Synthetic hercynite and production method thereof

A technology of iron-aluminum spinel and aluminum spinel, applied in the field of synthetic iron-aluminum spinel and its production, can solve the problems of small volume, unsuitable for large-scale promotion and use, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be specifically described below by way of examples.

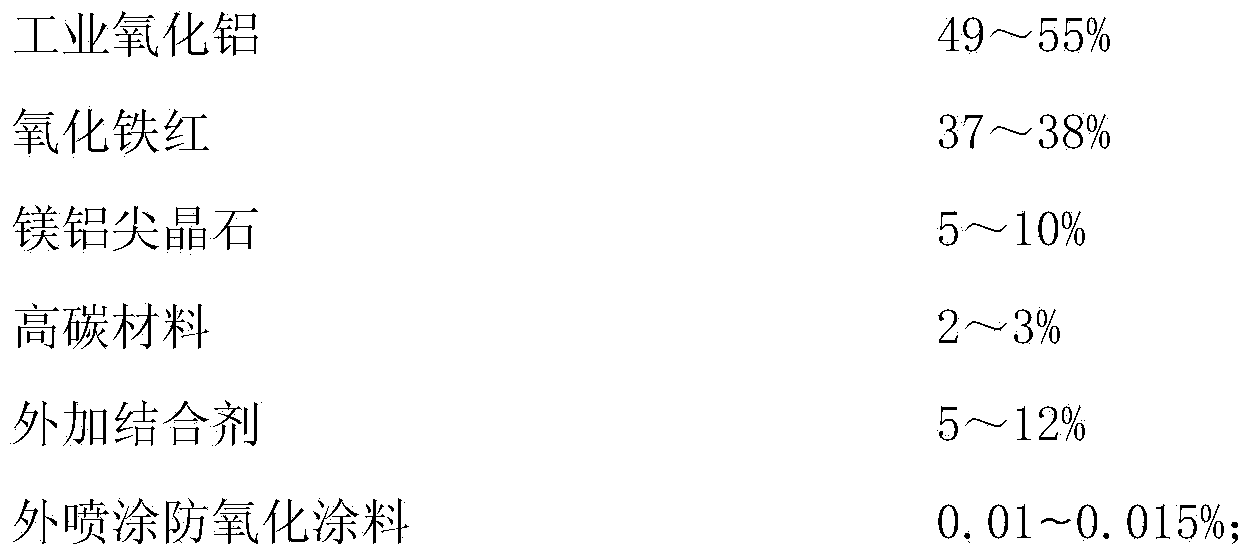

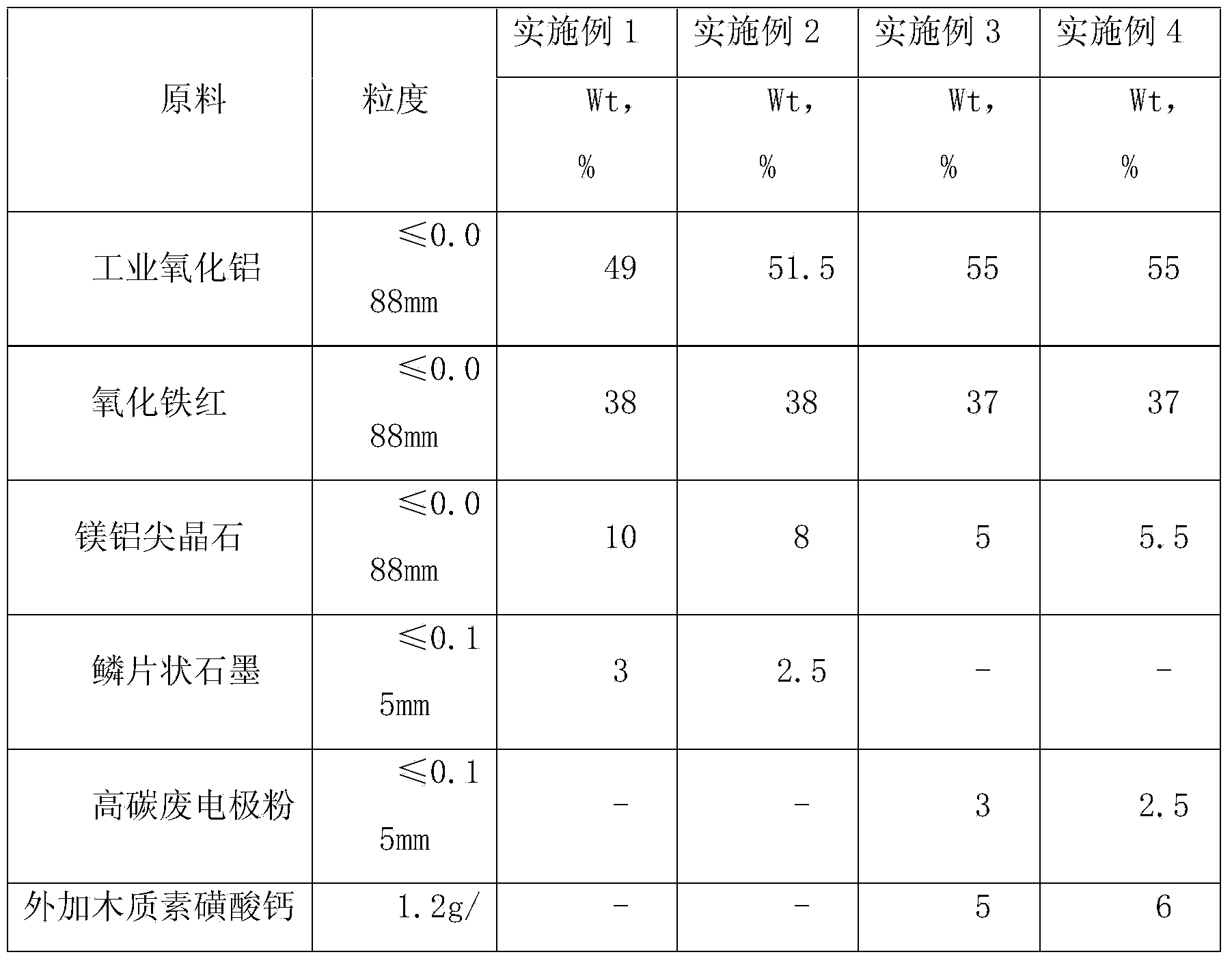

[0039] A kind of synthetic iron-aluminum spinel embodiment 1~4, its chemical composition and weight percentage content are shown in the following table:

[0040] A chemical composition and weight percentage content table of synthetic iron-aluminum spinel

[0041]

[0042]

[0043] A production method for synthesizing iron-aluminum spinel, the method steps are as follows:

[0044] a. Ingredients: Accurately weigh the required raw materials according to the above-mentioned embodiments 1-4, the chemical composition and weight percentage content table of a synthetic iron-aluminum spinel;

[0045] b. Pre-mixing: Put the prepared materials into the ball mill for co-milling for 30 minutes to fully mix the materials evenly;

[0046] c. Mixing: Add the pre-mixed mixture into the mixer, then add the binder to the material, and mix for 8-10 minutes;

[0047] d. Forming: Pour the mixed materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com