Dye-sensitized rare earth upconversion material and preparation method thereof

A rare earth up-conversion and dye sensitization technology, applied in the field of rare-earth up-conversion materials and their preparation, can solve the problems of low luminous efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

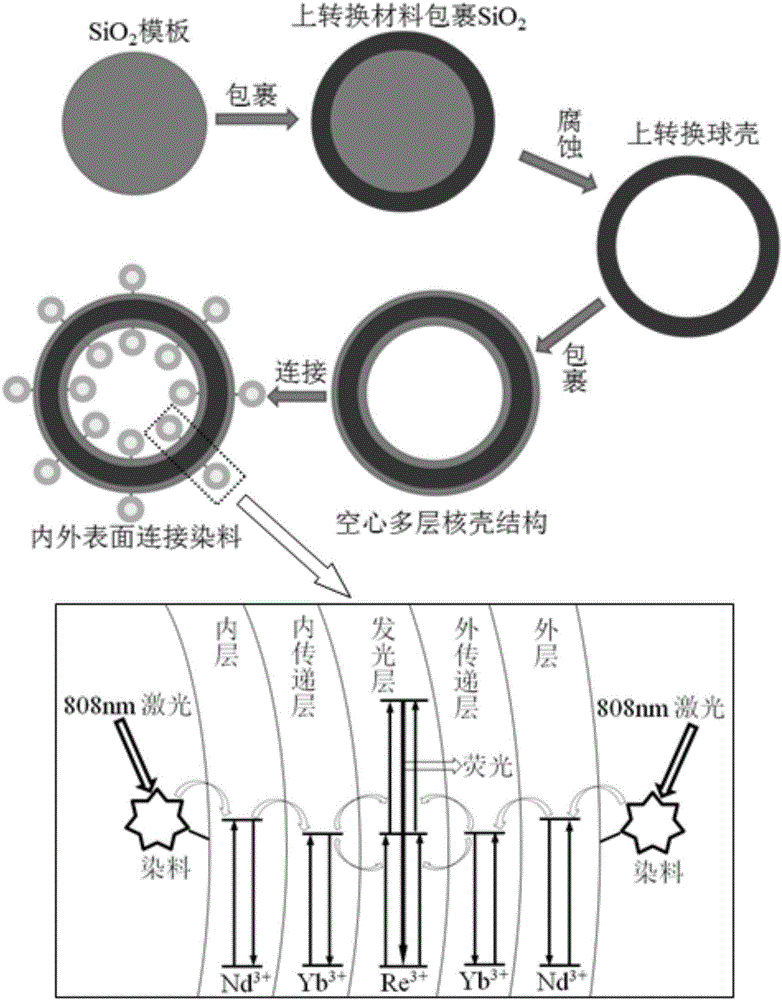

[0053] Example 1: Dye-sensitized Nd@Yb@Er / Yb@Yb@Nd doped NaYF in this example 4 The preparation of the hollow multilayer spherical shell is carried out in the following steps:

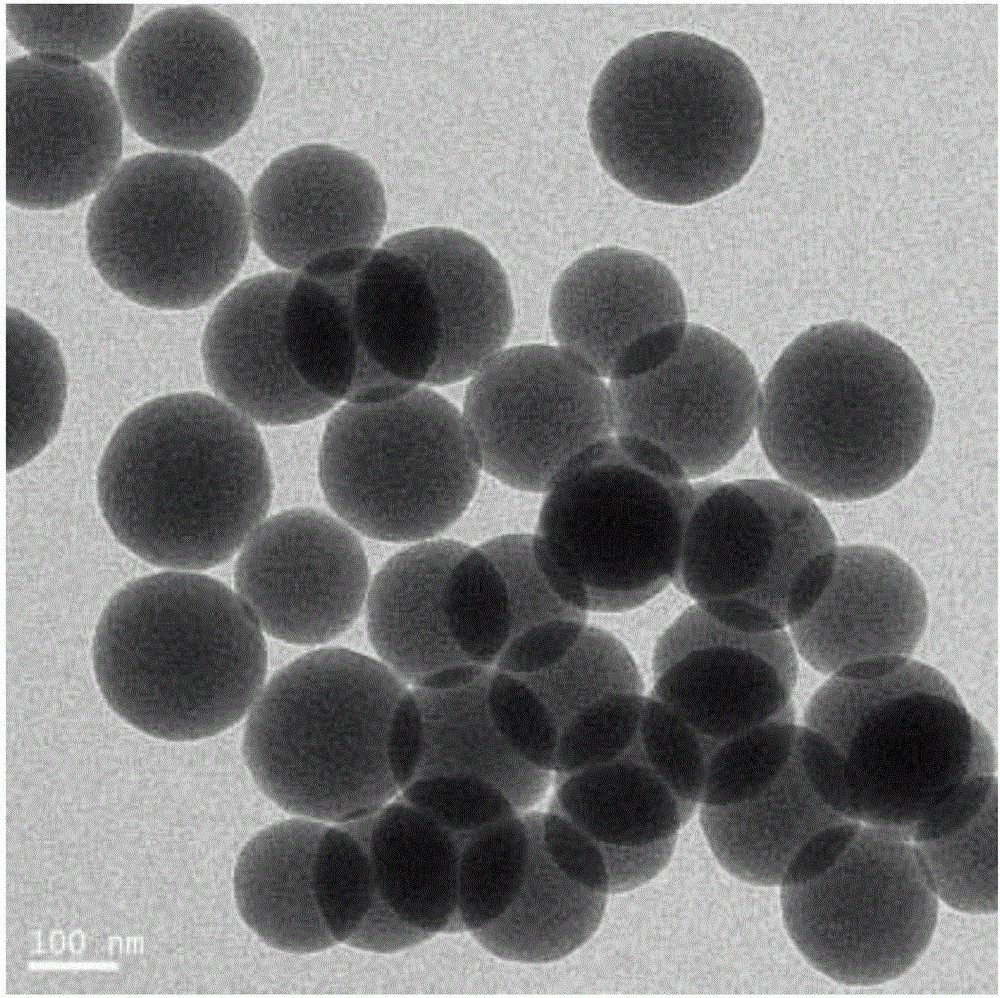

[0054] 1. SiO2 2 Preparation of nanosphere template: 4ml tetraethyl orthosilicate was quickly added to 65ml ethanol, 28ml deionized water and 7ml ammonia water and stirred for 2 hours. After washing three times with ethanol centrifugation, dry at 60°C for 12 hours to obtain SiO 2 . Prepared SiO 2 The TEM photo of figure 2 As shown, the product is a sphere with a diameter of about 100nm, and the size is relatively uniform;

[0055] 2. Preparation of luminescent layer:

[0056] (1) 30mg of SiO 2 The pellets were ultrasonically dispersed with 100 ml of deionized water at 40°C for 45 minutes, after which 0.25 mol of urea and a total of 0.5 mmol of YCl 3 , YbCl 3 , ErCl 3 Join (YCl 3 , YbCl 3 , ErCl 3 The molar ratio is 80:18:2) to continue ultrasonication, then transfer the mixture into a bea...

Embodiment 2

[0070] Embodiment 2: The difference between this embodiment and embodiment 1 is that the package of step 3 contains Yb 3+ The shell method and step 4 include Nd 3+ The thermal decomposition method of the shell is replaced by a hydrothermal method, and other steps and parameters are the same as in Example 1.

[0071] Wherein the inner transfer layer and the outer transfer layer of step 3 (i.e. the package contains Yb 3+ The specific method of preparation is: weigh the Yb(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O (the molar ratio of Yb to Y is 1:9), and 0.146g of EDTA were dissolved in 20ml of deionized water and stirred for 30 minutes. 0.2mmol of Er / Yb:NaYF 4 The spherical shell precursor and 0.262g of NaF were stirred and dispersed into 20ml of deionized water, and then slowly added to the rare earth nitrate solution and stirred for 30 minutes. After standing still for 2 hours, the supernatant was poured out, and the obtained white precipitate mixture was put into a re...

Embodiment 3

[0074] Example 3: In this example Nd@Yb@Er / Yb@Yb@Nd doped with LiYF 4 The preparation method of the hollow multi-layer spherical shell is different from Example 1 in that: the ErCl in Example 1 3 Replaced by the same molar number of TmCl 3 , NaOH in Example 1 is replaced by LiOH of the same molar number, and other steps and parameters are the same as in Example 1.

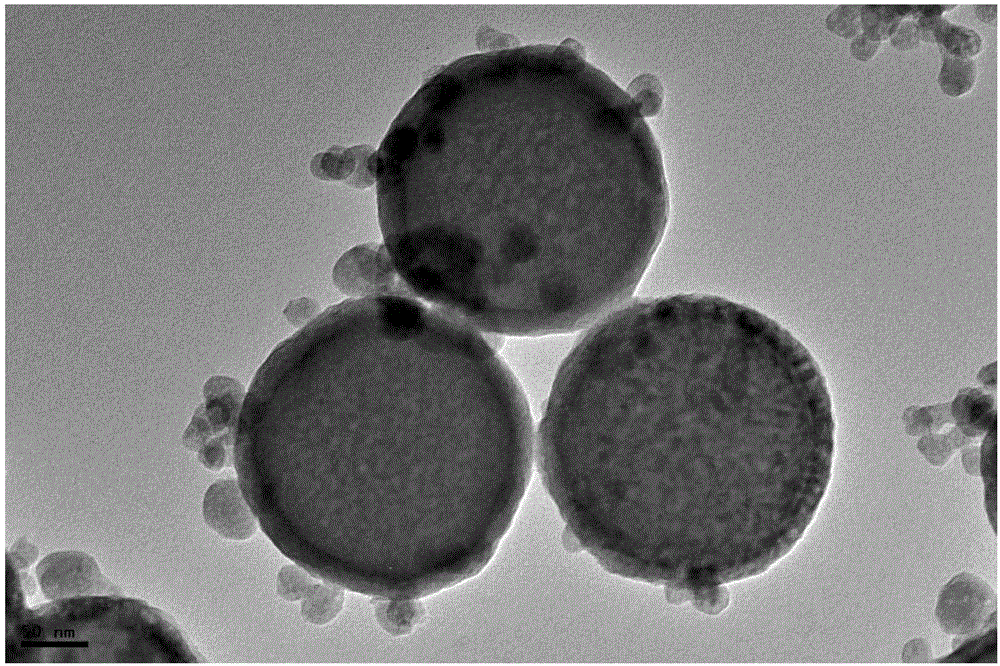

[0075] Figure 6 Given the dye-sensitized Nd@Yb@Tm / Yb@Yb@Nd doped LiLnF 4 The TEM image of the hollow multilayer spherical shell shows an obvious hollow structure; the corresponding up-conversion fluorescence comparison of the sample is as follows Figure 7 As shown, it can be seen that compared with conventional dye-sensitized up-conversion materials with the same concentration, the up-conversion efficiency of the bidirectional dye-sensitized product of the present invention is significantly improved under the same power density of 808nm laser irradiation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com