Supergravity sewage treatment device and supergravity sewage treatment technology

A sewage treatment device and technology for sewage treatment, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., to achieve the effect of improving capacity and increasing adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

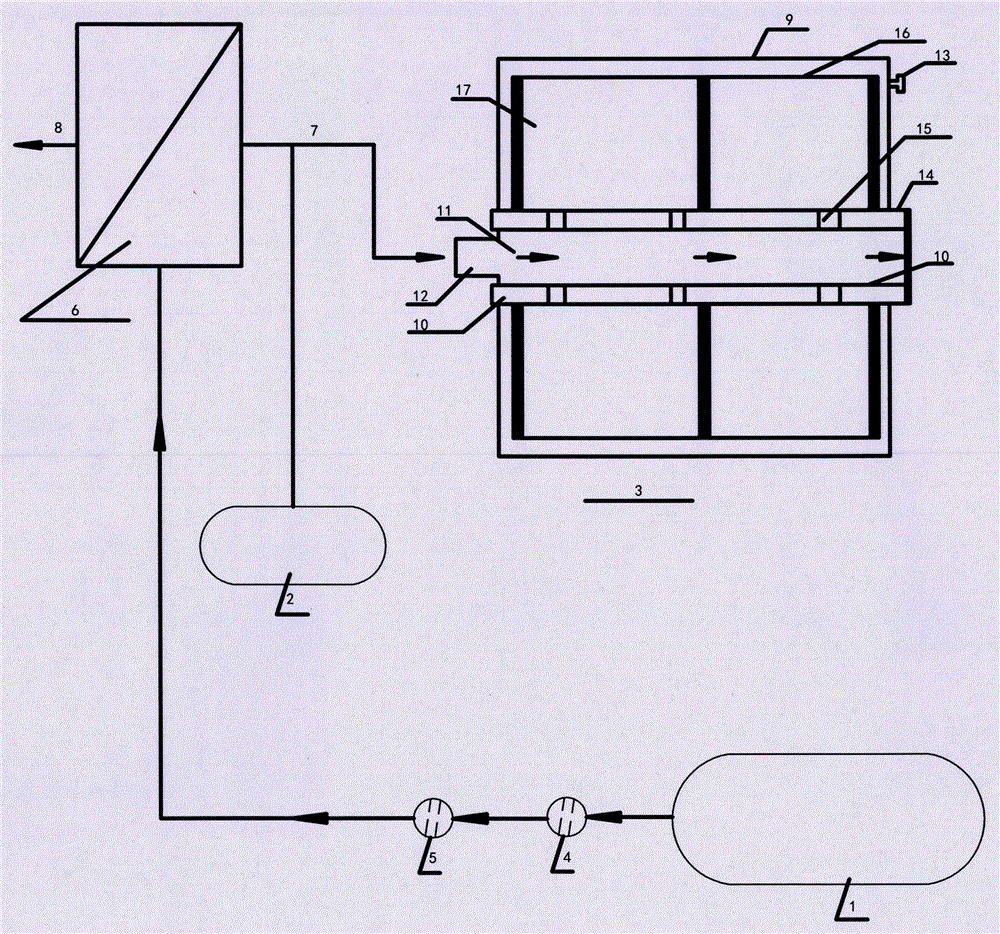

[0041] The high-gravity sewage treatment device of the present invention includes a storage tank 1 for storing electric desalination sewage or air-lifted water sewage, a lye tank 2 for storing demulsifiers, and a high-gravity machine 3; wherein a suitable one is selected The purpose of lye is to contact and exchange with electric desalination sewage to remove the impurities that need to be removed.

[0042] A filter is connected to the sewage outlet of the storage tank 1; a membrane module 6 is connected to the sewage outlet of the filter, wherein for the selection of the membrane module 6, it is preferably set to be composed of a multi-stage tubular membrane module 6, and the multi-stage tube The type membrane module 6 has a concentrated water outlet 7 and a purified water outlet 8; wherein, the purified water outlet 8 can be directly discharged to a sewage purification treatment plant for further subsequent treatment.

[0043]The supergravity machine 3 has a casing 9, on whi...

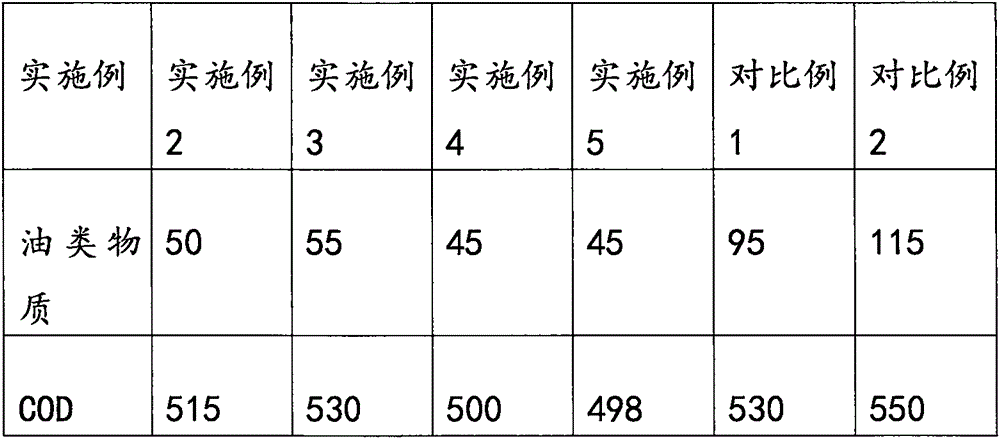

Embodiment 2

[0051] The supergravity sewage treatment process of the present invention, processing step is as follows:

[0052] (1) Perform filtration and impurity removal treatment on electro-desalted sewage at 40°C to filter out organic particles with a particle size greater than 50um;

[0053] (2) Cooling the sewage after removing impurities until its temperature is 40°C;

[0054] (3) Boost the pressure of the cooled sewage to 0.3MPa, set the temperature at 40°C, and enter the membrane module. The membrane material of the membrane module is a highly hydrophilic and super oleophobic membrane. Side concentration and enrichment, oil and water are separated;

[0055] (4) The concentrated oil and impurity concentrated water and demulsifier after membrane separation enter the fluid inlet of the supergravity machine under the rotating state, and spin into the packing area after passing through the rotating channel. In the packing area, the concentrated water and broken water The emulsion is ...

Embodiment 3

[0057] The supergravity sewage treatment process of the present invention, processing step is as follows:

[0058] (1) Filter and remove impurities from the air-lifted sewage at 50°C, and filter out organic particles with a particle size greater than 50um;

[0059] (2) Cooling the sewage after removing impurities until its temperature is 50°C;

[0060] (3) Boost the pressure of the cooled sewage to 1.0MPa, set the temperature at 50°C, and enter the membrane module. The membrane material of the membrane module is a highly hydrophilic and super oleophobic membrane. Side concentration and enrichment, oil and water are separated;

[0061] (4) The concentrated oil and impurity concentrated water and demulsifier after membrane separation enter the fluid inlet of the supergravity machine under the rotating state, and spin into the packing area after passing through the rotating channel. In the packing area, the concentrated water and broken water The emulsion is mixed with liquid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com