Inhaul cable protective sleeve with functional element and construction method thereof

A technology of functional components and construction methods, applied in bridge parts, buildings, bridge construction, etc., can solve the problems of cable weight, increased cross-sectional area, difficult processing of cable sheaths, and impact on cable performance, etc. Easy installation and post-maintenance, reduced cross-sectional area and weight, less processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] Yet another embodiment provides a construction method for the above-mentioned cable sheathing pipe with functional elements, the cable structure also includes prestressed tendons 7 inside the inner layer pipe 1; the construction method includes the following steps:

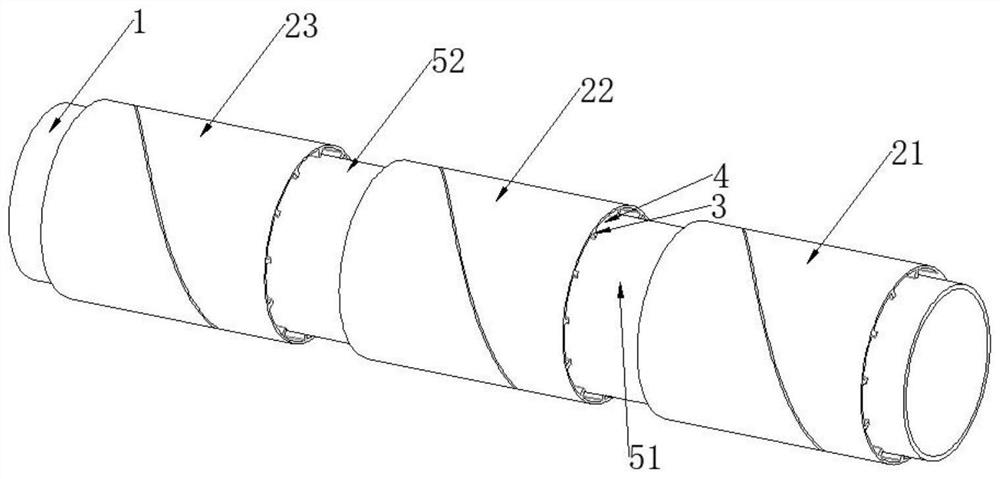

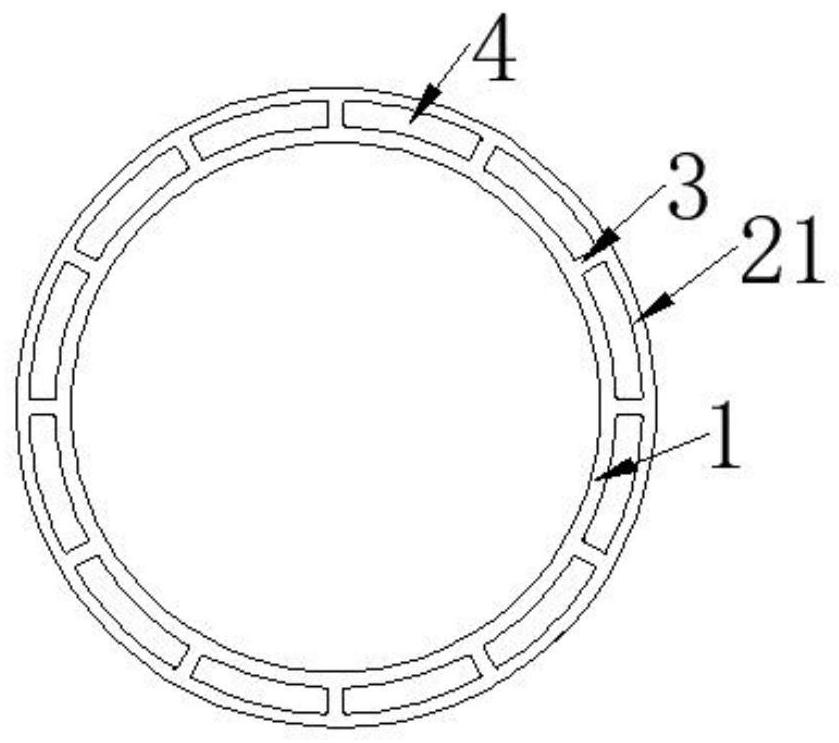

[0046] A) According to the length of the sheath tube required by the cable, a double-layer tube with reinforcing ribs 3 and cavity channel 4 is prepared by one-time extrusion molding of a mold; , the prepared inner tube 1, outer tube, rib 3 and cavity channel 4 are all continuous double-layer tubes;

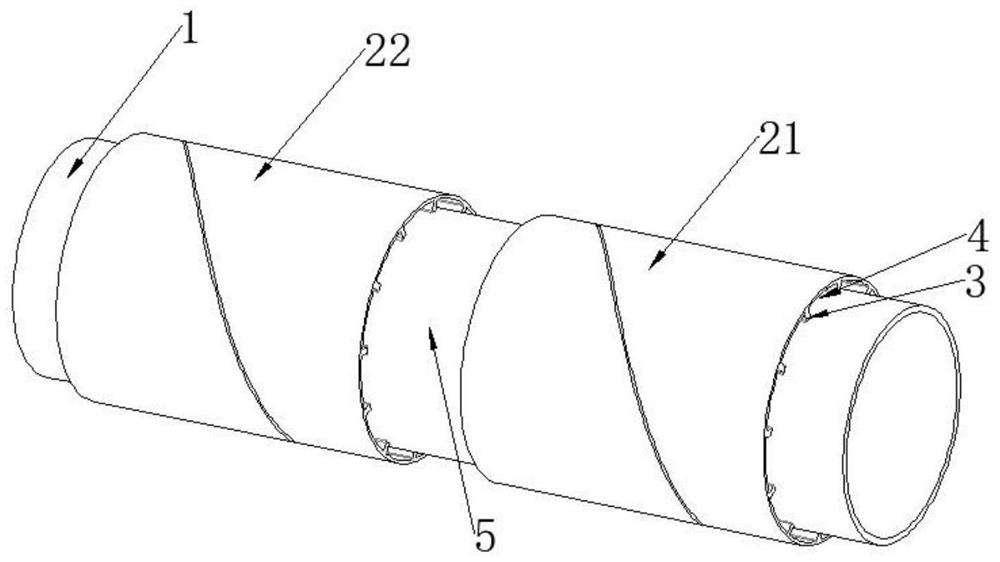

[0047] B) According to the transportation requirements, cut into N sections of double-layer pipes according to the length requirements; in order to facilitate transportation, the double-layer pipes can be cut into the length required for transportation;

[0048] C) According to the size and installation requirements of the functional components, respectively process the circumferential groove 5 on the N-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com