Cesium-tungsten bronze heat absorbent, preparation thereof and application of cesium-tungsten bronze heat absorbent in transparent ABS infrared welding

A technology of cesium tungsten bronze and endothermic agent, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of unattainable aesthetic effect, dark color of welding place, poor aging resistance, etc. Good laser fusion welding effect, smooth weld seam, simple composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

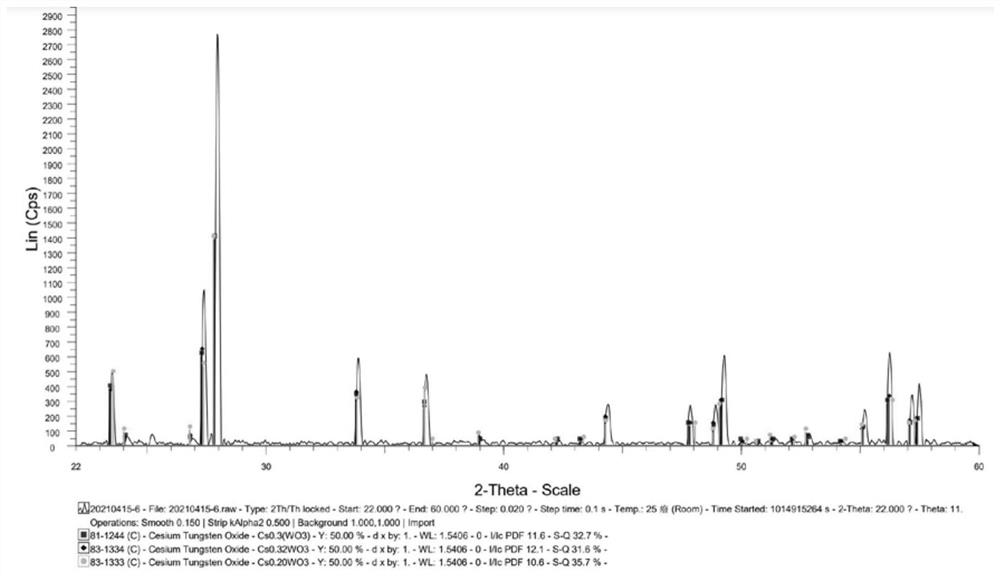

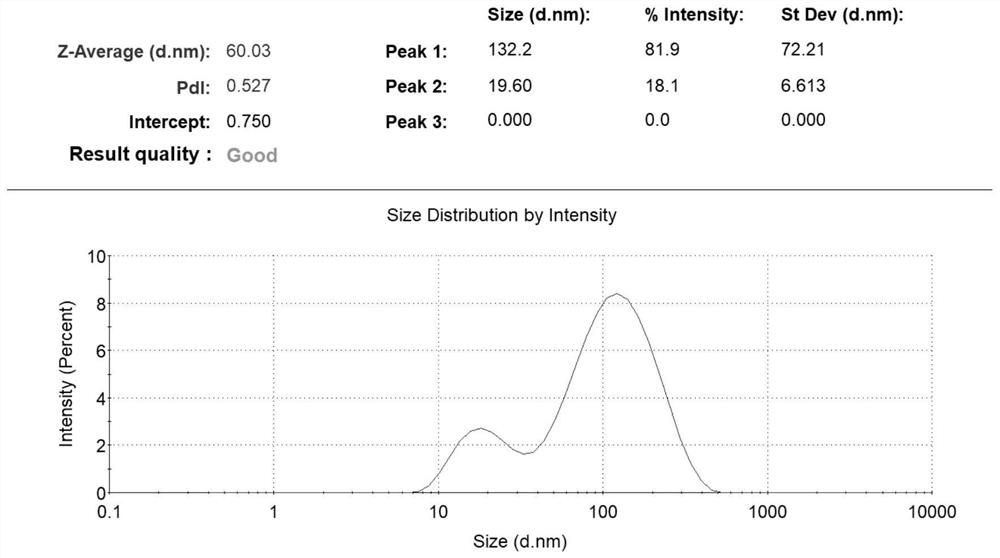

[0032] Step 1. Preparation of cesium tungsten bronze slurry: 5.7kg of toluene solvent and 0.3kg of dispersant were mixed and stirred for 30 minutes, and then 4.0kg of cesium tungsten bronze powder (Cs 0.2 WO 3 ), continue stirring and mixing for 30min, and the mixed slurry is ground to obtain a cesium tungsten bronze slurry with an average particle size of 60.03nm, and the particle size distribution is as follows: figure 2 .

[0033] Step 2. Preparation of cesium tungsten bronze endothermic agent: mix and stir 8.0kg transparent ABS resin (D90:100um), 1.5kg cesium tungsten bronze slurry, 0.2kg leveling agent, and 0.2kg acrylonitrile resin for 60 minutes to obtain cesium tungsten Bronze infrared heat absorber.

[0034] The cesium tungsten bronze endothermic agent prepared in Example 1 was applied to the place to be welded by 3D printing, and then welded. The welding test results are shown in Table 1.

Embodiment 2

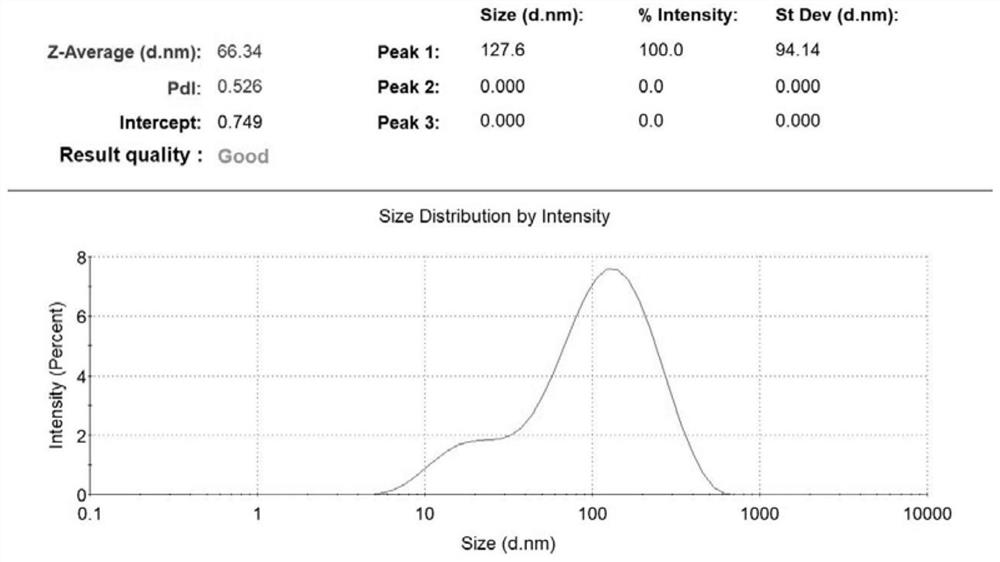

[0036] Step 1. Preparation of cesium tungsten bronze slurry: 4.5kg ethyl acetate and 0.5kg dispersant were mixed and stirred for 30min, then 5.0kg cesium tungsten bronze powder (Cs 0.3 WO 3 ), continue to stir and mix for 30min, and the mixed slurry is ground to obtain a cesium tungsten bronze slurry with an average particle diameter of 66.34nm, and the particle size distribution is as follows: image 3 .

[0037] Step 2. Preparation of cesium tungsten bronze endothermic agent: 8.6kg transparent ABS resin (D90:200um), 1.0kg cesium tungsten bronze slurry, 0.3kg leveling agent, 0.1kg acrylonitrile resin were stirred and mixed for 60 minutes to obtain cesium tungsten Bronze infrared heat absorber.

[0038] The cesium tungsten bronze endothermic agent prepared in Example 2 was applied to the place to be welded by silk screen printing, and then welded. The welding test results are shown in Table 1.

Embodiment 3

[0040] Step 1. Preparation of cesium tungsten bronze slurry: Mix and stir 5.1kg methyl ethyl ketone and 0.4kg dispersant for 30min, then add 4.5kg cesium tungsten bronze powder (Cs 0.32 WO 3 ), continue stirring and mixing for 30min, and the mixed slurry is ground to obtain a cesium tungsten bronze slurry whose average particle size is 73.99nm, and the particle size distribution is as follows: Figure 4 .

[0041] Step 2. Preparation of cesium tungsten bronze endothermic agent: 8.3kg of transparent ABS resin (D90:150um), 1.3kg of cesium tungsten bronze slurry, 0.25kg of leveling agent, and 0.17kg of acrylonitrile resin were stirred and mixed for 60 minutes to obtain cesium tungsten Bronze infrared heat absorber.

[0042] The cesium tungsten bronze endothermic agent prepared in Example 3 was coated on the place to be welded by 3D printing, and then welded. The welding test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com