Electromagnetic adsorption resonance vibration device and method

A technology of adsorption device and vibration device, which is applied in the direction of fluid using vibration, can solve the problems of reducing the residual tensile stress of the weld, improving the quality of the weld, and achieving the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

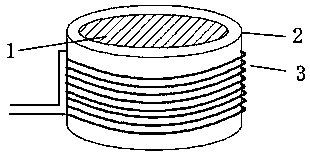

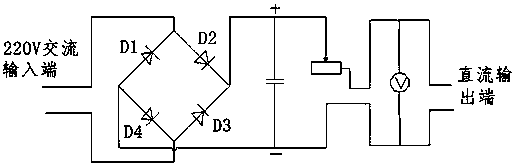

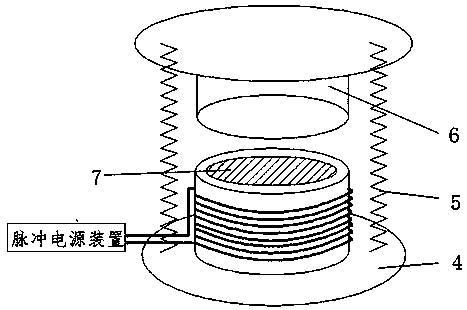

[0039] Please refer to Figure 1 to Figure 5, an electromagnetic adsorption resonance device, including a vibrating device 10, a cylindrical shell 8, a partition 9 and an electromagnetic adsorption device 2 11. The vibrating device is installed on the cylindrical shell, the interlayer is arranged between the vibrating device and the cylindrical shell, and the interlayer is located on the top surface of the cylindrical shell. The electromagnetic adsorption device 2 includes a mounting plate, an electromagnetic induction device 2 installed in a cylindrical shell, and a DC power supply device connected to the electromagnetic induction device 2; the electromagnetic induction device 2 is connected to the mounting plate, the bottom surface of the cylindrical shell is empty, and the cylindrical shell The bottom end is connected with the mounting plate, and the mounting plate is provided with bolt holes. Vibration device comprises base 4, spring 5, vibrating body 6 and electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com