GO@DA/sodium alginate/P(AAc-co-AAm) multifunctional hydrogel and preparation method thereof

A technology of aac-co-aam and sodium alginate, which is applied in the field of GO@DA/sodium alginate/P multifunctional hydrogel and its preparation, can solve the complex application, mechanical performance limitation, and the inability of conductive hydrogel To meet the actual needs of biosensors and other issues, to achieve the effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] 1) First use 0.02g GO and 10mg DA to make 20ml aqueous solution, self-polymerize under vigorous stirring to obtain GO@DA dispersion;

[0029] 2) Add 0.05g sodium alginate to the dispersion liquid in step 1), fully stir and dissolve, then add dropwise 6g AAc, 1gAAm, 0.105g MBAA and 0.05g Fe(NO 3 ) 3 9H 2 O mixed solution, vigorously stirred evenly;

[0030] 3) Add 0.225g of ammonium persulfate to the solution in step 2), stir evenly, cast in a mold, transfer to 60°C for reaction, and obtain GO@DA / sodium alginate / P(AAc-co-AAm) Multifunctional hydrogel.

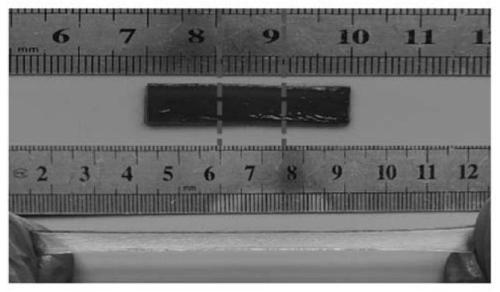

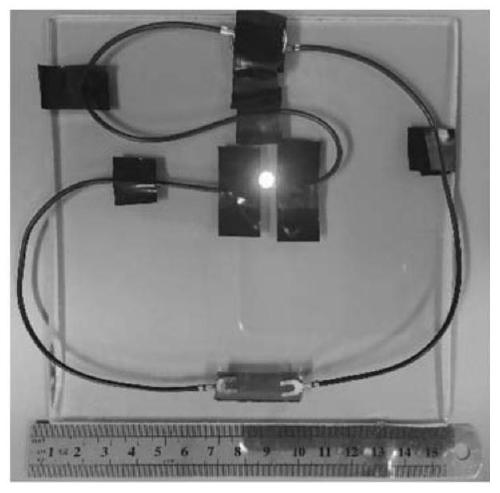

[0031] 4) The tensile strength, elongation at break, electrical conductivity, and adhesion strength of the gel are 148 kPa, 1403%, 2.58 S / m, and 13.7 kPa, respectively, and it has self-healing ability.

example 2

[0033] 1) First use 0.02g GO and 40mg DA to make 20ml aqueous solution, self-polymerize under vigorous stirring to obtain GO@DA dispersion;

[0034] 2) Add 0.05g sodium alginate to the dispersion liquid in step 1), fully stir and dissolve, then add dropwise 6g AAc, 1gAAm, 0.105g MBAA and 0.05g Fe(NO 3 ) 3 9H 2 O mixed solution, vigorously stirred evenly;

[0035] 3) Add 0.360g of ammonium persulfate to the solution in step 2), stir evenly, cast in a mold, transfer to 60°C for reaction, and obtain GO@DA / sodium alginate / P(AAc-co-AAm) Multifunctional hydrogel.

[0036] 4) The tensile strength, elongation at break, electrical conductivity, and adhesion strength of the gel are 96 kPa, 1621%, 3.07 S / m, and 15.9 kPa, respectively, and it has self-healing ability. Compared with Example 1, as the amount of DA increases, the tensile strength of the gel decreases, while the electrical conductivity, elongation at break and adhesive strength increase.

example 3

[0038] 1) First use 0.02g GO and 40mg DA to make 20ml aqueous solution, self-polymerize under vigorous stirring to obtain GO@DA dispersion;

[0039] 2) Add 0.15g sodium alginate to the dispersion liquid in step 1), fully stir and dissolve, then add dropwise 6g AAc, 1gAAm, 0.105g MBAA and 0.05g Fe(NO 3 ) 3 9H 2 O mixed solution, vigorously stirred evenly;

[0040] 3) Add 0.360g of ammonium persulfate to the solution in step 2), stir evenly, cast in a mold, transfer to 60°C for reaction, and obtain GO@DA / sodium alginate / P(AAc-co-AAm) Multifunctional hydrogel.

[0041]4) The tensile strength, elongation at break, electrical conductivity, and adhesion strength of the gel are 347 kPa, 1181%, 2.26 S / m, and 32.5 kPa, respectively, and it has self-healing ability. Compared with Example 2, as the amount of sodium alginate increased, the tensile strength and adhesive strength of the gel were enhanced, but the electrical conductivity and elongation at break decreased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com