Flexible insulator for grid component of ion thruster

A technology of ion thrusters and insulators, which is applied in the direction of using plasma, reverse thrust devices, machines/engines, etc., can solve the problem of reducing the variation of the grid spacing of the grid assembly, the inability to effectively release the grid sheet, and the variation of the grid spacing Increase and other problems, to achieve the effect of reducing the failure rate, improving work reliability and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

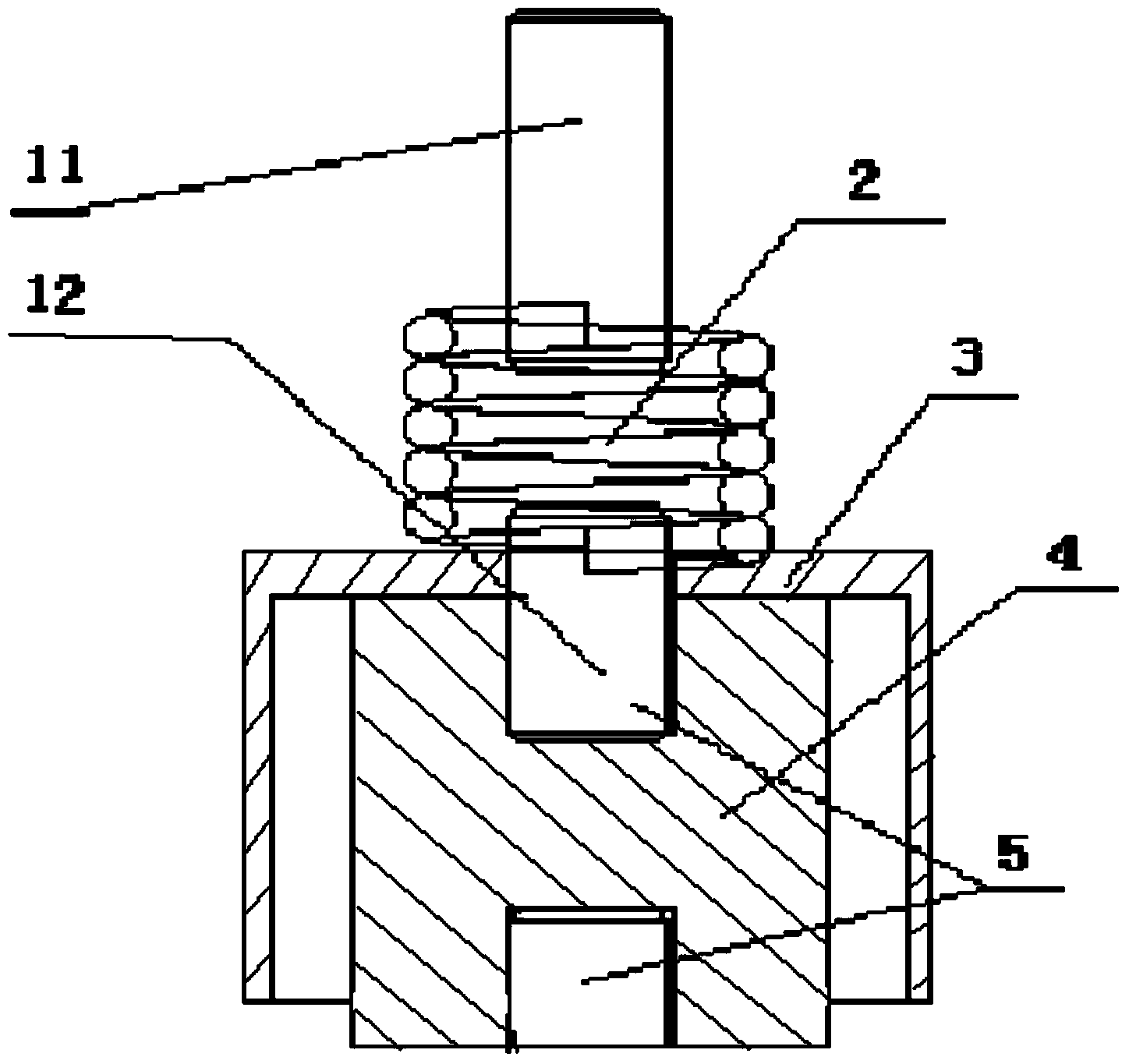

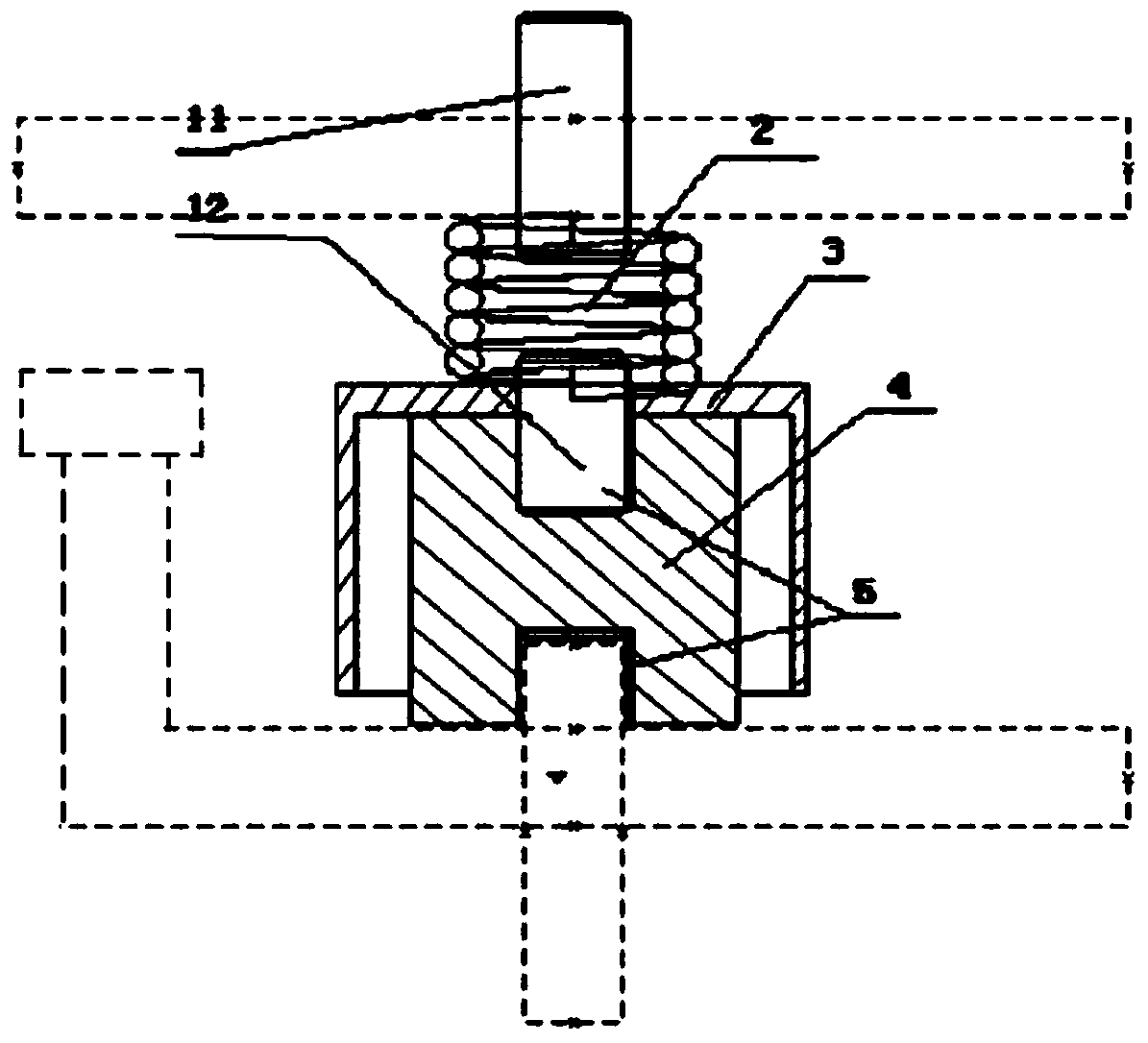

[0034] A flexible insulator is applied to the insulating support of the grid assembly of a 30cm ion thruster (working power 2.5kW-5.0kW). The maximum outline size of the flexible insulator is Ф13mm×16mm, and the specific dimensions are screw 11 and 12: M3×4mm; shape of spring 2: Ф5mm×6mm; shield 3: Ф13mm×8mm; insulating ceramic 4: Ф10mm×9mm; metal thread Hole 5: M3×4mm.

[0035] Use 12 flexible insulators as the insulating support of the 30cm ion thruster grid assembly, the insulators are evenly distributed around the 2 grid sheets, the first screw 11 passes through 12 small holes of Ф3.2mm in the grid sheet (0.5mm thick), Use M3 nuts to connect the grid sheet to the insulator, use 12 M3×4mm bolts to pass through 12 small holes of Ф3.2mm in the grid support ring, and connect with the metal threaded holes, and the grid support ring and the thrust The device is fixedly connected. The grid sheet releases the thermal stress deformation through the spring of the flexible insulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com