Embodiment 2

[0027] (1) Prepare piranha solution, prepare piranha solution with 98% concentrated sulfuric acid and 30% hydrogen peroxide at a volume ratio of 3:1, add graphene oxide raw material, stir for half an hour at room temperature, rinse and filter with pure water and dry, and Add 3 g of graphene oxide treated with piranha solution into 150.0 mL of isopropanol, add dropwise 0.02 g of silane coupling agent KH570, stir at 40°C for 4 hours, wash with water, filter, and spray dry to obtain the raw material of modified graphene oxide.

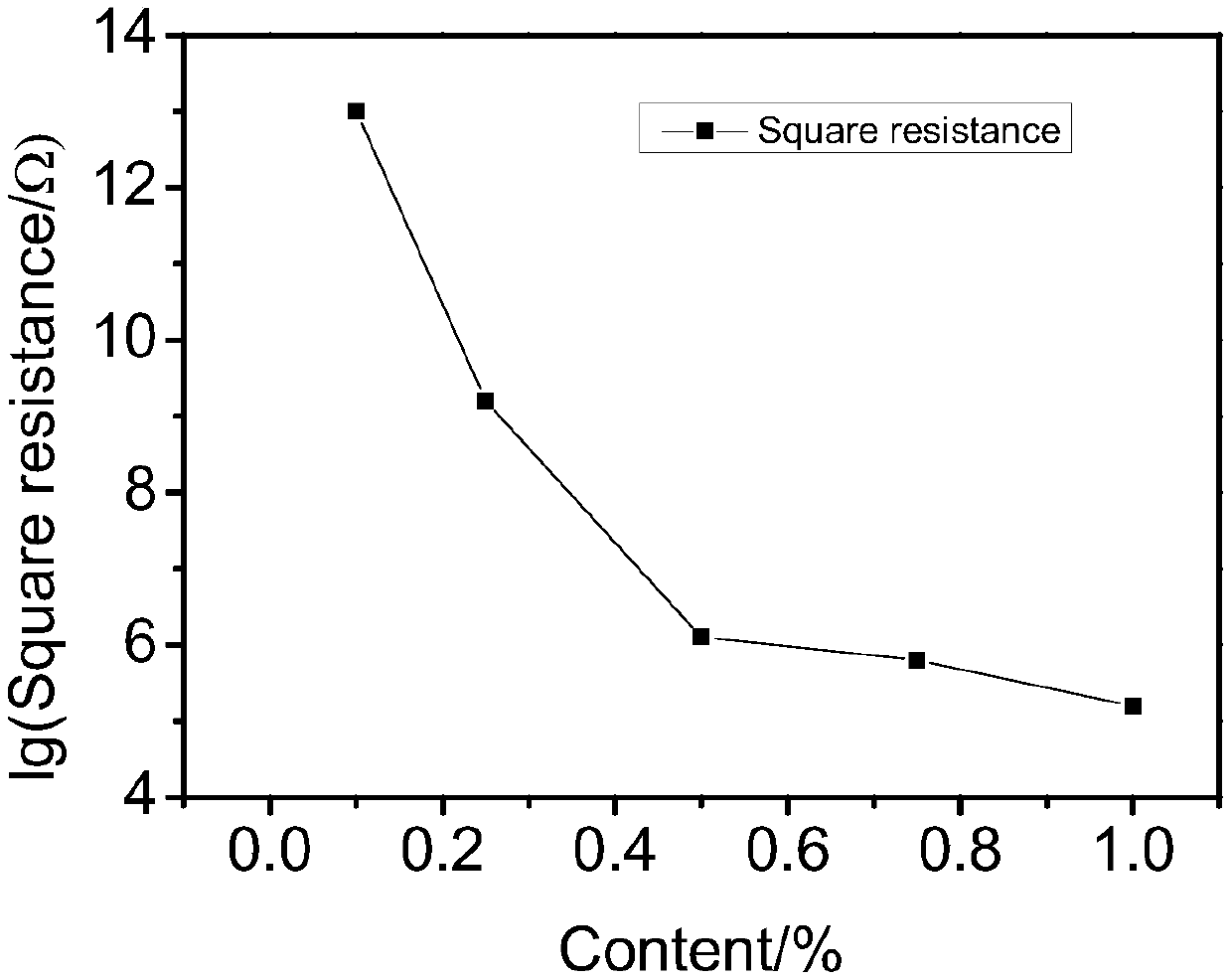

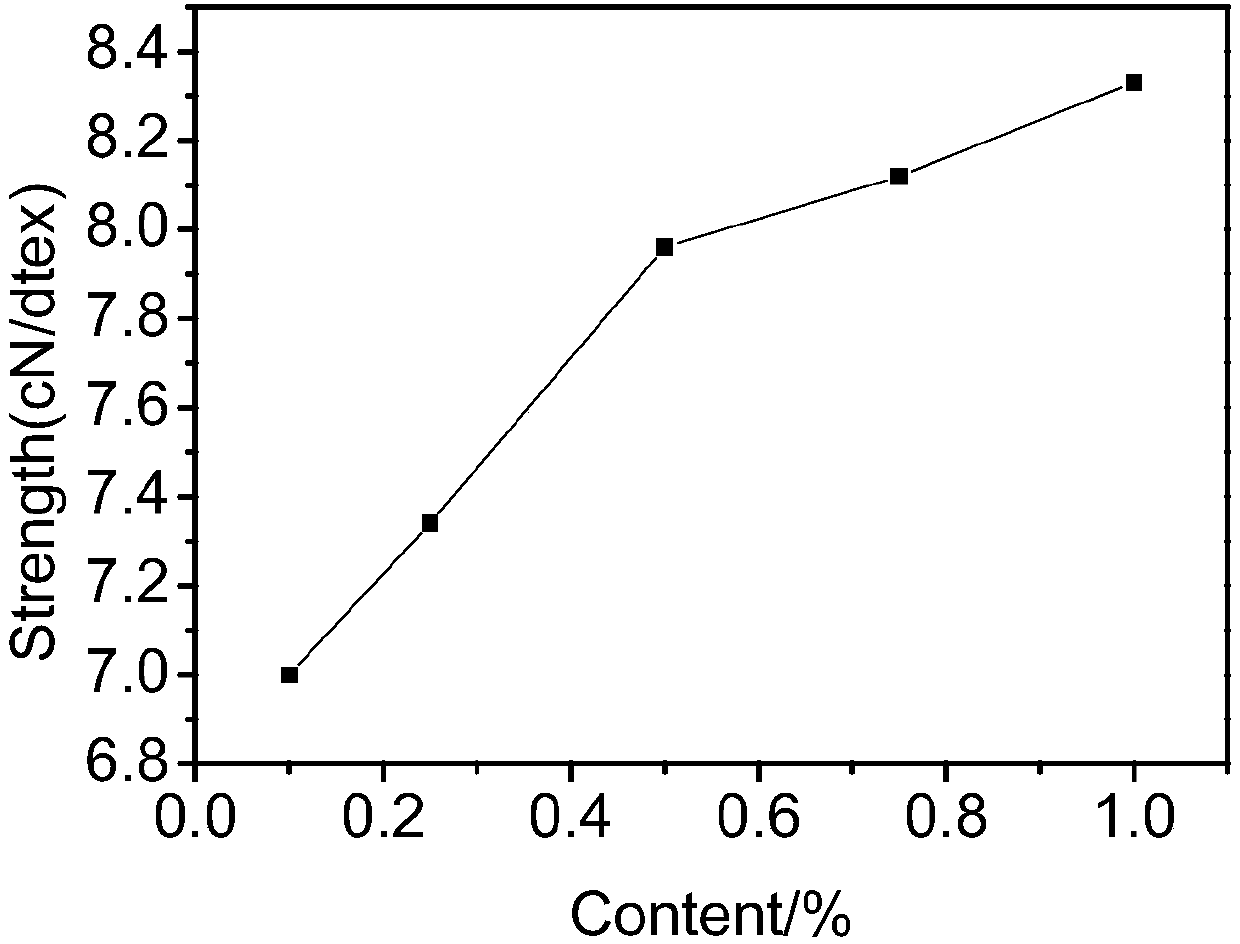

[0028] (2) Weigh 100g of propylene monomer, weigh 0.1g, 0.25g, 0.5g, 0.75g, 1g of modified graphene oxide respectively, mix evenly, and carry out prepolymerization under the catalysis of polypropylene catalyst under normal temperature conditions , and then polymerized at about 70°C, polymerized and then pelletized to prepare spinning raw materials. Usually, the polypropylene catalyst includes a cocatalyst, an electron donor and a Z-N catalyst. The prepoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com