Preparation technology suitable for electronic grade solid ethylenediamine tetramethylene phosphonic acid

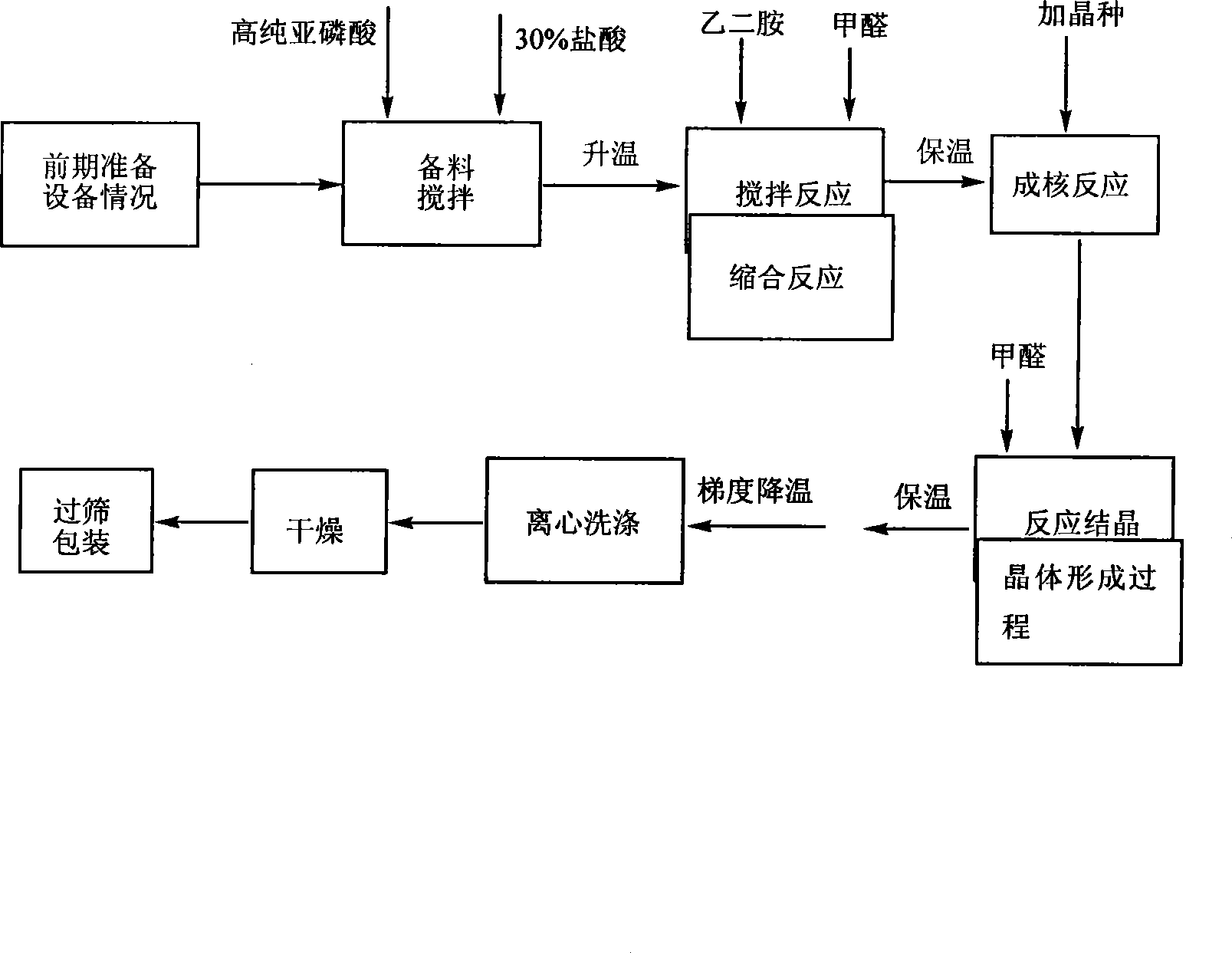

A technology of ethylenediaminetetramethylenephosphonic acid and preparation process, which is applied in the field of preparation technology of electronic grade solid ethylenediaminetetramethylenephosphonic acid, can solve the problem of not specifying the arsenic content, not specifying the purity, and reaching a certain level. requirements and other issues, to achieve the effect of being conducive to filtration operation, eliminating environmental pollution and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Rinse the reactor, condenser, pipeline, valve, metering tank, centrifuge and other equipment once with high-purity water. Put 2000kg of high-purity phosphorous acid and 2000kg of 30% hydrochloric acid into the reactor, start stirring slowly at a stirring rate of 60rpm, add 500kg of ethylenediamine dropwise at 50°C for 4 hours; 1800kg of formaldehyde, adding time of 2 hours, formaldehyde is kept at 75°C for 1 hour after dropping; after the temperature drops to 65°C, add 1200g of crystal nucleating agent ethylenediamine tetramethylene phosphonic acid solid, at this time, crystals are precipitated; After the temperature was raised to 85°C, 1100kg of formaldehyde was added dropwise for 1 hour. After the dropwise addition was completed, the temperature was kept for 2 hours; the temperature was gradually lowered to 15°C, and the gradient cooling rate was controlled at 25°C per hour. At this time, a large number of crystals were precipitated. Centrifuge with a centrifuge at a ...

Embodiment 2

[0046] Rinse the reaction kettle, condenser, pipeline, valve, metering tank, centrifuge and other equipment twice with high-purity water. Put 1200kg of high-purity phosphorous acid and 800kg of 30% hydrochloric acid into the reaction kettle, start stirring slowly at a stirring rate of 60rpm, add 320kg of ethylenediamine dropwise at 50°C for 2 hours; 800kg of formaldehyde, adding time of 2 hours, after dropping the formaldehyde, keep it at 75°C for 1 hour; after the temperature drops to 65°C, add 800g of crystal nucleating agent ethylenediamine tetramethylene phosphonic acid solid, at this time, crystals are precipitated; After the temperature was raised to 85°C, 800kg of formaldehyde was added dropwise for 1 hour. After the dropwise addition was completed, the temperature was kept for 2 hours; the temperature was gradually lowered to 35°C, and the gradient cooling rate was controlled at 15°C per hour. At this time, a large number of crystals were precipitated. Centrifuge with ...

Embodiment 3

[0048] According to the operating procedure of Example 1, 1000 g of crystal nucleating agent hydroxyethylene diphosphoric acid was added, and the others were the same as in Example 1. After testing, the active content of the product in terms of EDTMPA is 98%, and the content of arsenic is 0.2mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com