Clean production method for co-production of ammonium bicarbonate through combination of high purity carbon dioxide and melamine tail gas

A technology of carbon dioxide and melamine, applied in the direction of ammonium carbonate/acid carbonate, etc., can solve the problems of limited equipment processing capacity, low effective gas volume, increased power consumption, etc., to facilitate centrifugal separation and shorten the reaction Effect of time and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

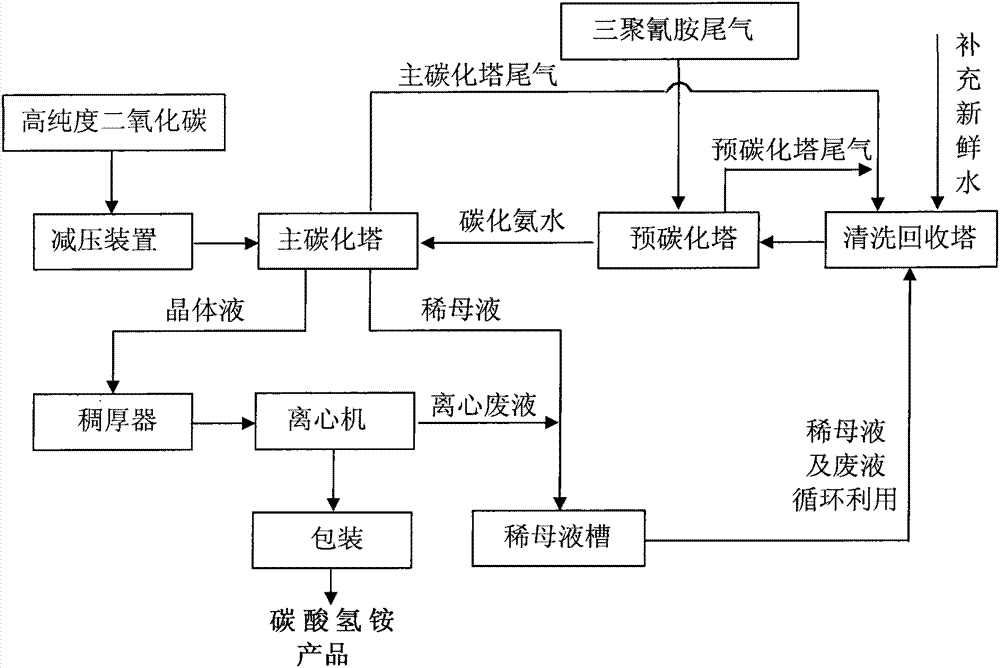

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] A clean production method of high-purity carbon dioxide combined with melamine tail gas to co-produce ammonium bicarbonate, such as figure 1 As shown, the method includes the following steps:

[0030] 1) After the carbon dioxide gas (pressure 3.0MPa, purity is 96% (V)) in the large nitrogen fertilizer plant is decompressed to 0.6MPa by the decompression device, enter the carbon dioxide gas buffer tank (the effect of setting the buffer tank is to keep the air flow Stable, no airflow pulse phenomenon);

[0031] 2) The melamine tail gas is absorbed and condensed through the pre-carbonization tower to form carbonized ammonia water (containing NH 3 14-18%, CO 2 18-22%), and introduce the top of the main carbonization tower for use;

[0032] 3) The carbon dioxide gas obtained in step 1) is sent into the main carbonization tower from the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com