Preparation method of antirust agent 2-(1, 3-benzothiazole-2-sulfenyl) succinic acid

A technology of benzothiazole and succinic acid, applied in organic chemistry and other directions, can solve problems such as affecting production and life, shortening life, affecting environmental protection, etc., and achieves the effects of high yield, simple process operation and high atom utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

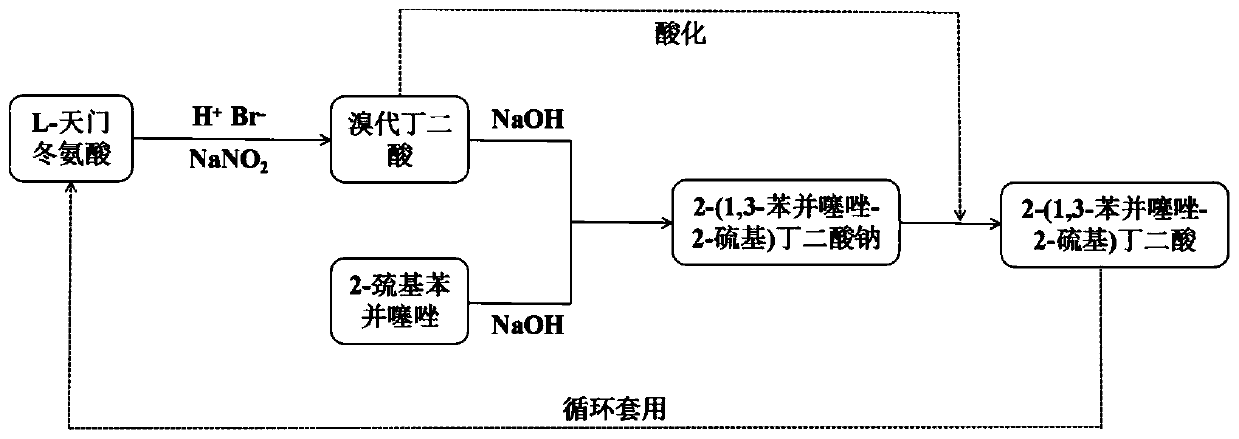

Method used

Image

Examples

Embodiment 1

[0035] Step 1: In a four-necked flask equipped with a stirring device and a thermometer, add 21 g of L-aspartic acid, 19.4 g of sodium bromide, 31.5 g of 98% concentrated sulfuric acid and 40 mL of secondary water, and stir to dissolve in an ice bath;

[0036] Step 2: Slowly add 43.5 g of 30% W sodium nitrite solution dropwise at 0°C for 2 hours, and continue to react at room temperature for 2 hours;

[0037] Step 3, the reaction solution was extracted with 3×20 mL ethyl acetate, and the solvent was removed under vacuum to obtain 28 g of bromosuccinic acid, with a yield of 90.35%;

[0038] Step 4: Add 20g of 2-mercaptobenzothiazole, 0.3g of anhydrous sodium sulfite and 40mL of secondary water into a 500mL four-neck bottle. Under the protection of nitrogen, start to add 15g of 32% sodium hydroxide solution dropwise at a constant speed. It takes 30min to complete the reaction Heat the system to 50°C, keep stirring for 30 minutes, the 2-mercaptobenzothiazole is completely dissolv...

Embodiment 2

[0046] Step 1: In a four-neck flask equipped with a stirring device and a thermometer, add 20 g of L-aspartic acid, 60.8 g of 40% hydrobromic acid, and 20 mL of secondary water, and stir to dissolve in an ice bath;

[0047] Step 2: Slowly add 41.4g of 30% W sodium nitrite solution dropwise at 0°C for 2 hours, and continue to react at room temperature for 2 hours;

[0048] Step 3, the reaction solution was extracted with 3×20mL ethyl acetate, and the solvent was removed under vacuum to obtain 28g of bromosuccinic acid with a yield of 95%;

[0049] Step 4: Add 20g of 2-mercaptobenzothiazole, 0.3g of anhydrous sodium sulfite and 40g of secondary water into a 500mL four-necked bottle, and under the protection of nitrogen, start to add 15g of 32% sodium hydroxide solution dropwise at a constant speed, which takes 30min, and the reaction Heat the system to 55°C, keep stirring for 30 minutes, the 2-mercaptobenzothiazole is completely dissolved, and adjust the pH of the reaction solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com