Patents

Literature

30results about How to "Guaranteed inner diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

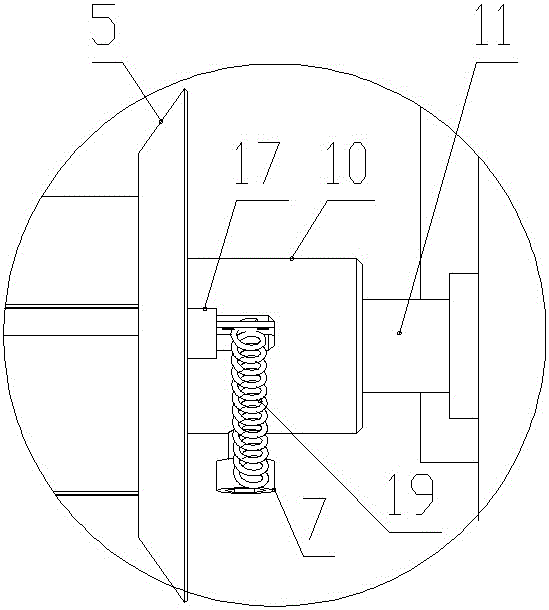

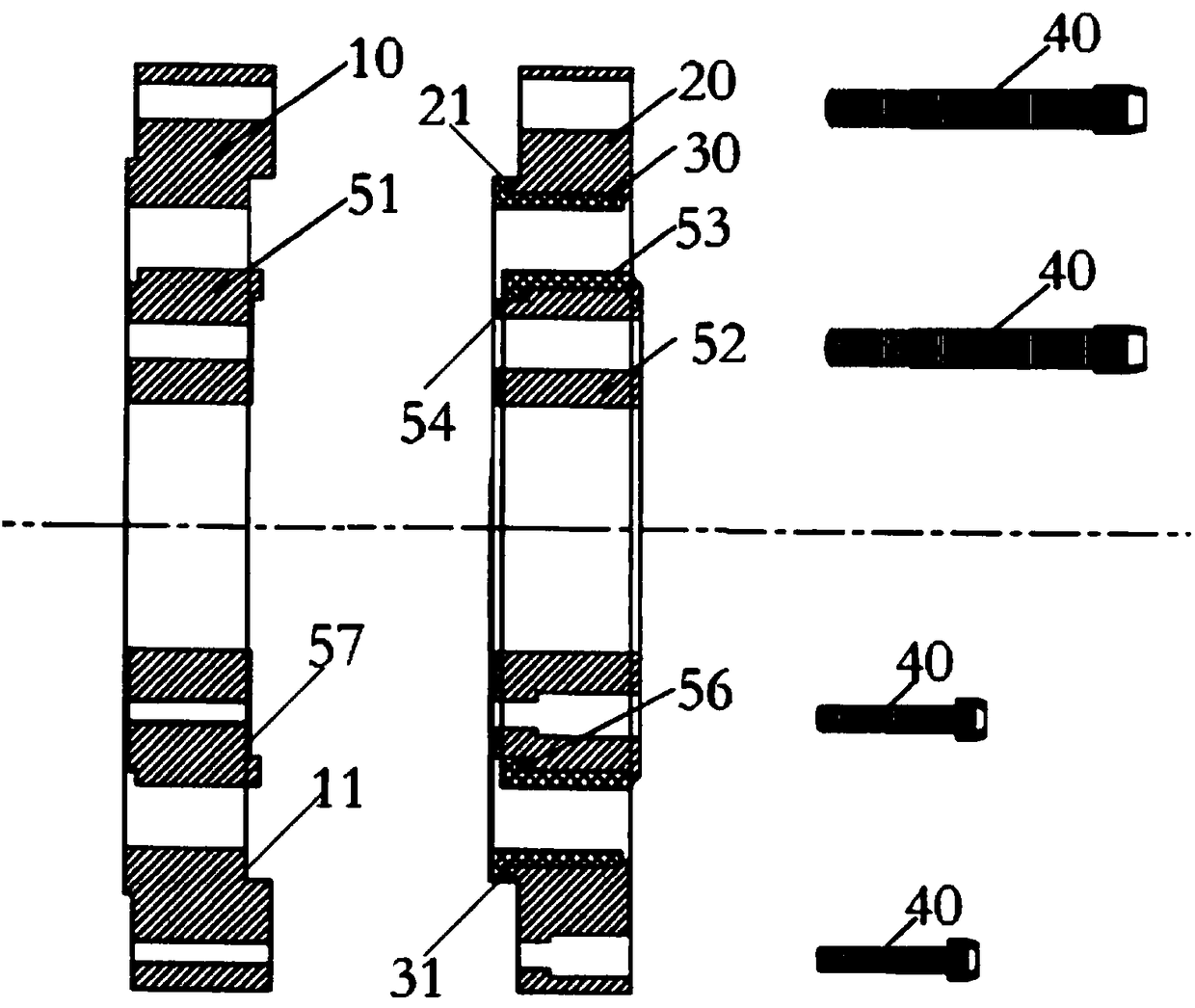

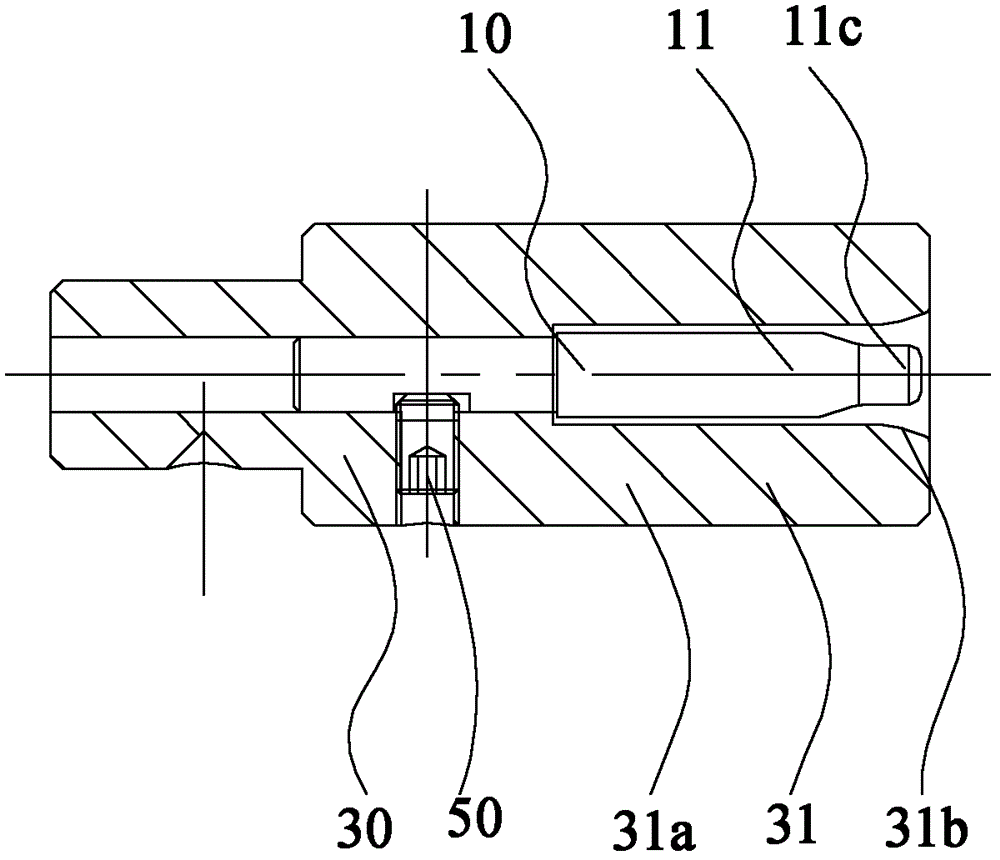

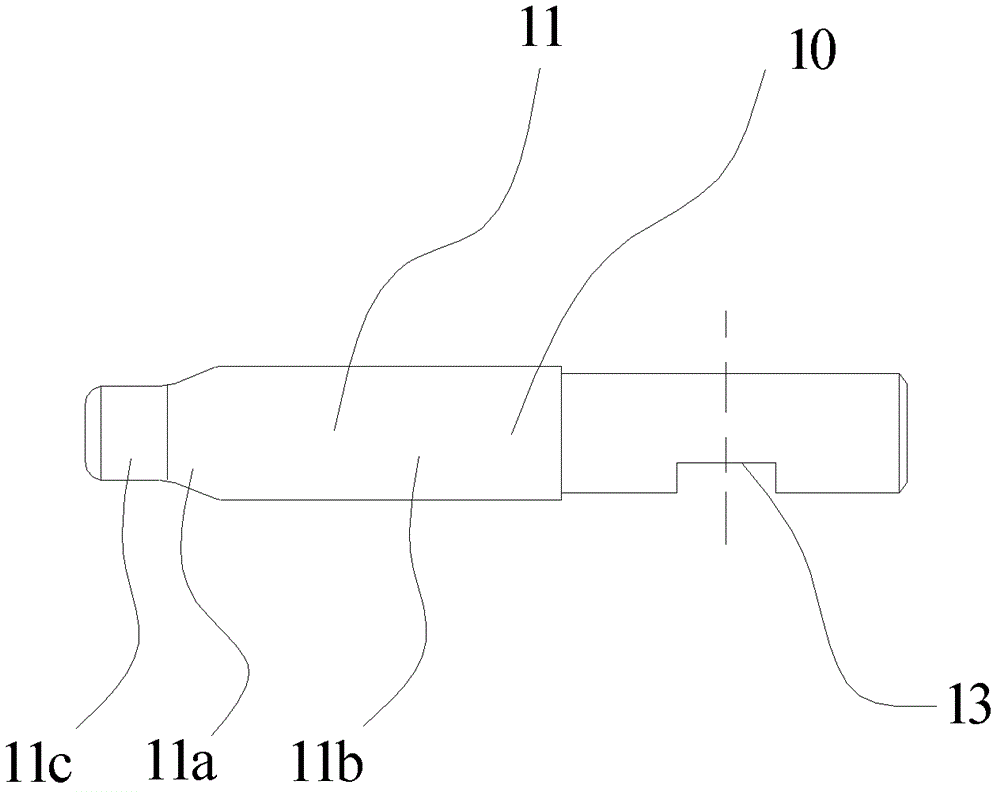

Punching head

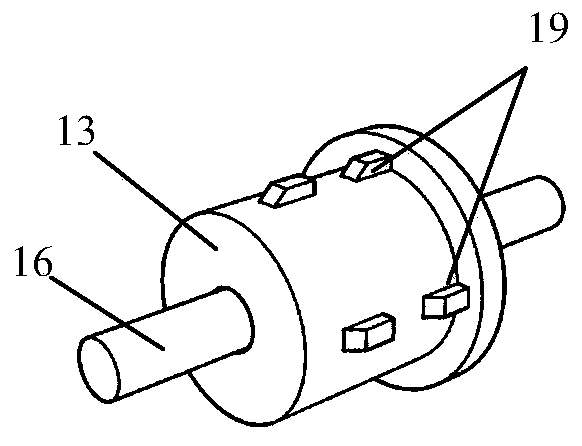

ActiveCN102962333AGuaranteed inner diameterSimplify the production processShaping toolsEngineeringPunching

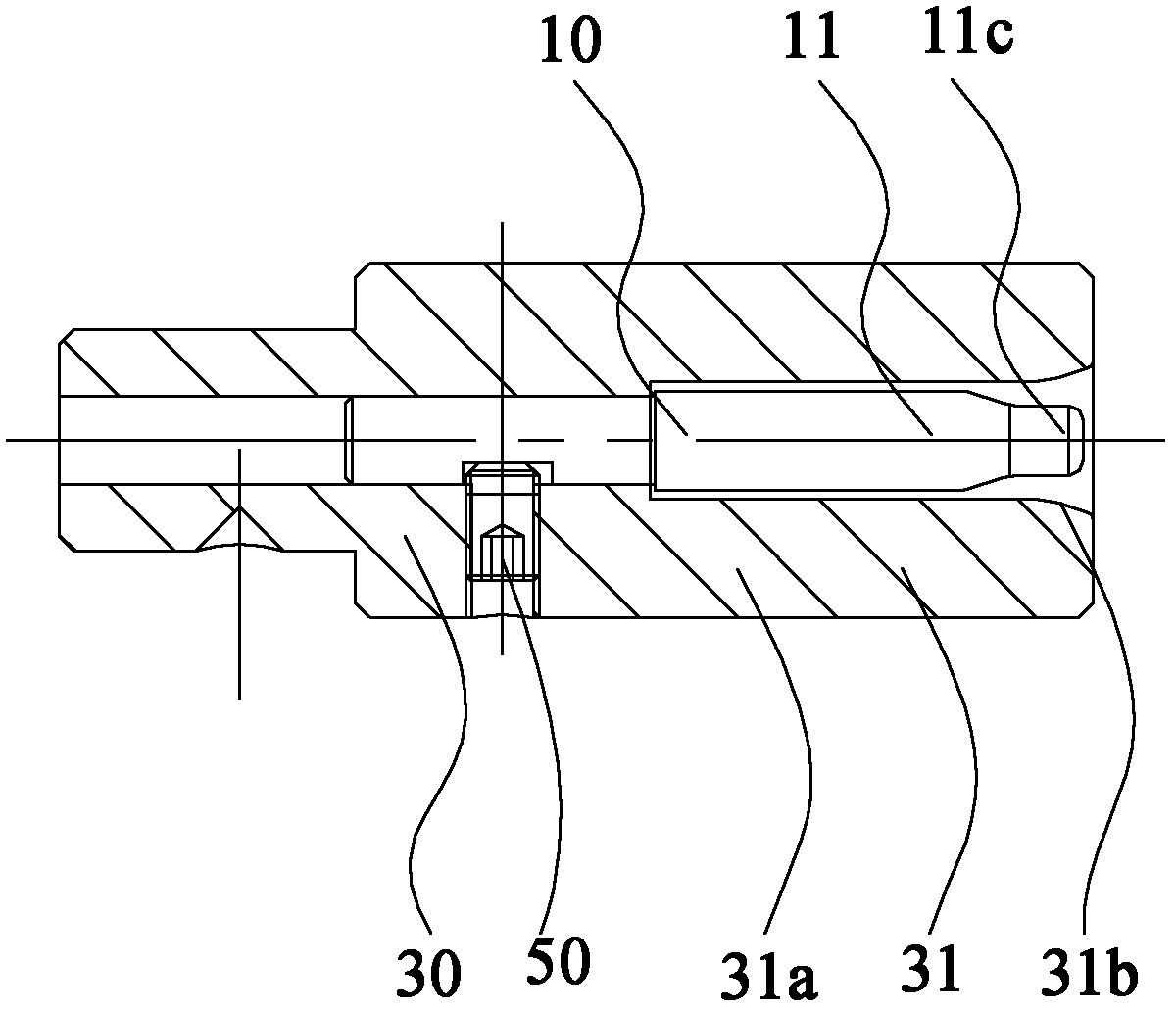

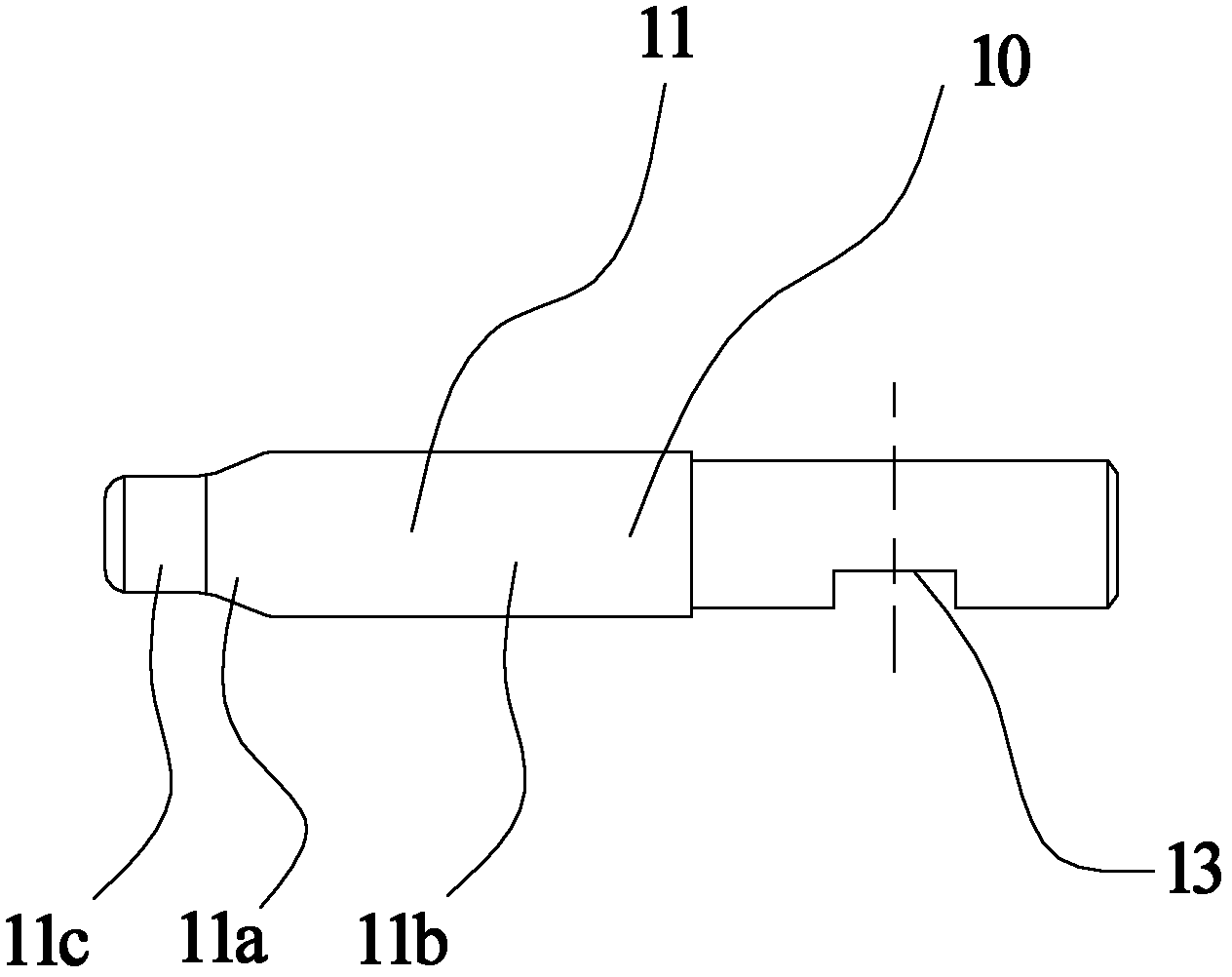

The invention provides a punching head, which comprises an expanding mold core (10) and a reducing jacket (30), wherein the first end of the expanding mold core (10) is an expanding end (11) and the second end of the expanding mold core (10) is a connecting end; and the expanding mold core (10) is installed in the inner hole of the reducing jacket (30), the first end of the reducing jacket (30) is a reducing end (31), and a gap is kept between the reducing end (31) and the expanding end (11). The punching head has the advantages of high production accuracy, simple production process and high efficiency.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

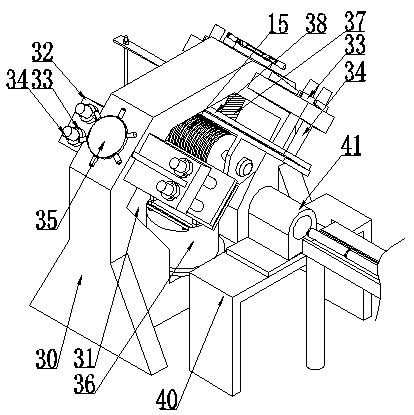

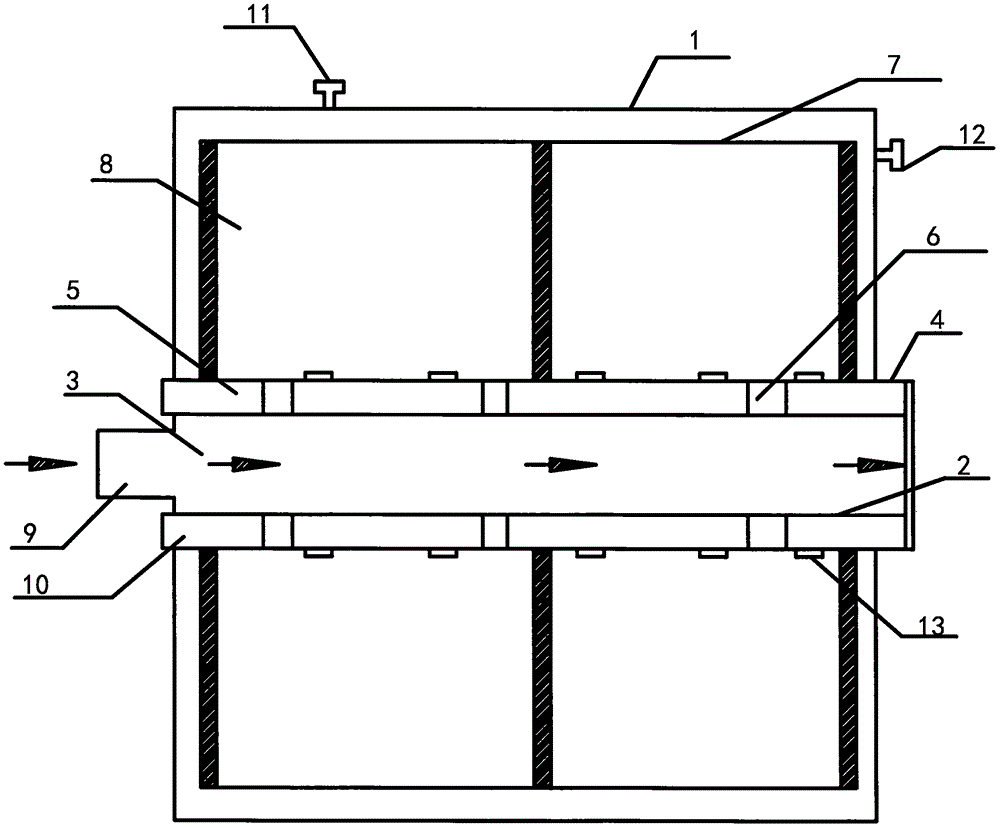

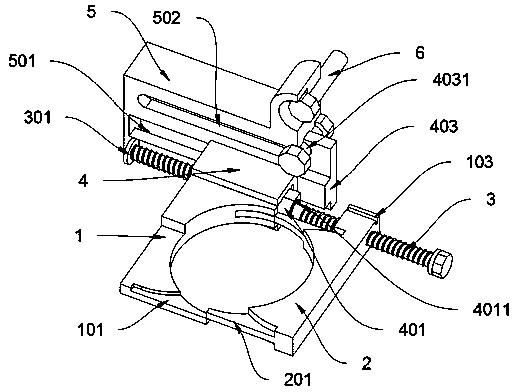

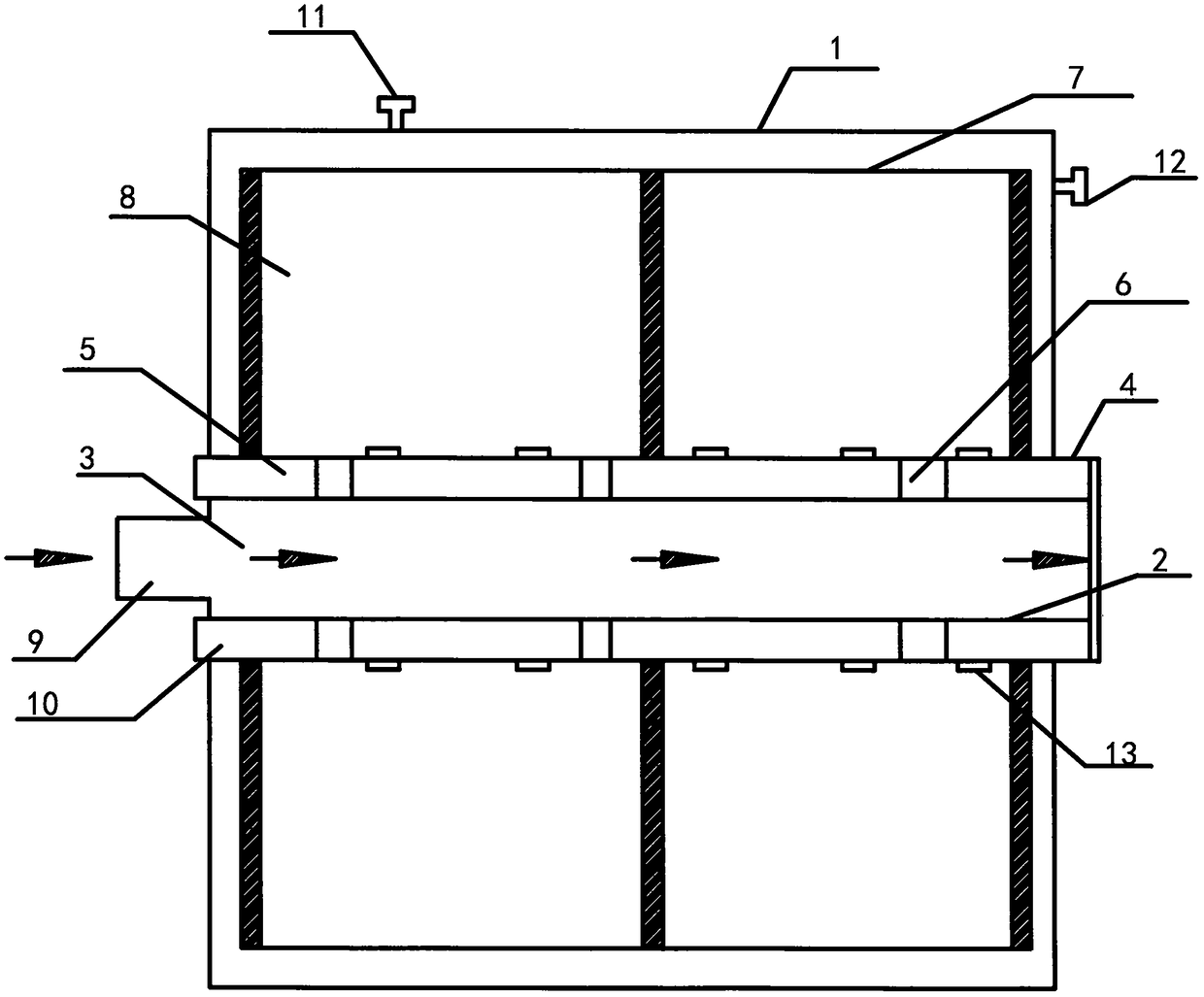

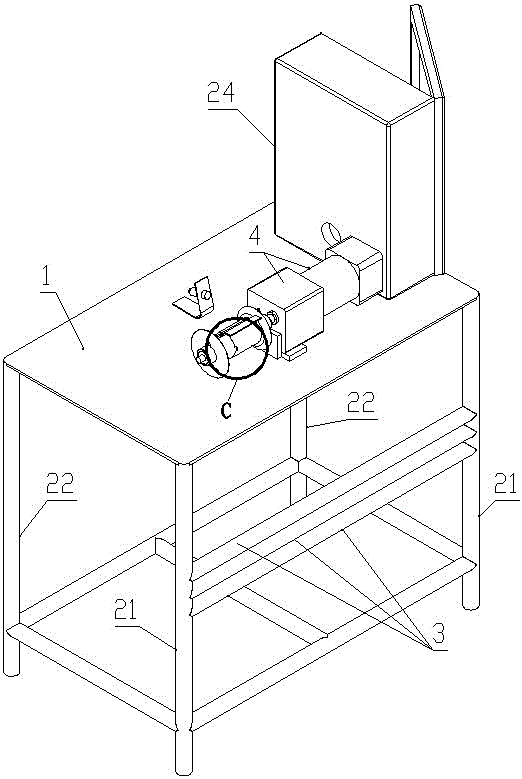

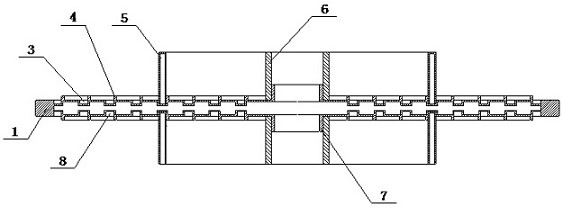

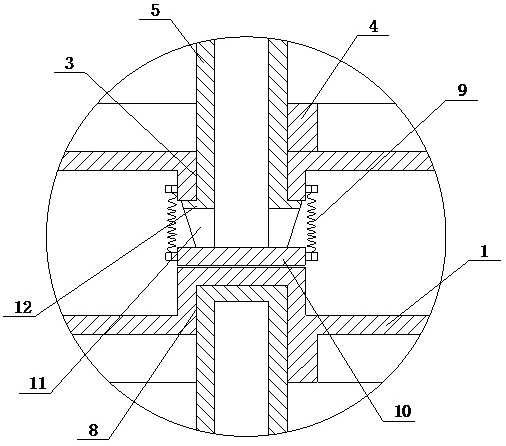

Extrusion and press molding equipment for fin heat exchange pipes

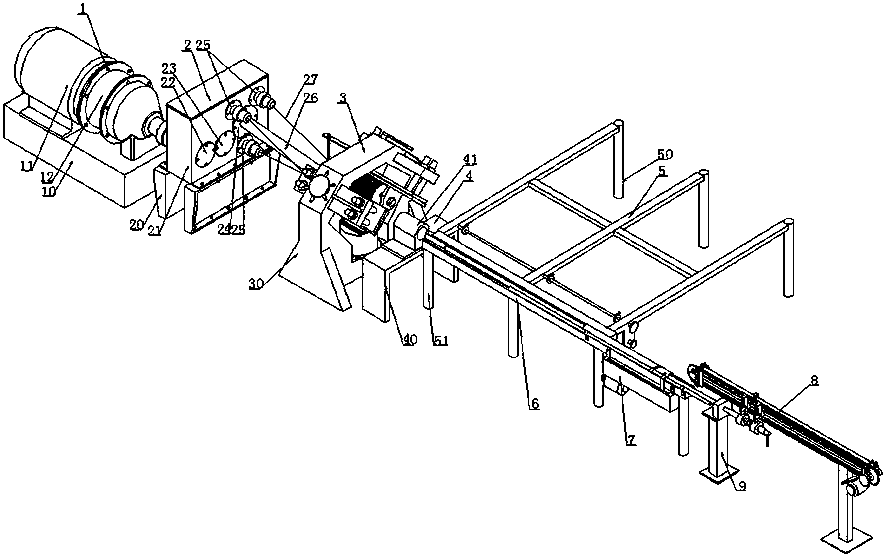

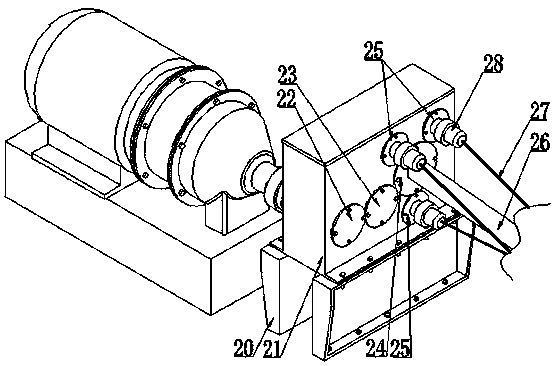

PendingCN109351879AHigh strengthGuaranteed inner diameterShaping toolsHeat exchange apparatusIntermediate frequencyEngineering

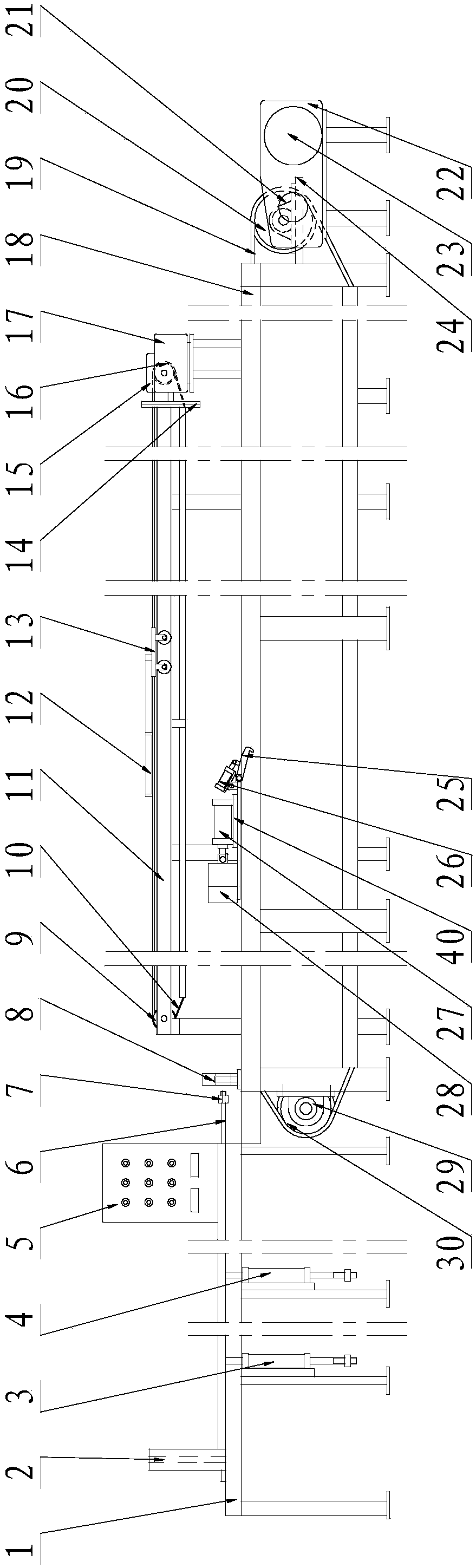

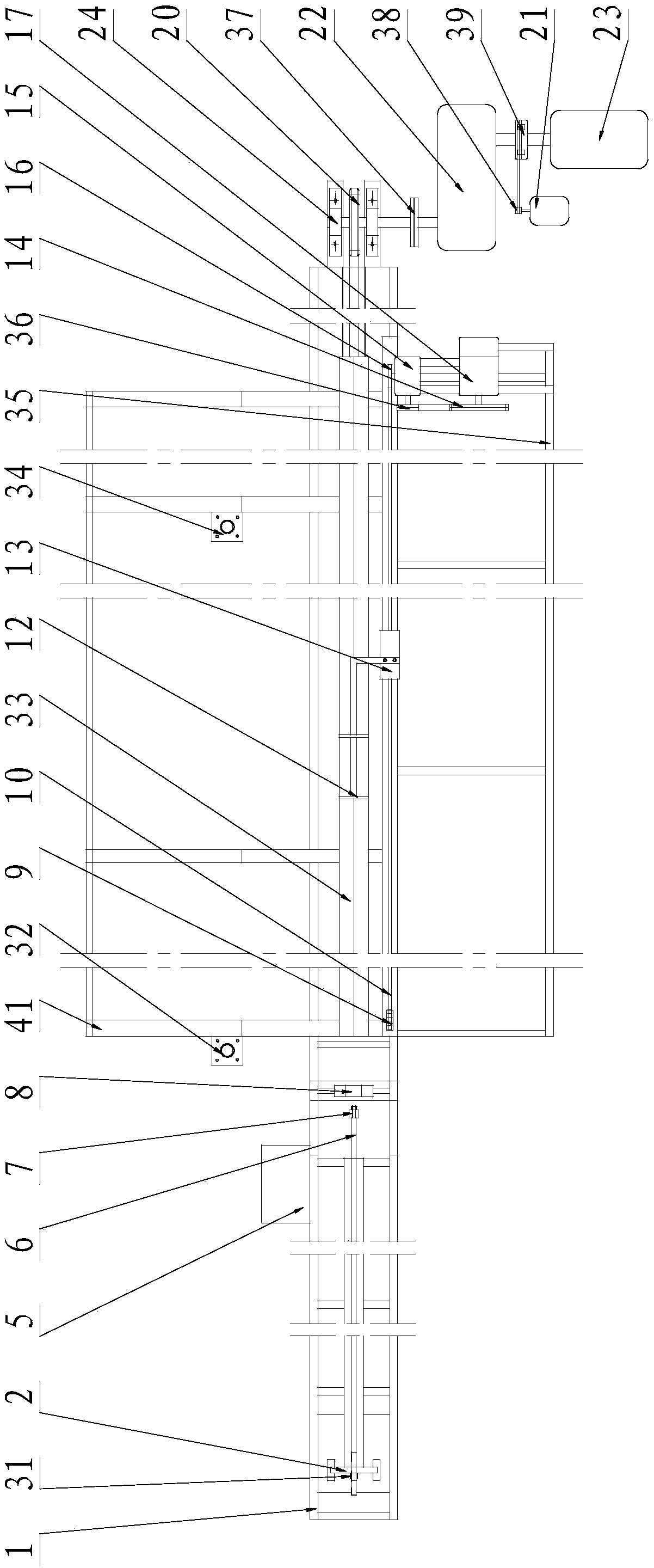

The invention discloses extrusion and press molding equipment for fin heat exchange pipes. The equipment comprises a power source module, wherein the power source module and a driving module are connected in a direct connection mode, the right side of the driving module is connected with a forming module, the forming module is adjacent to a heating module, and the right end of the heating module is connected with a feeding module; and a material table is arranged on the rear side of the feeding module, a metal pipe pushing module is fixedly arranged on the front side face of the feeding module, a supporting group is arranged on the right side of the feeding module, and an inner core pushing module is arranged at the top of the supporting group. The metal pipe is heated at a high temperature through medium-frequency heating by the equipment, the metal pipe is pushed to a front side extrusion and press module in the forming module and between a rear side extrusion and press module and abottom extrusion and press module, the external fins of the fin heat exchange pipes are molded through the extrusion and press of the front side extrusion and pres module, the rear side extrusion andpress module and the bottom extrusion and press module, so that the strength of the produced fin heat dissipation pipes is high, heat exchange performance is good, and the phenomenon of dust deposition in a using process can be effectively avoided.

Owner:张建梅

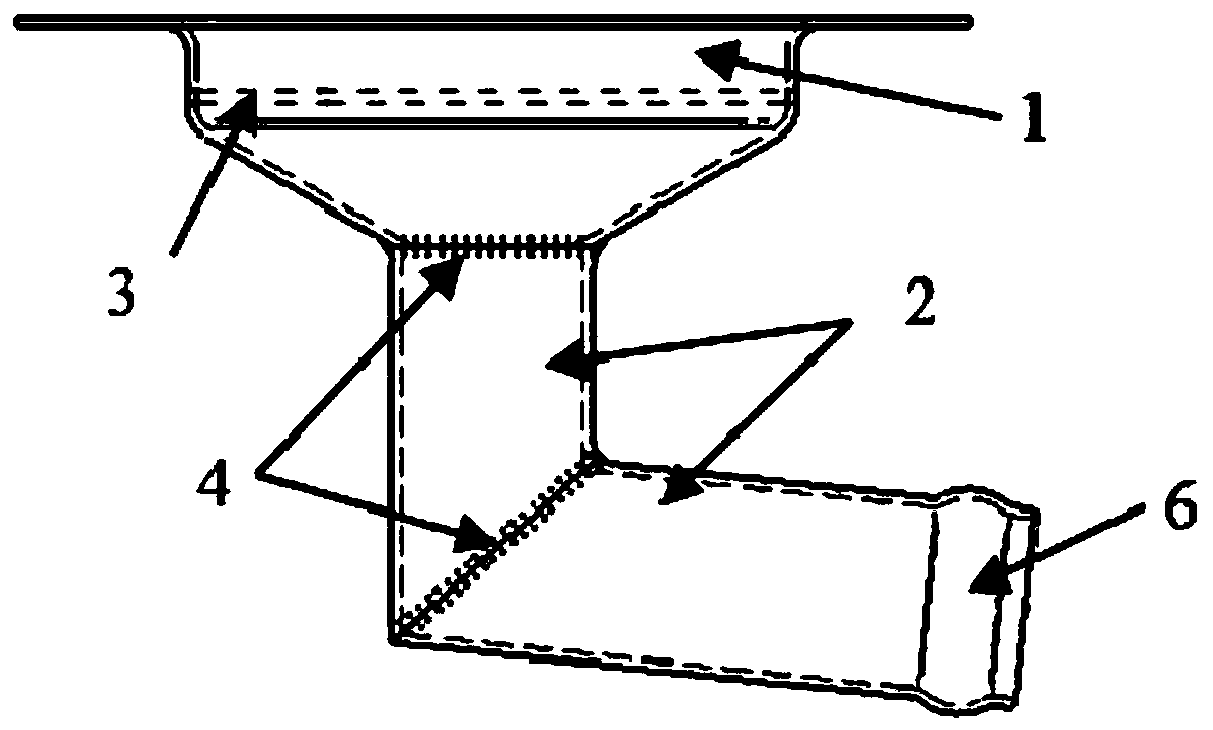

Forming method and device for simultaneously thickening pipe end shrinkage mouth

ActiveCN107639172AIncrease profitSmall machining allowanceShaping toolsMetal working apparatusHydraulic cylinderCircular disc

The invention discloses a forming method and device for simultaneously thickening a pipe end shrinkage mouth. The forming device comprises a hydraulic cylinder, a push head, a die, a filler block, heating bars, a cooling device and a heating device; a circular disc is connected to the hydraulic cylinder, a guiding cover is arranged on the circular disc, the push head is arranged on the hydraulic cylinder and penetrates through the guiding cover, the die is arranged at one side of the push head, the cooling device is arranged between the die and the push head, the die comprises a mold cavity and heating holes, the filler block is arranged in the mold cavity, and the heating bars are arranged in the heating holes, and are connected with the heating device; the filler block comprises a conical part and a reducing part, the conical part is arranged at one end of the filler block and is connected with the reducing part, and a material pushing rod is further arranged at one end of the reducing part. Through the design of the conical part of the filler block, a certain supporting effect is achieved on a pipe blank in a sudden-change area, the situation that the pipe blank gets unstable inwards when the pipe blank suffers from the axial compression stress is prevented, the forming technology is simple, the machining allowance is reduced, and the processing cost and production investment are lowered.

Owner:NANCHANG HANGKONG UNIVERSITY

Sulfur tail gas super-gravity desulfurization device

ActiveCN106744705AAchieve partial oxidationImplement spin-inGas treatmentDispersed particle separationSulfurLiquid storage tank

The invention relates to a sulfur tail gas super-gravity desulfurization device and process thereof. The sulfur tail gas super-gravity desulfurization device comprises an alkali liquid storage tank and a super-gravity machine; the device utilizes alkali liquid to desulfurize sulfur tail gas, and a unique super-gravity machine structure is provided; in the structure, a hollow rotary shaft with a fluid channel is formed in a shell in a manner of penetrating through the middle axis of the shell, and a sleeve with a gas channel function sleeves the hollow rotary shaft; meanwhile, a rotary channel, which is communicated with a filling region and is provided with a spiral channel, is also formed on the basis; fluid passes through the hollow rotary shaft and then self rotation of the fluid is realized through the rotary channel, and then the fluid enters the filling region; the liquid is crushed and torn into small liquid drops under the action of a centrifugal force of liquid and is in sufficient contact with liquid reverse-flow small bubbles, and a phase interface, which is rapidly updated, is provided; crushing and tearing mixing of the fluid and gas is further realized by utilizing the self-rotation under a rotary state; the sufficient degree of gas-liquid contact is improved, and furthermore, the better sulfur tail gas desulfurization effect is obtained.

Owner:北京清大华亿科技有限公司 +2

Sewer pipeline conveying pipe for sewage treatment and fixing device

InactiveCN111519733AChanging the clamping distanceGuaranteed installationPipe supportsSewer pipelinesStructural engineeringSewage treatment

The invention discloses a sewer pipeline conveying pipe for sewage treatment and a fixing device, and relates to the technical field of pipeline fixing devices. The fixing device solves the problem that the clamping position cannot be adjusted again after an existing pipeline fixing device is fixed, and the clamping and fixing distance cannot be adjusted by a clamping piece of the fixing device. According to the sewer pipeline conveying pipe for the sewage treatment and the fixing device, the fixing device comprises a positioning block a and a positioning block b, wherein the positioning blocka and the positioning block b are inserted into the left end and the right end of a fastening rod. After the device is fixed to a wall or the bottom of a cast-in-place slab through a fixing screw, amovable block can transversely move in a mounting base, the clamping positions of the positioning block a and the positioning block b are changed so as to adapt to the trend of a pipeline, normal mounting of the pipeline is guaranteed, and the positioning block b can be inserted into the positioning block a in a staggered mode, so that the clamping distance between the positioning block b and thepositioning block a is changed, and the fixing device can be suitable for clamping and fixing pipelines with different diameter models.

Owner:嘉兴新博信息科技有限公司

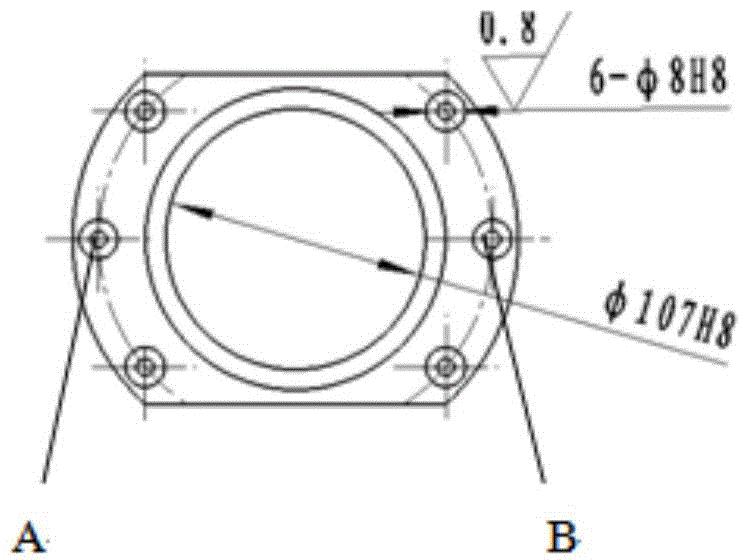

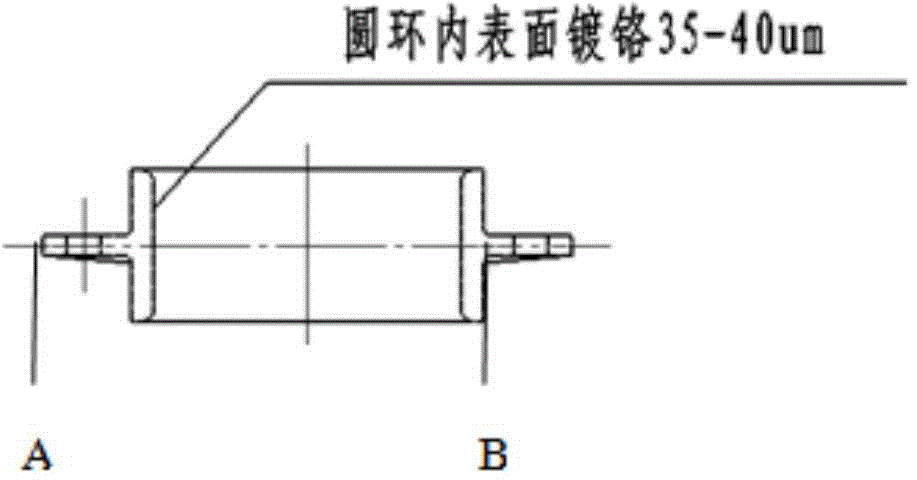

Chromium-plated tooling

The invention belongs to the field of surface treatment and particularly relates to a chromium-plated tooling. In the prior art, because a very poor depth capability in a chromium-plating process, uniformity degree of the thickness of a plating layer is difficult to ensure, so that only is a thick chromium can be plated, wherein the thickness is large than a required thickness by more than 50 [mu]m, and then the thick chromium is grinded until a use size in a mechanizing workshop. Another reason why a uniform thickness cannot be ensured is that an auxiliary anode during chromium-plating is required. Because a solution in a chromium trough is very low in transparency, the added auxiliary anode is very difficult to be ensured to be at a central position. Meanwhile, there is a potential risk that the anode contacts with the surface of a part, which causes electricity discharge and even causes part scrapping. The conventional production method is long in period, is high in cost and has quality potential risk. The chromium-plated tooling in the invention is convenient to use and is stable and reliable, and is suitable for producing aviation products as a tooling for plating chromium on inner bores. The tooling allows several parts to be electro-plated at the same time, is free of a grinding process after chromium-plating and can ensure inner diameter size and roundness of the part after chromium-plating to satisfy requirements.

Owner:HARBIN

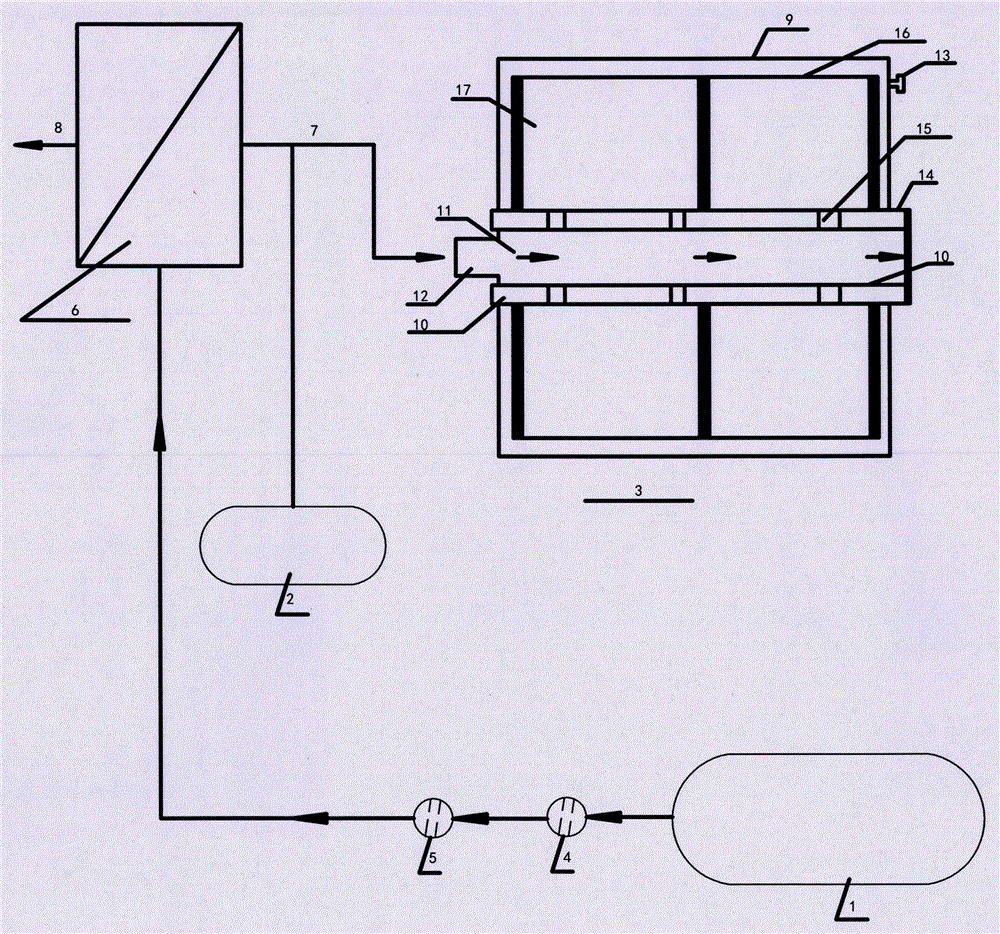

Supergravity sewage treatment device and supergravity sewage treatment technology

ActiveCN106830426AWell mixedImprove sufficiencyWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesDesalinationSewage

The invention relates to a supergravity sewage treatment device. Firstly, a filter and a membrane component are utilized for carrying out pretreatment on electro-desalting sewage, then alkali liquor in an alkali liquor tank is mixed with the sewage treated by the filter and the membrane component, the mixture enters a supergravity machine through a fluid channel of the supergravity machine, by virtue of a unique supergravity machine structure and a rotating channel which is formed between a hollow rotating shaft and a sleeve, is communicated with a filler region and is provided with a helical channel, spinning entrance of fluid through the rotating channel after passing the hollow rotating shaft is realized, intensive mixing of the sewage in the fluid and the alkali liquor is realized under the actions of a rotation acting force, a shearing force and a spinning acting force of the fluid at the moment that the fluid enters the filler region, and sufficient degree of liquid-liquid contact is improved, so that removal of the alkali liquor on oily substances and COD in the sewage is realized.

Owner:北京沃尔福环保科技有限公司

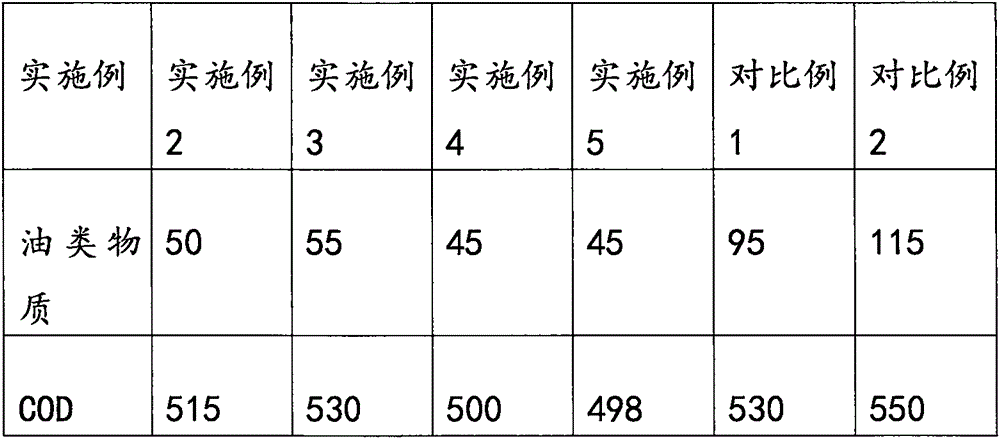

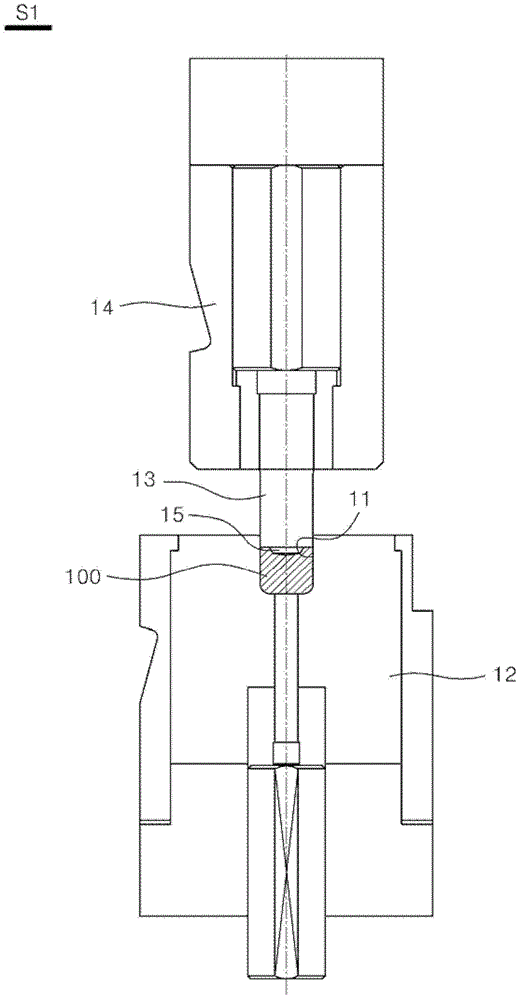

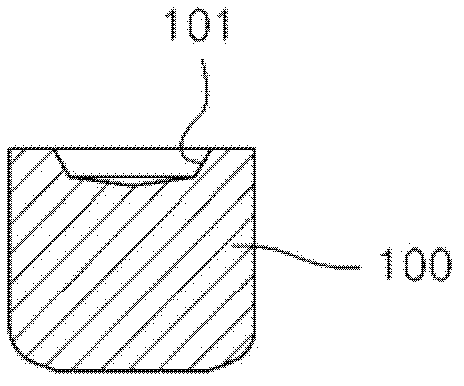

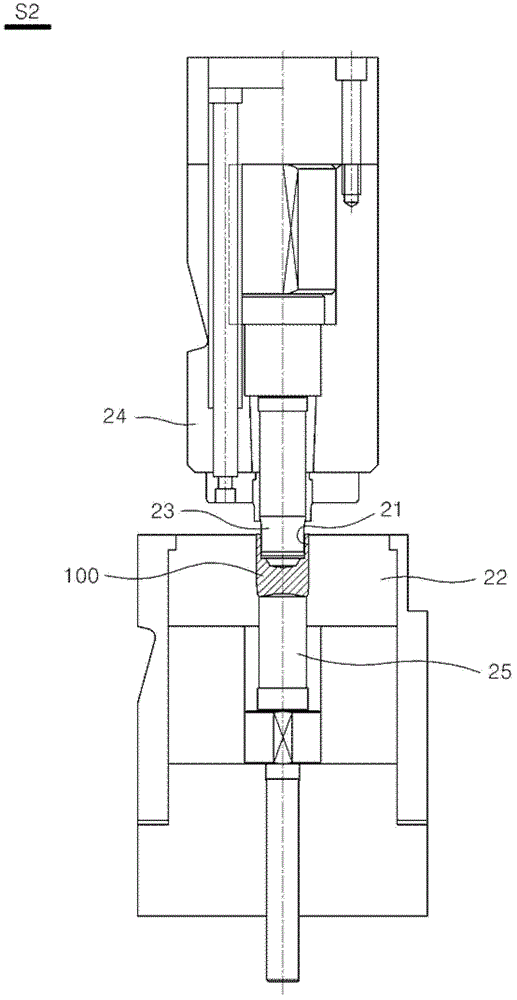

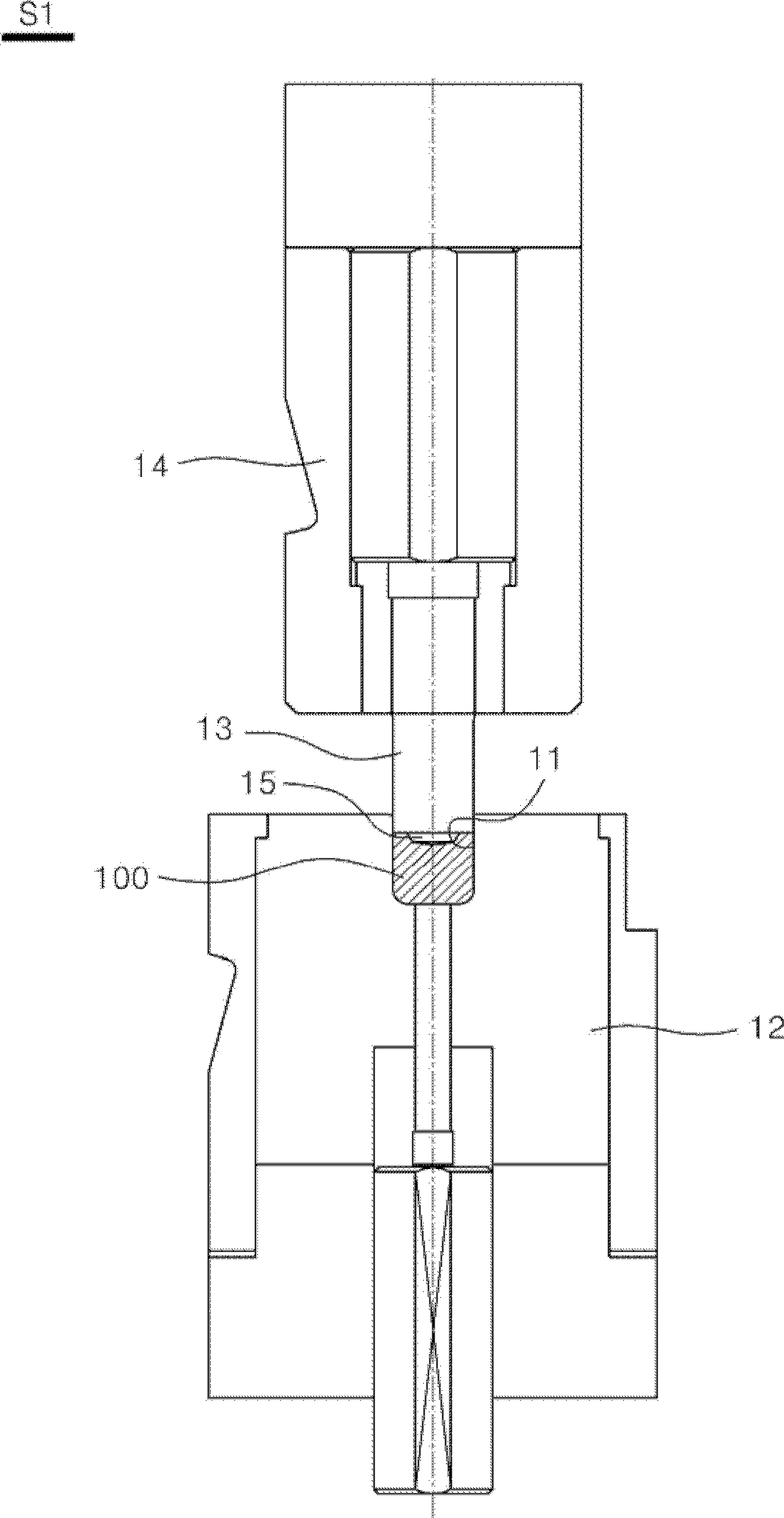

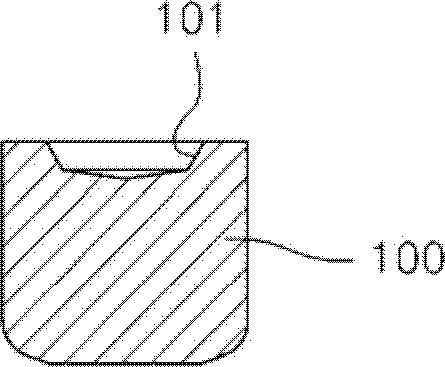

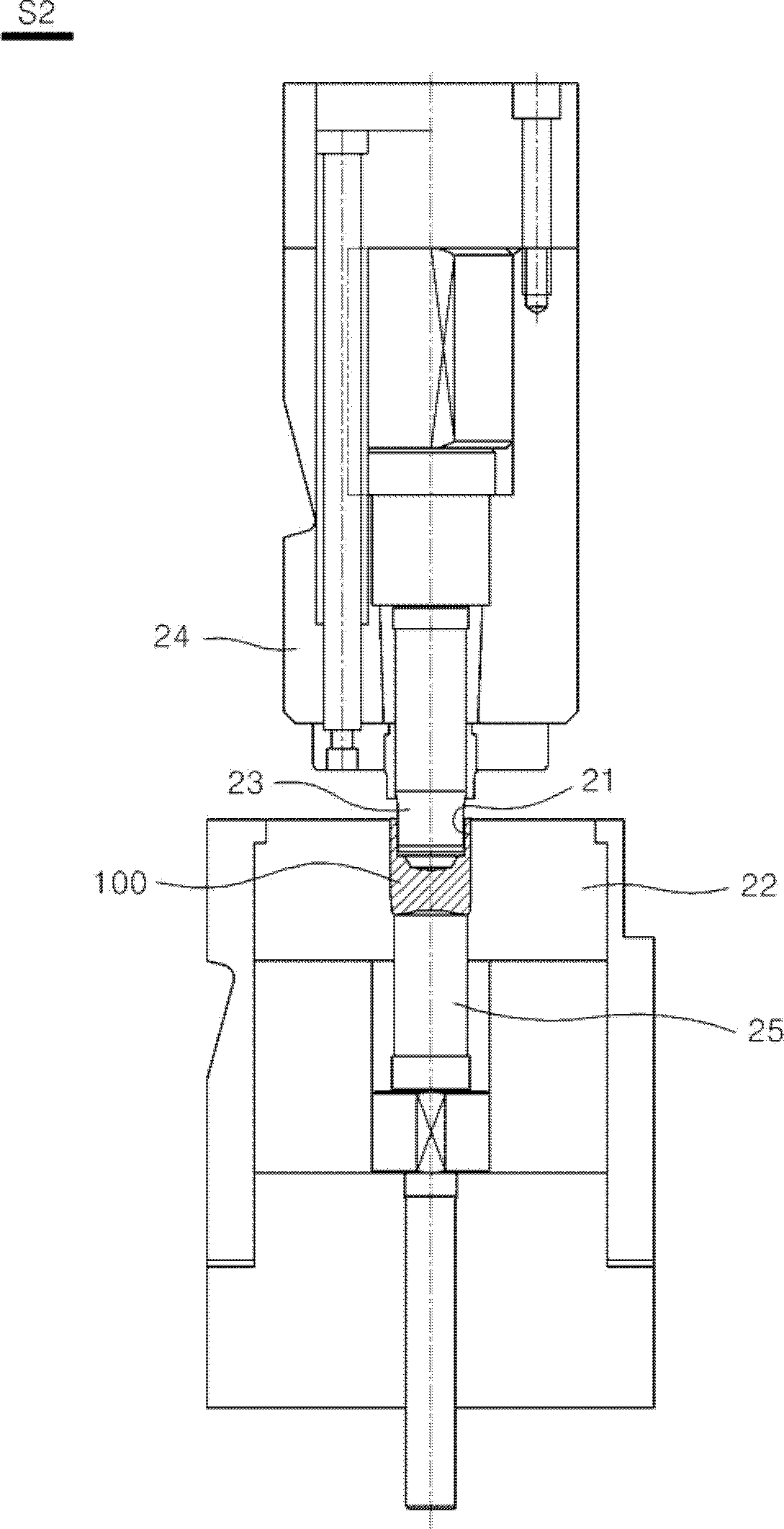

Manufacture method of break piston

ActiveCN103056209ASimple processGuaranteed inner diameterRailway componentsMetal-working apparatusCold formedEngineering

A brake piston manufacturing method is provided to simplify the process of making a piston, thereby improving productivity and work efficiency. CONSTITUTION: A brake piston manufacturing method comprises steps of: putting a material(100) into a first forming dies, pressing a first forming die of a first former cold forming machine to the material to process a position setting groove on the top of the material, putting the material into a second dies, pressing a second forming die of a second former cold forming machine to the material to process a first hollow portion(102) inside the material, putting the material into a third forming dies, pressing a third forming die of a third former cold forming machine to the material to chamfer a flow hole processing surface on the periphery of the first hollow portion of the material, putting the material into a fourth forming dies, pressing a fourth forming die of a fourth former cold forming machine to the material to process a third hollow portion(104) extended from the first hollow portion within the material.

Owner:KOWOO

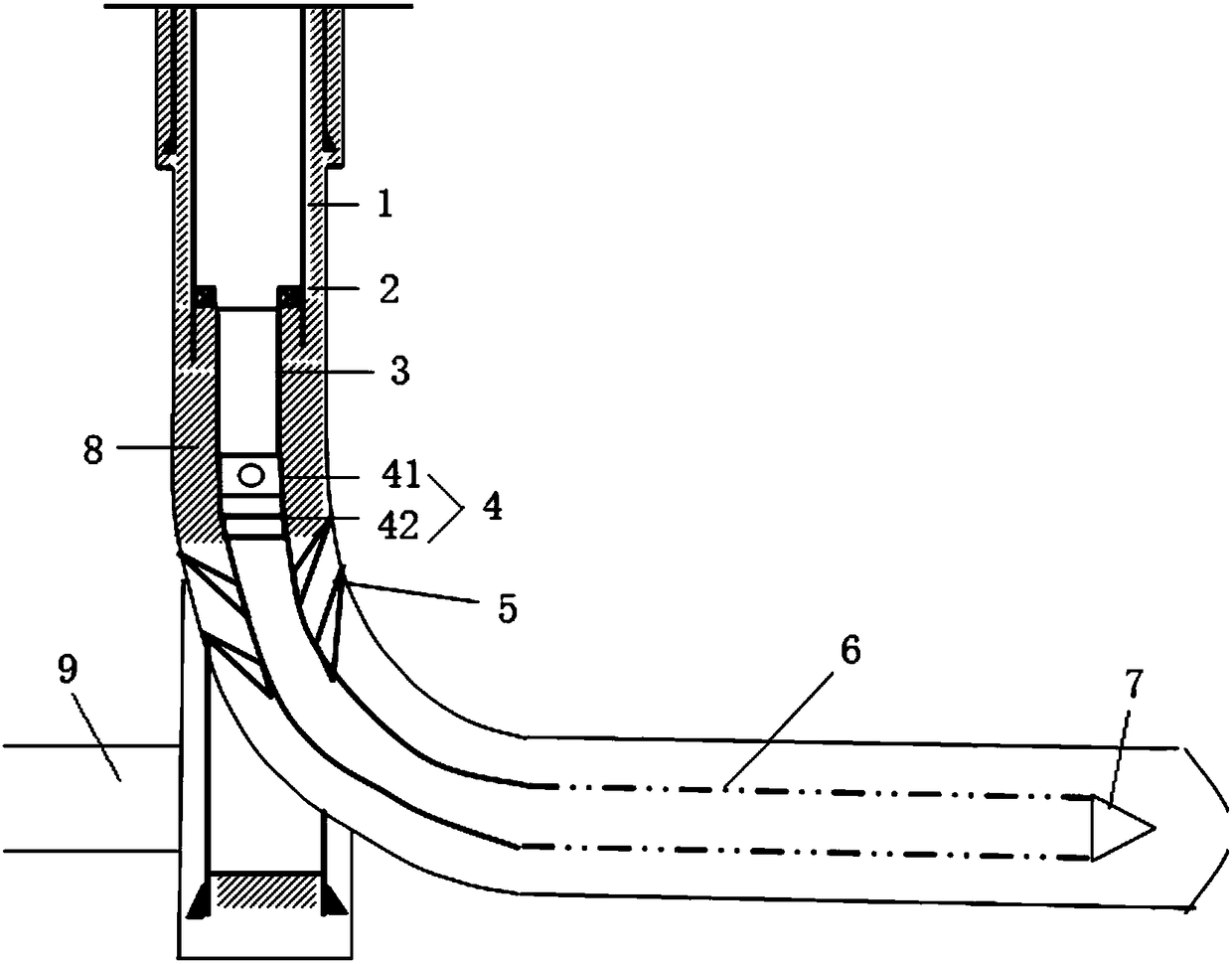

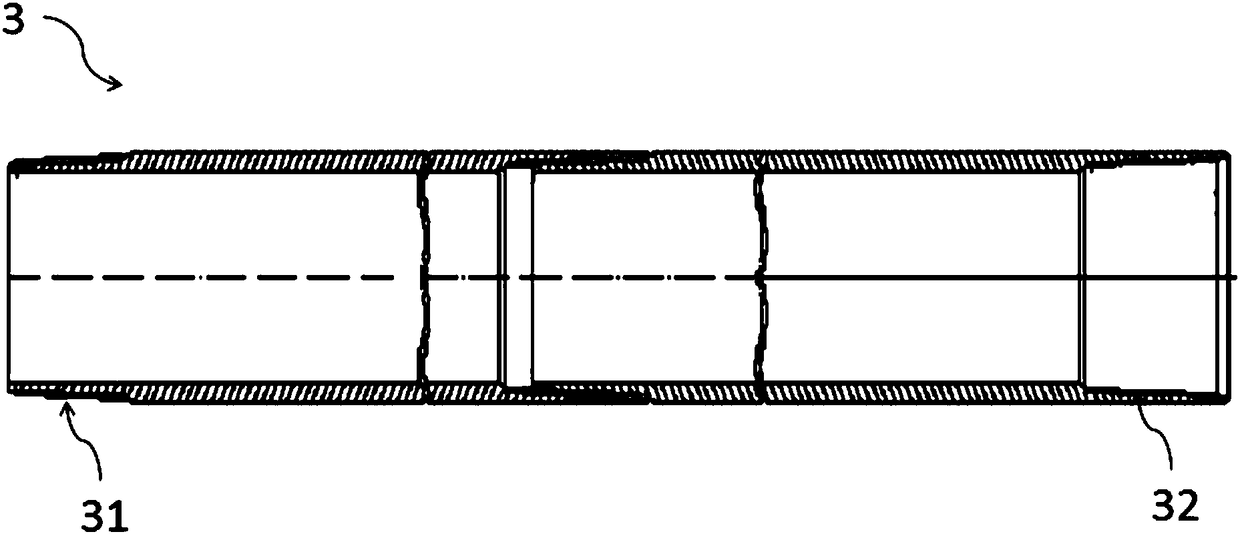

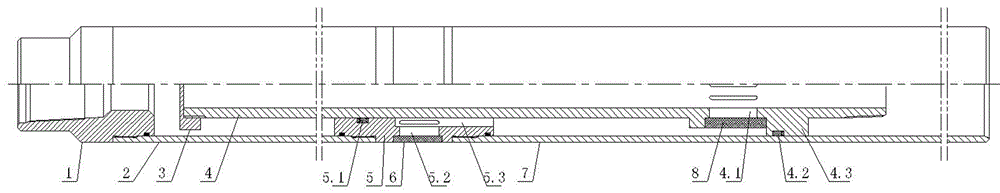

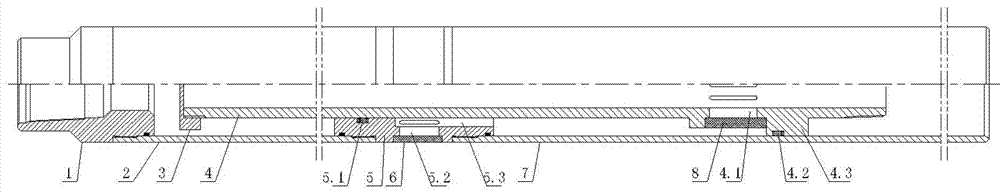

Sand control well completion tubular column

InactiveCN108204207AGuaranteed inner diameterHigh strengthDrilling rodsFluid removalWell cementingWell stimulation

The invention discloses a sand control well completion tubular column, and belongs to the technical field of oil and gas exploitation. The well completion tubular column comprises an original oil wellcasing, a tail tube hanger, a coupling-free casing section, a well cementation closing sleeve, a cement blocking piece and a coupling-free screen tube section; the tail tube hanger is hung in the original oil well casing and is internally provided with a casing touching-pressing rubber plug; the coupling-free casing section is connected to the tail tube hanger and formed by connecting a pluralityof casings which are connected through threads; the well cementation closing sleeve is connected into the coupling-free casing section, can achieve opening and closing on the coupling-free casing section, and can communicate the interior of the coupling-free casing section with the space between the well wall and the coupling-free casing; and the cement blocking piece is arranged on the coupling-free casing section in a sleeving mode, the coupling-free screen tube section is connected to the lower end of the coupling-free casing section, and the coupling-free screen tube section and the coupling-free casing section are connected through threads. According to the sand control well completion tubular column, the inner diameter of the well completion tubular column can be ensured so that later production, well stimulation and workover operation can be implemented.

Owner:PETROCHINA CO LTD

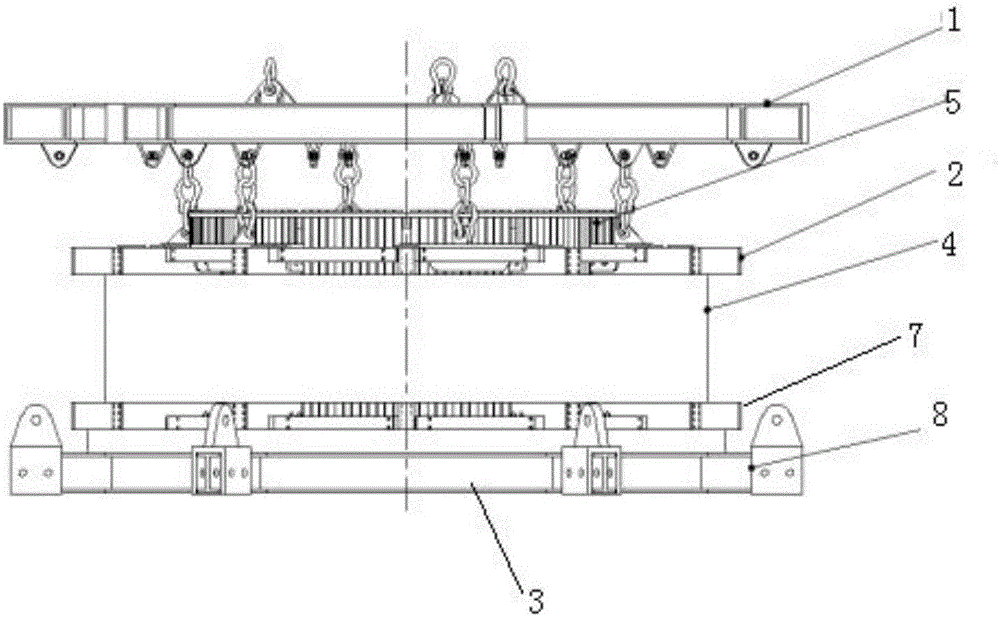

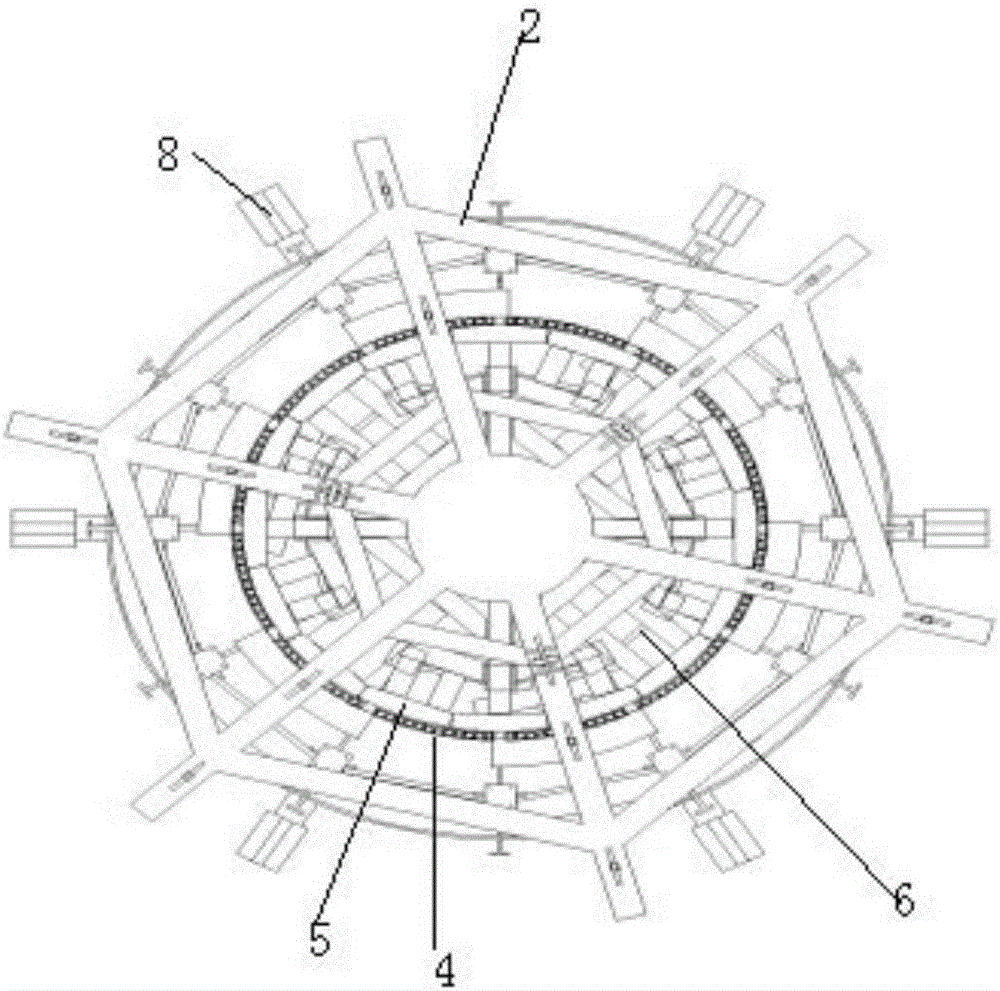

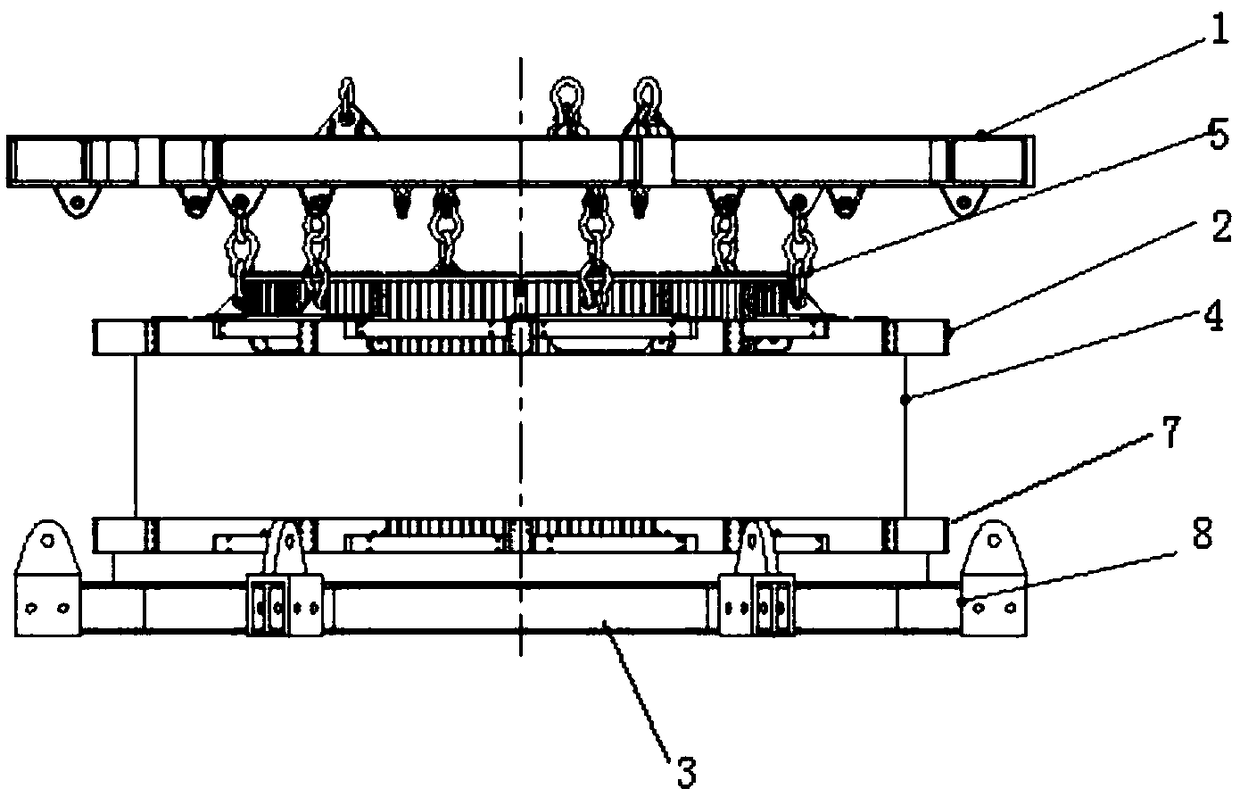

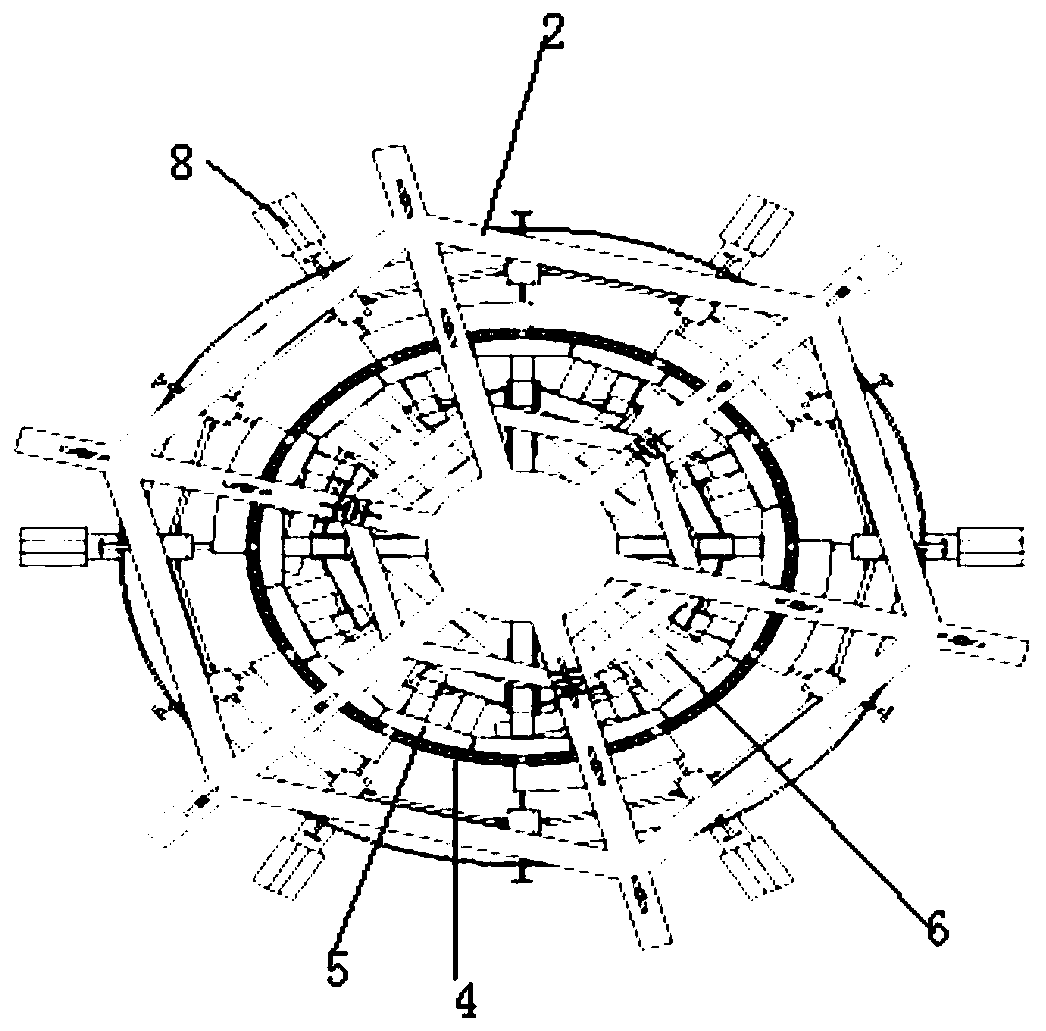

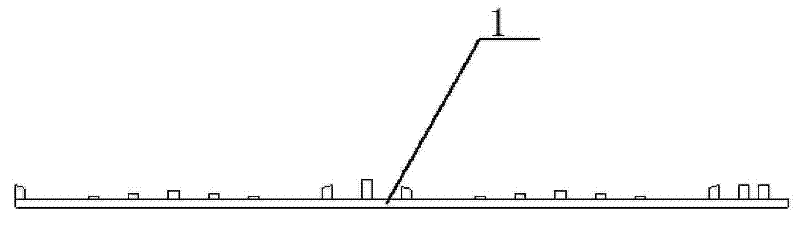

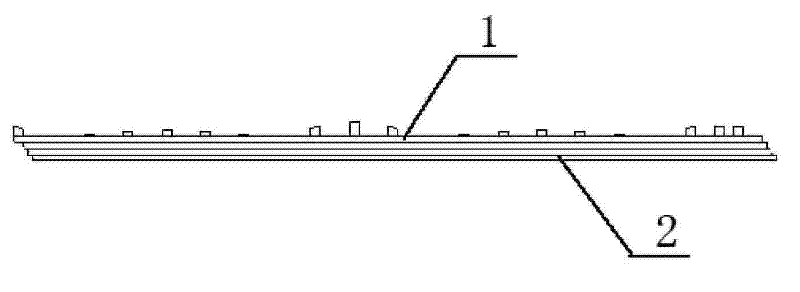

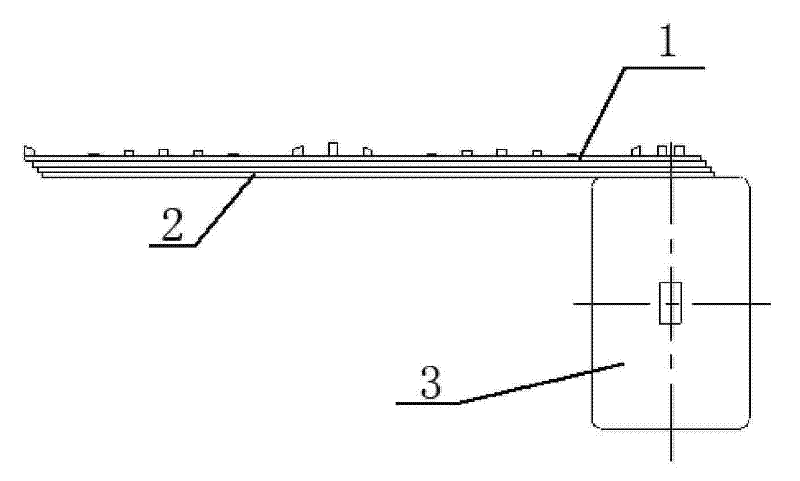

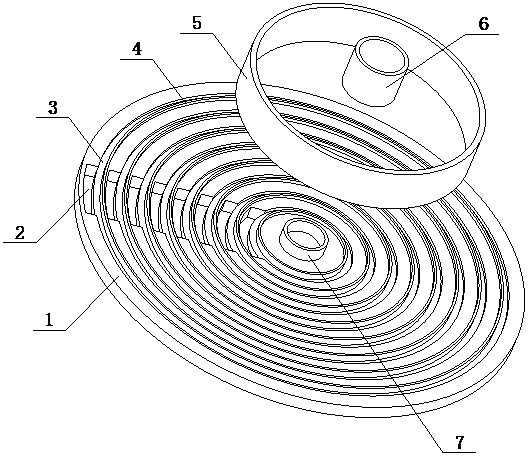

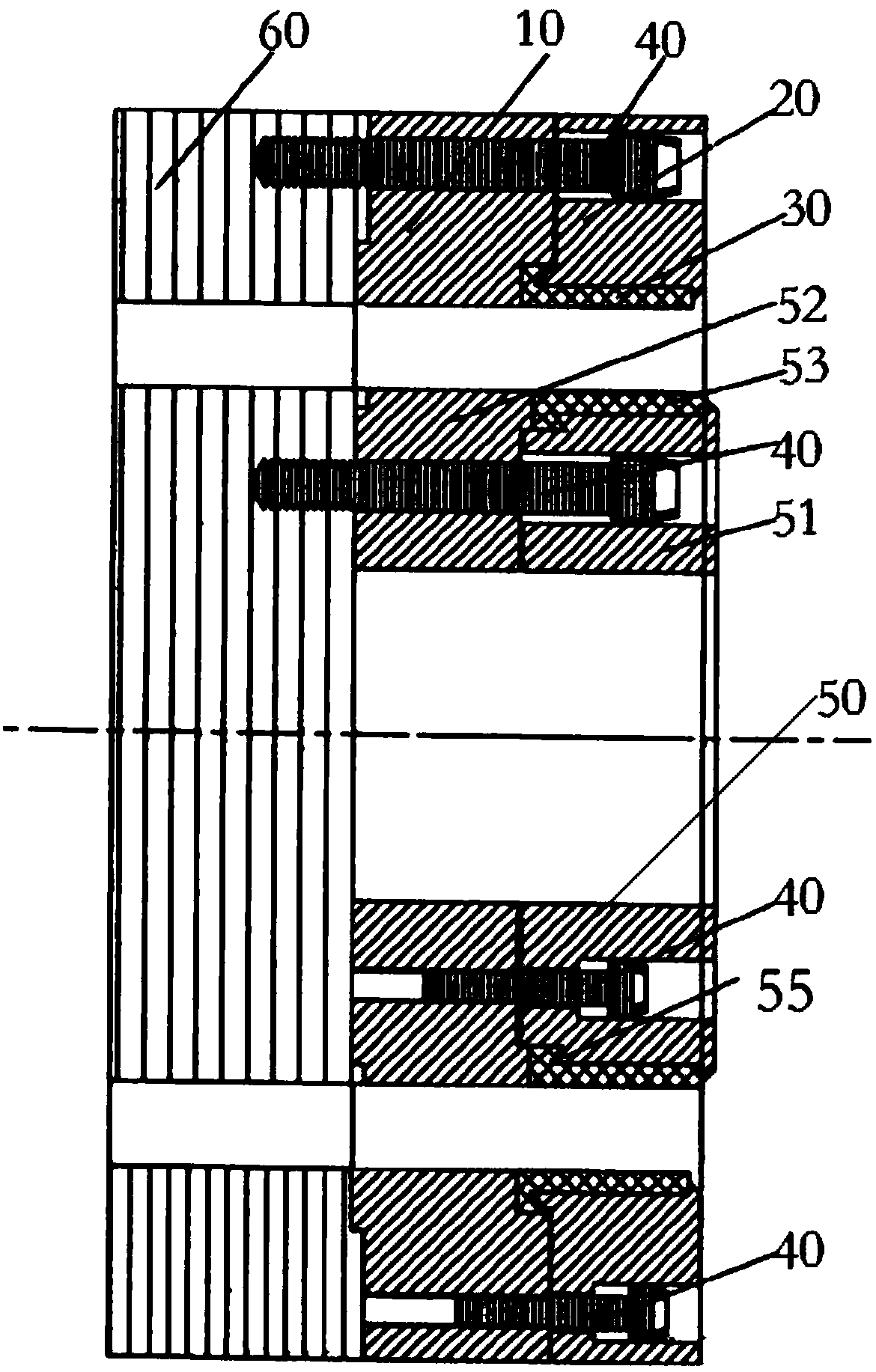

Smoothing reactor coil winding device

ActiveCN106158354AReduce bending difficultyReduce manufacturing costInductances/transformers/magnets manufactureBusbarEngineering

The invention relates to a smoothing reactor coil manufacturing device, which comprises a glue plate, a support body placed above the glue plate, a winding die arranged on the periphery of the support body for coil winding, and a coil hanger above it; An upper busbar and a lower busbar are respectively welded to the upper and lower coil outlets of the winding die, and the lower busbar is installed on the glue-connecting tray and a suspension is provided on the glue-connecting tray. The invention has a simple structure, the winding mold is spliced by steel pipes, and the production cost is low; the inner diameter of the coil and the tension force requirements during winding can be guaranteed; and the internal steel pipe is removed after the coil winding is completed, and the inner steel pipe does not need to be entered for internal operation, and the operation is convenient. At the same time, the coil sling and the crane are used for hoisting, the connection strength is reliable, and it is suitable for large-tonnage coils.

Owner:SHANDONG POWER EQUIP

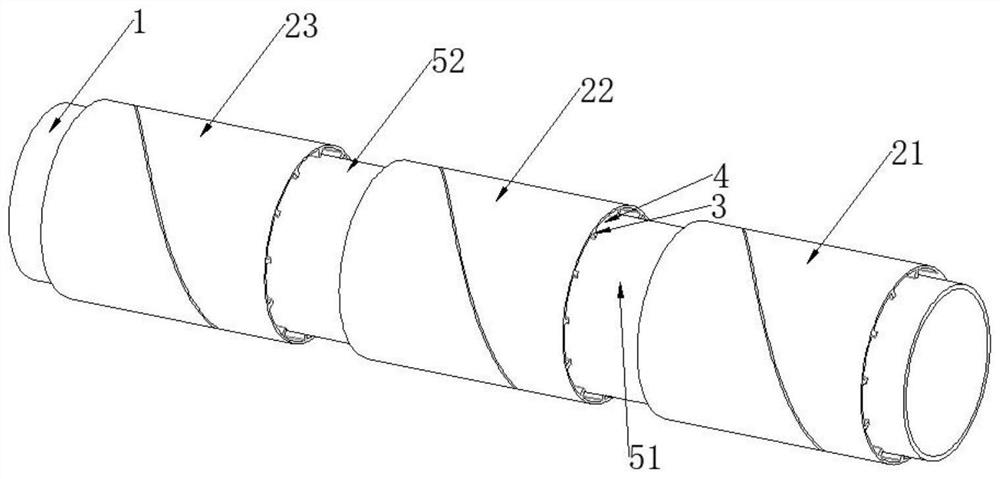

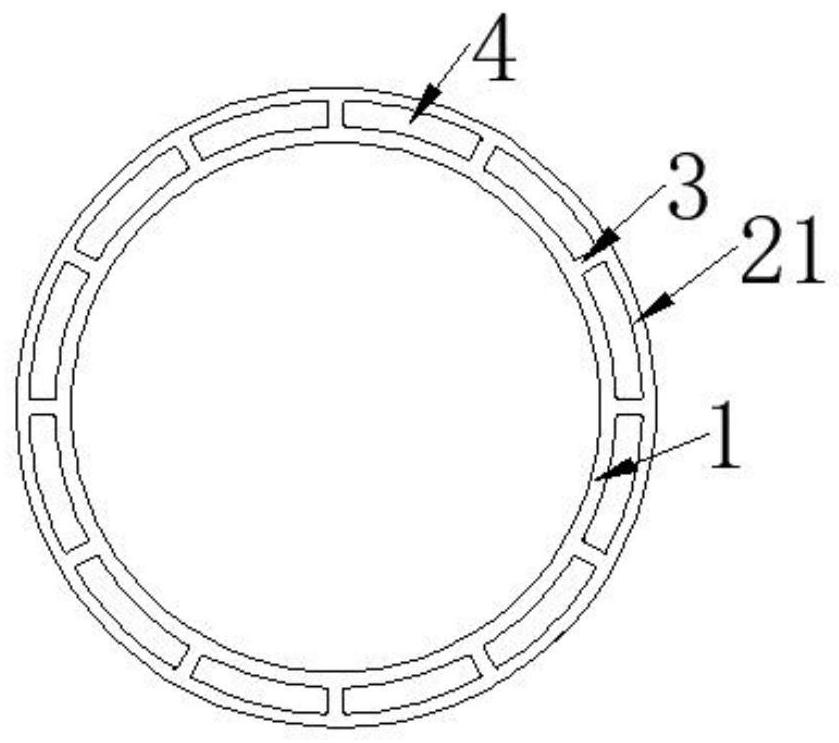

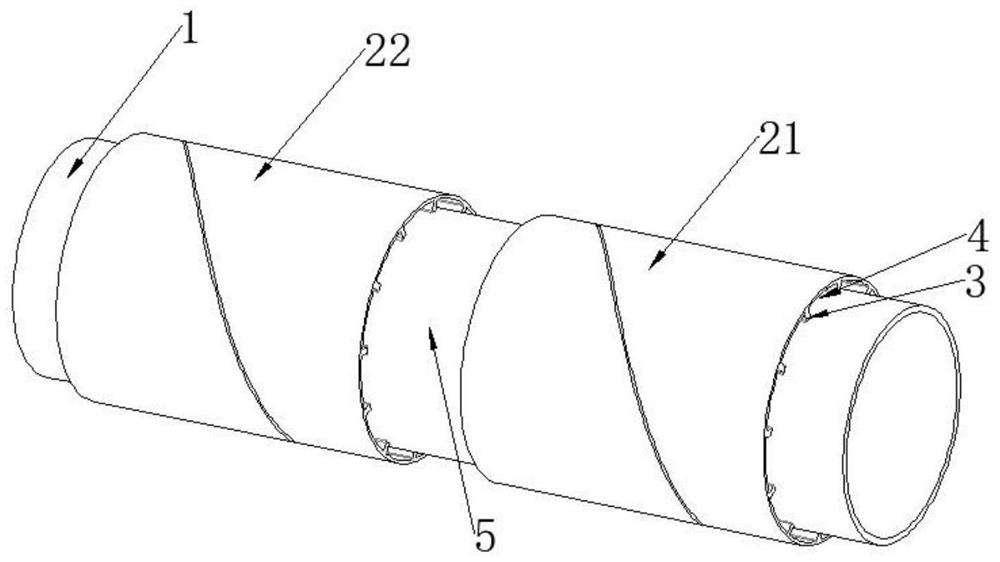

Inhaul cable protective sleeve with functional element and construction method thereof

ActiveCN112523085AReduce the cross-sectional areaReduce weightClimate change adaptationBridge structural detailsStructural engineeringMechanical engineering

The invention discloses an inhaul cable protective sleeve with functional elements and a construction method thereof. The protective sleeve comprises an inner layer pipe, an outer layer pipe, reinforcing ribs fixedly arranged between the inner layer pipe and the outer layer pipe and cavity channels between the adjacent reinforcing ribs, and the inner layer pipe, the outer layer pipe and the reinforcing ribs are all made of plastic; the cavity channel penetrates through the two ends of the outer-layer pipe where the cavity channel is located. At least two sections of outer-layer pipes are arranged at intervals, and annular grooves are formed between the opposite end parts of the adjacent outer-layer pipes; a functional element is installed in the annular groove and connected with the outer-layer pipes at the two ends in a sealed mode. According to the inhaul cable protective sleeve with the functional element and the construction method of the inhaul cable protective sleeve, machining is easy, the sealing performance is good, and compared with the prior art, the inhaul cable is light in weight and small in cross sectional area, and the performance of the inhaul cable is not affected.

Owner:LIUZHOU OVM MASCH CO LTD

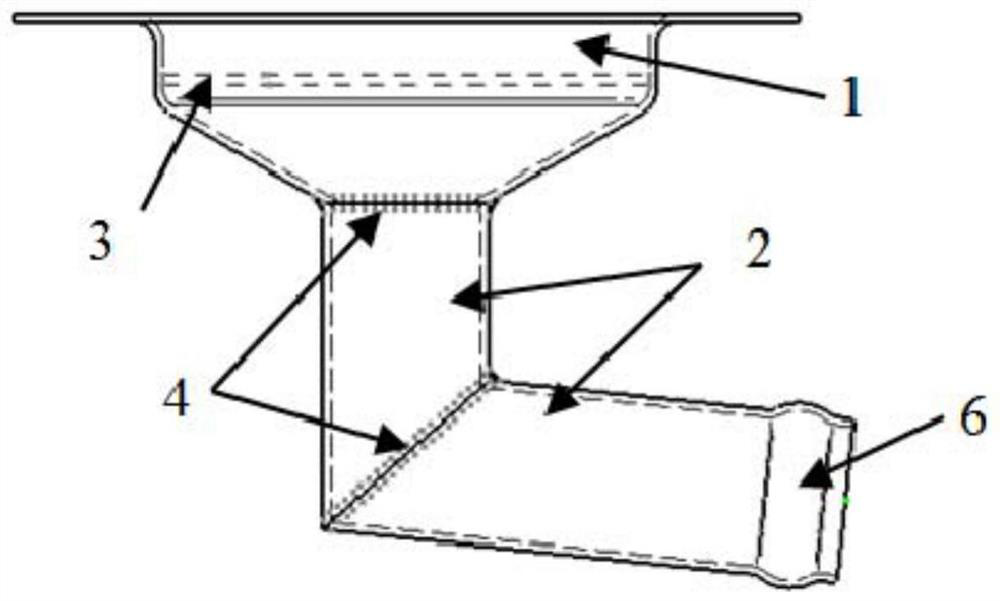

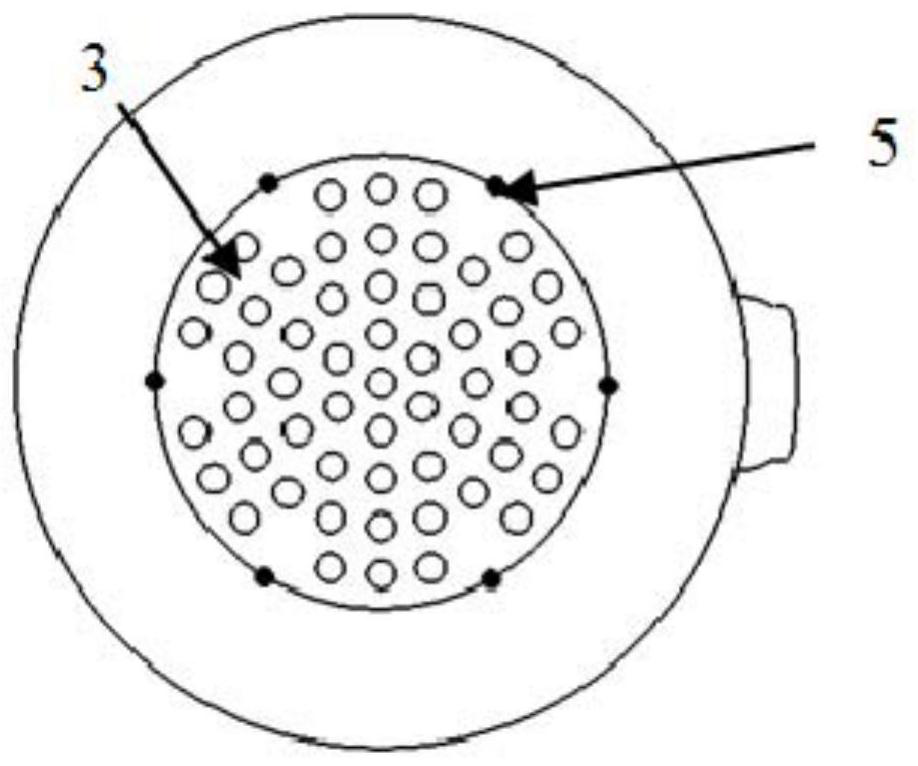

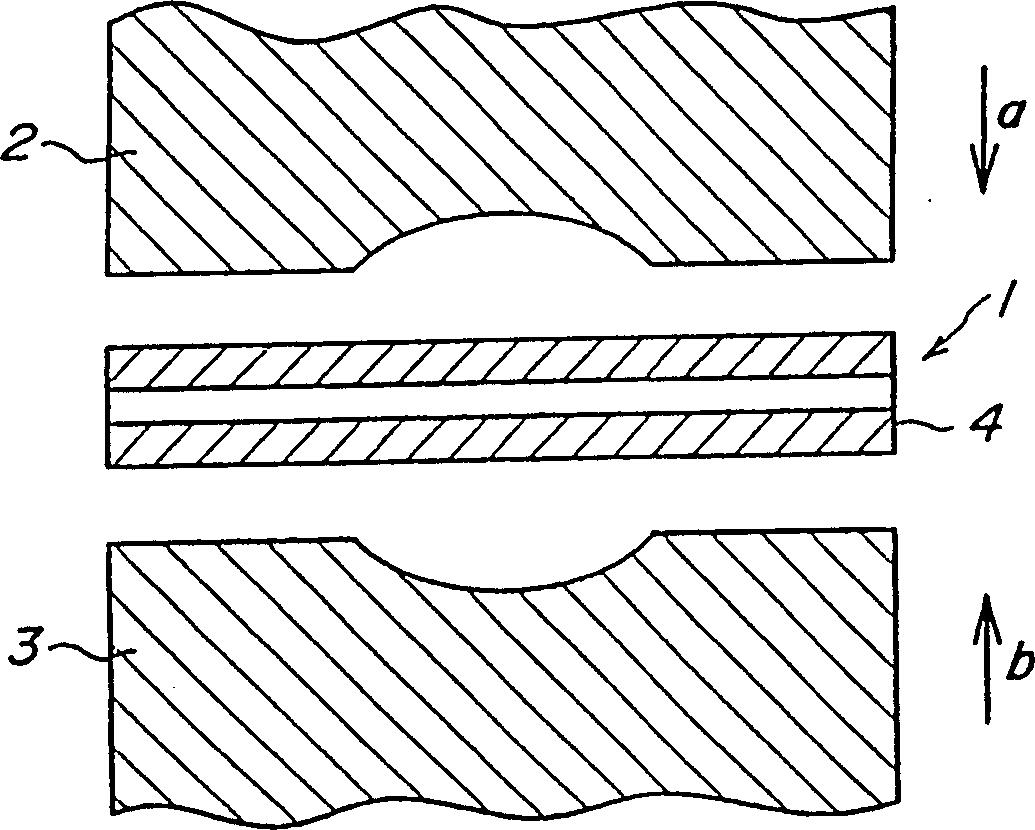

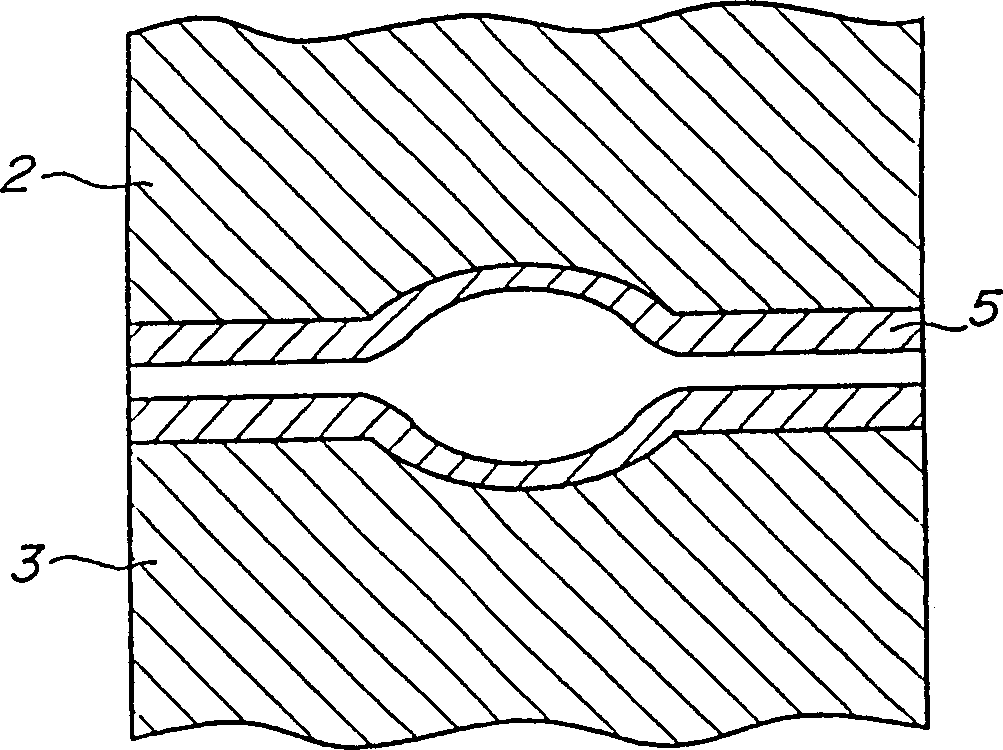

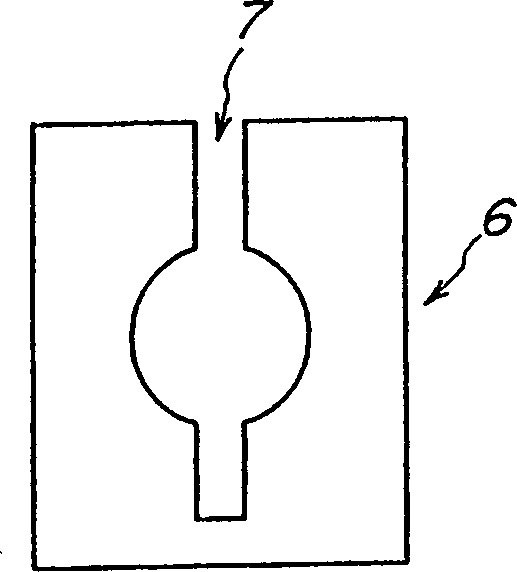

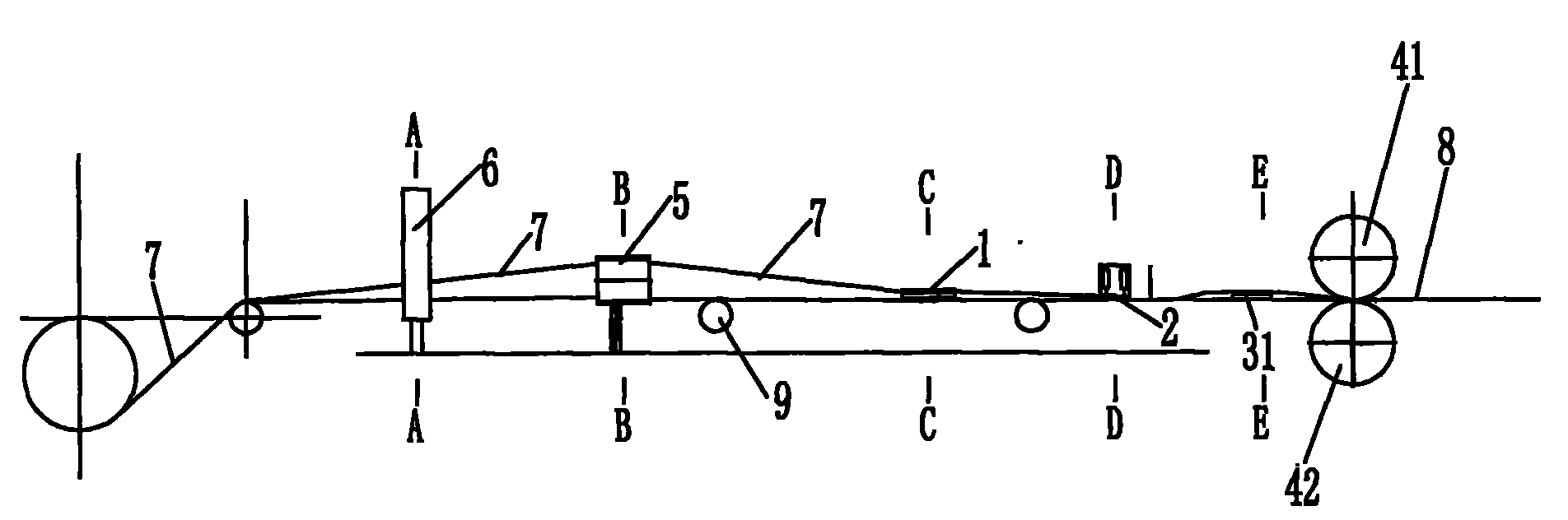

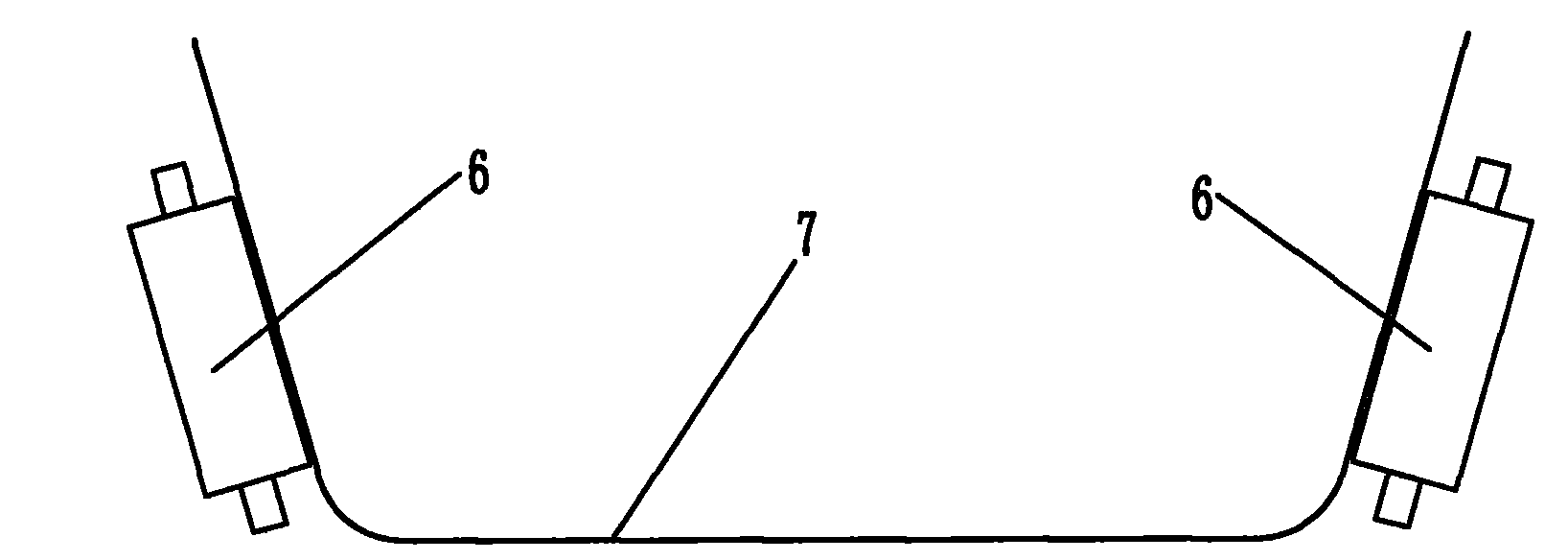

Equipment and process for producing water hose

ActiveCN101579919ASimple and ingenious structureEasy to manufactureTubular articlesEngineeringProduced water

The invention relates to equipment for producing a water hose, which comprises an outer forming die, an inner last die, an extruder and nip rolls matched in pairs up and down, wherein the extruder is provided with an extruder head; the outer forming die, the inner last die, the extruder head and the nip rolls are arranged from the back to front in turn; the shape of the cross section of the outer forming die comprises two up and down horizontal U-shaped outer sleeves; the upper wing of the upper U-shaped outer sleeve and the lower wing of the lower U-shaped outer sleeve are integrated into a whole through a side plate; and the shape of the cross section of the inner last die comprises an upper horizontal transverse plate and a lower horizontal transverse plate, an upper vertical plate and a lower vertical plate. The invention also provides a process for producing the water hose. The equipment and the process can improve the speed of the water hose production, have simple and ingenious equipment structure, and easy processing technique and operation, and ensure the accurate inside diameter of the water hose.

Owner:汕头市光华机械实业有限公司

A sulfur tail gas supergravity desulfurization device

ActiveCN106744705BAchieve partial oxidationImplement spin-inGas treatmentDispersed particle separationSulfurLiquid storage tank

The invention relates to a sulfur tail gas super-gravity desulfurization device and process thereof. The sulfur tail gas super-gravity desulfurization device comprises an alkali liquid storage tank and a super-gravity machine; the device utilizes alkali liquid to desulfurize sulfur tail gas, and a unique super-gravity machine structure is provided; in the structure, a hollow rotary shaft with a fluid channel is formed in a shell in a manner of penetrating through the middle axis of the shell, and a sleeve with a gas channel function sleeves the hollow rotary shaft; meanwhile, a rotary channel, which is communicated with a filling region and is provided with a spiral channel, is also formed on the basis; fluid passes through the hollow rotary shaft and then self rotation of the fluid is realized through the rotary channel, and then the fluid enters the filling region; the liquid is crushed and torn into small liquid drops under the action of a centrifugal force of liquid and is in sufficient contact with liquid reverse-flow small bubbles, and a phase interface, which is rapidly updated, is provided; crushing and tearing mixing of the fluid and gas is further realized by utilizing the self-rotation under a rotary state; the sufficient degree of gas-liquid contact is improved, and furthermore, the better sulfur tail gas desulfurization effect is obtained.

Owner:北京清大华亿科技有限公司 +2

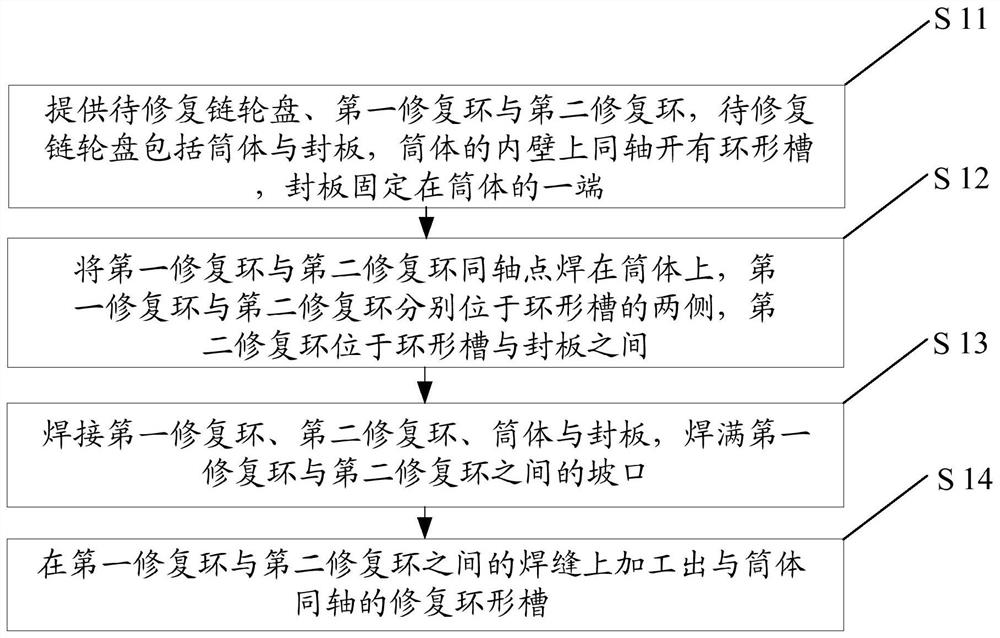

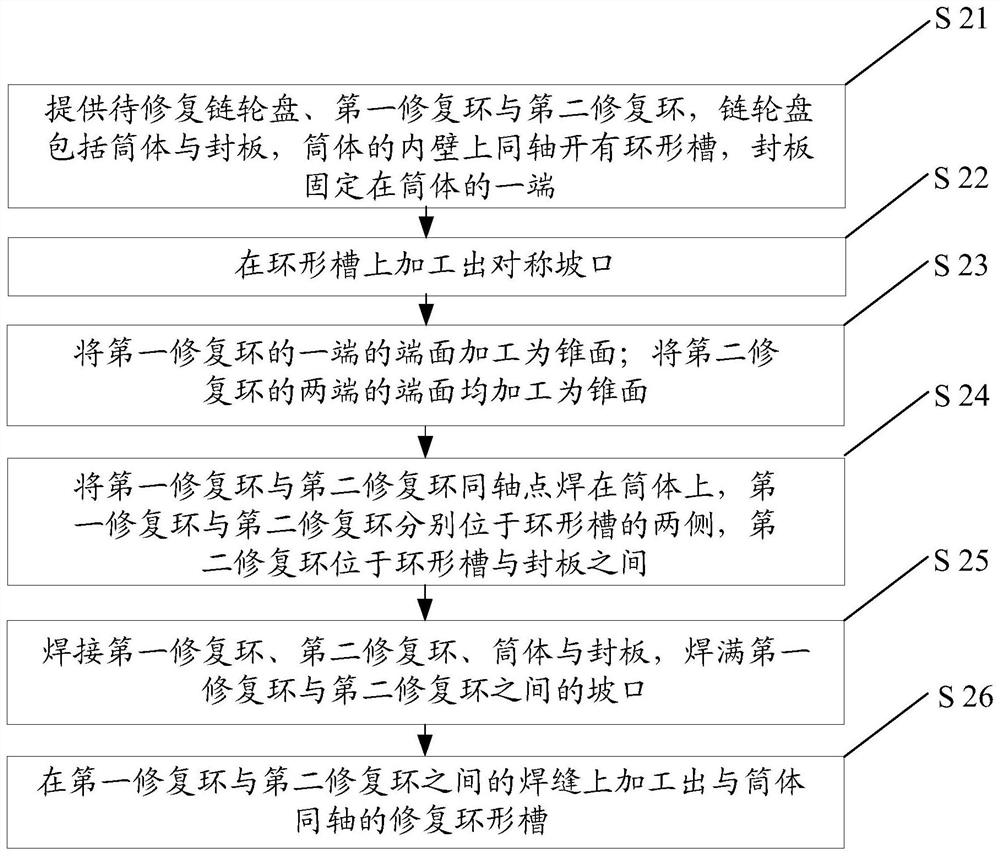

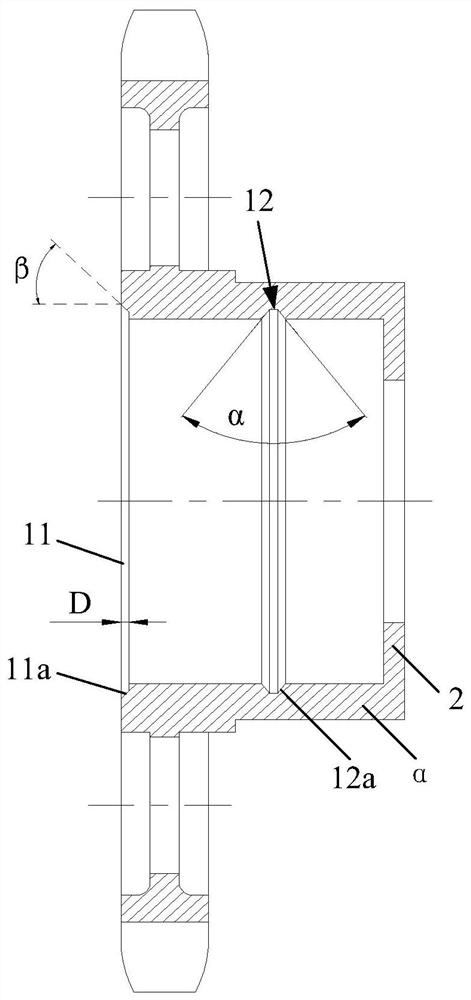

Chain wheel repair method

ActiveCN110480253BGuaranteed inner diameterMeet the use requirementsWelding apparatusStructural engineeringSprocket

The invention discloses a chain wheel disc repairing method, and belongs to the field of machining. When a chain wheel disc to be repaired is repaired, a first repairing ring and a second repairing ring are coaxially subjected to spot welding to the inner wall of a cylinder body of the chain wheel disc to be repaired, the first repairing ring and the second repairing ring are located on the two sides of an annular groove, the first repairing ring, the second repairing ring, the cylinder body and a seal plate are welded, after the first repairing ring and the second repairing ring are welded tothe cylinder body, the inner diameters of the first repairing ring and the second repairing ring are small relative to the cylinder body, and the first repairing ring and the second repairing ring can be applied to the environment where the chain wheel disc to be repaired needs to be used. Grooves between the first repairing ring and the second repairing ring are fully welded, an original annulargroove in the inner wall of the cylinder body between the first repairing ring and the second repairing ring can be fully welded, finally, a repairing annular groove coaxial with the cylinder body ismachined in the welding line between the first repairing ring and the second repairing ring, and the inner diameter of a chain wheel disc to be repaired and the use needs of the annular groove are ensured.

Owner:WUHAN MARINE MACHINERY PLANT

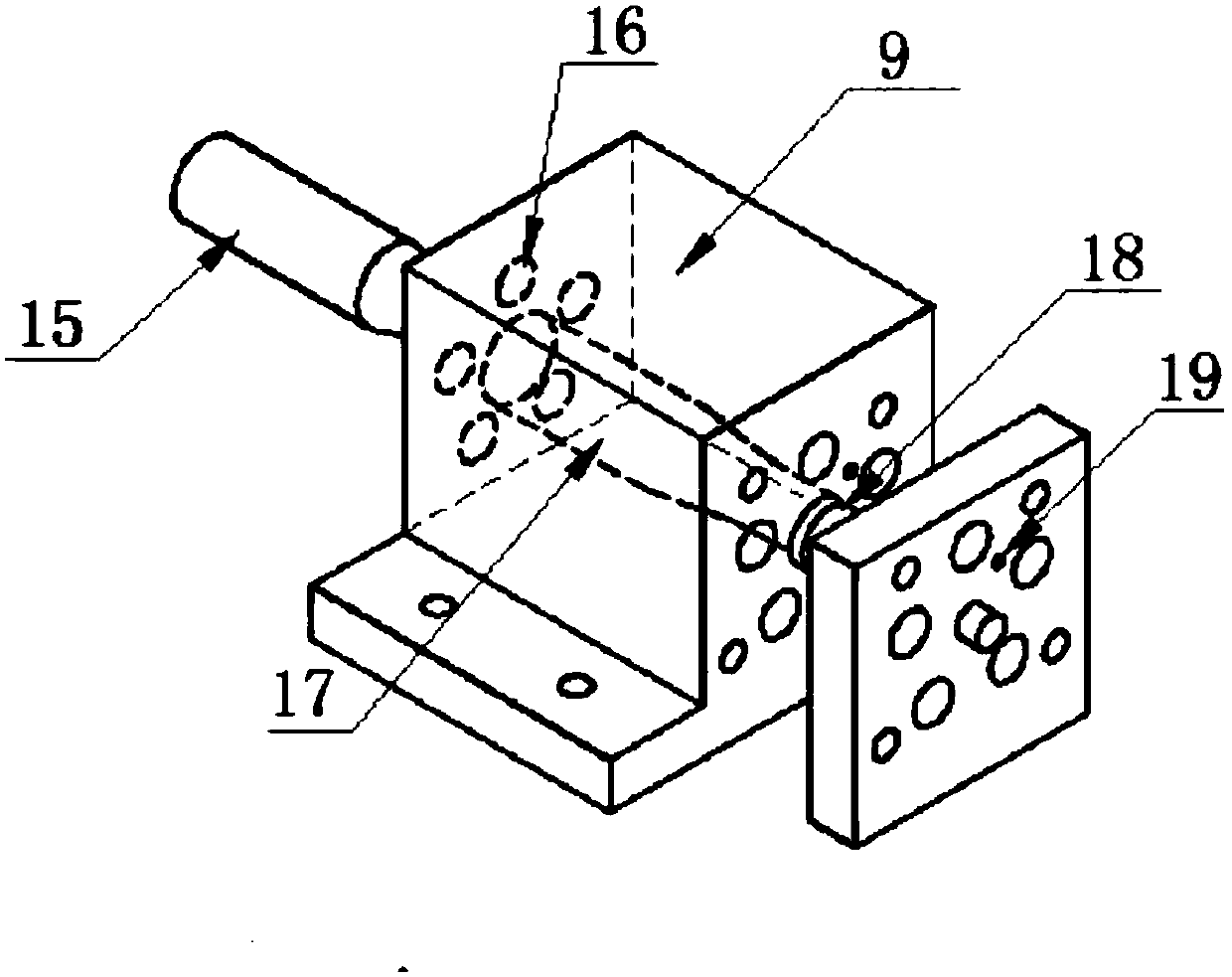

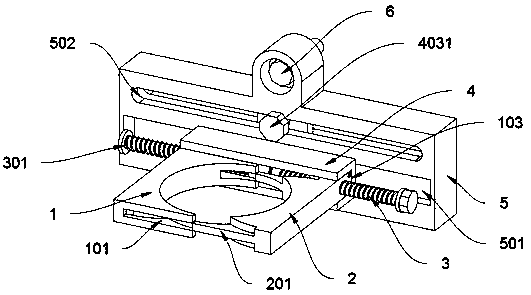

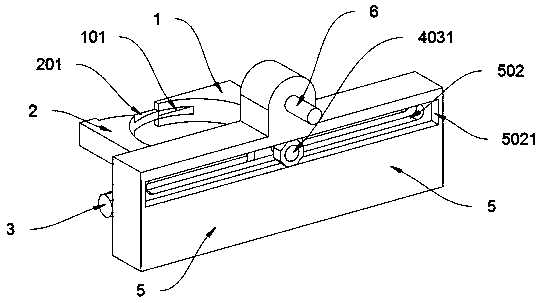

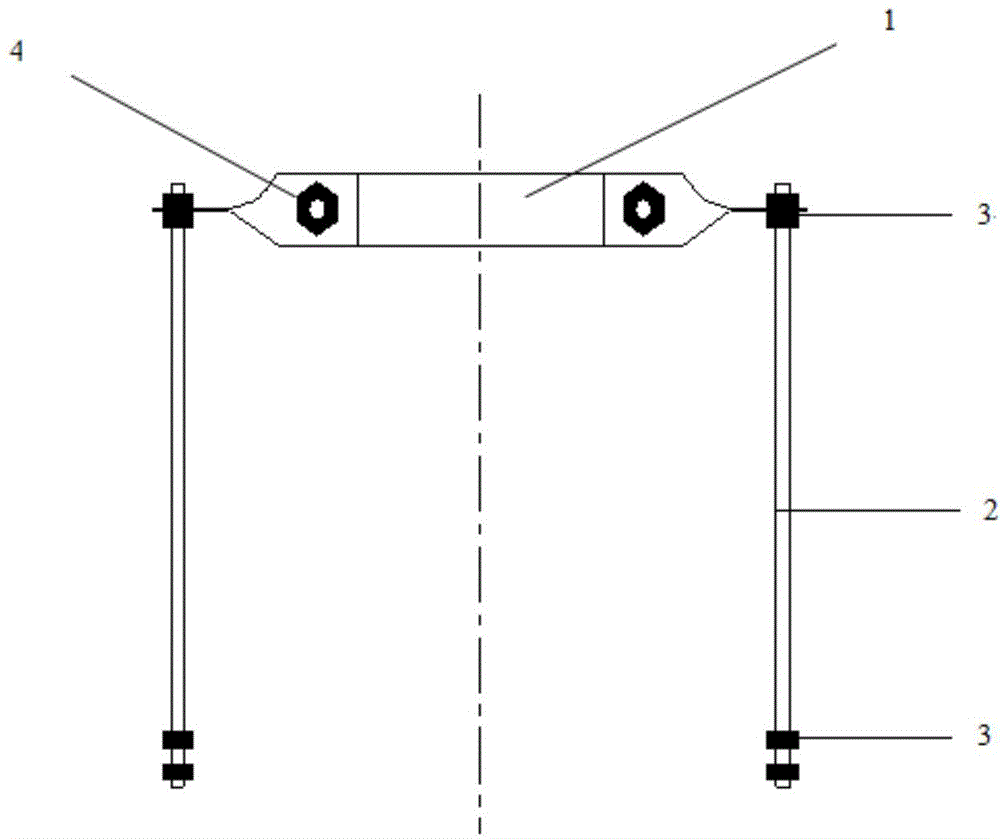

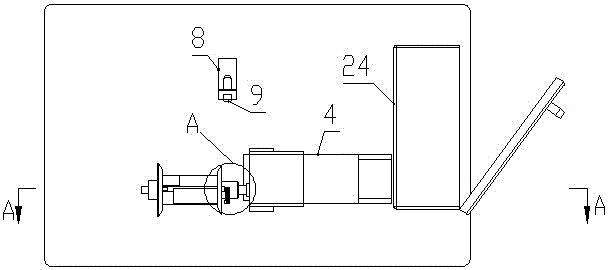

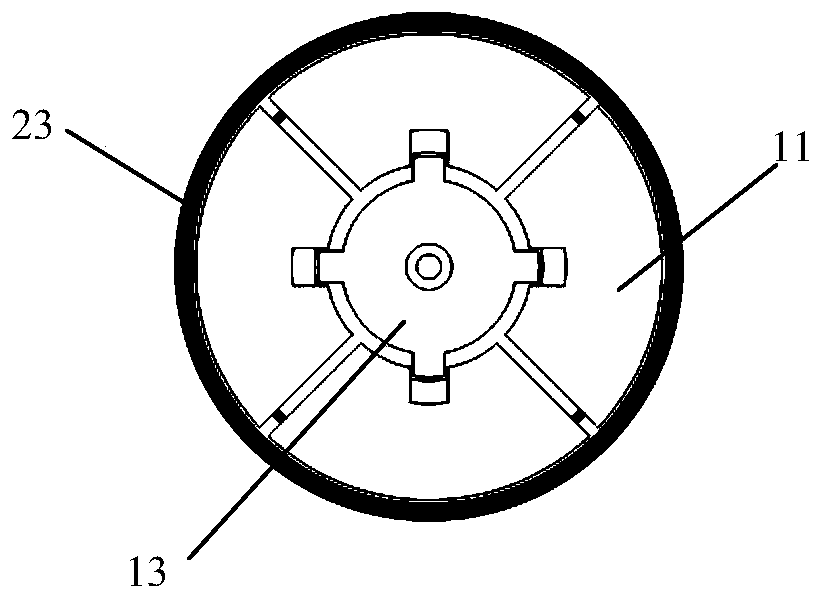

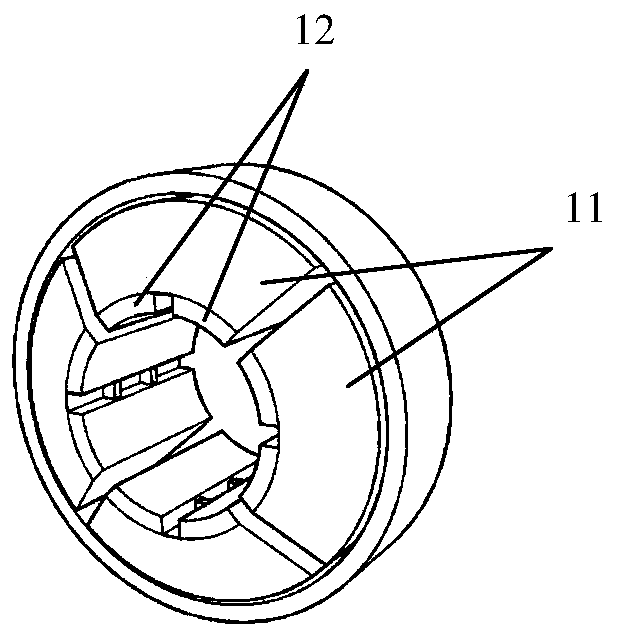

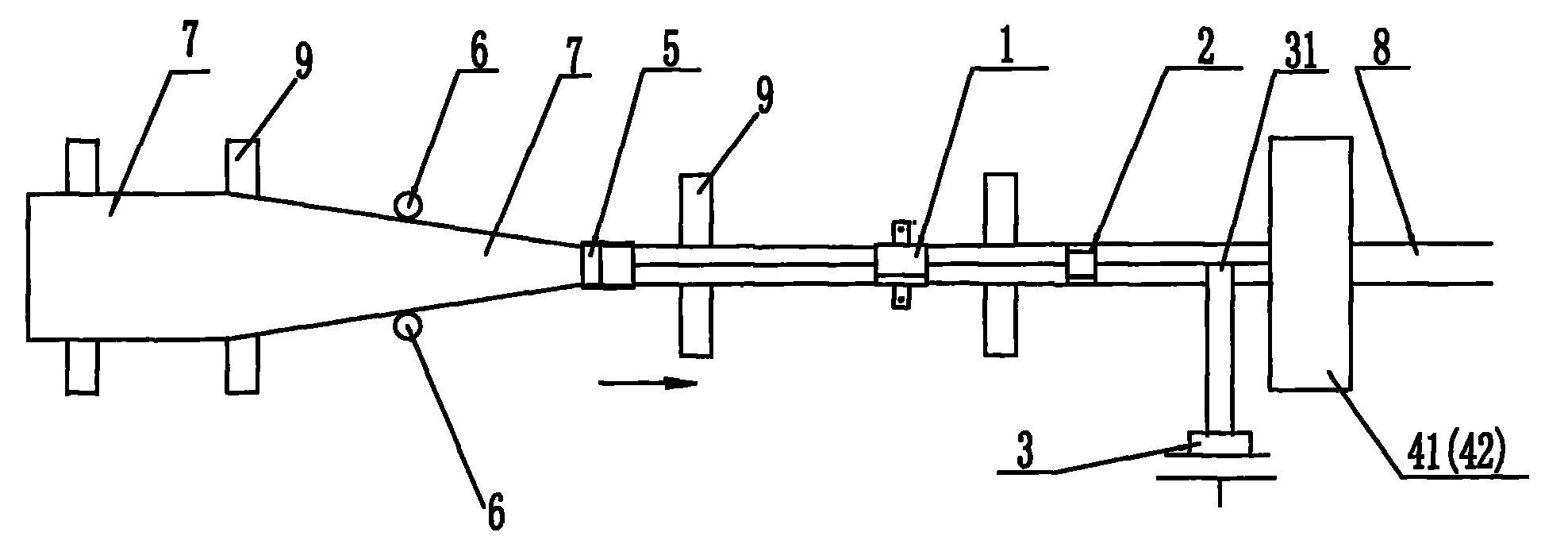

Automatic metal net filter layer winding machine and metal net filter layer winding method

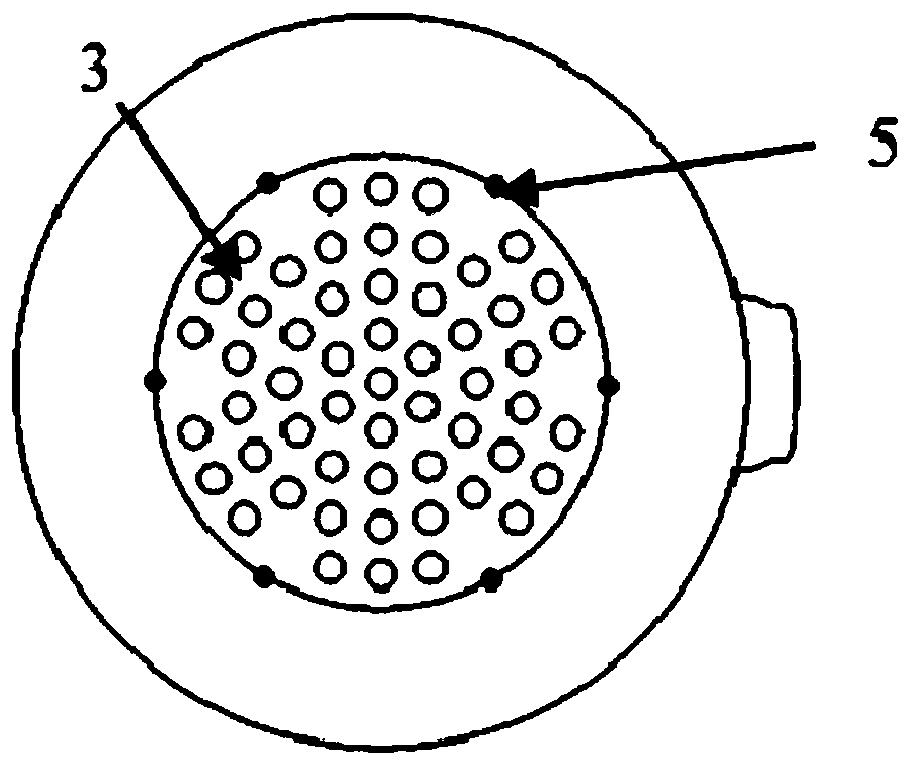

ActiveCN106081721AGuaranteed inner diameterPrecise control of the number of winding layersFilament handlingWire networkWinding machineInductor

The invention discloses an automatic metal net filter layer winding machine. The machine comprises a panel; the panel is downwards provided with four support legs; three tension rods are connected between two front support legs up and down at intervals; a winding speed reduction motor is arranged on a frame panel; an output shaft of the winding speed reduction motor is fixedly connected with a pressing winding device; the pressing winding device is provided with a fixed winding wheel and a movable winding wheel; the pressing winding device is provided with a magnetic material block; a sensor bracket is arranged on a panel behind the pressing winding device, and is provided with a magnetic inductor; and the magnetic inductor is aligned to the rotating surface of the magnetic material block. The invention further discloses a winding method of the automatic metal net filter layer winding machine. The automatic metal net filter layer winding machine effectively guarantees the inner diameter size of a metal net filter layer, the product winding tightness and the winding layer number of the filter layer; the width size of the metal net filter layer is controlled through the fixed winding wheel and the movable winding wheel; multiple trimming procedures are saved; the product quality is guaranteed; and the quality accident is prevented.

Owner:PINGYUAN FILTER

Downhole hollow oil well pump

ActiveCN105909503AImprove sealingGuaranteed inner diameterPositive displacement pump componentsFlexible member pumpsHorizontal wellsCoiled tubing

The invention discloses a downhole hollow oil well pump. The downhole hollow oil well pump comprises a barrel body, wherein a hollow piston rod anchored down a well is arranged inside the barrel body; an upstream end of the piston rod is closed; a downstream end of the piston rod is provided with a well fluid inlet; a sealing sleeve fixed to the barrel body sleeves the piston rod; the sealing sleeve and a sealing structure of the piston rod divide an inner cavity of the barrel body into an upper chamber, a middle sealing chamber and a lower chamber; first oil introduction holes connected with the middle sealing chamber are formed in the side wall of the piston rod; the first oil introduction holes are coated with first elastic sealing parts; second oil introduction holes connected with the middle sealing chamber and a space outside the barrel body are formed in the sealing sleeve; and the second oil introduction holes are coated with second elastic sealing parts. According to the downhole hollow oil well pump, simulated production can be achieved, a stable working condition is reached, a testing tool is controlled through lifting and putting down a continuous oil pipe to test capacity conditions of all layers, a good sealing property is achieved, inner diameters are sufficiently guaranteed under the condition that outer diameters are the same, and the downhole hollow oil well pump is particularly applicable to production testing of high-inclination wells and horizontal wells.

Owner:TOP WELL PETROLEUM TECH COMPANY

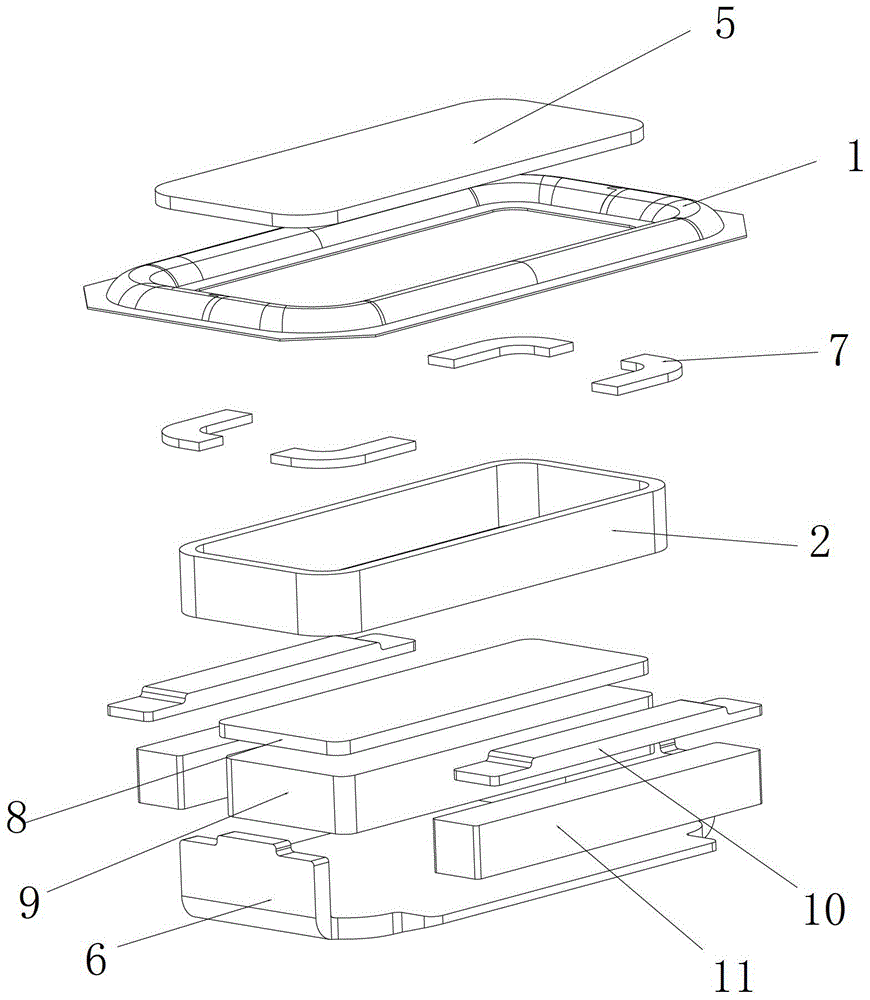

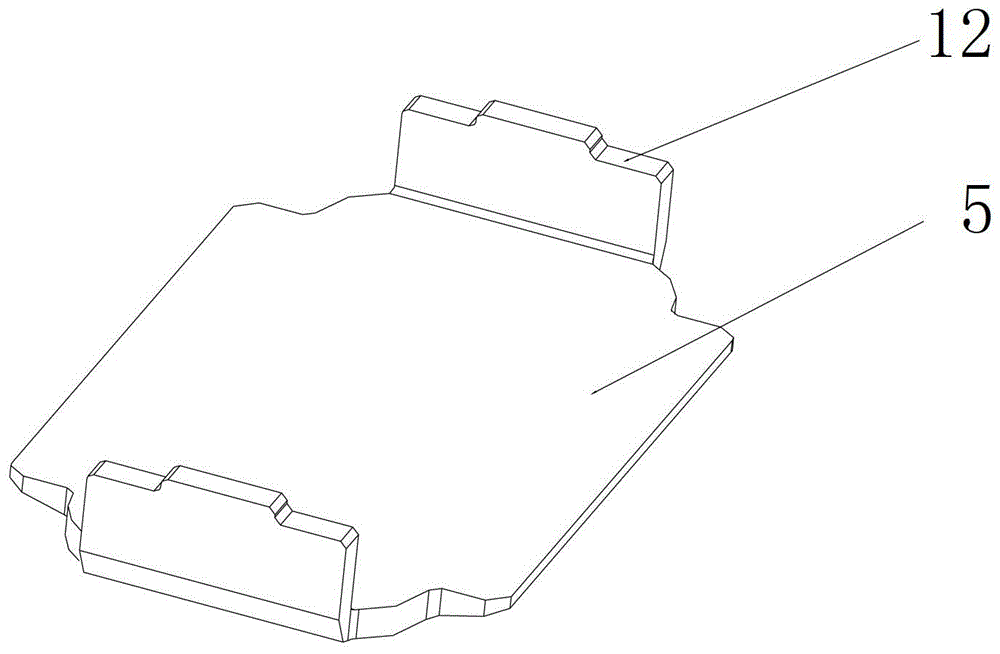

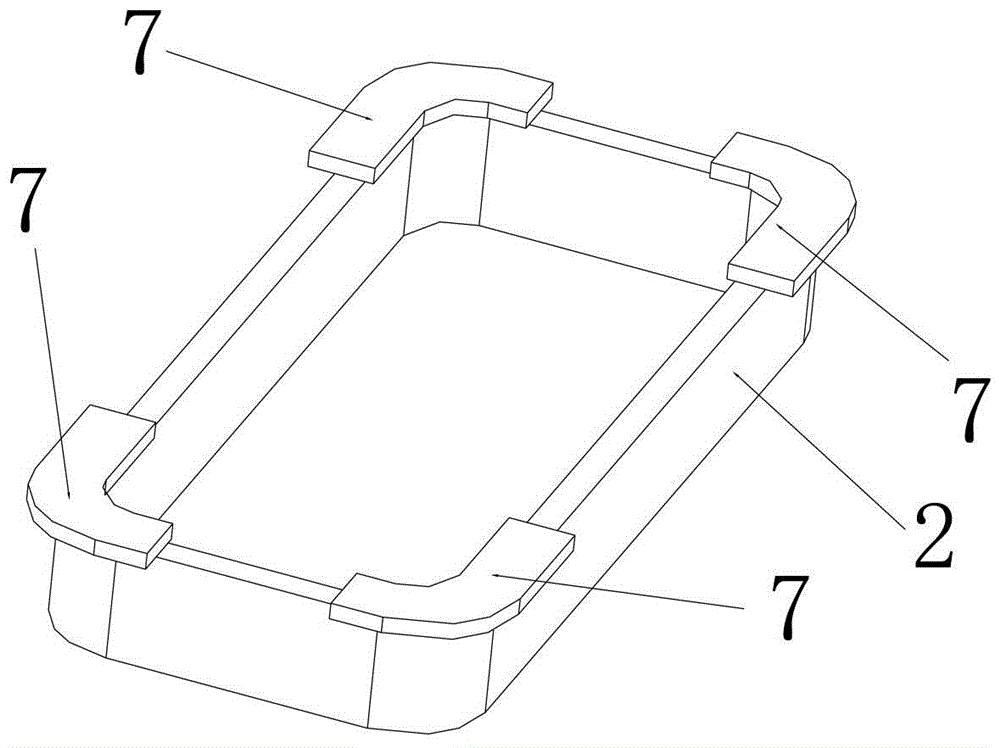

Micro-speaker and its vibration system manufacturing method

ActiveCN103338426BImprove acoustic performanceReduce Harmonic DistortionElectrical transducersEngineeringLoudspeaker

The invention provides a micro loudspeaker and a manufacturing method of the vibration system of the micro loudspeaker. The micro loudspeaker comprises the vibration system, a magnetic circuit system and an auxiliary system, wherein the vibration system and the magnetic circuit system are accommodated and fixed by the auxiliary system; the vibration system comprises a vibration diaphragm and a voice coil; the voice coil is jointed with the lower side of the vibration diaphragm and arranged in a magnetic gap formed by the magnetic circuit system; gaskets with discontinuous structures are arranged in the joint position of the vibration diaphragm and the voice coil. The manufacturing method of the vibration system of the micro loudspeaker comprises the following steps: firstly, the vibration diaphragm provided with a spherical top and the gaskets provided with connecting structures are respectively formed; secondly, the formed gaskets are arranged below the formed vibration diaphragm and fixed with the vibration diaphragm to form a whole; finally overall cutting is preformed to the jointed connecting structure and the spherical top corresponding to the connection structure. According to the invention, the distortion of the product can be reduced; the performance of the product with high power can be improved; the manufacturing method of the vibration system of the micro loudspeaker can guarantee the consistency and the assembly precision of the gaskets, and can lower the manufacturing cost.

Owner:GOERTEK INC

Coil Winding Device for Smoothing Reactor

ActiveCN106158354BAchieve demouldingGuaranteed inner diameterInductances/transformers/magnets manufactureBusbarEngineering

The invention provides a smoothing reactor coil winding device. The smoothing reactor coil winding device comprises an adhesive receiving disc, a support body arranged above the adhesive receiving disc, winding molds which are arranged on the periphery of the support body and used for winding coils and a coil lifting tool arranged above the coils; an upper busbar and a lower busbar are welded to extension heads, at the upper ends and the lower ends of the winding molds, of the coils, the lower busbar is installed on the adhesive receiving disc, and a lifting piece is arranged on the adhesive receiving disc. The smoothing reactor coil winding device is simple in structure, the winding molds are formed by splicing steel tubes, and the making cost is low; the requirements on the coil inner diameter and tightening force during the winding process can be guaranteed; after winding of the coils is completed and internal steel tubes needs to be dismantled, a person does not need to enter the device for operation, and operation is convenient. The coil lifting device and the lifting piece are simultaneously adopted for hoisting, the connection strength is reliable, and the smoothing reactor coil winding device is suitable for large-tonnage coils.

Owner:SHANDONG POWER EQUIP

Preparation method of quadrate foil type coil insulation paper roll

ActiveCN101661838BReduce deviationImprove fitTransformers/inductances coils/windings/connectionsCoils manufactureCardboardTransformer

The invention relates to a preparation method of a quadrate foil type coil insulation paper roll, which belongs to the technical field of transformer coil production process. The technical scheme comprises the following process steps: (1) a paper panel is cut to meet requirements in a drawing for width, and curtain type oil groove is bond well; (2) the curtain type oil duct and the paper panel are laminated; (3) the bond paper panel and the curtain type oil duct are arranged on a mould; (4) a copper coil is wrapped by exerting slight tension or no tension; and (5) after a paper coil is completed by wrapping, the last support strip of the curtain type oil duct is just arranged on the upper part of the bond position of the paper panel. The invention has the advantages that the contact between the copper coil and the paper panel and between the mould and the paper panel is favorable by winding the copper coil to wind the paper panel and the curtain type oil duct on the mould along with the copper coil, the inner diameter of the coil is ensured, deflection of the copper coil because of the gap between the paper panel roll and the mould is reduced, the time for making the paper roll isomitted, working efficiency is increased, and thus, the aim that one stone kills two birds is achieved.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

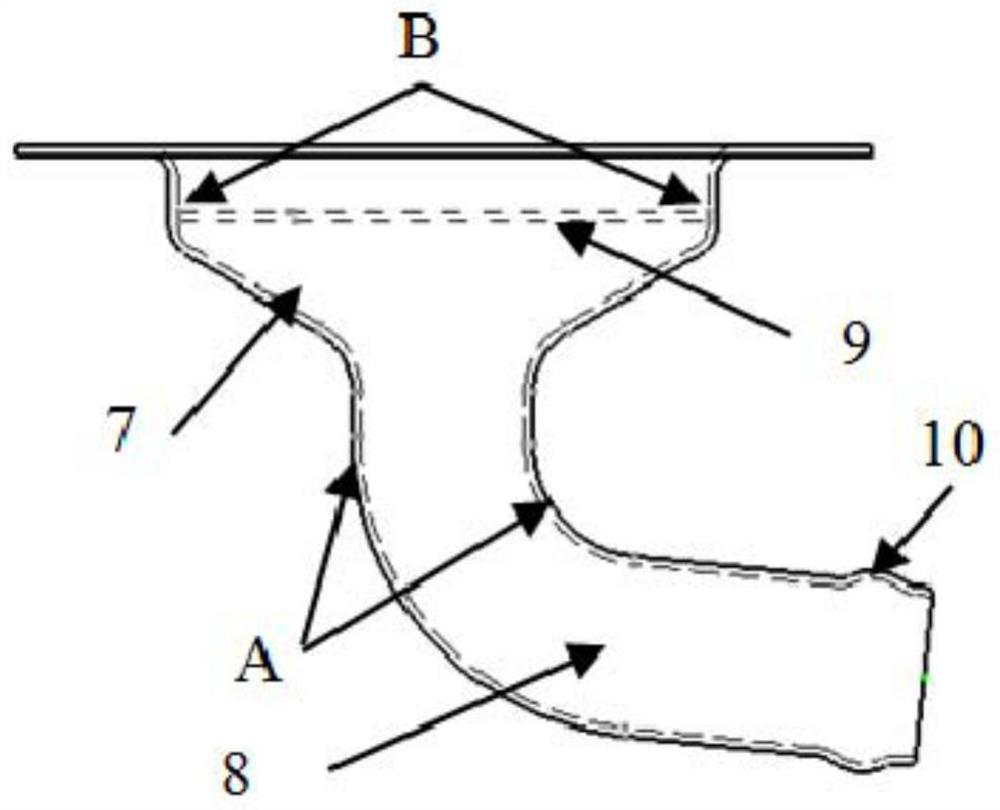

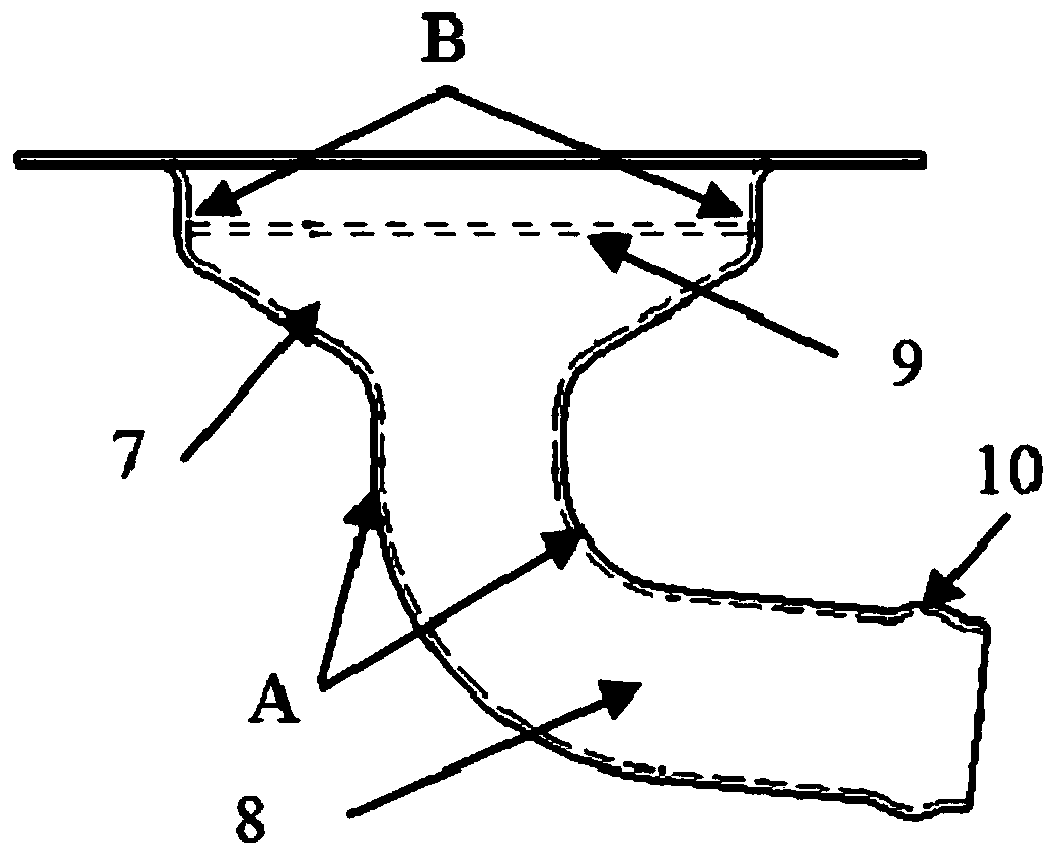

An integrally formed excretory channel with variable cross-section

ActiveCN110864176BReduce in quantityBend radius is not affectedPower plant arrangements/mountingSiphonsCatheterEngineering physics

The invention belongs to the field of helicopter structure design. The present invention provides an integrally formed discharge channel with variable cross-section. The cup body 7, conduit 8, filter screen 9 and protrusion 10 of the variable-section discharge channel are integrally formed by melting metal powder by laser, which simplifies the process and reduces the number of parts. Long-term work in the marine environment does not produce corrosion defects, and the overall deformation of the parts is small.

Owner:CHINA HELICOPTER RES & DEV INST

Induction coil winding device and use method thereof

PendingCN114446634AGuaranteed number of turnsGuaranteed pitchCoil arrangementsCoils manufactureEngineeringPhysics

The invention discloses an induction coil winding device and a use method thereof. According to the winding device and the use method thereof, a plurality of cooling winding sleeves of the same or different specifications can be assembled according to different winding requirements to support and guide an induction coil, and a cooling device can be used for cooling and shaping the induction coil. The cooling winding device is characterized by comprising a supporting assembly, a cooling winding sleeve arranged on the supporting assembly and a conveying pipe arranged on the supporting assembly, the side wall of the cooling winding sleeve is of a hollow structure, and the cooling winding sleeve has various specifications and can be matched with the supporting assembly to be assembled according to different winding requirements; and the conveying pipe is matched with the supporting assembly to convey a cooling medium into the cooling winding sleeve to cool and shape the induction coil.

Owner:JIANGSU VILORY ADVANCED MATERIALS TECH CO LTD

Lining part for pipe bending operation

The invention discloses a lining part for pipe bending operation. The lining part comprises at least three outer blocks; all the outer blocks are fixed together through snap spring to form an olive-shaped hollow structure; the cross section of the hollow structure is matched with a pipe in shape; the outer blocks are provided with outer block internal teeth; an inner column is arranged in the hollow structure; the inner column is provided with inner column external teeth; the inner column is divided into a left inner column and a right inner column; and the left inner column and the right inner column are connected by a connecting device comprising a left universal ball, a right universal ball and a connecting rod, thus, by pulling the connecting rod, the inner column moves relative to theouter blocks, the outer blocks are inwardly contracted under the action of the snap spring, and the lining part is pulled out of the pipe. The lining part is simple in structure, when the lining partis tightly attached to the pipe, the lining part is pulled out smoothly after being bent, the inner diameter of a bent area of the pipe is effectively ensured, and the inner wall of the pipe is not liable to be damaged.

Owner:贵州航天智慧农业有限公司

Light emitting container for high-pressure discharge lamp and manufacturing method thereof

InactiveCN1155987CThin wallContinuous thickeningVessels or leading-in conductors manufactureGas discharge lamp detailsEngineeringTerminal unit

Owner:NGK INSULATORS LTD

Manufacture method of break piston

ActiveCN103056209BSimple processGuaranteed inner diameterRailway componentsMetal-working apparatusCold formedEngineering

A brake piston manufacturing method is provided to simplify the process of making a piston, thereby improving productivity and work efficiency. CONSTITUTION: A brake piston manufacturing method comprises steps of: putting a material(100) into a first forming dies, pressing a first forming die of a first former cold forming machine to the material to process a position setting groove on the top of the material, putting the material into a second dies, pressing a second forming die of a second former cold forming machine to the material to process a first hollow portion(102) inside the material, putting the material into a third forming dies, pressing a third forming die of a third former cold forming machine to the material to chamfer a flow hole processing surface on the periphery of the first hollow portion of the material, putting the material into a fourth forming dies, pressing a fourth forming die of a fourth former cold forming machine to the material to process a third hollow portion(104) extended from the first hollow portion within the material.

Owner:KOWOO

Integrally-formed variable-section drainage channel

ActiveCN110864176AReduce in quantityBend radius is not affectedPower plant arrangements/mountingSiphonsStructural engineeringPipe

The invention belongs to the field of helicopter structure design, and provides an integrally-formed variable-section drainage channel. The variable-section drainage channel comprises a cup body 7, aguide pipe 8, a filter screen 9 and a protrusion 10. The variable-section drainage channel is integrally formed by melting metal powder through laser, the process is simplified, the number of parts isreduced, corrosion defects are avoided after long-term work in the marine environment, and the overall deformation of the parts is small.

Owner:CHINA HELICOPTER RES & DEV INST

Mouth mold and mold for forming plastic pipe material

PendingCN108274720AImprove surface qualityGuaranteed inner diameterConnection tableMaterials science

The invention relates to a mouth mold and mold for forming a plastic pipe material. The mouth mold comprises a mold bell mouth supporting ring, a mold socket ring and a polytetrafluoroethylene ring. The inner side face of the mold socket ring is sleeved with the polytetrafluoroethylene ring; the bottom of the polytetrafluoroethylene ring extends outwards to form a connecting platform, and the endface of the connecting platform is provided with a dovetail groove; and the bottom of the mold socket ring extends outwards to form a spliced table which is matched with the dovetail groove. Accordingto the mouth mold and mold for forming the plastic pipe material, due to the inner side face of the polytetrafluoroethylene ring, sizing on the plastic pipe material is formed, so that the surface quality of the plastic pipe material can be improved; meanwhile, by forming the dovetail groove in a connection table, in cooperation with a spliced table at the bottom of the mold socket ring, the spliced table is made matched with the dovetail groove, and therefore due to the structural design of the dovetail groove and the spliced table, during heating expansion and deforming, the spliced table expands, the size of the dovetail groove changes small, and the spliced table and the dovetail groove can be matched more closely, so that the inner diameter size and the quality of polytetrafluoroethylene ring can be guaranteed.

Owner:湖北统领塑胶科技有限公司

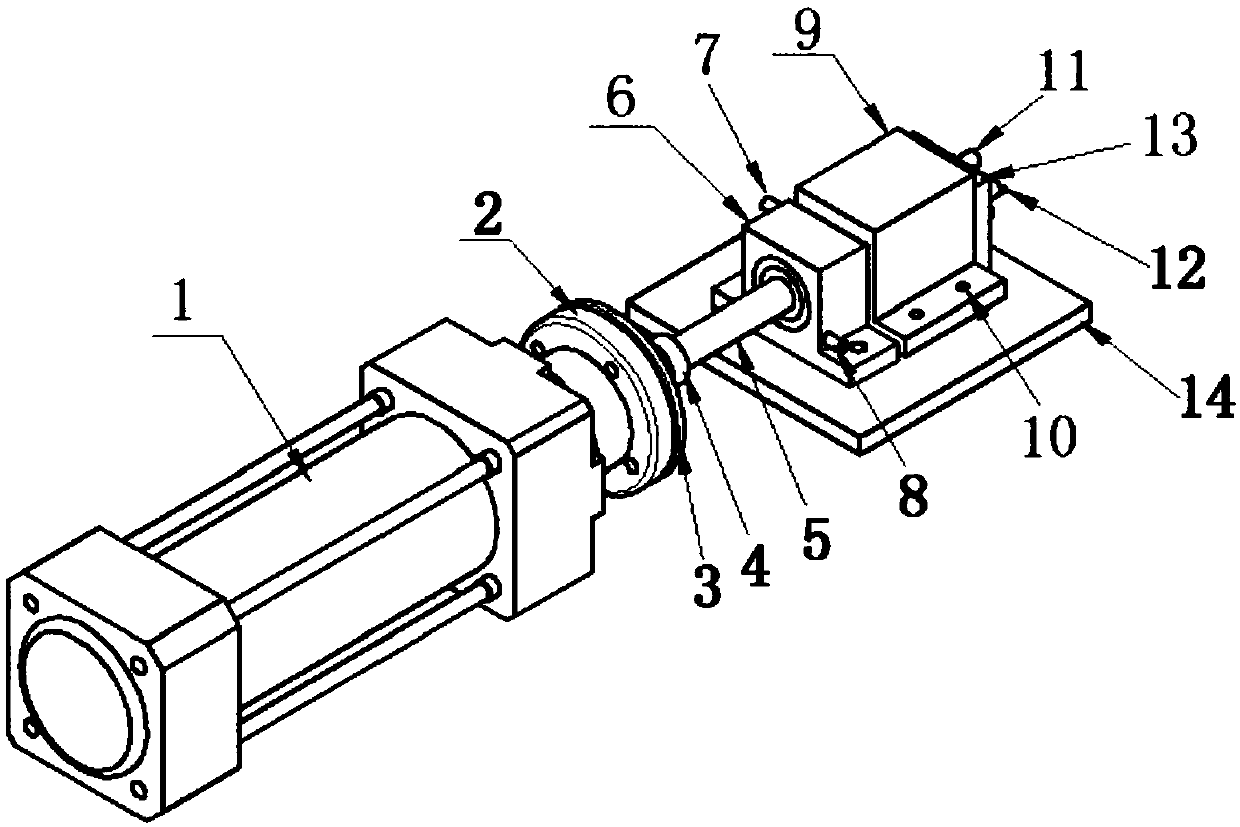

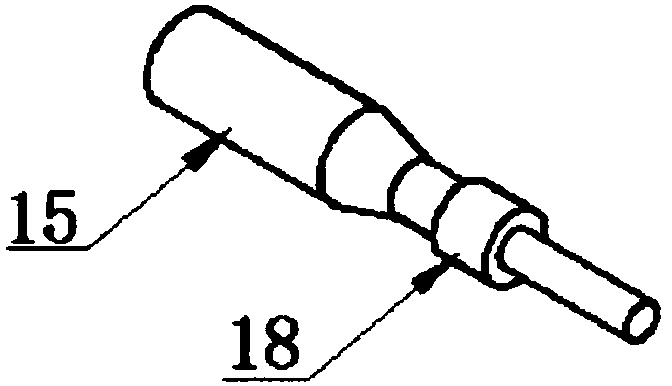

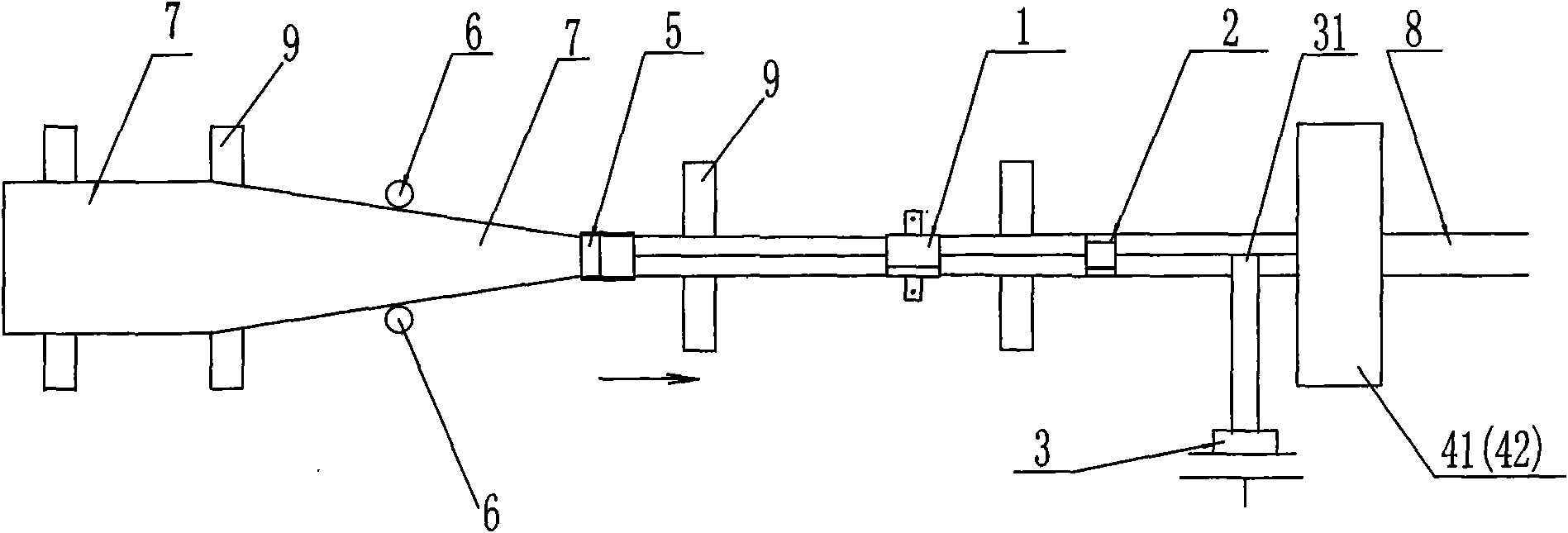

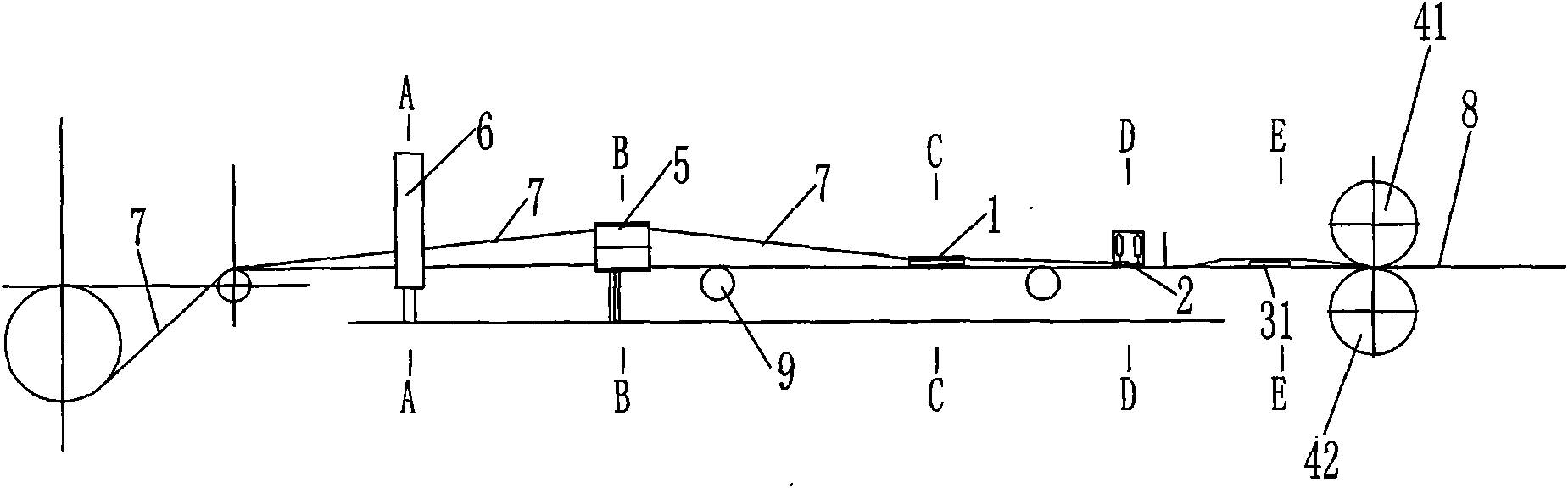

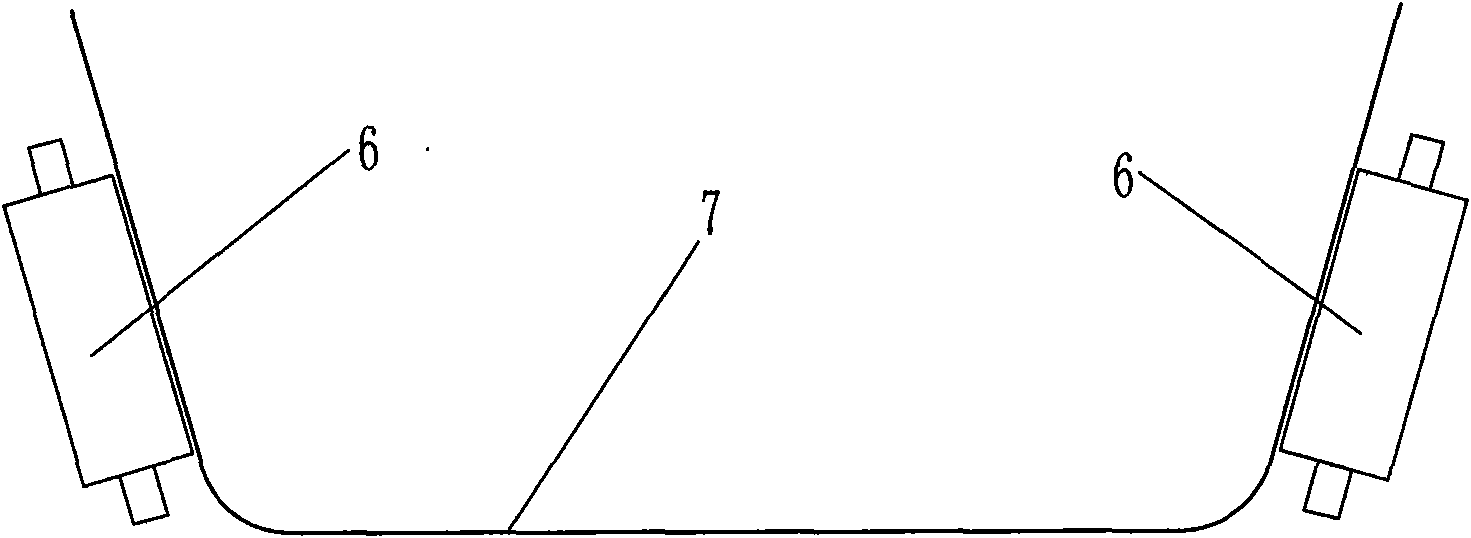

Core pulling aluminum tube drawing machine

PendingCN107913912AHigh precision inside and outsideGuaranteed outer diameterTube drawingEngineering

The invention discloses a core pulling aluminum tube drawing machine and relates to the technical field of non-ferrous metal pipe processing equipment. The machine comprises a core pulling mechanism,a feeding mechanism and a drawing mechanism, wherein the core pulling mechanism is arranged at one end of the drawing mechanism; the feeding mechanism is arranged on the upper part of the drawing mechanism; the core pulling mechanism comprises a core pulling rack 1, a core pulling rod slide groove 2, a core pulling rod 6, a core pulling mold core 7 and a core pulling rod lifting cylinder; the corepulling rod slide groove 2 is arranged at one end of the core pulling rack 1; one end of the core pulling rod 6 is vertically-slidably arranged in the core pulling rod slide groove 2 in a penetratingmanner; the core pulling mold core 7 is arranged at the other end of the core pulling rod 6; the core pulling rod lifting cylinder is vertically arranged on the lower part of the core pulling rack 1;and the core pulling rod 6 is supported on the upper part of the upwardly-extending cylinder shaft. The machine has the characteristics of automatic tube threading, automatic drawing, high internal and external precision of pipes and the like and can be used for drawing not only aluminum alloy tubes but also other non-ferrous metal tubes.

Owner:QIYANG HONGTAI ALUMINUM IND

An underground hollow oil well pump

ActiveCN105909503BImprove sealingGuaranteed inner diameterPositive displacement pump componentsFlexible member pumpsHorizontal wellsPiston rod

Owner:TOP WELL PETROLEUM TECH COMPANY

Equipment and process for producing water hose

ActiveCN101579919BSimple and ingenious structureEasy to manufactureTubular articlesEngineeringProduced water

Owner:汕头市光华机械实业有限公司

Punching head

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com