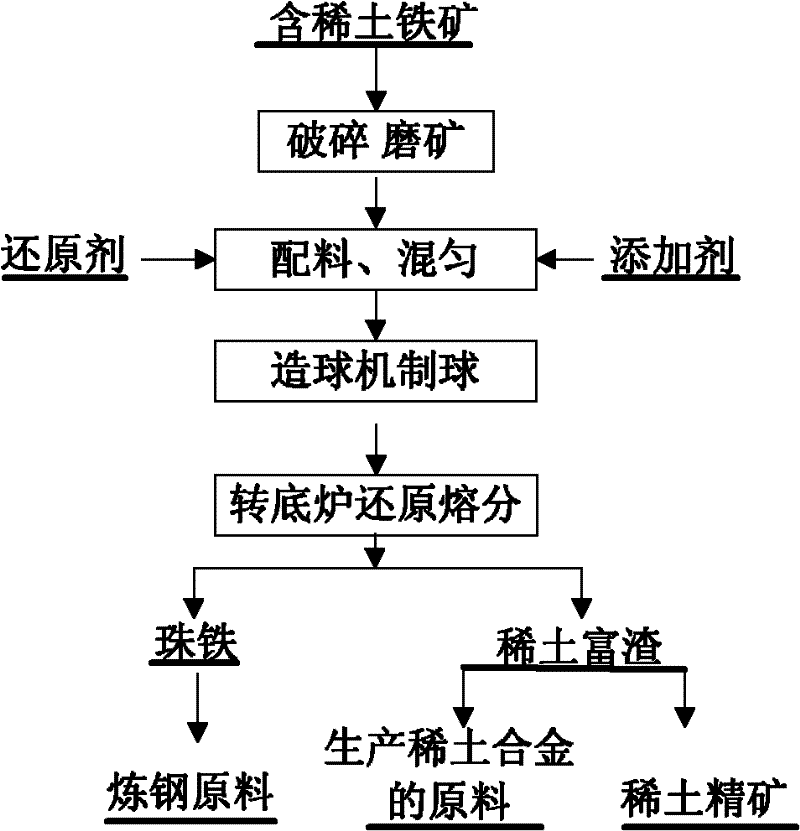

Method for separating and enriching iron and rare earth in rare earth crude ore containing iron

A technology for separation and enrichment of rare earths, which is applied in the field of ironmaking and can solve problems such as difficulty in enrichment and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

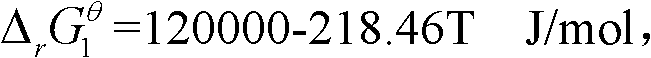

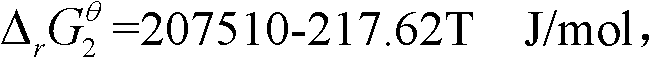

Method used

Image

Examples

Embodiment 1

[0055] Will contain 30.20% iron, containing RE 2 o 3 5.50% raw ore powder, 13% coal powder by weight of iron-containing rare earth raw ore, and 2% binder by weight of the total of iron-containing rare earth raw ore and coal powder are transported to the mixer through a belt for mixing, and the mixing is adjusted. Homogenize moisture to 7%. The mixed material is conveyed to the double-roller ball pressing machine through the belt to make carbon-containing pellets, the pressure is 15MPa, and the size of the pellets is 40×30×20mm pillow-shaped ellipsoid. Lay 3-5mm thick carbon powder on the refractory material at the bottom of the rotary hearth furnace, and evenly spread the dried pellets on the carbon powder, generally 1-2 layers. The temperature in the rotary hearth furnace is 1400-1450°C, the residence time of the pellets in the rotary hearth furnace is 9-20 minutes, and then the pellets are discharged from the discharge port by the discharge machine. The discharged product...

Embodiment 2

[0060] will contain RE 2 o 3 6.56% iron-containing rare earth raw ore powder, 12% iron-containing rare earth raw ore weight coal powder, 2% iron-containing rare earth raw ore additive MgO, and 2% binder of the total weight of iron-containing rare earth raw ore and coal powder It is transported to the mixer through a belt for mixing, and the moisture content of the mixed material is adjusted to 8%. The mixed material is conveyed to the double-roller ball pressing machine through the belt to make carbon-containing pellets, the pressure is 15MPa, and the size of the pellets is 40×30×20mm pillow-shaped ellipsoid. Lay 3-5mm thick carbon powder on the refractory material at the bottom of the rotary hearth furnace, and evenly spread the dried pellets on the carbon powder, generally 1-2 layers. The temperature in the rotary hearth furnace is 1400-1450°C, the residence time of the pellets in the rotary hearth furnace is 9-20 minutes, and then the pellets are discharged from the disch...

Embodiment 3

[0068] will contain RE 2 o 3 5.95% iron-containing rare earth raw ore powder, 12% iron-containing rare earth raw ore weight coal powder, 5% iron-containing rare earth raw ore additive MgO and 2% binder of the total weight of iron-containing rare earth raw ore and coal powder It is transported to the mixer through a belt for mixing, and the moisture content of the mixed material is adjusted to 9%. The mixed material is conveyed to the double-roller ball pressing machine through the belt to make carbon-containing pellets, the pressure is 15MPa, and the size of the pellets is 40×30×20mm pillow-shaped ellipsoid. Lay 3-5mm thick carbon powder on the refractory material at the bottom of the rotary hearth furnace, and evenly spread the dried pellets on the carbon powder, generally 1-2 layers. The temperature in the rotary hearth furnace is 1400-1450°C, the residence time of the pellets in the rotary hearth furnace is 9-20 minutes, and then the pellets are discharged from the discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com