Synthesis method of novel SBQ photosensitive monomer

A synthesis method and monomer technology, which are applied in the synthesis field of new SBQ photosensitive monomers, can solve the problems of large operation load of equipment, reduced reaction selectivity, and increased environmental protection pressure in waste acid water treatment volume, and achieve a simple production process and environmental protection. Friendly, overcoming harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

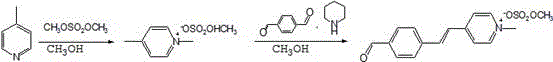

[0034] Synthetic method of the present invention specifically comprises the steps:

[0035] (1) Synthesis of intermediate 4-picoline (containing substituted picoline) quaternary ammonium salt:

[0036] Add methanol and 4-picoline into the reactor, add dimethyl sulfate dropwise under the condition of lower than 10°C, and keep the temperature under stirring for 5~8h after dropping, and the holding temperature is 20~50°C; The colorless transparent solution is the intermediate 4-picoline quaternary ammonium salt solution; wherein: the molar ratio of dimethyl sulfate and 4-picoline (containing substituted pyridine) is 1: (1 ~ 1.2); The amount added is 1 to 10 times the amount of 4-picoline.

[0037] (2) Product SBQ monomer synthesis:

[0038] Add methanol, terephthalaldehyde and a catalyst into the reactor, add dropwise or all at once the intermediate solution obtained in step (1) at the reflux temperature, and filter after reflux for 5 to 8 hours, freeze and crystallize the filt...

Embodiment 1

[0041] Embodiment 1 (adopting each described material proportion and temperature condition, reaction time)

[0042] 1) Synthesis of intermediate 4-picoline quaternary ammonium salt

[0043] Add 20 mL of methanol and 9.5 g of 4-picoline into the reaction flask, drop 13 g of dimethyl sulfate at a temperature lower than 10°C, and keep it at 20°C for 6 hours to obtain an intermediate solution for later use.

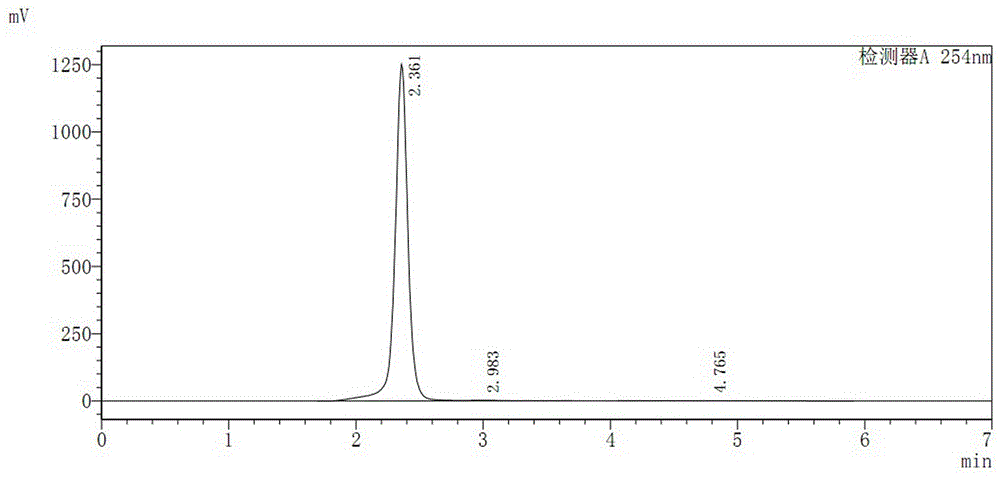

[0044] 2) Synthesis of SBQ

[0045] Add 20.7 grams of terephthalaldehyde, 1.0 grams of hexahydropyridine, and 30 mL of methanol into the reaction flask, and add the intermediate solution dropwise at reflux temperature. Wash 2 to 3 times to obtain 15 grams of SBQ crude product, the product in the filtrate can be further recovered, and the crude product yield is 63%.

[0046] 3) SBQ crude product purification

[0047] Add 15 grams of SBQ crude product and 25 grams of methanol to the reactor, stir in an oil bath at 80°C for 0.5h, filter, discard the filter cake impurities, ad...

Embodiment 2

[0052] 1) Synthesis of intermediate 4-picoline quaternary ammonium salt

[0053] Add 50 mL of methanol and 18 g of 4-picoline into the reaction flask, drop 25.3 g of dimethyl sulfate at a temperature lower than 10°C, and keep the temperature at 20°C for 5 hours to obtain an intermediate solution for later use.

[0054] 2) Synthesis of SBQ monomer

[0055] Add 70 grams of terephthalaldehyde, 3 grams of hexahydropyridine, and 100 mL of methanol into the reaction flask. At the reflux temperature, add the intermediate dropwise. After the dripping, continue to reflux for 6 hours, cool down to room temperature, filter, and wash twice with 500 mL of ethyl acetate. 40 grams of the crude product were obtained, and the yield of the crude product was 59%.

[0056] 3) SBQ monomer purification

[0057] Add 40 grams of crude SBQ and 72 grams of methanol to the reactor, reflux in an oil bath at 80°C for 0.5 h, filter, add 18 grams of water and 1.2 grams of acetic acid to the filtrate, diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com