Infrared focal plane array and infrared thermal imaging system based on infrared focal plane array

An infrared focal plane and infrared thermal imaging technology, which is applied in the field of infrared thermal imaging, can solve the problems of complex process steps, high device blind element rate, and high difficulty in the preparation of infrared thermal imagers, achieving low cost and avoiding 1/f noise , Reduce the effect of thermal response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

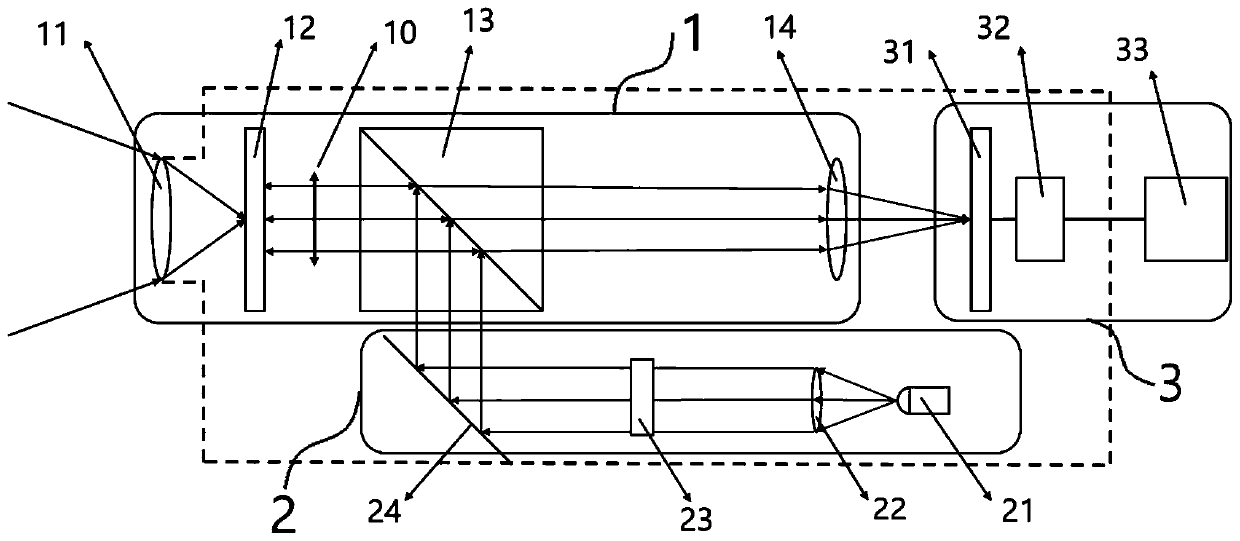

[0066] This embodiment provides an infrared thermal imaging system, such as figure 1 As shown, it includes a wavelength conversion module (1), a readout signal generation module (2) and an imaging display module (3);

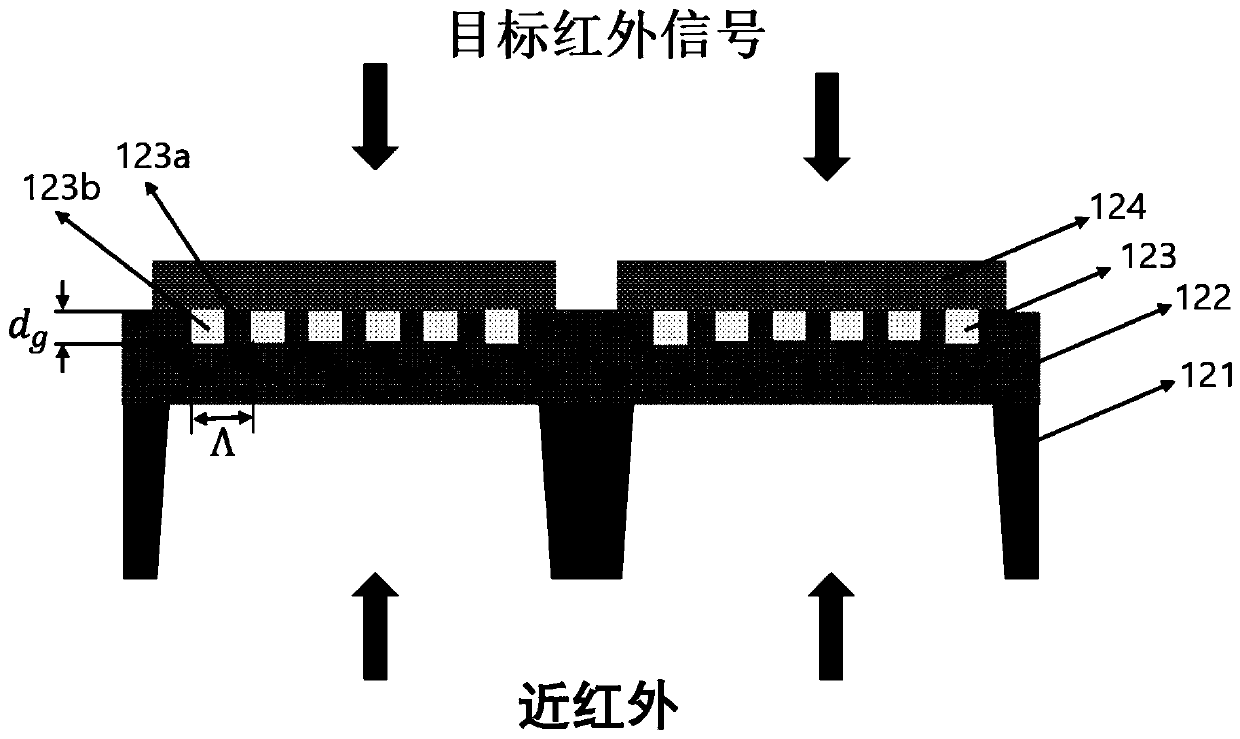

[0067] The wavelength conversion module (1) includes an infrared lens (11), an infrared focal plane array (12), a polarizer (10), and a first beam splitter (13) arranged sequentially along the optical path, wherein the infrared focal plane The planar array (12) includes several periodically arranged array units, and each array unit includes a substrate (121), a thermal insulation support layer (122), a sub-wavelength grating structure and an infrared absorption layer ( 124), opening a window on the back of the substrate (121) corresponding to the region where the sub-wavelength grating structure is located so that light enters the sub-wavelength grating structure through the heat-insulating support layer (122);

[0068] The readout signal generating module (2) ...

Embodiment 2

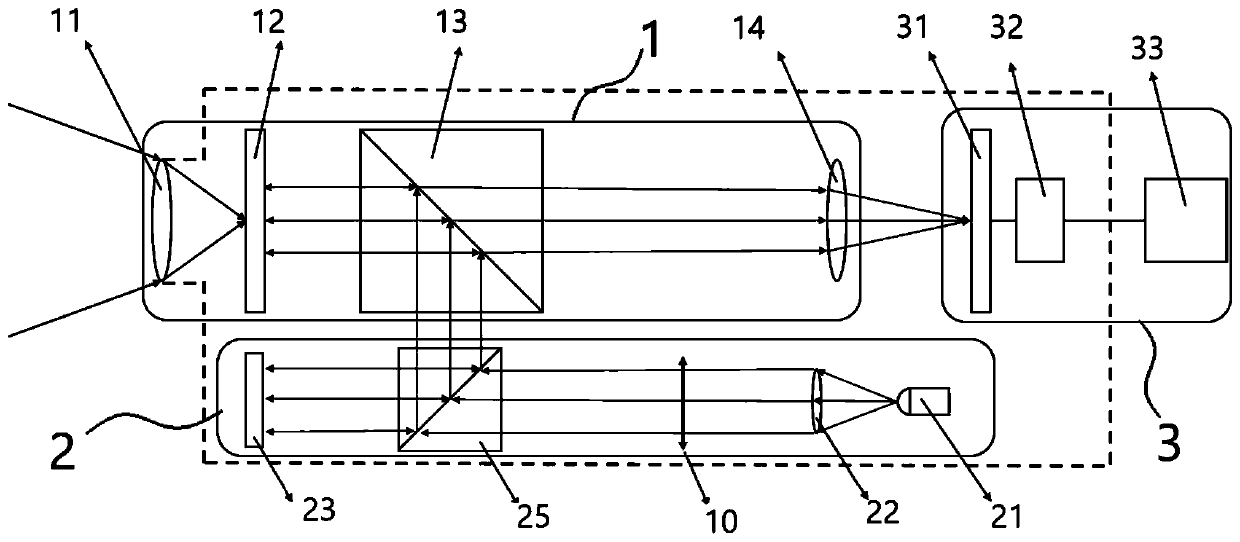

[0092] This embodiment provides an infrared thermal imaging system, such as figure 2 As shown, it includes a wavelength conversion module (1), a readout signal generation module (2) and an imaging display module (3);

[0093] The wavelength conversion module (1) includes an infrared lens (11), an infrared focal plane array (12) and a first beam splitter (13) arranged sequentially along the optical path, wherein the infrared focal plane array (12) includes several array units arranged periodically, each array unit includes a substrate (121), a thermal insulation support layer (122), a sub-wavelength grating structure and an infrared absorption layer (124) arranged sequentially from top to bottom, and the substrate ( On the back of 121), there is a window corresponding to the area where the sub-wavelength grating structure is located so that light enters the sub-wavelength grating structure through the heat-insulating support layer (122);

[0094] The readout signal generating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com