Preparation method for methylammonium iodide

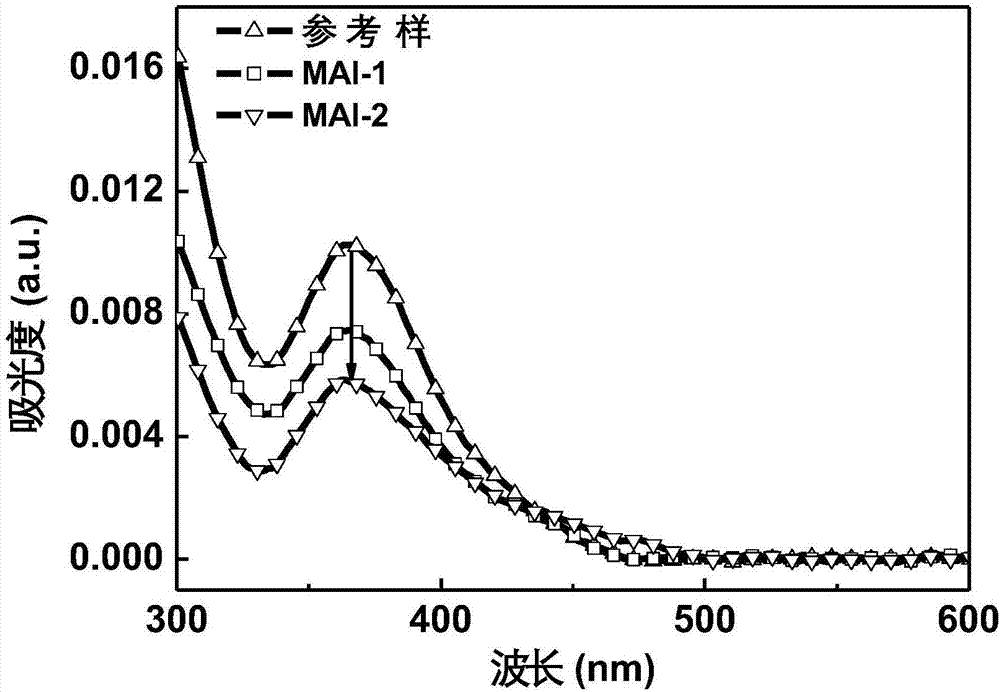

A technology of methyl ammonium iodide and methylamine, which is applied in the field of preparation of methyl ammonium iodide, can solve the problems of poor performance of perovskite films, reduced iodine content, low density of defect states, etc., so as to improve the purity and defect. The effect of low density of states and large crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

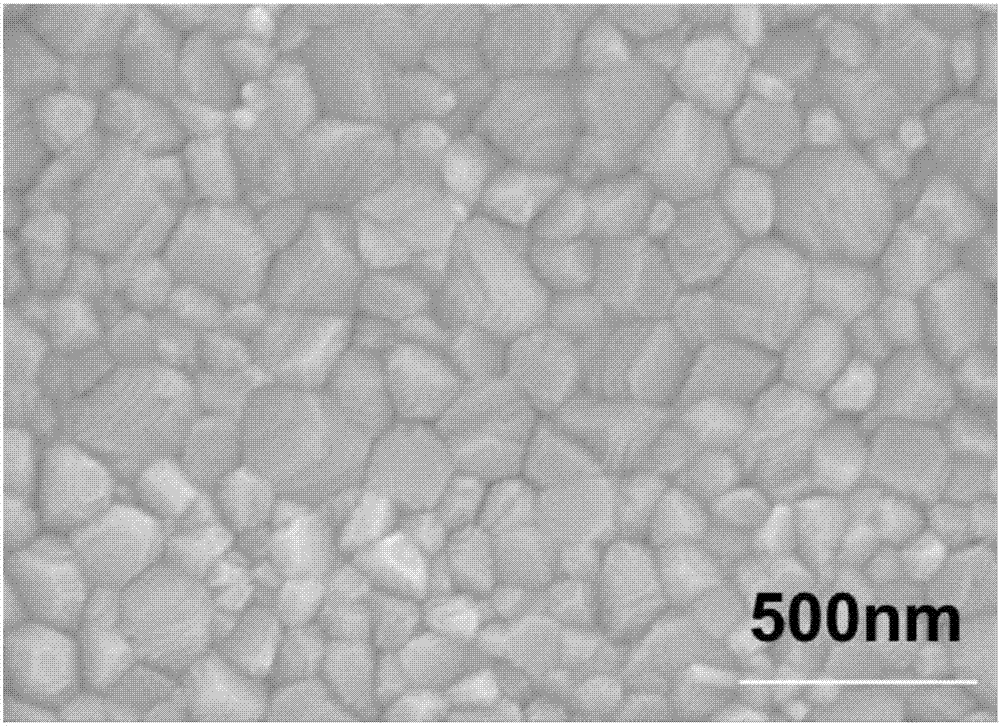

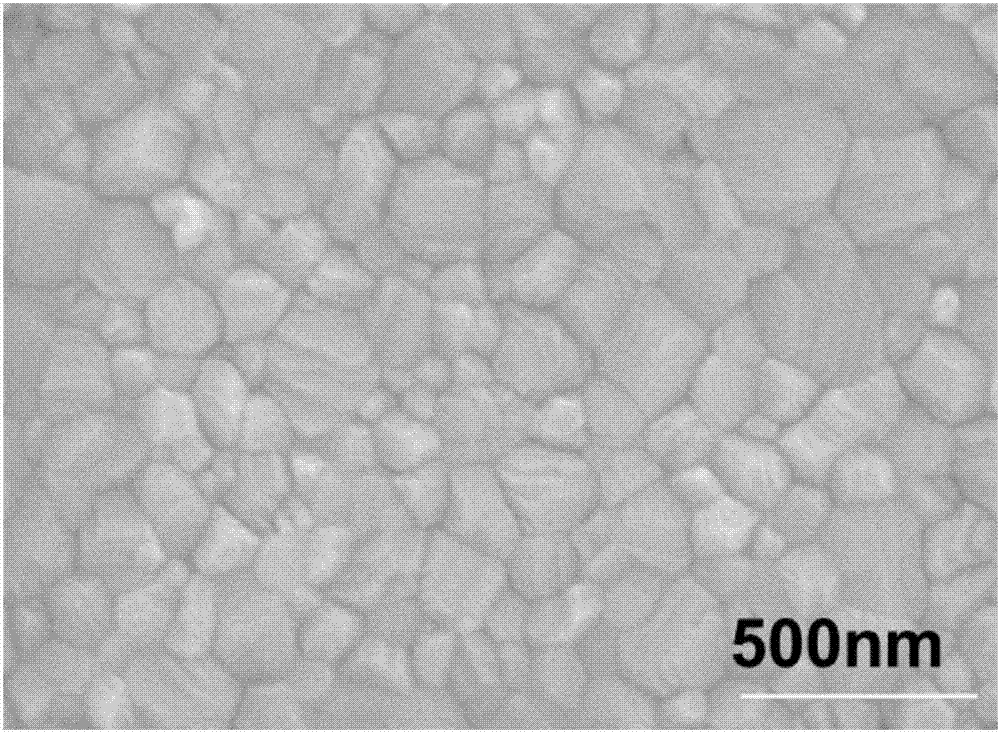

[0027] Fabrication of perovskite solar cells: SnO 2 The solution was spin-coated on a clean ITO conductive glass substrate at 3000rpm, spin-coated for 30s, and then spin-coated SnO 2 The final ITO conductive glass was annealed at 150°C for 30 minutes to form SnO on the ITO conductive glass. 2 Electron transport layer; the perovskite precursor solution was spin-coated on SnO at 4000rpm 2 On the electron transport layer, spin-coat for 25s, and then anneal the ITO conductive glass spin-coated perovskite precursor solution at 65°C for 1min, then anneal at 100°C for 2min. 2 A perovskite film is formed on the electron transport layer; the spiro-OMeTAD solution is spin-coated on the perovskite film at 3000rpm for 30s to form a hole transport layer on the perovskite film; Gold is evaporated on it as an electrode to obtain a flat heterojunction perovskite solar cell;

[0028] The SnO 2 Solution preparation: SnO with a mass fraction of 15% 2 The stock solution of the aqueous soluti...

Embodiment 1

[0033] (1) The hydriodic acid that the mass fraction is 30% methylamine aqueous solution and the mass fraction is 57% is mixed, and the mol ratio of methylamine and hydrogen iodide in the mixed solution is 1:1.2; Under nitrogen protection, mix The solution was placed in an ice-water bath and reacted in the dark for 5 hours to obtain an aqueous solution of methylammonium iodide;

[0034] (2) using a rotary evaporator to remove the solvent water in the methyl ammonium iodide aqueous solution by rotary evaporation at 40° C. to obtain the methyl ammonium iodide crystal crude product;

[0035] (3) Under the protection of nitrogen, first add the crude methylammonium iodide crystals to 12.5mmol / L methylamine ethanol solution, and heat to 90°C, after the crude methylammonium iodide crystals are completely dissolved, a mixed solution is obtained Add diethyl ether to the mixed solution until the crystals just precipitate, stop heating, cool to the crystals no longer precipitate, filter ...

Embodiment 2

[0038] (1) The hydriodic acid that the mass fraction is 30% methylamine aqueous solution and the mass fraction is 57% is mixed, and the mol ratio of methylamine and hydrogen iodide in the mixed solution is 1:1.2; Under nitrogen protection, mix The solution was placed in an ice-water bath and reacted in the dark for 5 hours to obtain an aqueous solution of methylammonium iodide;

[0039] (2) using a rotary evaporator to remove the solvent water in the methyl ammonium iodide aqueous solution by rotary evaporation at 40° C. to obtain the methyl ammonium iodide crystal crude product;

[0040] (3) Under the protection of nitrogen, first add the crude methylammonium iodide crystals to 12.5mmol / L methylamine ethanol solution, and heat to 90°C, after the crude methylammonium iodide crystals are completely dissolved, a mixed solution is obtained Add diethyl ether to the mixed solution until the crystals just precipitate, stop heating, cool to the crystals no longer precipitate, filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com