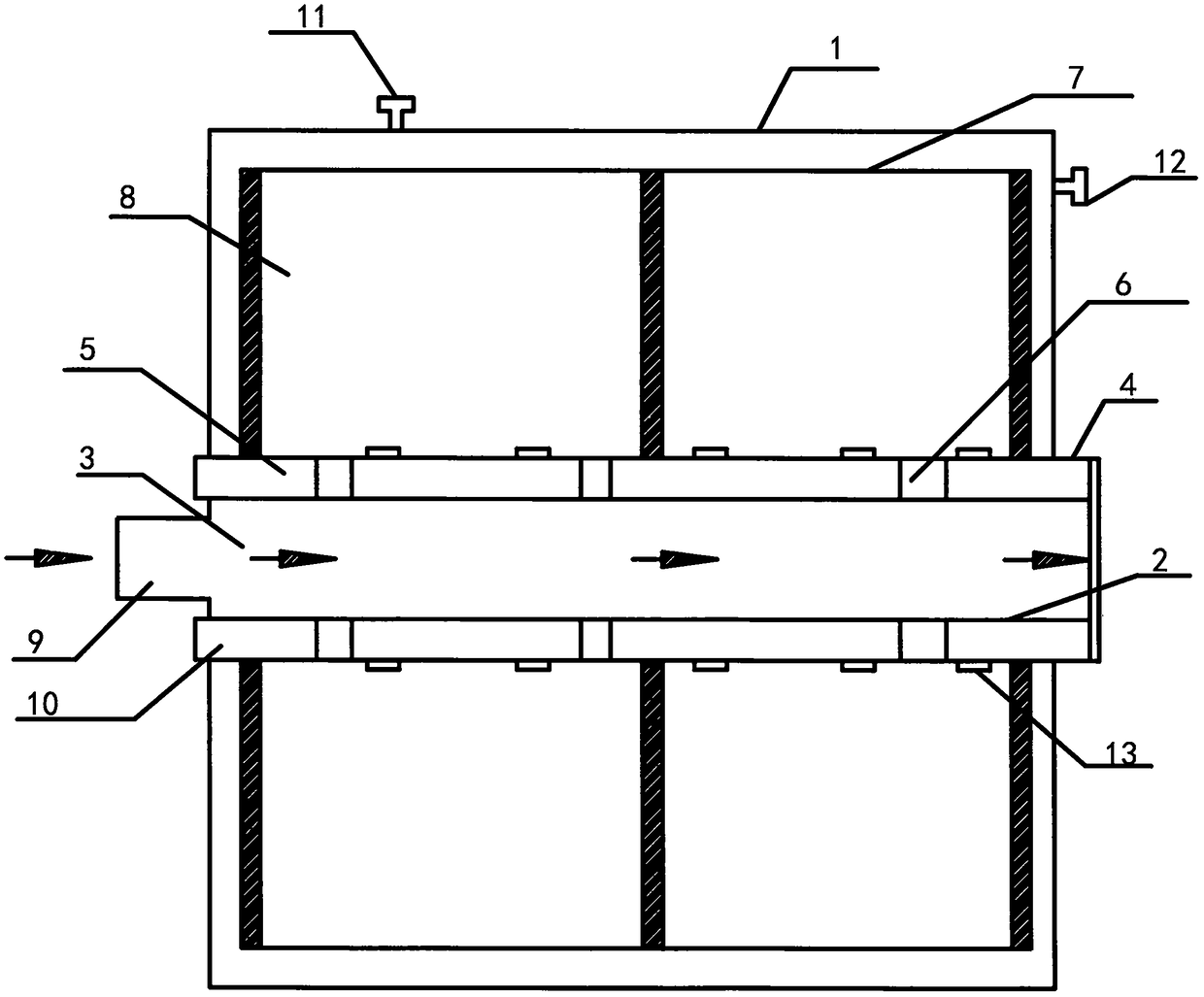

A sulfur tail gas supergravity desulfurization device

A desulfurization device and supergravity technology, which is applied in the field of sulfur tail gas supergravity desulfurization devices, can solve problems such as sulfur tail gas desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

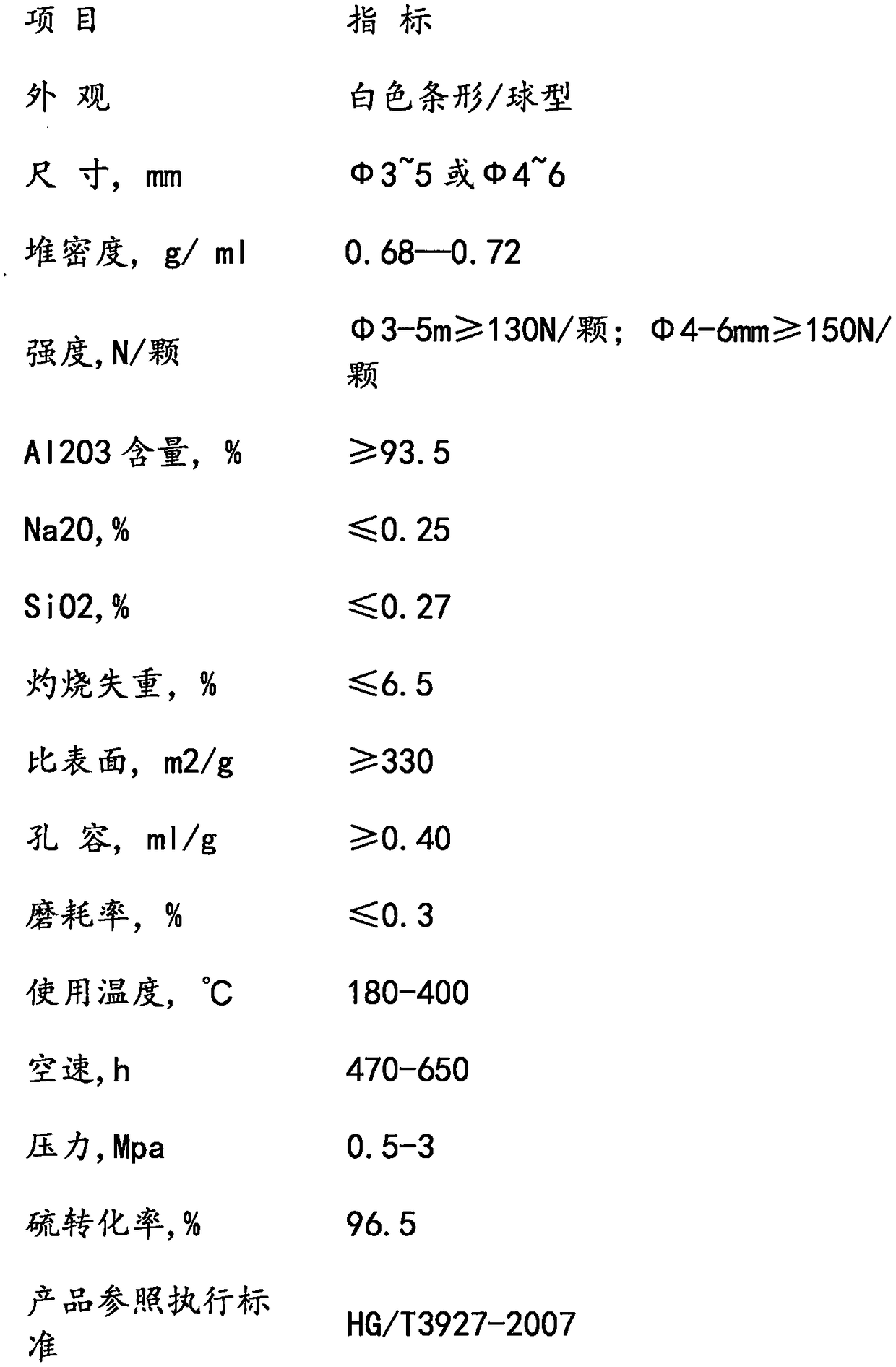

Embodiment 1

[0051] This embodiment discloses a sulfur tail gas supergravity desulfurization process, which includes the following steps:

[0052] (1) The sulfur tail gas enters the combustion furnace and burns at 500°C;

[0053] (2) Cool down the burned gas until the gas temperature reaches 400°C;

[0054] (3) The gas after cooling enters the first-stage reactor, and under the action of a catalyst, the reaction of preparing sulfur element is carried out, and the temperature is set to 400 ° C during the reaction;

[0055] (4) The gas after the primary reaction enters the secondary reactor for the reaction of preparing sulfur element again, and the reaction temperature is set to 380°C;

[0056] (5) After the reaction, the liquid sulfur is captured by the trap, and the gas enters the hydrogenation reactor, and the hydrogenation reaction is carried out at 320°C under the action of the catalyst;

[0057] (6) Utilize amine liquid to wash and absorb the gas after the hydrogenation reaction;

...

Embodiment 2

[0061] This embodiment discloses a sulfur tail gas supergravity desulfurization process, which includes the following steps:

[0062] (1) The sulfur tail gas enters the combustion furnace and burns at 900°C;

[0063] (2) Cool down the burned gas until the gas temperature reaches 430°C;

[0064] (3) The gas after cooling enters the first-stage reactor, and under the action of a catalyst, the reaction of preparing sulfur element is carried out, and the temperature is set to 380° C. during the reaction;

[0065] (4) The gas after the primary reaction enters the secondary reactor for the reaction of preparing sulfur element again, and the reaction temperature is set to 350°C;

[0066] (5) After the reaction, the liquid sulfur is captured by the trap, and the gas enters the hydrogenation reactor, and the hydrogenation reaction is carried out at 380°C under the action of the catalyst;

[0067] (6) Utilize amine liquid to wash and absorb the gas after the hydrogenation reaction;

...

Embodiment 3

[0070] This embodiment discloses a sulfur tail gas supergravity desulfurization process, which includes the following steps:

[0071] (1) The sulfur tail gas enters the combustion furnace and burns at 1300°C;

[0072] (2) Cool down the burned gas until the gas temperature reaches 450°C;

[0073] (3) The gas after cooling enters the first-stage reactor, and under the action of a catalyst, the reaction of preparing sulfur element is carried out, and the temperature is set to 480 ° C during the reaction;

[0074] (4) The gas after the first-stage reaction enters the second-stage reactor for the reaction of preparing sulfur element again, and the reaction temperature is set to 450° C.;

[0075] (5) After the reaction, the liquid sulfur is captured by the trap, and the gas enters the hydrogenation reactor, and under the action of the catalyst, 420 ℃ for hydrogenation reaction;

[0076] (6) Utilize amine liquid to wash and absorb the gas after the hydrogenation reaction;

[0077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com