Glyphosine intercalated structural selective infrared absorbing material as well as preparation method and application thereof

A technology of infrared absorption and glyphosate, which is applied in the direction of chemical instruments and methods, and other chemical processes, to achieve the effects of easy preparation, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

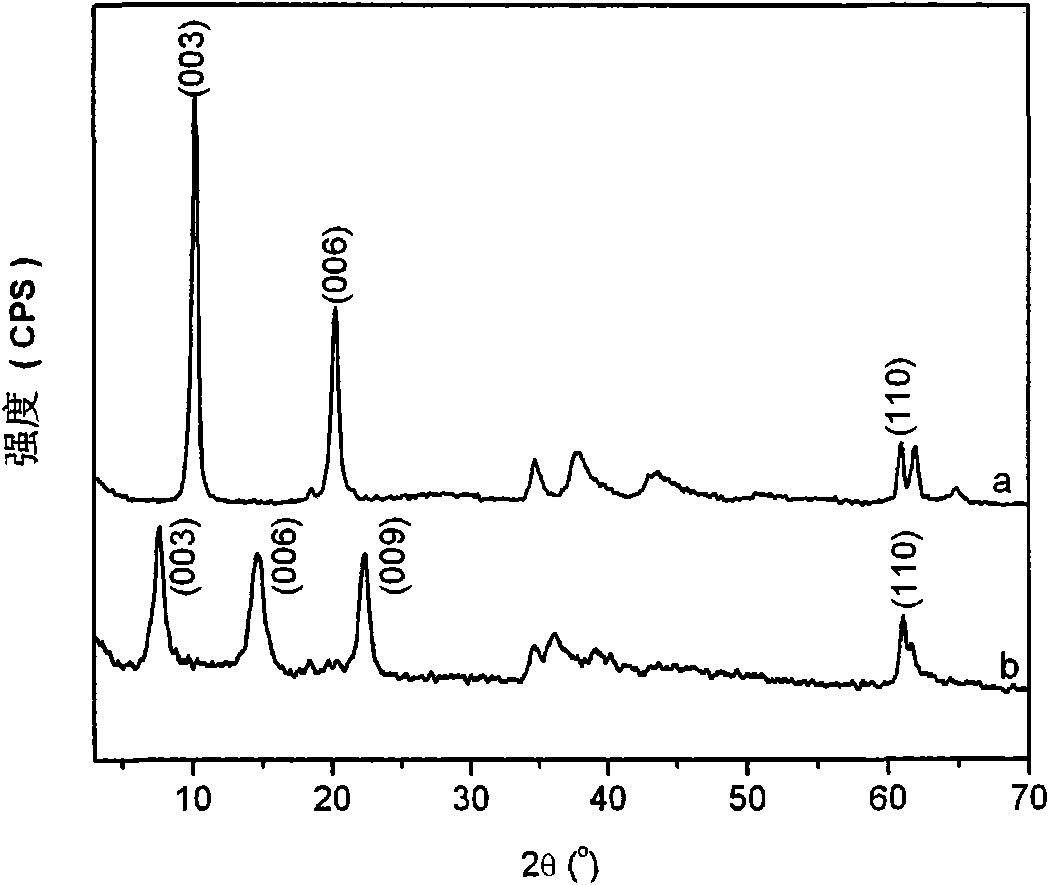

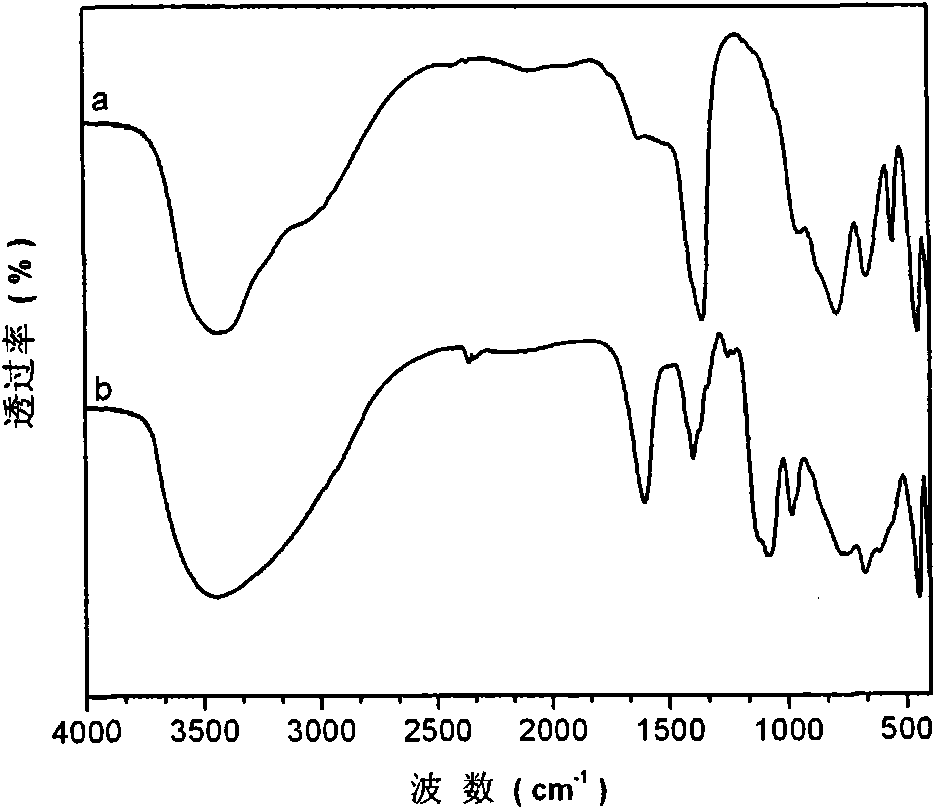

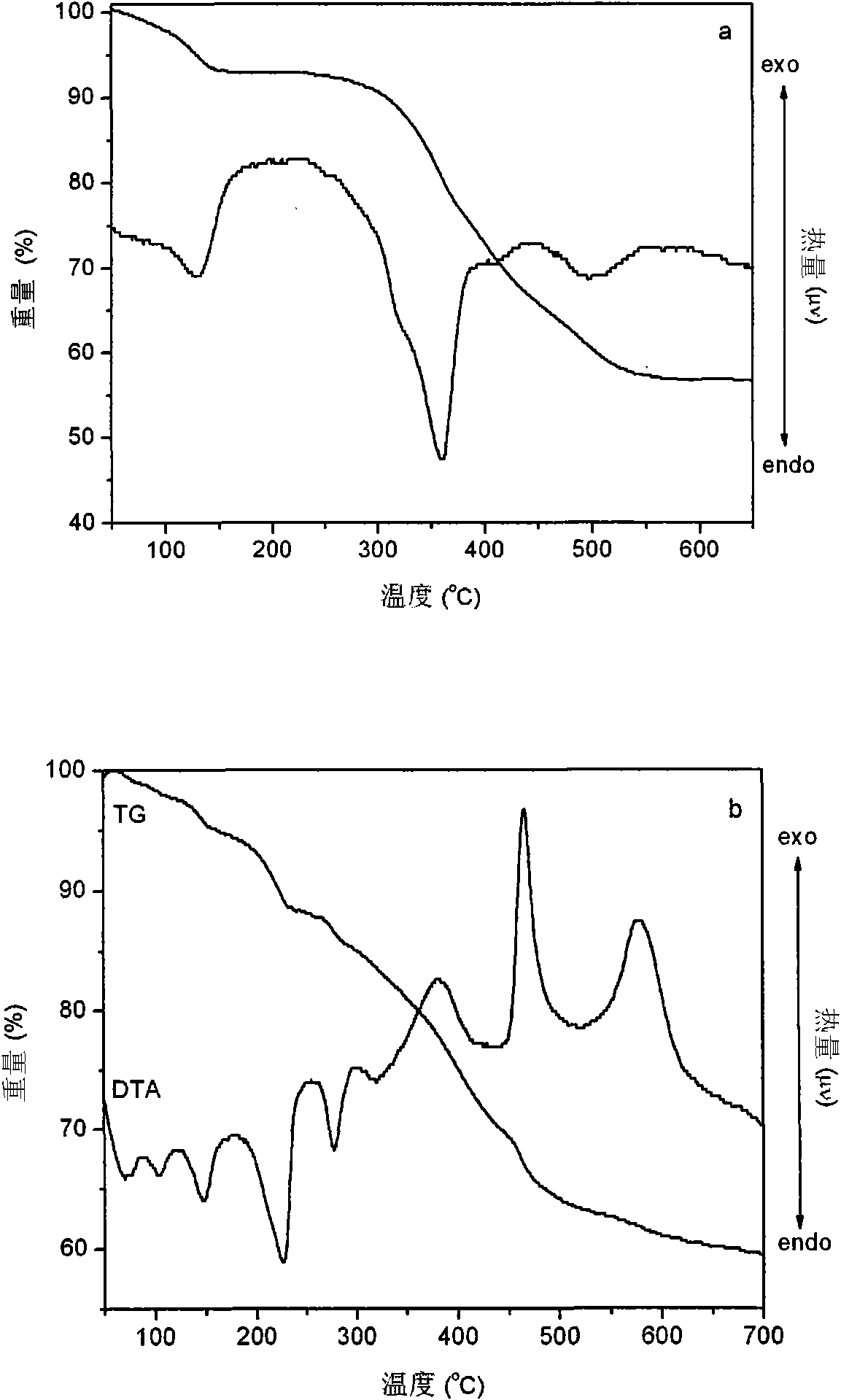

Embodiment 1

[0033] Step A: 45.0g (0.12mol) of solid Al(NO 3 ) 3 9H 2 O and 61.5g (0.24mol) of solid Mg(NO 3 ) 2 ·6H 2 O dissolves in removing CO 2 Prepare 300ml of mixed salt solution A in deionized water; and dissolve 28.8g (0.72mol) of solid NaOH in deionized water to prepare 300ml of alkali solution B. Rapidly nucleate the alkali solution and the salt solution in a fully back-mixed rotary liquid film reactor at room temperature, crystallize the obtained slurry at 100°C for 6 hours, and centrifuge to separate the obtained sample until the pH value is close to 7 to obtain hydrotalcite. body filter cake. After sampling and drying, its molecular formula was determined to be MgAl-NO 3 -LDHs, its Mg 2+ / Al 3+ =2:1.

[0034] Get 96g (0.17mol) of the above filter cake to remove CO 2 Ultrasonic dispersion with deionized water to prepare a 300ml suspension.

[0035] Step B: Weigh 31g (0.1156mol) of GLYP and dissolve in CO removal 2 Prepare 300ml of solution in deionized water, and a...

Embodiment 2

[0043] Step A: 45.0g (0.12mol) of solid Al(NO 3 ) 3 9H 2 O and 61.5g (0.24mol) of solid Mg(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to make 300ml mixed salt solution A; another 23.04g (0.567mol) solid NaOH and 25.4g (0.24mol) solid NaOH 2 CO 3 Dissolve in deionized water to make 300ml alkaline solution B. Rapidly nucleate the alkali solution and the salt solution in a fully back-mixed rotary liquid film reactor at room temperature, crystallize the obtained slurry at 100°C for 6 hours, and centrifuge to separate the obtained sample until the pH value is close to 7 to obtain hydrotalcite. body filter cake. After sampling and drying, its molecular formula was determined to be MgAl-CO 3 -LDHs, its Mg 2+ / Al 3+ =2:1.

[0044] Take 90g (0.17mol) of the above filter cake and disperse it ultrasonically with ethylene glycol solution to prepare a 300ml suspension.

[0045] Step B: Weigh 23g (0.0867mol) of GLYP and dissolve it in deionized water to make a 300ml solut...

Embodiment 3

[0049] Step A: 45.0g (0.12mol) of solid Al(NO 3 ) 3 9H 2 O and 71.4g (0.24mol) solid Zn(NO 3 ) 3 ·6H 2 O dissolves in removing CO 2 300ml of mixed salt solution A was prepared in deionized water; another 28.8g (0.72mol) of solid NaOH was dissolved in 2 Prepare 300ml of alkaline solution B in deionized water. Rapidly nucleate the alkali solution and the salt solution in a fully back-mixed rotary liquid film reactor at room temperature, crystallize the obtained slurry at 100°C for 6 hours, and centrifuge to separate the obtained sample until the pH value is close to 7 to obtain hydrotalcite. body filter cake. After sampling and drying, its molecular formula was determined to be ZnAl-NO 3 -LDHs, whose Zn 2+ / Al 3+ =2:1.

[0050] Get 92g (0.17mol) of the above filter cake to remove CO 2 Ultrasonic dispersion with deionized water to prepare a 300ml suspension.

[0051] Step B: Weigh 31g (0.1156mol) of GLYP and dissolve in CO removal 2 300ml solution was prepared in de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com