Nanofiber membrane, preparation method thereof and application of nanofiber membrane to oil-water separation

A nanofiber membrane, oil-water separation technology, applied in the field of its preparation and nanofiber membrane, can solve the problems of porosity and pore size that are not conducive to oil-water separation, lack of three-dimensional structure of fiber membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

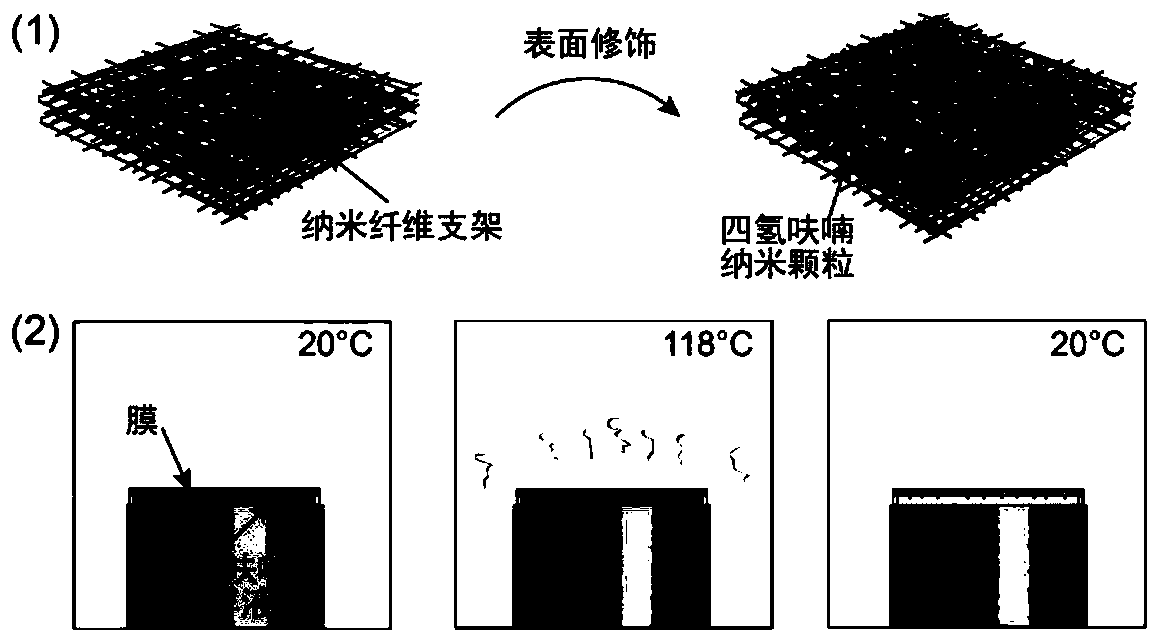

[0037] The present invention provides a method for preparing a nanofiber membrane described in the above technical solution, comprising the following steps:

[0038] Disperse polytetrafluoroethylene nanoparticles in water to obtain PTFE emulsion;

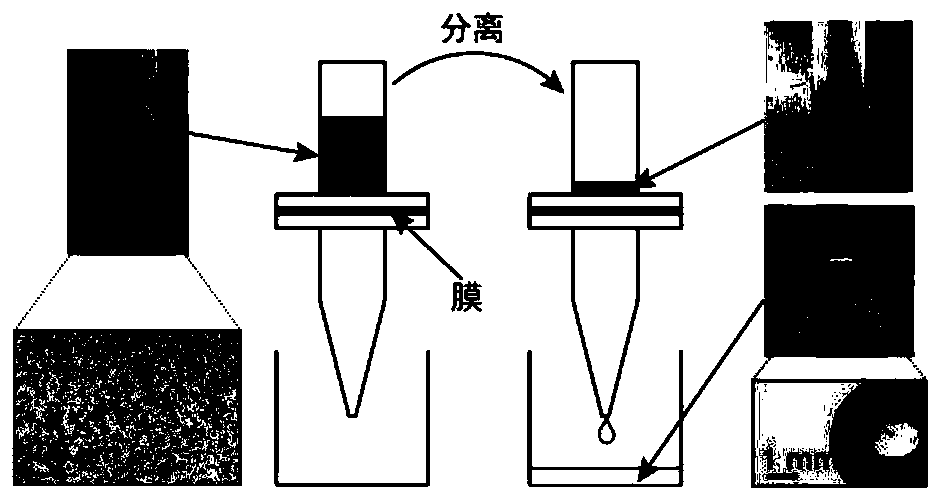

[0039] Fix the cross-shaped nanofiber membrane on the substrate, leave a gap of about 3 mm between the substrate and the fiber membrane, then squeeze the PTFE emulsion into the gap, and dry to obtain the nanofiber membrane.

[0040] The invention disperses polytetrafluoroethylene nanoparticles in water to obtain PTFE emulsion. In the present invention, the concentration of the PTFE emulsion is preferably 0.1-15wt%; more preferably 0.3-10wt%.

[0041] After obtaining the PTFE emulsion, the present invention fixes the cross-shaped nanofiber membrane on the base, leaving a gap of about 3mm between the base and the fiber membrane, then squeezes the PTFE emulsion into the gap, and dries to obtain the nanofiber membrane.

[0042] In the...

Embodiment 1

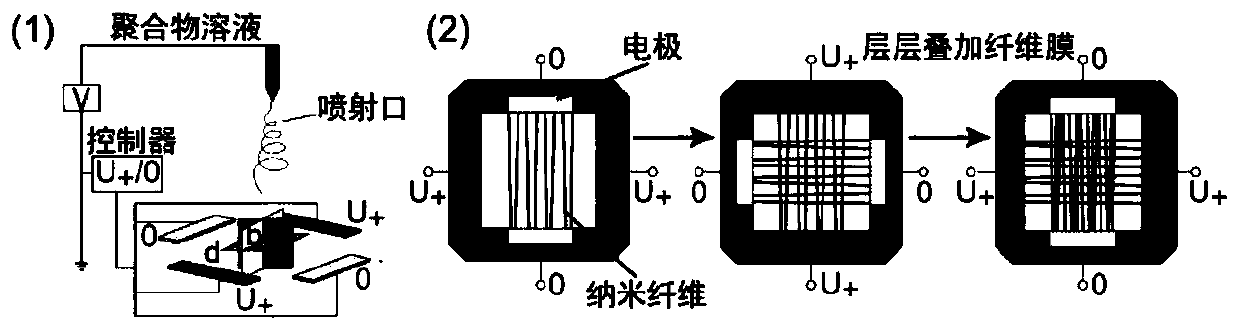

[0059] figure 1 A schematic diagram of the preparation process for preparing a cross-shaped nanofiber membrane in Example 1 of the present invention;

[0060] 1) At room temperature, mix dimethylformamide and tetrahydrofuran at a mass ratio of 1:1 as a solvent, and then add polyurethane particles into the solvent so that the mass fraction is 25%, to obtain a spinning solution;

[0061] 2) Adjust the height and position of the spinning nozzle so that the front end is vertically facing the grounded electrode on the left, the rear end of the spinning nozzle is connected to the injection pump through a catheter, the conductive part of the spinning nozzle is connected to a high-voltage DC power supply, and then the two horizontal One electrode is grounded, and the two electrodes in the vertical direction are connected to a high potential, about 1 to 3KV;

[0062] 3) Adjust the high-voltage DC power supply to about 10-15KV, and then feed the spinning solution through the syringe pu...

Embodiment 2

[0072] When the receiving substrate is a whole piece of conductor, the fibrous film with disordered internal fiber arrangement is collected. The mechanical properties (single stretching and cyclic stretching curves) of cross-shaped nanofiber membranes and disordered fiber membranes are as follows: Figure 5 as shown, Figure 5 Schematic diagram of the oil-water separation of the nanofibrous membrane prepared in Example 1 of the present invention, wherein (c) is the single tensile stress-strain curve of the ordered membrane and the disordered membrane; (d) is the stress of the ordered membrane stretched one hundred times Strain curve; (e) is the stress-strain curve of the disordered film stretched 100 times. From Figure 5 It can be seen that the maximum stress of the cross membrane in a single tensile test is close to 6MPa, and the maximum stress of the disordered membrane is lower than 3MPa. In the cyclic stretching experiment, when the number of stretching is 100, the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com