Graphene aerogel thermal fabric

A graphene airgel and graphene technology, applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems of low thermal conductivity, no warmth and comfort, and light and quick-drying thermal fabrics to achieve softness and comfort , the effect of promoting blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

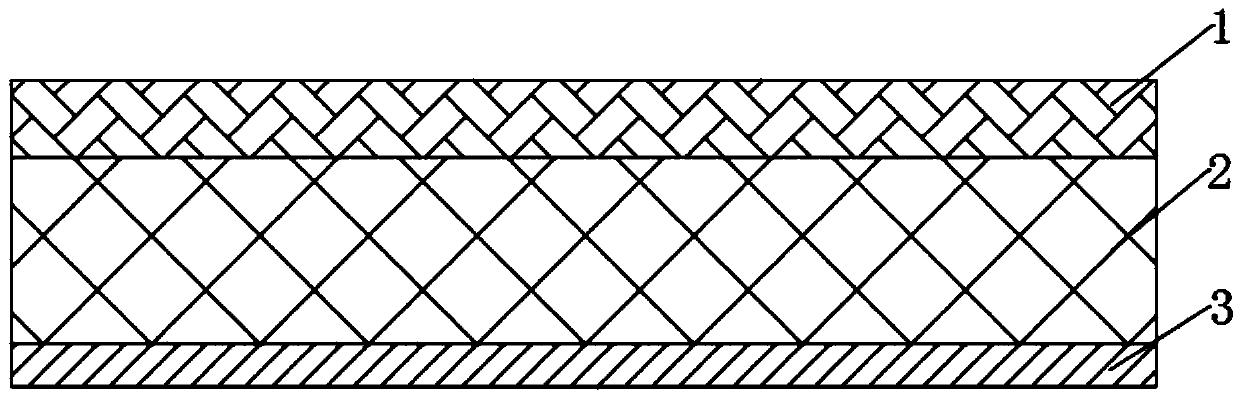

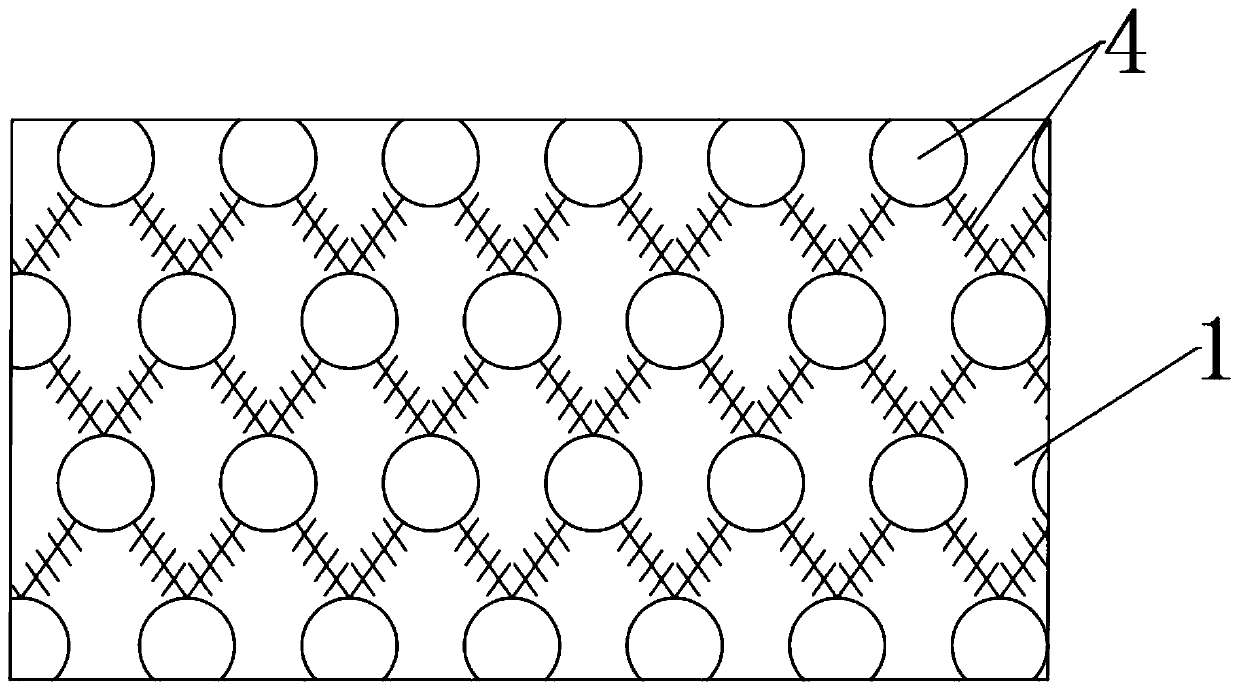

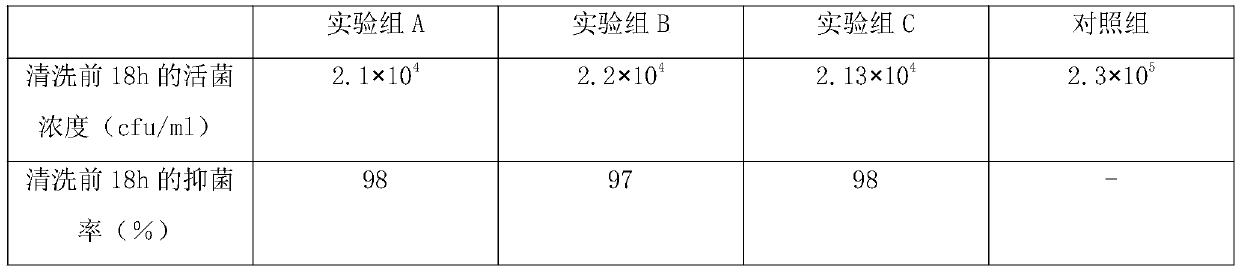

[0022] A graphene airgel thermal fabric, comprising an upper layer 1, a spacer layer 2 and a lower layer 3, the spacer layer 2 connects the upper layer 1 and the lower layer 3, the upper layer 1 is woven with cellulose fiber yarn, and the spacer layer 2 adopts Weaving of silica airgel yarn, the lower layer 3 is woven with graphene pure spinning yarn, the upper layer 1 and the lower layer 3 are woven together by airgel yarn, and the upper layer 1 has a uniform air-permeable structure 4, The air-permeable structure 4 is evenly arranged circular air holes and air grooves. The spacer layer 2 connects the upper layer 1 and the lower layer 2 by weaving. The upper layer 1, the spacer layer 2 and the lower layer 3 are integrally woven. 1. The spacer layer 2 and the lower layer 3 are fed by TECHNIT D3 circular knitting machine with three threads, the cellulose fiber yarn is used as the bottom yarn, the graphene yarn and the airgel yarn are used as sand filling, and the three threads are...

Embodiment 2

[0024] A graphene airgel thermal fabric, comprising an upper layer 1, a spacer layer 2 and a lower layer 3, the spacer layer 2 connects the upper layer 1 and the lower layer 3, the upper layer 1 is woven with cellulose fiber yarn, and the spacer layer 2 adopts Silica airgel yarn weaving, lower layer 3 is graphene and silica airgel blended yarn weaving, upper layer 1 and lower layer 3 are woven together by airgel yarn, upper layer 1 has Uniform breathable structure 4, the spacer layer 2 connects the upper layer 1 and the lower layer 2 by weaving, the upper layer 1, the spacer layer 2 and the lower layer 3 are integrally woven, and the upper layer 1, the spacer layer 2 and the lower layer 3 are passed through TECHNIT D3 circular knitting machine, three-thread yarn feeding, cellulose fiber yarn as the base yarn, graphene yarn and airgel yarn as sanding, three threads are woven at the same time, so that the airgel yarn is completely hidden in the cellulose fiber yarn The upper lay...

Embodiment 3

[0027] A graphene airgel thermal fabric, comprising an upper layer 1, a spacer layer 2 and a lower layer 3, the spacer layer 2 connects the upper layer 1 and the lower layer 3, the upper layer 1 is woven with cellulose fiber yarn, and the spacer layer 2 adopts Weaving of silica airgel yarn, the lower layer 3 is woven with graphene pure spinning yarn, the upper layer 1 and the lower layer 3 are woven together by airgel yarn, and the spacer layer 2 is connected by weaving the upper layer 1 and the lower layer 3. The lower layer 2, the upper layer 1, the spacer layer 2 and the lower layer 3 are integrally woven and formed, and the upper layer 1, the spacer layer 2 and the lower layer 3 are passed through a TECHNIT D3 type circular machine to perform three-thread feeding, and the cellulose fiber yarn As the bottom yarn, graphene yarn and airgel yarn are used as sanding, and the three threads are woven at the same time, so that the airgel yarn is completely hidden between the cellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com