Mesoporous composite copper catalyst for preparing carbon monoxide from methanol as well as preparation method and application of mesoporous composite copper catalyst

A carbon monoxide and copper catalyst technology, which is applied in the direction of catalyst activation/preparation, carbon monoxide, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of increasing the specific surface area of the catalyst, low atom utilization rate, catalyst deactivation, etc. , to achieve the effect of solving catalyst deactivation, increasing atom utilization rate, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

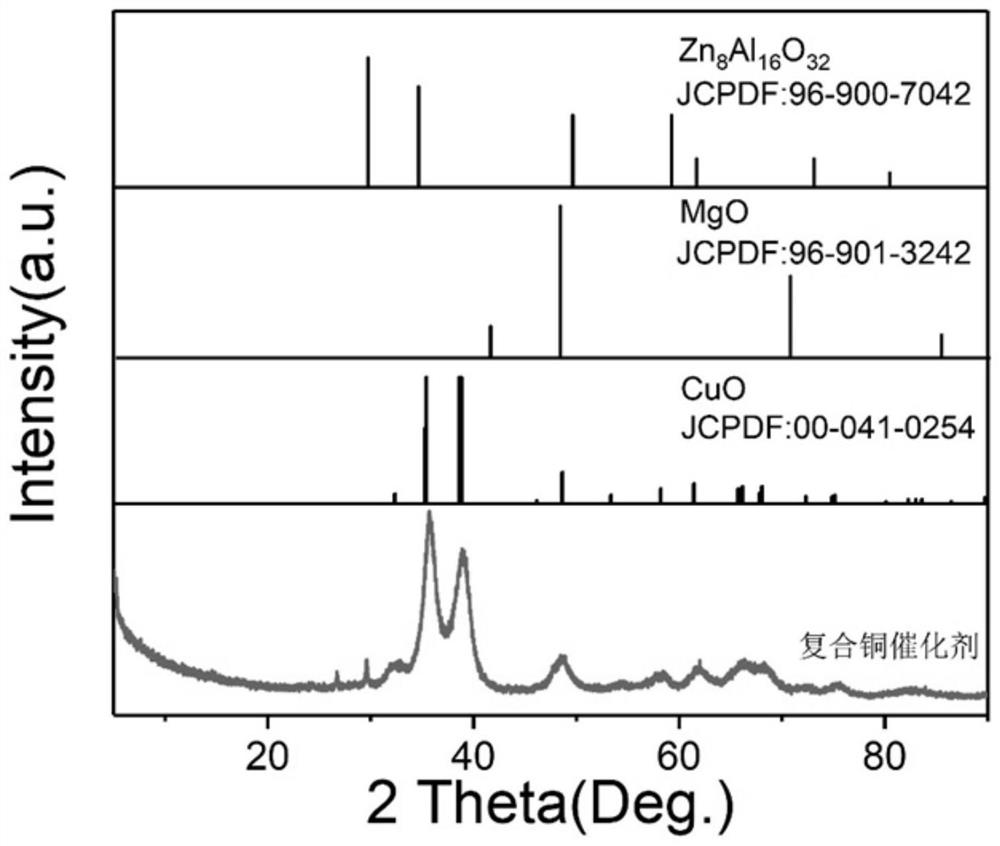

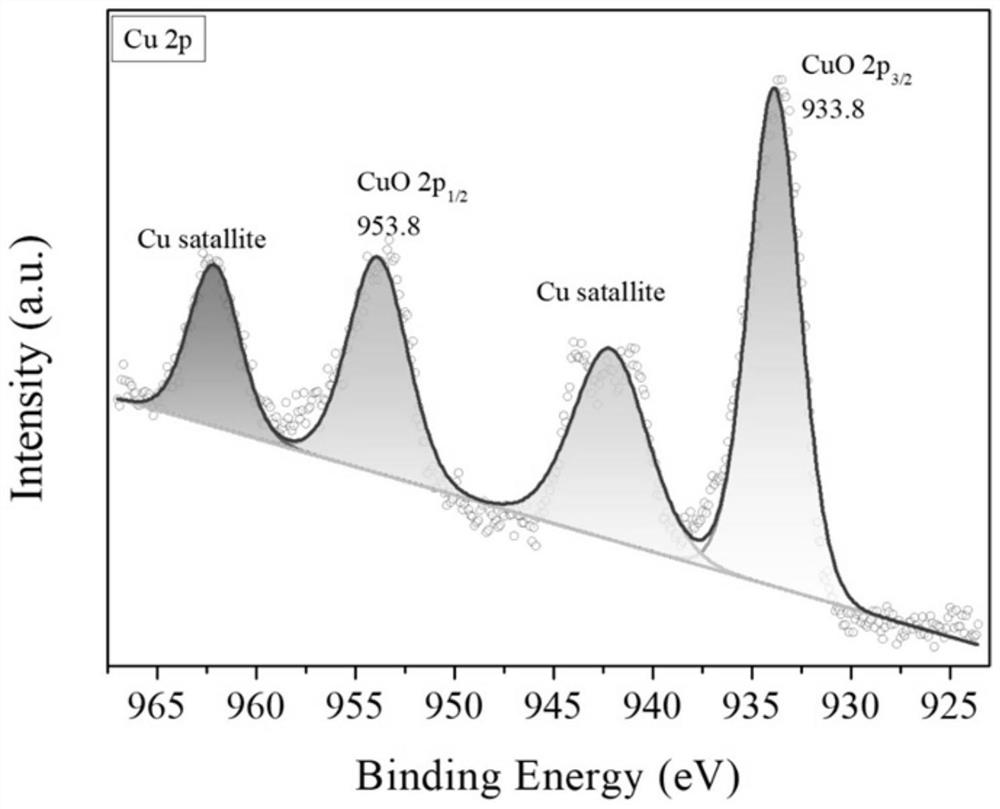

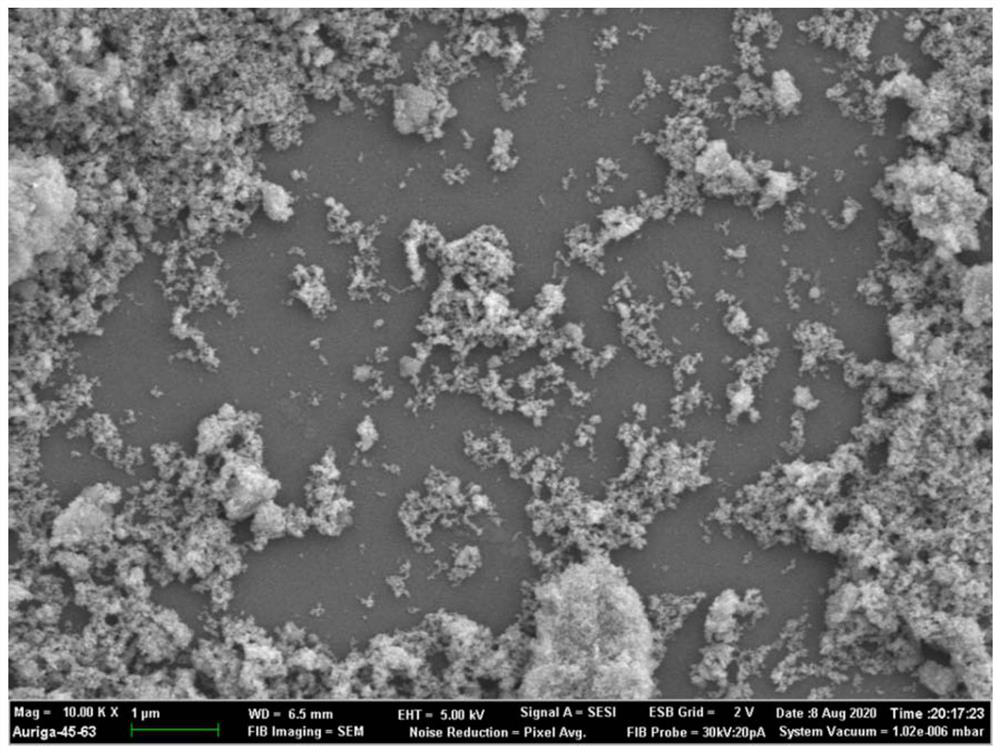

[0045] A mesoporous composite copper catalyst for producing carbon monoxide from methanol, the preparation method comprising the following steps:

[0046] (1) Stir the triblock copolymer P123, deionized water, and 35wt% hydrochloric acid solution in a volume ratio of 1:20:1 at 35°C and 400 rpm for 6 hours, and then add the same mass of triblock copolymer P123. The n-butanol was continued to stir for 1 h, then fumed silica powder or ethyl orthosilicate solution with twice the mass of n-butanol was added, stirred for 12 h at 35°C and 400 rpm to form a gel, and finally transferred to a hydrothermal kettle. 130°C hydrothermal for 96h, suction filtration, washing with deionized water, and then calcining the washed product at 700°C for 6h to obtain a hard templating agent;

[0047] (2) Disperse 50 g of the hard template agent obtained in step (1) in 800 mL of deionized water, and add active component precursors (60 g copper nitrate, 10 g magnesium nitrate, 18 g aluminum nitrate, 11....

Embodiment 2

[0055] A mesoporous composite copper catalyst for producing carbon monoxide from methanol, the preparation method comprising the following steps:

[0056] (1) Stir the triblock copolymer P123, deionized water, and 35wt% hydrochloric acid solution in a volume ratio of 1:15:1 at 35°C and 400 rpm for 3 hours, and then add the same mass of triblock copolymer P123. The n-butanol was continued to stir for 1 h, and then fumed silica powder or ethyl orthosilicate solution with twice the mass of n-butanol was added, stirred for 24 h at 35 ° C and 400 rpm to form a gel, and finally transferred to a hydrothermal kettle. 130°C hydrothermal for 72h, suction filtration, washing with deionized water, and then calcining the washed product at 550°C for 8h to obtain a hard template agent;

[0057] (2) Disperse 40 g of the hard template agent obtained in step (1) in 800 mL of deionized water, and simultaneously add active component precursors (50 g of copper nitrate, 10 g of magnesium nitrate, 2...

Embodiment 3

[0063] A mesoporous composite copper catalyst for producing carbon monoxide from methanol, the preparation method comprising the following steps:

[0064] (1) Stir the triblock copolymer P123, deionized water, and 35wt% hydrochloric acid solution at a volume ratio of 1:16:1 at 35°C and 300rpm for 5h, and then add the same mass of triblock copolymer P123. The n-butanol was continued to stir for 1 h, and then fumed silica powder or ethyl orthosilicate solution with twice the mass of n-butanol was added, stirred for 16 h at 35 °C and 400 rpm to form a gel, and finally transferred to a hydrothermal kettle. 130°C hydrothermal for 96h, suction filtration, washing with deionized water, and then calcining the washed product at 700°C for 10h to obtain a hard templating agent;

[0065] (2) Disperse 50 g of the hard template agent obtained in step (1) in 700 mL of deionized water, and simultaneously add active component precursors (55 g of copper nitrate, 9.5 g of magnesium nitrate, 15 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com